Navigating your options for a concrete pump sale in Sri Lanka is about more than just price; it’s about finding a reliable partner for your specific projects. The intense heat, monsoon rains, and unique job sites across the island demand equipment built for durability and performance. Choosing the right pump is the key to ensuring your projects in Sri Lanka stay on schedule and within budget. This guide will help you understand your best choices, ensuring you invest in a solution that truly works for you.

Choosing the Right Pump for Your Sri Lanka Job Site

The first and most crucial choice you’ll make is about the heart of the concrete pump machine in Sri Lanka: its power source. This isn’t just a technical detail; it’s about what will keep your project running smoothly in the real-world conditions of Sri Lanka.

Power Source: Diesel or Electric? A Quick Comparison

Choosing the right power source is crucial for your project’s efficiency. The decision often comes down to the reliability of your site’s power supply and the nature of your work. Use the table below to see which option best fits your needs in Sri Lanka.

|

|

|

|---|---|---|

| Diesel Powered Concrete Pump | Type | Electric Powered Concrete Pump |

| High. Self-powered; ideal for remote sites or areas with frequent power cuts. | Power & Independence | Grid-dependent. Requires a stable, on-site electricity connection. |

| Large-scale projects, remote locations, and initial construction phases without grid power. | Best For | Urban projects, indoor applications, enclosed spaces, and sites with reliable power. |

| Fuel costs can be higher, but offset by unmatched mobility and independence. | Operating Cost | Generally lower; electricity is more cost-effective than diesel for prolonged use. |

| Produces on-site emissions. | Environmental Impact | Zero on-site emissions; a cleaner option for sensitive environments. |

| Total flexibility. Your project continues, rain or shine, regardless of the local power grid. | Key Advantage | Quiet & cost-efficient. Lower noise and running costs for suitable sites. |

So, Which One is for You?

This choice is simple:

If your site lacks reliable power or is in a remote area, a diesel concrete pump is your only practical choice.

If you are working within a city like Colombo or Kandy on a site with stable power, and value lower noise and emissions, an electric pump will be more economical.

Not sure about your site’s conditions? Our team can advise you based on your specific location and project plan.

Pump Type: Boom, Mixer, or Trailer? Your Quick Guide

Choosing the right type of concrete pump is about matching the machine’s strengths to your project’s specific demands in Sri Lanka. Here’s a clear breakdown of your main options.

Boom Pumps: Unmatched Reach for Large-Scale Efficiency

When your project demands speed, height, and precision, boom pumps are the answer. They are essential for major constructions across the island.

The concrete pump car in Sri Lanka is the most common choice for large-scale urban projects. With a boom reach of up to 58 meters and an output of up to 120 m³/h, it delivers concrete quickly to great heights. Its integrated truck chassis allows for fast relocation between sites, making it ideal for major projects in Colombo or on new highway developments.

Does your site have challenging terrain? The crawler-mounted boom concrete pump, with a climbing ability of 35°, is built for mud, slopes, and confined spaces where a truck cannot go. With a maximum reach of 25 meters and an output of 50 m³/h, it’s the go-to solution for difficult-to-access locations in the hill country or undeveloped areas.

A versatile option that balances mobility and performance. With a boom reach of up to 33 meters and an output of 89 m³/h, it offers great flexibility for medium to large projects that require efficient movement between multiple sites.

Mixer Pumps: The Ultimate All-in-One Solution

For small to medium-sized projects, mixer concrete pumps combine mixing and pumping into one machine, saving you time, space, and cost.

Engineered for superior concrete quality and uninterrupted operation. With a max output of 40 m³/h, its unique mixing system ensures 360° mixing with no dead angles for a more uniform mix. An extra-large hopper and intelligent control system work together to significantly reduce the risk of pipe blockages, making it ideal for projects where consistency and efficiency are paramount.

Built for powerful pumping over long distances. This model of concrete mixer pump for sale in Sri Lanka also delivers 40 m³/h but can reach an impressive 150m vertically or 600m horizontally. It is a reliable choice for remote locations like rural farm roads or off-grid sites, and is available in both diesel and electric versions to suit your site’s power availability.

