Asphalt Plant South Africa 40–400 t/h – Drum & Batch Types| Complete Asphalt Solutions with Local Support & Quick Deployment|Efficient Production + Installation, Training & Spare Parts

Struggling with road delays, power cuts, or costly asphalt supply in South Africa? You’re not alone. Many contractors face the same challenges — unstable electricity, long transport distances, and tight government tender deadlines. That’s why we offers reliable and energy-efficient asphalt plant solutions for South Africa, built to handle local conditions. From diesel-powered mobile plants to high-capacity stationary units, our asphalt plant helps you produce asphalt anytime, anywhere — keeping your projects on track and your profits growing.

Every asphalt road and bridge project in South Africa has its own challenges. Choosing the right asphalt mixing plant in South Africa is key — read on to see how our solutions can meet local needs and keep your projects on track.

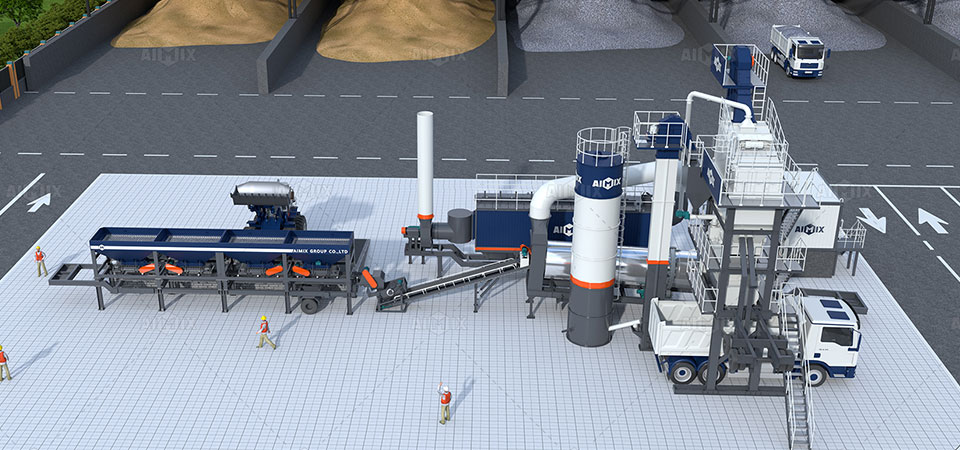

Find the Perfect Asphalt Plant for Your South African Projects

Need reliable asphalt for Johannesburg highways, Durban streets, or remote Limpopo projects? we offers stationary and mobile batch type asphalt plants, drum type continuous asphalt plants, and portable asphalt mixers, designed to handle local challenges and keep your projects on schedule. Read on to find the best asphalt mixing solution for your project.

Stationary Batch Type Asphalt Plant

- Production Capacity: 40-400 t/h

- Mixing Cycle: 45s

- Hot Selling Models: ALQ80, ALQ100, ALQ120, ALQ160

- Asphalt Temperature: 140-180 ℃

- Dust filter: Gravity/Cyclone/Bag/Water dust filter

ALQ Series Stationary Asphalt Batch Plant Features

- High Capacity: High-capacity production, ideal for highways and city roads.

- Precise Weighing: Aggregate error ±0.5%, asphalt and powder ±0.25%.

- Automated Control: One-key start and remote monitoring reduce manual labor.

- Durable: Key components last up to a million tons, suitable for long-term operation.

- Eco-friendly: Multiple dust control options meet city emission standards.

Mobile Asphalt Batch Mix Plant

- Production Capacity: 40-160 t/h

- Mixing Cycle: 45s

- Hot Selling Models: ALYQ80, ALYQ90

- Asphalt Temperature: 120-180 ℃

- Dust filter: Gravity/Cyclone/Bag/Water dust filter

ALYQ Series Mobile Asphalt Plant Features

- Fast Setup: Allows 24-hour installation and production, no foundation needed.

- Smart Operation: AI control system with remote app reduces labor by 50%.

- Efficient Mixing: Increases output by 10 tons/hour, about 100 tons/day extra.

