The construction waste recycling industry is refers to a series of activities involving the generation, collection, transportation, treatment and utilization of construction waste. It is emerging as a high-potential sector driven by green policies, advanced technologies, and rising demand for recycled materials. For contractors, developers, and environmental investors, this isn’t just a compliance strategy, it’s a profitable future. The question now is: are you ready to turn rubble into revenue? How to turn? Here AIMIX can offer you the best construction waste recycling solutions.

AIMIX Empowers Smart Construction Waste Recycling with Full-Scale Crushing Solutions

In today’s era of sustainable construction, construction demolition waste recycling is a necessity. AIMIX, a trusted manufacturer of rushing equipment in China, delivers complete, field-proven crushing solutions to transform construction and demolition waste into valuable materials. With a sharp focus on mobility, efficiency, and environmental responsibility, AIMIX proudly offers two innovative products tailored for on-site construction waste disposal:

Designed for quick transitions between job sites,the 3-in-1 wheeled mobile crusher plant offers unmatched speed and versatility for contractors who need results on the move. With rapid setup and intuitive operation, it’s an ideal choice for commercial building tear-downs and medium-scale construction rubbish disposal jobs.

APY3 Series Wheeled Mobile Crusher – Fast setup, Fast Profit

- Capacities: 50-400 tph

- Main crushers: impact crusher machine

Key Advantages

- Quick Relocation – Three-axis axle chassis design allows for quick movement and convenient transfer

- Low Operation Cost – Integrates feeding, crushing and screening, integrates the crushing process and reduces operating costs

- Low Energy Consumption – The whole mobile crusher machine adopts energy-saving motor, which has low energy consumption and saves 30% energy

The crawler mobile crusher is designed to go where traditional machines can’t. Mounted on a heavy-duty tracked chassis, it conquers rough terrain and tight urban sites with ease. Ideal for large-scale demolition or remote-area builders waste recycling, this crawler crusher plant integrates crushing, screening, and conveying into one robust system.

APYL Series Crawler Mobile Crusher – Unmatched Power, Ultimate Mobility

- Capacities: 100-400 tph

- Main crusher: impact crusher

Key Advantages

- Excellent off-road mobility – Equipped with a hydraulically driven crawler chassis, which has stronger off-road performance. It can adaptable to extreme construction environments such as urban demolition.

- “Crushing While Walking” Capability – Wireless remote control operation, it can be moved and operated instantly at the work site at any time without additional traction equipment. Strong operating flexibility, saving transportation and loading and unloading time

Designed Specifically For Construction Waste Recycling: Six Unique Designs Make Crushing Cleaner And More Efficient

In the field of construction waste recycling, many devices rely on traditional structures and are difficult to cope with new generation engineering requirements such as dust control, energy consumption optimization and continuous operation. AIMIX breaks this limitation and independently develops a more forward-looking mobile crushing solution based on the actual needs of construction waste recycling. From crushing efficiency to environmental performance, from structural optimization to intelligent control, each design is derived from real feedback from front-line construction scenes, truly achieving multiple breakthroughs in high efficiency, low consumption, environmental protection and safety. The following are the six highlights of the AIMIX mobile crushing plant solutions.

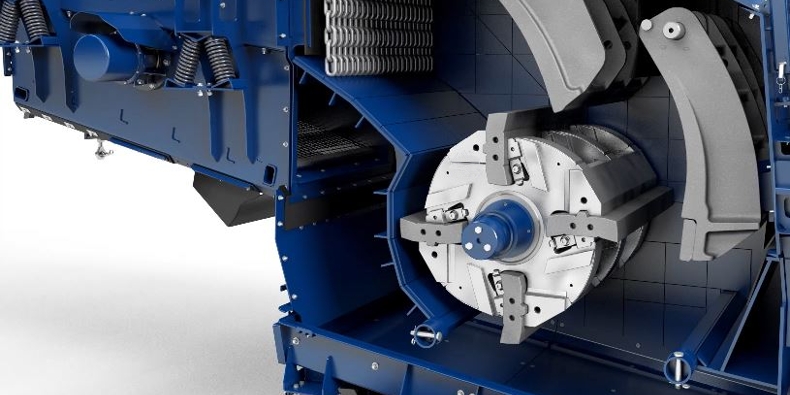

High Efficient Crushing

The main impact crusher machine adopts heavy-duty rotor design and fine processing to meet the requirements of two-stage crushing. It has large crushing ratio and ensures good finished product particle shape.

Longer Service Life of Belts

The tail drum adopts a slag discharge design, which effectively prevents the belt from scratches and wear and ensures stable operation. Besides, the buffer bed design of the impact crusher’s lower main belt provides good impact resistance and sealing, further improving durability. These measures reduce maintenance frequency and improve economic benefits.

Environmentally Friendly

AIMIX offers a comprehensive dust removal solution that reduces dust in raw material areas with fog cannons, uses telescopic dust hoods in unloading areas, equips belt conveyors with protective covers, and employs negative pressure dust removal for impact crusher discharge. These measures effectively maintain a clean work environment and meet environmental protection standards.

Integrated Intelligent Control

Featuring a one-click start system with both PLC touchscreen and manual button control, the setup streamlines operations and boosts productivity by up to 30%. It also simplifies training, reducing both time and associated costs for operators.

IoT-Based Remote Monitoring

The system enables real-time tracking of equipment performance, sends proactive maintenance alerts, and minimizes unexpected breakdowns. It significantly extends the service life of the stone crusher plant and enhances operational reliability.

Smart Feeding

Equipped with remote-controlled dosing, the feeder allows precise adjustment of material flow to match production demands. It ensures continuous, stable crushing and helps keep projects on schedule with higher efficiency.

Widespread Applications: From Demolition to New Construction

Track Crusher and Screener Used for Construction Waste Disposal in Malaysia

- Processing capacity: 200tph

- Output size: 5-10, 10-20, 20-40 mm

- Applications: the recycled aggregates used for Expressway construction

- Configurations: vibrating feeder + crawler impact crusher + crawler vibrating screen + belt

Client’s reviews: “Excellent after-sales service! The engineer patiently installed and trained how to operate the remote control of crushers. The heady-rotor design on the crusher has improved the shape of the finished particles, meeting our road construction demands.”

Wheeled Mobile Crusher for Construction Trash Disposal in Colombia

- Processing capacity: 150tph

- Output size: 0-1/4’-3/4′-1′-2′(0-5-19-25-50mm)

- Applications: Aggregate production for subway construction

- Configurations: vibrating feeder + mobile impact crusher + vibrating screen + belt

Client’s reviews: “Smart operation. I like its quick starts through my finger one-click. Amazing integerated design on the equipment. It not only saved land space, but greatly streamlines operations and improves productivity. ”

300tph Crawler Crusher Operation in Saudi Arabia

- Processing capacity: 300tph

- Output size: 15-40mm

- Applications: recycled aggregate as the materials for road paving

- Configurations: crawler type impact concrete crusher + crawler vibrating screen

Customer reviews: “After using this equipment in our projects, our c&d disposal speed has increased significantly. It is a good crusher that is worth the investment!”

Crawler Crusher Working in the Philippines

- Capacity: 150tph

- Finished Product Sizes: 10-25mm

- Applications: aggregate production for building construction

- Configuration: crawler impact crusher and vibrating screen, etc

Customer Reviews: “I didn’t expect such a professional team. AIMIX helped me realize how much goes into choosing the right construction trash disposal crusher. Thanks to their sales, tech, and after-sales teams, I’ve successfully turned waste into profit and started a second business.”

Potential Equipment Used in Construction Waste Recycling

Collection and Cleaning

Excavators and wheel loaders are responsible for collecting and cleaning the construction waste, digging the waste out of the construction site or stockpile area and carrying it.

Crushing and Screening

Crushing equipment is used to pulverize the waste construction material into the right particle size to enable subsequent processing or reuse. After crushing, the construction waste needs to be sorted by screening equipment to separate out different sizes and types of construction waste for sorting and reuse.

End-Use Solutions for Recycled Aggregates from Construction Debris Disposal

Concrete Batching Plant

The recycled aggregate materials from construction debris recycling can be used as a substitute for natural aggregates in the production of concrete at concrete batching plants. This helps reduce the demand for virgin aggregates and diverts waste from landfills.

Asphalt Mixing Plant

Recycled aggregate materials from building debris disposal can be incorporated into the asphalt mix at asphalt mixer plants. This allows construction and demolition waste to be repurposed rather than sent to disposal sites, while also reducing the need for virgin aggregates in the asphalt production process.

Concrete Paving Machines

The aggregate can be used as a component in the concrete mixture fed into concrete paving machines during road and pavement construction projects. This supports the circular economy by utilizing waste materials and lessens the environmental impact compared to using all new aggregates.

Asphalt Paving Machines

The materials can be blended into the asphalt mix that is laid down by asphalt paving machines. Incorporating these recycled materials into the paving process helps conserve natural resources and reduces construction waste sent to landfills.

Types of Construction Wastes

Construction Debris

This is waste generated during the construction of buildings and structures, including but not limited to:

- Concrete blocks

- Bricks

- Tiles

- Stone

- Steel

- