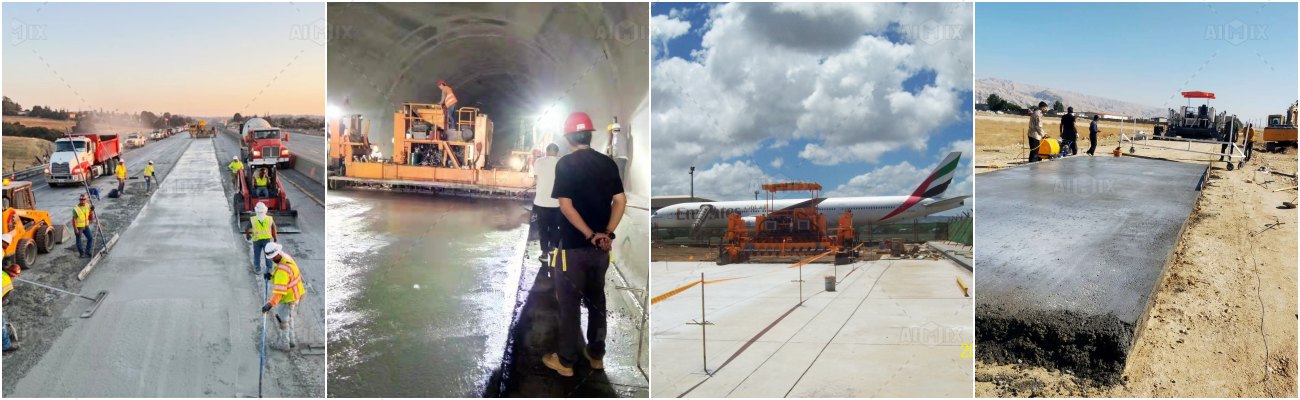

A concrete paving machine is essential for today’s road construction, offering speed, accuracy, and long-lasting results. Our slipform concrete paving machines are designed to create smooth, strong, and uniform concrete surfaces. With advanced automation and stable performance, they are perfect for highways, airport runways, and large projects. These machines help you finish work faster, cut labor needs, and lower overall costs.

Typical Models of Slipform Concrete Paving Machines

Our slipform concrete paving machines cover a range of models, including CP4500, CP6000, CP8000, and CP8500, each designed to suit different road projects requirements. Get to know the concrete paving machine specifications shown as below.

CP4500 Concrete Paver Machine

- Model: CP4500

- Paving width: 2500~4500 mm

- Paving thickness: 0~350 mm

- Paving flatness: 3mm/3m

- Paving speed: 10 m/min

- Travel speed: 1.5 km/h

- Climbing capacity: 10%

- Travel mode: Two tracks

- Engine: 127kW (QSB5.9-C130)

- Hydraulic vibrating bar: 167HZ/10pcs

- Overall dimension: 4150*5790*2770

- Machine weight: 20~23 tons

CP6000 Concrete Paving Machine

- Model: CP6000

- Paving width: 3500~6000 mm

- Paving thickness: 450 mm

- Paving flatness: 3mm/3m

- Paving speed: 10 m/min

- Travel speed: 1.5 km/h

- Climbing capacity: 10%

- Travel mode: Two tracks

- Engine: 160kW (VOLVO)

- Hydraulic vibrating bar: 167HZ/13pcs

- Overall dimension: 4150*7290*2770

- Machine weight: 22~26 tons

CP8000 Concrete Paving Equipment

- Model: CP8000

- Paving width: 4250 (3500) ~ 8000 mm

- Paving thickness: 500 mm

- Paving flatness: 3mm/3m

- Paving speed: 10 m/min

- Travel speed: 1.5 km/h

- Climbing capacity: 10%

- Travel mode: Two tracks

- Engine: 185 kW (VOLVO)

- Hydraulic vibrating bar: 167HZ/18pcs

- Overall dimension: 4150*9290*2770

- Overall weight: 23~28 tons

CP8500 Concrete Pavement Machine

- Model: CP8500

- Paving width: 4250 (3500) ~ 8500 mm

- Paving thickness: 500 mm

- Paving flatness: 3mm/3m

- Paving speed: 10 m/min

- Travel speed: 1.5 km/h

- Climbing capacity: 10%

- Travel mode: Two tracks

- Engine: 210 kW (VOLVO)

- Hydraulic vibrating bar: 167HZ/18pcs

- Overall dimension: 4150*9790*3100

- Overall weight: 23~30 tons

Concrete Paver Machine for Sale: Airport Road Project in Iran

- Client’s requirements: Need an efficient and high-standard equipment for paving airport roads.

- Our solution: CP8000 concrete paver equipment with extra vibrating bar.

- Paving width: 8000mm

- Paving thickness: 300mm

- Achievement: The concrete sipform paver machine works efficiently on site, achieving pavement width, thickness, and flatness that fully comply with airport road standards.

- Customer feedback: “We are very satisfied with Aimix’s paver equipment, as well as the professional on-site guidance and prompt service. We look forward to working with Aimix again on our upcoming projects.”

Key Features of Our Concrete Road Paving Machine

- Wide Screed with Fine-Tuning Mechanism: Ensures smooth, even pavement and allows simple, fast, and precise operation.

- Anti-Chipping and Edge Protection: Prevents concrete edges from collapsing, resulting in superior pavement quality.

- Integrated Multi-Process Operation: Completes concrete paving, screeding, vibrating, tamping, and extrusion forming in a single pass, including intermediate and side steel reinforcement insertion.

- Hydraulic Independent Wheel Drive: Fully hydraulic drive with constant-speed microcomputer control and display screen, featuring self-diagnosis for easy maintenance.

- Automatic Leveling and Tracking: Maintains flat, straight, and smooth curves throughout the pavement.

- Intelligent and Ergonomic Design: User-friendly layout improves operator comfort and reduces fatigue.

- Imported Key Components: High-quality imported parts enhance reliability and extend the machine’s service life.

Applications of Concrete Pavement Machine

Highways and Roads

Slipform paver machines are essential for building modern highways and expressways. They provide smooth, strong road surfaces that can handle heavy traffic flow while minimizing the need for frequent maintenance.

Airport Runways

Runways require exceptional durability and precision. Concrete paver machines deliver uniform, high-strength surfaces that withstand the extreme pressure of takeoffs and landings, ensuring safe and reliable airport operations.

Industrial Areas

In ports, logistics hubs, and large industrial zones, paver machines create heavy-duty pavements designed to support the continuous movement of trucks, containers, and machinery, offering both strength and longevity.

Urban Infrastructure

From sidewalks and bike lanes to public squares and transit corridors, concrete paving equipment help shape urban environments with even, durable surfaces that improve safety and accessibility for pedestrians and cyclists.

Selecting the Right Concrete Slipform Paver: Efficiency, Quality, and Reliability

Choosing the right concrete paving machine is crucial to ensure high-quality, durable pavements while optimizing efficiency and project timelines. The wrong choice may result in uneven surfaces, delays, and higher costs. Key factors to consider include project type, pavement specifications, control systems, cost efficiency and others.

Identify the Project Type

Each project type has unique paving needs: airports require precision and strength, highways need smoothness and consistency, while industrial zones demand heavy-duty durability. Identifying the project type ensures proper machine selection for width, thickness, and overall performance.

Consider Pavement Specifications

Concrete paving machines have limitations on width, thickness, and lane coverage. Key factors include:

- Paving Thickness: Ensure the paving machine can effectively manage the required concrete depth, maintaining consistency and durability across the entire road surface.

- Minimum and Maximum Paving Width: Choose a machine offering adjustable paving widths to precisely match diverse project specifications and roadway design requirements.

- Single-Lane or Double-Lane Paving: Decide whether the machine is capable of paving one lane at a time or handling simultaneous multi-lane operations.

- Reinforcement Integration: Certain advanced paving machines allow direct insertion of intermediate and side reinforcement bars, while others require pre-embedded reinforcement placement.

Maintaining strict adherence to pavement specifications guarantees uniform, smooth, and long-lasting road surfaces with optimal quality and performance.

Availability of Construction Drawings

When selecting a concrete paver, it is important to confirm whether construction drawings are available. These drawings provide essential details such as pavement dimensions, layout, and reinforcement requirements, helping ensure the chosen machine matches the project’s specifications accurately.