- Accurate Weighing: Error as low as 1%, saving up to 80 tons of material per day.

- Eco-Friendly: Gravity and bag dust systems meet urban and suburban standards.

Stationary Asphalt Drum Mix Plant

- Production Capacity: 20-120 t/h

- Asphalt Temperature: 120-180 ℃

- Hot Selling Models: ALT40, ALT80, ALT120

- Finished Asphalt Storage Bin: 3-9 tons

- Dust filter: Bag/Water dust filter

ALT Series Drum Type Stationary Asphalt Plant Features

- Continuous Production: Suitable for county highways and village road networks.

- Smart Control: Optimized drum reduces heat loss, saves 10–15% energy.

- Durable Structure: Fixed installation reduces frequent relocation costs.

- Cost-Effective: Low initial investment, economical for long-term projects.

- Efficient Construction: Centralized site work can shorten construction time by 20%.

Mobile Asphalt Drum Mix Plant

- Production Capacity: 20-120 t/h

- Dust filter: Bag/Water dust filter

- Hot Selling Models: ALYT40, ALYT80, ALYT100

- Asphalt Temperature: 120-180 ℃

- Cold Aggregate Feeding Capacity: 3.5m³ – 6.5m³

ALYT Series Mobile Type Drum Mix Plant Features

- Quick Deployment: Allows 3–5 days relocation, ideal for mountains and bridges.

- Low-Center Design: Passes hilly terrain and avoids low cables safely.

- Stable Output: Continuous drum mixing ensures quality in varying climates.

- Energy Efficient: Low emissions reduce dust, meeting environmental regulations.

- Flexible Investment: High initial cost but low relocation cost for multiple projects.

ALB Series Portable Asphalt Mixer Introduction

ALB-2ALB-5ALB-10ALB-15ALB-20

- Output Capacity: 2-20 t/h

- Price Range: $20,000-$35,000

- Cycle Time: 10-15 min/batch

- Asphalt Temperature: 120-210 ℃

ALB Series Key Benefits

- Multiple Models: Various capacity for patching or small roads.

- Mobile: Trailer-mounted, compact, easy to reach sites.

- Independent: Diesel generator included, works off-grid.

- Efficient Mixing: Ensures uniform asphalt quality.

- Energy Saving: Low fuel consumption with dust control.

From Johannesburg highways to Durban streets and Limpopo rural roads, our asphalt mixing plant in South Africa is built for performance, flexibility, and durability. Discover the detailed technical specs that ensure consistent asphalt quality, efficient operation, and smooth project execution.

Technical Specifications — Know Your Ideal Asphalt Plants in South Africa

To ensure your project runs smoothly and efficiently in South Africa, it’s crucial to understand the exact capabilities of each asphalt plant. From production capacity and mixing precision to fuel consumption and mobility, these specifications help you choose the right equipment for city roads, highways, or rural projects. Scroll down to see all the key parameters for every plant type.

ALQ Series Stationary Asphalt Batch Plant — For Highways & City Roads in South Africa

| Model | ALQ40 | ALQ60 | ALQ80 | ALQ100 | ALQ120 | ALQ160 | ALQ200 | ALQ240 | ALQ320 |

|---|---|---|---|---|---|---|---|---|---|

| Capacity | 40 t/h | 60 t/h | 80 t/h | 100 t/h | 120 t/h | 160 t/h | 200 t/h | 240 t/h | 320 t/h |

| Cold Aggregate Hoppers | 4×4.5m³ | 4×6.5m³ | 4×7.5m³ | 4×7.5m³ | 5×7.5m³ | 5×12m³ | 5×12m³ | 5×12m³ | 6×15m³ |

| Dryer Size | φ1.2m×5.2m | φ1.5m×6m | φ1.5m×6.7m | φ1.65m×7m | φ1.8m×8m | φ2.2m×9m | φ2.6m×9m | φ2.6m×9.5m | φ2.8m×10.2m |

| Fuel consumption | 70-300kg / h | 100-400kg / h | 120-600kg / h | 150-1000kg / h | 150-1000kg / h | 150-1400kg / h | 180-1800kg / h | 180-1800kg / h | 260-2500kg / h |

| Vibrating Screen (Layer) | 4 layers | 4 layers | 4 layers | 4 layers | 5 layers | 5 layers | 5 layers | 5 layers | 6 layers |

| Mixer Capacity | 500kg | 800kg | 1000kg | 1250kg | 1500kg | 2000kg | 2500kg | 3000kg | 4000kg |

| Cycle Time | 45s | 45s | 45s | 45s | 45s | 45s | 45s | 45s | 45s |

| Filter Area | 230m² | 300m² | 420m² | 480m² | 550m² | 650m² | 700m² | 1050m² | 1350m² |

| Asphalt Temperature | 140-180 ℃ | 140-180 ℃ | 140-180 ℃ | 140-180 ℃ | 140-180 ℃ | 140-180 ℃ | 140-180 ℃ | 140-180 ℃ | 140-180 ℃ |

| Total Power | 170kw | 200kw | 300kw | 350kw | 380kw | 490kw | 550kw | 670kw | 865kw |

ALYQ Series Mobile Asphalt Batch Plant — Fast Setup for Multi-Site Projects

| Model | ALYQ60 | ALYQ80 | ALYQ100 | ALYQ120 | ALYQ160 | |

|---|---|---|---|---|---|---|

| Capacity | t / h | 60 | 80 | 100 | 120 | 160 |

| Mixer capacity | kg | 800 | 1200 | 1300 | 1700 | 2200 |

| Mixing cycle | s | 45 | 45 | 45 | 45 | 45 |

| Total power | Gasoline(kW) | 54 | 63.5 | 104.5 | 125 | 157.5 |

| Coal(kW) | 75 | 86.5 | 127.5 | 169 | 205 | |

| filter area | m2 | 370 | 420 | 480 | 510 | 620 |

ALT Series Stationary Drum Type Asphalt Plant — Continuous Production for County Roads

| Courts Models | ALT20 | ALT40 | ALT60 | ALT80 | ALT100 |

|---|---|---|---|---|---|

| Capacity | 20 t/h | 45 t/h | 60 t/h | 80 t/h | 100 t/h |

| The ability to | 40kw | 75kw | 120kw | 165kw | 200kw |

| Cold Aggregate Hoppers | 3.5m³×1 | 4m³×4 | 4m³×4 | 6.5m³×4 | 6.5m³×4 |

| Finished Product Hopper | 3t | 3t | 7t | 7t | 9t |

| Asphalt Temperature | 120-180 ℃ | ||||

| Fuel consumption | 13-15kg/t | ||||

| Asphalt Tank | 10 t | 20 t | 30 t | 30 t | 35 t |

| Control room | 2.2m | 2.2m | 3m | 3m | 3.5m |

| Option | Bag dust filter | ||||

ALYT Series Mobile Drum Type Asphalt Plant — Flexible Deployment in Hilly & Mountain Roads

| Model | ALYT20 | ALYT40 | ALYT60 | ALYT80 | ALYT100 | ALYT120 |

|---|---|---|---|---|---|---|

| Output | 20t/h | 45t/h | 60t/h | 80t/h | 100t/h | 120t/h |

| Power | 34kw | 65kw | 105kw | 135kw | 170kw | 200KW |

| Cold Aggregate Feeding System | 3.5m³×1 | 4m³×4 | 4m³×4 | 6.5m³×4 | 6.5m³×4 | 6.5m³×4 |

| Finihsed Asphalt Storage Bin | 2m³ | 2.5m³ | 4.5m³ | 5m³ | 7m³ | 7m³ |

| Asphalt Temperature | 120-180℃ | 120-180℃ | 120-180℃ | 120-180℃ | 120-180℃ | 120-180℃ |

| Fuel Consumption(Fuel Oil) | 5-7.5kg/t | 5-7.5kg/t | 5-7.5kg/t | 5-7.5kg/t | 5-7.5kg/t | 5-7.5kg/t |

| Fuel Consumption(Burning Coal) | 13-15kg/t | 13-15kg/t | 13-15kg/t | 13-15kg/t | 13-15kg/t | 13-15kg/t |

| Asphalt Tank | 10t | 20t | 30t | 30t | 35t | 35t |

| Option | bag dust collector / water dust collector | bag dust collector / water dust collector | bag dust collector / water dust collector | bag dust collector / water dust collector | bag dust collector / water dust collector | bag dust collector / water dust collector |

| Whole Plant Option | whole mobile / semi-mobile / fixed | whole mobile / semi-mobile / fixed | whole mobile / semi-mobile / fixed | whole mobile / semi-mobile / fixed | whole mobile / semi-mobile / fixed | whole mobile / semi-mobile / fixed |

ALB Series Mobile Asphalt Mixer Machine — Compact & Mobile for Urban Repair & Small Projects

| Model | 0.38-0.4 m³ | 0.5 m³ | 0.7 m³ | 1 m³ | 1.5 m³ | 2 m³ | 3 m³ (Dual Tank) |

|---|---|---|---|---|---|---|---|

| Chassis Type | Mini Trailer Tricycle | Mini Trailer Tricycle | 4-Wheel | 6-Wheel | 6-Wheel | 6-Wheel | 6-Wheel |

| Diesel Generator | Changchai Diesel Engine | Changchai Diesel Engine | Weifang Diesel Engine | Weifang Diesel Engine | Weifang Diesel Engine | Weifang Diesel Engine | Weifang Diesel Engine |

| Power Output | 12 kW | 12 kW | 30 kW | 30 kW | 30 kW | 30 kW | 30 kW |

| Main Burner | 200,000 kcal | 200,000 kcal | 400,000 kcal | 440,000 kcal | 440,000 kcal | 440,000 kcal | 440,000 kcal (2 units) |

| Secondary Burner | 200,000 kcal | 200,000 kcal | 200,000 kcal | 200,000 kcal | 210,000 kcal | 220,000 kcal | 220,000 kcal |

| Mixing Tank Temperature | 120-165℃(Adjustable) | 160-210℃(Adjustable) | 160-210℃(Adjustable) | 160-210℃(Adjustable) | 160-210℃(Adjustable) | 160-210℃(Adjustable) | 160-210℃(Adjustable) |

| Fuel Type | Diesel | Diesel | Diesel | Diesel | Diesel | Diesel | Diesel |

| Fuel Consumption | 2.5-5L per batch | 4-5L per batch | 4-5L per batch | 5-6L per batch | 6-7L per batch | 6-7L per batch | 8-10L per batch |

| Mixing Motor | 2.2 kW | 5.5 kW | 5.5 kW | 5.5 kW | 5.5 kW | 5.5 kW | 5.5 kW |

| Dust Removal System | / | Water Dust Removal | Water Dust Removal | Water Dust Removal | Water Dust Removal | Water Dust Removal | Water Dust Removal |

| Tank Capacity (m³) | 1 m³ | 1.75 m³ | 2.35 m³ | 3.25 m³ | 4.25 m³ | 5 m³ | 4.25 m³ * 2 |

| Mixing Volume (tons/m³) | 0.25 m³ / 0.5 tons | 0.5 m³ / 1 ton | 0.7 m³ / 1.4 tons | 1 m³ / 2 tons | 1.5 m³ / 3 tons | 2 m³ / 3 tons | 1.5 m³ / 3 tons (Dual Tank) |

| Production Time Per Batch | 10-15 min/batch | 10-15 min/batch | 10-15 min/batch | 10-15 min/batch | 10-15 min/batch | 10-15 min/batch | 10-15 min/batch (Dual Tank) |

| Production Capacity (T/h) | 2-3 T/h | 4-6 T/h | 5.6-8.4 T/h | 8-12 T/h | 12-15 T/h | 15-18 T/h | 18-20 T/h |

| Applications | Small road repairs, manhole repairs | Road repairs, courtyard paving | Road repairs, courtyard paving | Road repairs, courtyard paving | Road repairs, courtyard paving | Road repairs, courtyard paving | Road repairs, courtyard paving |

| Inverter | 380V-24V | 380V-24V | 380V-24V | 380V-24V | 380V-24V | 380V-24V | 380V-24V |

| Hot Melt Kettle Capacity | 200L | 400L | 400L | 500L | 500L | 500L | 500L |

| Vibration System / Air Pump (Slag Removal Device) | / | 0.1/8 type air pump (0.1 m³ flow) | 0.1/8 type air pump (0.1 m³ flow) | 0.1/8 type air pump (0.1 m³ flow) | 0.1/8 type air pump (0.1 m³ flow) | 0.1/8 type air pump (0.1 m³ flow) | 0.1/8 type air pump (0.1 m³ flow) |

| Material Ratio | 3%-5% oil-stone ratio (new material) | 3%-5% oil-stone ratio (new material) | 3%-5% oil-stone ratio (new material) | 3%-5% oil-stone ratio (new material) | 3%-5% oil-stone ratio (new material) | 3%-5% oil-stone ratio (new material) | 3%-5% oil-stone ratio (new material) |

| Automatic Loading Hopper | / | Hoist Bottom Discharge | Hoist Bottom Discharge | Hoist Bottom Discharge | Hoist Bottom Discharge | Hoist Bottom Discharge | / |

| Weight (Tons) | 1.8 T | 3.8 T | 4.2 T | 4.8 T | 5.6 T | 5.6 T | 6.5 T |

| Starting Method | Electric Control | Electric Control / Electric Start | Electric Control / Electric Start | Electric Control / Electric Start | Electric Control / Electric Start | Electric Control / Electric Start | Electric Control / Electric Start |

| Dimensions (LWH, mm) | 5200*1600*2000 | 5200*1600*2000 | 6000*2000*2750 | 6200*2300*2950 | 6600*2300*2950 | 6900*2300*3250 | 6600*3300*2950 |

| Material | Double-layer manganese plate (single layer thickness 5.75mm), rock wool insulation layer 5cm*6 | Double-layer manganese plate (single layer thickness 5.75mm), rock wool insulation layer 5cm*6 | Double-layer manganese plate (single layer thickness 5.75mm), rock wool insulation layer 5cm*6 | Double-layer manganese plate (single layer thickness 5.75mm), rock wool insulation layer 5cm*6 | Double-layer manganese plate (single layer thickness 5.75mm), rock wool insulation layer 5cm*6 | Double-layer manganese plate (single layer thickness 5.75mm), rock wool insulation layer 5cm*6 | Double-layer manganese plate (single layer thickness 5.75mm), rock wool insulation layer 5cm*6 |

Having explored the technical specifications of our asphalt plants, it’s clear how each model can meet specific project needs. But before deciding on the right equipment, understanding the South African market dynamics and investment opportunities is crucial. Let’s dive into why establishing an asphalt mixing plant South Africa here can be a strategic and profitable move.

Why Invest in an Asphalt Plant in South Africa — Key Insights & Market Drivers

Planning to start or expand an asphalt plant business in South Africa? Here’s what you need to know about the market scale, infrastructure momentum, investment environment, and long-term opportunities that make South Africa one of Africa’s most promising asphalt markets.

Expanding Market Size & Sustainable Growth Potential

Rapidly Expanding Asphalt Market

South Africa’s asphalt market is valued at USD 1.13 billion (2024) with a projected CAGR of 5%, driven by road renewal and maintenance demand.

Strong National Infrastructure Spending

The government plans to invest over R940 billion (~USD 50 billion) in roads, bridges, water, and energy projects over the next three years, supporting asphalt production growth.

Multilateral Financial Support

The World Bank approved a USD 1.5 billion loan (2025) for transport modernization, energy efficiency, and logistics projects, increasing asphalt paving requirements.

Increased Capital Expenditure & PPPs

Over R1 trillion in public infrastructure spending is planned through 2027, leveraging blended finance and Public-Private Partnerships to accelerate road development.

✅ These factors signal a robust and diversified long-term demand for asphalt production — from urban road resurfacing to highway expansion and new township development.

Vast Road Network & Maintenance Backlog

![]()

One Of Africa’s Largest Road Networks

South Africa’s total road network spans approximately 750,000 km, ranking among the top 20 globally. This includes national, provincial, and municipal roads.

![]()

National and Provincial Management

SANRAL manages about 21,400 km of highways, while provinces and municipalities oversee the remaining network, creating broad asphalt demand.

![]()

Severe Infrastructure Maintenance Gap

The Department of Transport estimates a R197 billion maintenance and rehabilitation backlog due to years of underinvestment and heavy road use.

![]()

High Wear Rate/Short Resurfacing Cycles

On busy freight corridors and industrial routes, road lifespan averages 10–20 years, far shorter than global averages due to heavy traffic and climate wear.

![]()

Urban Expansion Driving Local Demand

Rapid urbanization in Gauteng, KwaZulu-Natal, and Western Cape increases road usage and boosts demand for new and upgraded pavements.

✅ In short, South Africa’s extensive road system and large maintenance gap ensure steady, recurring asphalt demand — not just for new builds, but also for resurfacing, repair, and municipal upgrades.

Regional Infrastructure Momentum & Project Hotspots

- Gauteng Province: South Africa’s economic hub, home to Johannesburg and Pretoria, focuses on highway expansions (N1, N12, N14 corridors) and urban road rehabilitation.

- KwaZulu-Natal: Heavy port and logistics activity around Durban requires high-capacity asphalt production for port access roads and industrial routes.

- Western Cape: The Cape Town metro region leads in eco-friendly and smart-road programs, often requiring advanced asphalt technologies (low-emission asphalt plants, reclaimed asphalt).

- Northern Cape & Eastern Cape: Mining logistics and inter-provincial transport corridors (e.g., N10, N6) continue to drive demand for high-temperature and long-haul asphalt mixes.

Long-Term Investment Outlook

| Indicator | 2024–2025 Value | Trend / Impact |

|---|---|---|

| Asphalt Market Size | USD 1.13 billion | Stable ↑ 5% CAGR |

| Road Network Length | 750,000 km | Constant maintenance demand |

| Infrastructure Budget | R940 billion (3 years) | + PPP expansion |

| Maintenance Backlog | R197 billion | Creates urgent resurfacing needs |

| Urbanization Rate | ~67% (2025) | Boosts city road & housing projects |

| Loan Support | USD 1.5 billion (World Bank) | Enables road & energy synergy |

With the strong market growth, robust infrastructure investment, and long-term demand for asphalt in South Africa, the next question is clear: who will actually benefit most from owning or operating an asphalt plant South Africa for sale? Understanding some factors is essential for making informed investment decisions. Let’s explore and see which solution fits your projects best.

Who Really Needs an Asphalt Plant in South Africa? — A Customer Guide

If you are a road contractor, municipal maintenance team, or private construction company in South Africa, you might need an asphalt plant. This guide walks you through the key customer segments, so you can quickly identify the right asphalt mixing solution for your projects.

National and Provincial Road Authorities

- Typical Customers: SANRAL, provincial road departments

- Project Scenarios: Routine maintenance of national and provincial roads, road widening, major upgrades, and bridge construction

- Key Concerns: High output, consistent performance, long-term durability

- Recommended Plant Types: Stationary batch asphalt plants or large drum/batch asphalt plants in South Africa

- Why it matters:

South Africa’s road network is extensive, with resurfacing cycles often within 10–20 years, requiring continuous production capacity.

Long-term government projects demand stable, engineering-grade equipment to meet strict quality and schedule requirements.

Large Contractors and EPC Companies

- Typical Customers: Large local groups or joint ventures handling government or private BOT projects

- Project Scenarios: Highways, industrial parks, city expressways, or logistics corridors

- Key Concerns: Project schedule, contract compliance, material quality, stable output

- Recommended Plant Types: High-capacity batch or drum asphalt plants with automated operation

- Why it matters:

Owning your own best hot mix asphalt manufacturing plant South Africa ensures timely delivery and reduces reliance on external supply.

Large-scale projects require continuous production, making fixed or semi-mobile high-capacity asphalt plants a safe choice.

