Concrete pump UAE solutions are essential for supporting the country’s fast-paced urbanization and ambitious infrastructure projects. In a nation known for its towering skyscrapers and complex construction demands, concrete pumps ensure faster, safer, and more accurate delivery of concrete. From Dubai’s high-rises to Abu Dhabi’s road networks, the use of concrete pumps significantly boosts productivity and project efficiency across the UAE.

Types of Concrete Pump in UAE

Aimix has three types of concrete pump UAE for sale and the mobile type is the most popular one.

Mobile Concrete Pump

Aimix provides three kinds of mobile concrete pump UAE, all with long boom and vertical shaft pan mixer. They solve the troublesome and time-consuming of pipe placement. The boom concrete pump and concrete mixer work in perfect harmony, covering the entire process of mixing, pumping, and distributing. This collaboration reduces equipment scheduling costs and expands the operational radius by 50%.

Concrete Pump Truck with Pan Mixer

- Advantages:

- 1. The concrete pump truck UAE is equipped with a fully hydraulic vertical shaft planetary type mixing system for highly efficient mixing without 360° dead zone, it achieves over 30% improvement in concrete uniformity and density.

- 2. Adopting double shaft mixing technology, it can increase the single batch processing capacity by two times.

- 3. It features a truck chassis structure, boosting relocation efficiency by 60% and enabling “immediate operation upon arrival and quick relocation upon completion.”

-

Boom Length: 26m30m33m38m

- Max Concrete Output: 120m³/h

- Hot Model: AMY33

- Application: Urban high-rise construction, expressway bridges, industrial complexes

Crawler Chassis Concrete Pump with Pan Mixer

- Advantages: Equipped with an all-terrain tracked chassis and an adaptive hydraulic suspension system, it provides a climbing capability of 35°. Besides, with a function of 360° zero-radius turning, it enables “zero-preparation construction” in extreme conditions such as mud, desert, and mountainous terrain, improving passability by 60%.

-

Boom Length: 8m15m18m20m25m

- Max Concrete Output: 50m³/h

- Hot Model: AMY18

- Application: Slope stabilization, hydropower plants, plantation infrastructure

Wheel Chassis Concrete Pump with Pan Mixer

- Advantages: Designed with an engineering chassis structure,the wheeled boom concrete pump and mixer can realize “immediate operation upon arrival and quick relocation upon completion,” and the transfer efficiency is increased by 60%.

-

Boom Length: 20m26m30m33m

- Max Concrete Output: 89m³/h

- Hot Model: AMY20, AMY26

- Application: Affordable housing, rural schools, township drainage

Stationary Concrete Pump

- Function: Transport concrete through pipelines to a specified location

- Model: ABT30, ABT40, ABT60, ABT80, ABT90

- Production Range: 30-90 m³/h

- Engine Type: Electric/diesel

- Applications: Mass concrete pours, high-rise cores, hydroelectric dams, industrial flooring

- Advantages: The stationary concrete pump is suitable for high-rise construction, large foundations, and infrastructure projects where access may be challenging.

Concrete Mixing Pump

Aimix provides concrete mixing pumps with two different kinds of mixer- pan mixer and drum mixer.

Pan Mixer Concrete Mixing Pump

- Max Concrete Output: 40m³/h

- Model: ABJW40C, ABJW60C, ABJW80C

- Application: Large-scale infrastructure, industrial complexes, cross-state highways

- Advantages: The vertical shaft mixer sales has dual hydraulic drive. It mixes concrete with two mixing shafts which increase the mixing speed by 2.3 times.

Drum Mixer Concrete Mixing Pump

- Model: ABJZ30, ABJZ40

- Production Range: 30-40 m³/h

- Engine Type: Electric/diesel

- Application: Urban housing upgrades, rural community centers, heritage restoration

- Advantages: It is a cost-effective choice for projects require moderate quality concrete mixture.