Trailer Pumps: Powerful, Flexible, and Cost-Effective

If you need dedicated pumping power at an excellent value, the our concrete trailer pump for sale in Sri Lanka is a reliable workhorse. It can be towed to any site and is available in both diesel and electric versions to suit your power availability.

Our trailer type diesel concrete pump Sri Lanka (Models ABT30C-ABT90C) deliver a powerful output ranging from 30 to 90 m³/h, capable of reaching 260 meters vertically or an impressive 1200 meters horizontally. They are indispensable for remote sites without a stable power grid.

Our electric trailer pumps (Models ABT30D-ABT90D) offer the same robust output with lower operating costs, ideal for projects in urban areas with reliable electricity.

Which type is right for you? The best choice depends entirely on your project’s scale, location, and access. Contact us with your project details, and our local experts in Sri Lanka will help you select the most efficient and profitable solution.

Understanding the specifications of each pump is crucial, but the true test of any equipment is its performance in the field. We have a history of supplying reliable concrete pumps to contractors across Sri Lanka, helping them meet their project goals with efficiency and confidence.

Customer Case: Shipped Reliable Diesel Pumps for a Sri Lankan Project

We were pleased to supply and deliver two units of our ABT80C diesel trailer pumps to a valued client in Sri Lanka for a significant new construction project. This model can pump 80 cubic meters every hour. We recommend this type based on our customer’s project and its own reliability:

- Durable Control Systems: The pumps feature fully enclosed electrical cabinets and a robust PLC system built with international components like Schneider and Mitsubishi, ensuring stable operation and easier maintenance.

- Simple & Strong Hydraulics: The double-circuit hydraulic system is designed for longevity and consistent performance, a key advantage for continuous operation.

- End-to-End Support: We managed the complete supply chain, from initial transport to secure port packing, ensuring a smooth delivery process for our client.

This successful deployment is a testament to our ability to provide not just machinery, but dependable solutions backed by comprehensive support.

It’s clear that choosing the right pump is pivotal. This decision is often shaped by the specific demands of the projects you’re undertaking. Many of Sri Lanka’s most significant national initiatives require robust, reliable, and efficient equipment to meet their ambitious goals. Understanding these projects can serve as an excellent benchmark for selecting the ideal pump for your own endeavors.

Sri Lanka’s National Projects: Your Blueprint for Pump Selection

Understanding the specifications of each pump is crucial, but the true test of any equipment is its performance in the field. Looking at the country’s major infrastructure initiatives provides a perfect blueprint for selecting the right pump for your own project’s scale and demands.

The following table matches real-world Sri Lankan projects with the ideal concrete pumps, serving as a practical guide for your equipment choice.

| National Project Example | Project Scale & Challenge | Recommended AIMIX Pump | Key Reasons for the Match |

|---|---|---|---|

| Central Expressway Project | Large-scale, linear project requiring high-output pumping, often in areas with limited grid power. | Diesel Trailer Pump (e.g., ABT80C) & Truck-Mounted Boom Pump | The ABT80C's high output (up to 90 m³/h) and long-distance pumping (1200m horizontal) are ideal for groundwork. Boom Pumps (up to 58m reach) provide efficiency for bridges and complex structures. |

| Colombo Port City Development | Major urban reclamation with high-rise structures, requiring precise placement at height and volume. | Truck-Mounted Boom Pump | Boom Pumps offer the necessary reach (up to 58m), output (up to 120 m³/h), and speed for rapid construction of high-rise buildings in a controlled environment. |

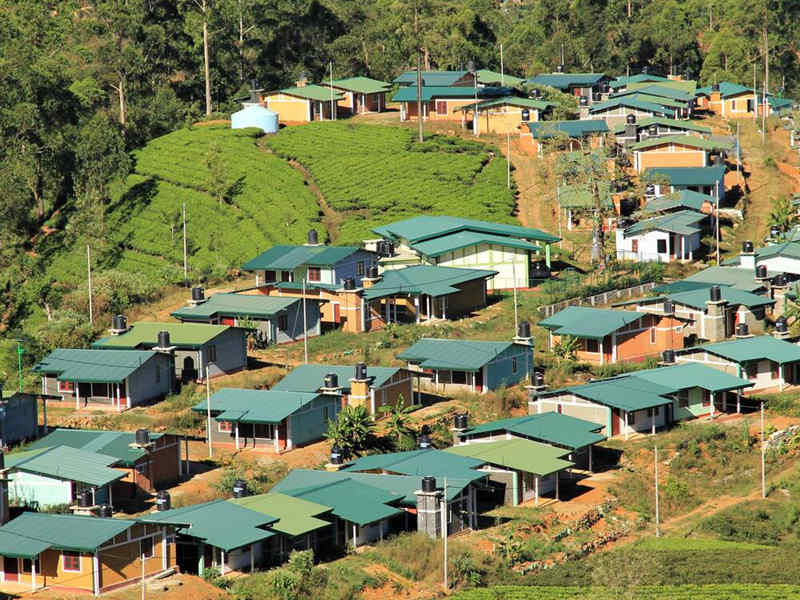

| Rural Road & Housing Initiatives | Smaller, scattered projects in remote locations with challenging access and unstable/no power. | Diesel Mixer Pump (e.g., ABJZ40C) | This all-in-one solution mixes and pumps, perfect for sites without ready-mix concrete supply. Its diesel engine ensures independence from the grid, and it can pump 150m vertically. |

How to Use This Guide: Simply identify which project type most closely resembles your own in terms of size, location, and concrete requirements. The recommended pump type is your starting point for an efficient and profitable operation.

Building upon the insights from national projects, it’s crucial to address the specific on-ground challenges that characterize construction in Sri Lanka. The country’s unique tropical environment presents a distinct set of hurdles that can impact project timelines and costs. Understanding these challenges—and the proven strategies to overcome them—is key to ensuring the success of your project, regardless of its scale.

Effective Solutions for Common Construction Challenges in Sri Lanka

Here is a practical guide to navigating common Sri Lankan construction challenges, with a focus on effective solutions and the role of reliable equipment like concrete pumps.

Managing Heavy Rainfall and High Humidity

Sri Lanka’s tropical climate means contractors must expertly manage prolonged rainy seasons and high humidity, which can severely impact concrete work and site operations.

- Challenge: Frequent rain leads to waterlogged sites, delays in curing, and difficulties in controlling the moisture content of sand aggregates. It’s common for the upper layer of sand piles to be dry while the bottom remains wet, resulting in inconsistent concrete mix quality.

- Solutions & Pump Strategy:

- Advanced Site Planning: Implement detailed weather scheduling, using visual rain charts to pre-plan tasks around forecasted rain.

- Improve Drainage: Use a base layer of no-fines concrete under sand stockpiles. This highly permeable layer allows water to drain quickly, helping to unify the moisture content of sand aggregates and significantly reducing drying time.

- Pump Advantage: Diesel-powered trailer pumps or mixer pumps offer crucial independence from grid power, which can be unreliable during heavy storms. Their mobility also allows for quick repositioning away from flood-prone areas on site.

Navigating Complex Geology and Terrain

The island’s varied topography includes rocky subsurface in some areas and soft peat soil in others, demanding adaptable techniques for foundation work and earthmoving.

- Challenge: Projects often encounter hard rock layers that are difficult to penetrate for piles, or unstable soft peat soil that compromises roadbed stability.

- Solutions & Pump Strategy:

- For Rocky Ground: Use enhanced drilling tools, such as alloy steel drill bits for deep mixing piles, to improve penetration rates and durability in rock strata.

- For Soft Soil: Conduct trial sand pile and static load tests to determine optimal pile spacing and treatment depth for stabilizing soft peat soil foundations.

- Pump Advantage: Crawler-mounted boom pumps are ideal for slippery, unstable ground with their excellent climbing ability (up to 35°) and minimal ground pressure. For linear projects like roads, high-pressure trailer pumps can convey concrete over long distances (e.g., 1200m horizontally), avoiding the need to relocate the pump frequently.

Sourcing Materials and Ensuring Quality

Access to consistent, high-quality construction materials can be a challenge, particularly outside major urban centers like Colombo.

- Challenge: Limited local availability of certain materials or varying quality standards can lead to project delays and necessitate careful quality control.

- Solutions & Pump Strategy:

Local Sourcing with Rigorous QC: Partner with reliable local suppliers and establish on-site material testing labs. Training local staff in quality inspection techniques ensures consistent standards. - Pump Advantage: Pan mixer pumps ensure superior mixing quality (360° mixing with no dead angles) and produce over 30% more uniform and dense concrete. This is vital when working with locally sourced materials that may have variable characteristics, as it guarantees consistent final concrete quality directly on site.

Operating in Confined Urban Sites

Construction in densely built urban areas like Colombo or near sensitive structures often means working within extremely tight spaces.

- Challenge: Limited space for material storage, equipment movement, and crane operations, coupled with the need to minimize disruption to surrounding traffic and buildings.

- Solutions & Pump Strategy:

Meticulous Logistics Planning: Implement just-in-time material delivery and use smaller, modular equipment. For projects like deep foundation pits, use techniques such as secant pile walls to create a water-tight barrier in tight spaces. - Pump Advantage: Mini concrete mixer pump for sale in Sri Lanka or compact trailer pumps are perfect for confined sites. Their small footprint and agility allow them to operate where larger equipment cannot. Furthermore, boom pumps with long reach can place concrete precisely from a single setup point outside the cramped work area, minimizing movement and maximizing efficiency.

By integrating these proven strategies and choosing the right equipment, you can effectively mitigate the unique challenges of building in Sri Lanka. A reliable concrete pump, selected with these conditions in mind, becomes more than just a machine—it’s a cornerstone for achieving efficiency, quality, and project success.

Following the exploration of Sri Lanka’s national projects and specific on-site challenges, you likely have some practical questions. This FAQ section is designed to address those common queries with clear, straightforward information to help you make a confident decision.

Here are answers to some of the most frequently asked questions by our Sri Lankan clients.

FAQ: Your Concrete Pump Questions Answered

1. What import duties apply to concrete pumps in Sri Lanka?

This is a crucial question for budgeting. The import process involves a few key cost components based on the pump’s value (CIF value: Cost, Insurance, and Freight).

- Import Duty: The standard duty rate can vary. However, under the Asia Pacific Trade Agreement (APTA), which includes Sri Lanka, a preferential rate may apply.

- Value Added Tax (VAT): A VAT of 15% is typically applied to the CIF value plus the import duty.

- Port and Handling Charges: These are variable fees charged by the port authority and logistics providers.

- Our Support: While we cannot give a definitive final figure, we can provide a pro-forma invoice with a detailed product value. We strongly recommend you consult with a licensed Sri Lankan customs clearing agent for the most accurate calculation based on the latest regulations. We can also assist by ensuring all shipping documents are accurate and complete.

2. If my equipment breaks down in Kandy, how will you support me?

We understand that downtime costs you money, and reliable support is essential. Our support system is designed for a rapid response, no matter where you are in Sri Lanka.

- Remote Troubleshooting: Our technical team is available via WhatsApp or phone for immediate remote diagnostics. Many issues can be resolved quickly through guided troubleshooting.

- Supply of Spare Parts: We maintain a stock of critical spare parts (like S-Valve seals, cutting rings, and hydraulic filters) for prompt shipment. For urgent needs, we can arrange air freight to minimize waiting time.

- Comprehensive Documentation: We provide detailed operation manuals, hydraulic circuit diagrams, and troubleshooting guides in English to empower your team.

3. What is the price range for a mini concrete pump?

The price of a mini concrete pump varies significantly based on its specifications, brand, and configuration.

Getting an Exact Quote: The best way to get a precise price is to contact us with your specific requirements. Please let us know your project’s required vertical/horizontal pumping distance, the type of concrete you’ll use, and your preferred power source (diesel/electric). We will then provide a detailed quotation for the model that best fits your needs and budget.

Line pumps cpower and the diamstance.

4. Are your pumps suitable for Sri Lanka’s climate and common building materials?

Absolutely. This is a core part of our design and product selection for the Sri Lankan market.

- Climate: Our diesel engines are chosen for their ability to perform in high temperatures. The electrical systems feature fully enclosed control boxes that protect against high humidity and occasional heavy rain.

- Building Materials: Our pumps, particularly those with S-Valve technology, are designed to handle the common aggregate sizes and standard concrete mixes used in Sri Lanka. We can advise on the optimal settings for your specific mix.

5. Do you offer financing or leasing options?

We understand that large capital expenditures require flexibility. We currently do not provide direct financing or equipment for learsing. However, we can assist you by providing all necessary documentation (e.g., pro-forma invoices, product specifications) to support your loan application with your local bank in Sri Lanka.

We hope this clarifies your questions. If you have any more, please do not hesitate to reach out. Our team is here to provide the details you need to move forward with your project.

Maximizing Your Return on Investment

Making a smart equipment purchase is the first step. The next—and equally important—step is ensuring it becomes a lasting and profitable asset for your business. Here are practical strategies used by successful contractors across Sri Lanka to get the most value from their concrete pumps.

Protect Your Investment with Proactive Maintenance

Think of maintenance not as a cost, but as the best insurance against costly downtime. A well-maintained pump retains its value and performance for years.

- Follow the Schedule: Adhere strictly to the recommended daily, weekly, and monthly maintenance checks for lubrication, filter changes, and system inspections.

- Use Genuine Parts: Always use original spare parts. Non-genuine parts may seem cheaper initially but often lead to premature wear and more expensive repairs.

- Train Your Team: Ensure your operators know how to perform basic checks and recognize early signs of potential issues.

Generate Income During Project Downtime

Your pump doesn’t have to sit idle between your own projects. It can become an independent source of revenue.

- Partner with Rental Companies: Establish relationships with local equipment rental companies in Colombo, Kandy, or other major cities. They can find clients for you during your quiet periods.

- Network with Other Contractors: Connect with contractors who specialize in different types of work. Your pump could be the perfect solution for their short-term needs.

- Use Online Platforms: List your equipment on Sri Lankan construction and classifieds websites to reach a wider audience of potential renters.

Plan for the Future: Resale Value

A concrete pump is a durable asset. When you’re ready to upgrade or your business needs change, a well-cared-for machine can be sold for a significant return.

- Keep Full Service Records: A complete and well-documented maintenance history is extremely valuable to a potential buyer and can significantly increase the resale price.

- Consider the Market: Models that are popular and well-supported in Sri Lanka (like the diesel-powered pumps we discussed) tend to have stronger resale value.

- Prepare the Equipment: Before sale, ensure the pump is thoroughly cleaned and serviced. A good appearance and smooth operation make a strong impression.

By implementing these strategies, you move from simply owning a pump to actively managing a valuable business asset. Have questions about maintaining or marketing your specific model? Our team can provide detailed guidance and support to help you succeed.

Purchasing a concrete pump is a significant decision, but it’s the support behind it that truly defines your long-term success. Our partnership doesn’t end with the sale; it’s where it begins. We are committed to ensuring your pump delivers maximum value and productivity for years to come, right here in Sri Lanka.

Aimix – Your Support Network

We understand that you need a partner who can respond quickly and effectively. That’s why we’ve built a robust support system tailored for Sri Lanka:

- Dedicated After-Sales Team: Your project has a dedicated point of contact. Our team provides remote troubleshooting via WhatsApp or phone, operational guidance, and helps you coordinate any service needs efficiently.

- Comprehensive Training: We provide detailed operational and basic maintenance training for your team, ensuring you can operate the equipment safely and with confidence from day one.

We’ve explored the essential concrete pump in Sri Lanka for your projects, addressed local challenges, and shown how to maximize your investment. Start your business from cooperating with Aimix today!