Municipal and Local Road Maintenance Teams

- Project Scenarios: Urban streets, secondary roads, small community paving or repair projects

- Key Concerns: Cost-effectiveness, flexibility, ease of operation

- Recommended Plant Types: Compact or mobile asphalt plant for sale South Africa

- Why it matters:

Work sites are often dispersed, requiring rapid relocation and on-demand asphalt supply.

Budget-conscious projects need equipment that is easy to operate and maintain.

Mining, Industrial Parks, and Ports

- Project Scenarios: Internal roads, logistics areas, port access roads

- Key Concerns: Durability, fast response, heavy-load tolerance

- Recommended Plant Types: Durable mobile or medium-capacity drum asphalt plants

- Why it matters:

Harsh work conditions and heavy vehicle traffic require reliable, long-lasting equipment.

Quick response for emergency repairs or temporary works improves operational continuity.

Small Contractors and SMMEs

- Project Scenarios: Small town roads, community streets, temporary or emergency projects

- Key Concerns: Low investment, simple operation, easy maintenance

- Recommended Plant Types: Compact or portable asphalt plants for sale South Africa

- Why it matters:

Low-cost, high-flexibility solutions allow participation in municipal tenders or joint projects.

Easy to operate and maintain, reducing complexity and speeding up small-scale construction.

Now that we’ve explored who benefits most from owning an asphalt plant for sale in South Africa, the next step is to see where and how these asphalt mixer plants are actually used. Understanding the main application areas will help you identify the projects that can maximize your investment and operational efficiency.

Key Applications of Asphalt Plants Across South Africa

High-quality asphalt is the backbone of durable roads. Whether you are working on national highways, city streets, industrial parks, or rural roads, asphalt plants for sale in south africa ensure a reliable supply of material for every project. Below, we highlight the main areas where asphalt plants deliver the greatest value for South African construction and maintenance projects.

National Highway Upgrades

Used for upgrading major highways like the N2 and N3, ensuring smooth and durable road surfaces for long-distance travel.

Urban Road Building & Maintenance

Supports city road projects in Cape Town, Johannesburg, and Durban, providing consistent asphalt for resurfacing and new streets.

Municipal Road Networks

Ideal for provincial and local roads, streets, and pedestrian pathways, helping municipalities maintain safe and efficient transportation.

Industrial Developments

Supplies asphalt for access roads, parking areas, and internal roads in industrial parks and commercial zones.

Rural Road Construction

Supports the construction and rehabilitation of rural roads, improving connectivity for local communities and economic growth.

Specialized Infrastructure Projects

Used in airports, ports, and major interchanges (e.g., EB Cloete Interchange) requiring precise mixes for durability and heavy loads.

Having seen the main applications of asphalt plants across South Africa, it’s clear how versatile and essential these plants are for various projects. Let’s now look at proven global projects, where similar solutions have successfully delivered efficient production, consistent quality, and long-lasting results.

Proven Asphalt Plant Solutions Driving Infrastructure Worldwide

Across deserts, cities, industrial zones, and rural networks, our asphalt plants have consistently delivered high efficiency, durable performance, and reliable quality. These global projects showcase how our equipment adapts to diverse conditions, helping contractors and infrastructure developers complete roads and paving projects with confidence and precision.

Become Our Asphalt Plant Partner in South Africa

Who sells asphalt plants in South Africa? As one of full-service asphalt plant manufacturers in South Africa with decades of production and R&D experience, we offer not only high-quality equipment but also a comprehensive support system for partners in South Africa. Our network ensures fast technical assistance, reliable maintenance, and access to proven technology for long-term success.

Join us as a local partner and bring world-class asphalt solutions to your projects, backed by an asphalt plant supplier Mozambique and service provider you can trust.

Ready to Boost Your Asphalt Road Projects in South Africa?

Looking to secure reliable, high-performance asphalt solutions for your roads, highways, or industrial sites? Our asphalt plants combine proven technology, efficient production, and full support to help you complete projects on time and on budget. Don’t wait—request a quote about the asphalt plant South Africa price today and see how we can drive your next project’s success.