Specifications of Concrete Pump Machine UAE

| Items | Key Parameters | Units | ABJZ30C | ABJZ30D | ABJZ40C | ABJZ40D |

|---|---|---|---|---|---|---|

| whole performance of machine | Max. theo. concrete output(L./H) | M3/h | 30 | 30 | 40 | 40 |

| Mixer rated feed capacity | m3 | 0.56 | 0.56 | 0.56 | 0.56 | |

| Mixer rated discharge capacity | m3 | 0.35 | 0.35 | 0.45 | 0.45 | |

| Max.concrete pumping pressure(H./L.) | MPa | 10 | 10 | 10 | 10 | |

| Distribution valve type | S Valve | S Valve | S Valve | S Valve | ||

| Hopper capacity | L | 400 | 400 | 400 | 400 | |

| Power system | Diesel engine model | Weichai | ||||

| Electrical engineering power | KW | 37 | 37 | 82 | 45 | |

| Rotate speed | r/min | 1480 | 1480 | 2200 | 1480 | |

| Hydraulic system | Circuit type | Open circuit | Open circuit | Open circuit | Open circuit | |

| Pumping system pressure | MPa | 26 | 26 | 32 | 26 | |

| Capacity of oil tank | L | 260 | 260 | 350 | 370 |

| Items | Key Parameters | Units | ABT40C | ABT60C | ABT80C |

|---|---|---|---|---|---|

| Whole performance of machine | Max. theo. concrete output(L./H) | M3/h | 40/26 | 67/45 | 84/45 |

| Max.concrete pumping pressure(H./L.) | MPa | 10/8 | 13/7 | 16/7 | |

| Distribution valve type | S Valve | S Valve | S Valve | ||

| Concrete cylinder diameter×stroke | mm | Φ180×1200 | Φ200×1650 | Φ200×1800 | |

| Hopper capacity x feeding height | L/mm | 400/1100 | 800/1400 | 800/1400 | |

| Outlet diameter | mm | Φ150 | Φ180 | Φ180 | |

| Power system | Diesel engine model | Weichai | Wechai | Wechai | |

| Diesel engineering power | KW | 82 | 129 | 176 | |

| Rotate speed | r/min | 2200 | 2200 | 2200 | |

| Hydraulic system | Circuit type | Open circuit | Open circuit | Open circuit | |

| Pumping system pressure | MPa | 32 | 32 | 32 | |

| Mixing system pressure | MPa | 10 | 10 | 10 | |

| Capacity of oil tank | L | 370 | 560 | 560 | |

| Other parameters | Max. Theoretical Vertical/Horizontal Conveying Distance | m | 120/500 | 180/1000 | 260/1200 |

| Max. aggregate diameter | mm | Slick/scree:40 | Slick/scree:40 | Slick/scree:40 | |

| Inside diameter of delivering pipe | mm | Φ125 | Φ125 | Φ125 | |

| Dimensions:length×width×height | mm | 5000x1850x1700 | 5800x2000x1750 | 6300x2100x2350 | |

| Total weight | kg | 4500 | 6500 | 6900 |

| Items | Key Parameters | Units | ABT40D | ABT60D | ABT80D |

|---|---|---|---|---|---|

| Whole performance of machine | Max. theo. concrete output(L./H) | M3/h | 40/26 | 60/36 | 84/46 |

| Max.concrete pumping pressure(H./L.) | MPa | 10/8 | 13/7 | 16/9 | |

| Distribution valve type | S Valve | S Valve | S Valve | ||

| Concrete cylinder diameter×stroke | mm | Φ180×1300 | Φ200×1650 | Φ200×1800 | |

| Hopper capacity x feeding height | L/mm | 400/1250 | 800/1400 | 800/1400 | |

| Outlet diameter | mm | Φ150 | Φ180 | Φ180 | |

| Electrical engineering power | KW | 45 | 90 | 110 | |

| Rotate speed | r/min | 1480 | 1480 | 1480 | |

| Hydraulic system | Circuit type | Open circuit | Open circuit | Open circuit | |

| Pumping system pressure | MPa | 28 | 28 | 32 | |

| Mixing system pressure | MPa | 10 | 10 | 10 | |

| Capacity of oil tank | L | 370 | 560 | 560 | |

| Other parameters | Max. Theoretical Vertical/Horizontal Conveying Distance | m | 120/500 | 160/800 | 200/1000 |

| Max. aggregate diameter | mm | Slick/scree:40 | Slick/scree:40 | Slick/scree:40 | |

| Inside diameter of delivering pipe | mm | Φ125 | Φ125 | Φ125 | |

| Dimensions:length×width×height | mm | 4500x1750x1600 | 5500x2000x1750 | 5800x2100x2350 | |

| Total weight | kg | 3200 | 6000 | 6300 |

Concrete Pump Solutions for Major UAE Cities

Here shows our concrete pump solutions matching with representative projects in each city and explaining the suitability:

Dubai – Burj Khalifa & Future Skyscrapers

- Project: Burj Khalifa (828m, world’s tallest building) & upcoming super-tall towers

- Recommended Pump: AMY38 (38m Boom Pump Truck)

- Reason: High-rise construction demands long boom reach (38m) and high output (120m³/h) for fast-paced vertical pumping. The lightweight design ensures maneuverability in dense urban sites.

Abu Dhabi – Al Maryah Central Tower & Infrastructure

- Project: Al Maryah Central (mixed-use high-rise) & major road networks

- Recommended Pump: ABT80 (Stationary Concrete Pump)

- Reason: Large-scale foundations and core walls require high-pressure pumping (80m³/h) with diesel/electric options for uninterrupted pours in extreme heat.

Sharjah – Al Faya Lodge & Desert Resorts

- Project: Al Faya Lodge (luxury desert construction)

- Recommended Pump: AMY18 (Crawler Chassis Pump)

- Reason: Remote desert sites need crawler mobility and remote-controlled operation for precision placement in rugged terrain.

Ajman – Affordable Housing & Urban Expansion

- Project: Ajman Uptown (residential high-rises)

- Recommended Pump: AMY26 (Wheel Chassis Pump)

- Reason: Compact urban sites benefit from wheel-mounted booms (26m) that require less space than truck-mounted pumps while maintaining efficiency.

Fujairah – Port & Hydroelectric Projects

- Project: Fujairah Port expansion & dam constructions

- Recommended Pump: ABJW40C (Pan Mixer Concrete Pump)

- Reason: Large infrastructure projects need dual-shaft mixing (40m³/h) for high-volume, consistent concrete supply near coastal sites.

Umm Al-Quwain – Industrial & Warehouse Complexes

- Project: UAQU Industrial Zone

- Recommended Pump: ABJZ30 (Drum Mixer Pump)

- Reason: Cost-effective 30m³/h drum mixing suits mid-scale industrial floors and warehouses with moderate concrete demand.

Ras Al Khaimah– Mountain Resorts & Tourism Projects

- Project: Jebel Jais Mountain Resorts

- Recommended Pump: AMY20 (Crawler Pump with 20m Boom)

- Reason: Steep slopes require crawler stability and shorter boom reach (20m) for precise placement in mountainous terrain.

Each project is unique, the projects and their matching concrete pump solutions above shows you some examples. Please feel free to contact us and our project managers will help you find the concrete pump UAE suitable for your project.

Concrete Pump Price in UAE

| Boom Concrete Pump Price: | Truck Type: at least 80,000 USD Crawler Type: 62,000-73,000 USD Wheel Type: 81,000-92,000 USD |

| Mixer Concrete Pump South Africa Price: | Pan Mixer Type: 32,000-35,000 USD Drum Mixer Type: 18,000-28,000 USD |

| Concrete Pump Stationary Price in UAE: | 12,000-43,000 USD |

Future Development of UAE Construction Equipment Industry

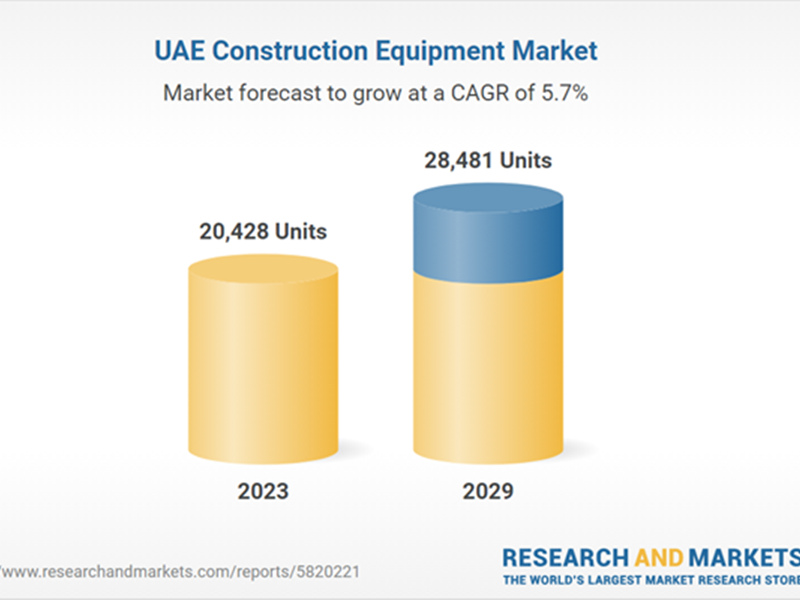

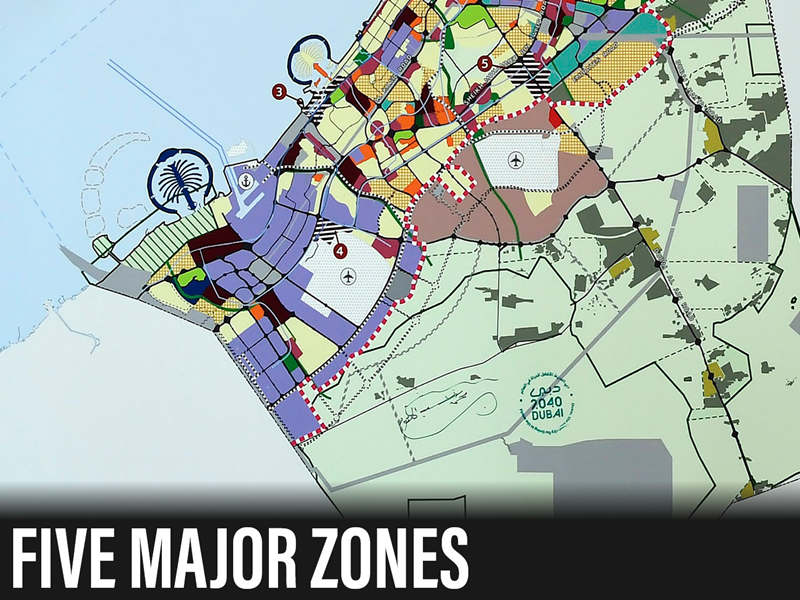

The UAE construction equipment market, particularly the concrete pump segment, is poised for robust growth, driven by the nation’s ambitious infrastructure agenda, policy frameworks, and technological advancements. With the market size projected to expand from 20,428 units in 2023 to 28,481 units by 2029 (CAGR 5.70%), concrete pumps will play a pivotal role in delivering high-efficiency solutions for large-scale projects(from research and market platform UAE construction equipment market report). Below are the key drivers and trends shaping the sector:

Government-Led Infrastructure Investments

Railway Expansion: Projects like the Dubai Metro Blue Line (30 km, 14 stations) and the National Rail Network (1,200 km linking all seven emirates) require advanced concrete pump Dubai solutions for viaducts, stations, and tunnel construction.

Tourism Infrastructure: Abu Dhabi’s $10 billion tourism investment (2024–2030) will drive construction of theme parks, hotels, and cultural sites, necessitating high-capacity concrete pumps for rapid, precision work.

Urban Mobility: The Dubai Harbor Access Project ($117.3 million contract awarded in March 2024) highlights the need for concrete pump for sale in Dubai to optimize traffic infrastructure development.

Mega Projects and Real Estate Growth

High-Rise Construction: Projects like the 25-story residential tower in Jumeirah Village Circle underscore the reliance on concrete pumps for vertical construction efficiency.

Renewable Energy and Smart Cities: The UAE’s focus on solar farms and smart city projects (e.g., Dubai Sustainable City) requires specialized pumping equipment to handle large volumes of concrete for foundations and structural components.

Technological Innovation and Sustainability

The UAE’s concrete pump market is set to thrive on the back of unprecedented infrastructure spending, technological innovation, and sustainability mandates. As mega projects and urban development accelerate, advanced pumping systems will remain indispensable for achieving speed, precision, and environmental compliance. Stakeholders investing in smart, energy-efficient solutions are well-positioned to capitalize on this growth trajectory.

Aimix Advantages

Extensive Global Reach

Aimix has successfully exported construction machinery to over 150 countries and regions worldwide, including the UAE, Indonesia, Brazil, the Philippines, and Uzbekistan.

Worldwide Branch Network

We have established more than six overseas branches in key markets such as the Philippines, Indonesia, Malaysia. These Aimix branches serve as local service centers, providing prompt support and product availability.

Over 100 Global Service Outlets

Aimix operates over 100 service outlets globally, ensuring timely maintenance, spare parts supply, and technical assistance for our clients.

Proven Industry Experience

With more than 30 years of experience in manufacturing and exporting construction machinery, Aimix is renowned for delivering high-quality and stable-performance equipment.

Certified Quality Assurance

Our products are certified by international standards such as ISO and CE, ensuring compliance with global quality and safety benchmarks.

Customer-Centric Solutions

Aimix offers customized concrete solutions tailored to meet the specific needs of different projects and clients, enhancing efficiency and performance.

Commitment to Innovation

We continuously invest in research and development to innovate and improve our product offerings, incorporating advanced technologies to enhance user experience.