Control System

Modern slipform concrete paving machines feature advanced microcomputer control systems that maintain constant screed speed and precise adjustment. Automatic leveling and tracking ensure uniform pavement thickness, straight alignment, and smooth curve transitions. The user-friendly display and built-in fault diagnosis simplify operation and maintenance, reducing errors and improving efficiency across large-scale paving projects.

Multi-Process Capabilities

Modern slipform paving machines can complete several tasks in a single pass, including:

- Concrete placement and distribution

- Screeding and leveling

- Vibrating and compaction

- Shaping and extrusion

- Reinforcement insertion

Paver Machines with integrated multi-process capability save time, reduce labor, and ensure consistent pavement quality.

Reliability and Maintenance

High-quality components and reliable systems reduce downtime and maintenance costs:

- Imported or high-quality critical parts (e.g. VOLVO engine)

- Easy access for maintenance and inspection

- Availability of spare parts and technical support

Budget and Cost Efficiency

When choosing a paving machine, consider total cost of ownership:

- Initial purchase cost (mainly concrete paving machine price)

- Labor and operational cost savings due to automation

- Long-term durability reducing replacement frequency

How a Concrete Paving Machine Works: Step-by-Step Process

Concrete paving machines, especially slipform types, are designed to handle the entire paving workflow in a single pass. This not only improves efficiency but also ensures high-quality, durable road surfaces. Here’s how the process works step by step:

Concrete Placement

Fresh cement concrete is carefully loaded into the machine’s hopper, where it is evenly and continuously distributed across the designated paving area. The controlled flow is meticulously regulated to prevent gaps, voids, or inconsistencies, ensuring that the concrete forms a smooth and uniform base. This precise placement creates a strong foundational layer for the pavement, promoting long-term stability and minimizing the risk of surface defects.

Screeding and Leveling

The screed spreads the concrete evenly to achieve the required thickness and begins the process of smoothing the surface. Advanced automatic leveling systems continuously monitor the grade, making real-time adjustments to maintain a consistent slope and precise alignment. This ensures that the pavement has a uniform surface, optimal drainage, and a professional finish that meets engineering specifications.

Vibrating and Compaction

Built-in vibrators compact the freshly laid concrete, eliminating trapped air pockets and ensuring consistent density throughout the pavement layer. Proper compaction enhances the strength of the concrete, improves durability, and contributes to a longer service life. It also helps reduce the risk of cracking or premature wear under heavy traffic loads.

Shaping and Extrusion

The concrete paving machine carefully shapes the concrete into the desired road profile, accurately forming edges and maintaining a consistent width across the entire surface. This step produces a precise, continuous pavement structure that is ready for reinforcement installation and final finishing. Accurate shaping also ensures uniform thickness and a smooth transition between adjacent pavement sections.

Reinforcement Integration

Steel reinforcement bars can be incorporated during the paving process to further enhance structural strength:

- Intermediate Bars: Strategically placed within the pavement to improve internal structural integrity and resist cracking.

- Side Bars: Installed along the edges to provide additional support, helping the pavement withstand lateral forces and increasing overall durability.

Final Finishing

After the main paving process, trowels, brushes, or other specialized finishing tools refine the surface texture. This final step prepares the pavement for proper curing, ensuring a smooth, aesthetically pleasing, and high-quality concrete surface. The result is a durable roadway capable of handling heavy traffic while maintaining long-term performance and minimal maintenance requirements.

Why This Process Matters

By integrating placement, screeding, compaction, shaping, reinforcement insertion, and finishing in a single workflow, slipform concrete paving machines:

- Reduce labor requirements and operational time.

- Deliver uniform, durable, and precise pavements.

- Minimize errors and maintenance needs, maximizing long-term performance.

Cooperate with Aimix for Reliable and Efficient Concrete Paving Machines

Partnering with Aimix, one of the trusted concrete paving machine manufacturers, ensures access to high-quality paver machines featuring advanced control systems, customizable options and robust construction.

In addition to reliable equipment, We also provide full professional support, including installation guidance, operator training, maintenance, and technical assistance. Contractors can select the ideal paver machines to match their specific requirements and timelines. Choosing Aimix concrete paver machines ensures reliable, high-performance, and cost-effective solutions for successful construction projects. Conact us today for concrete paver machine price!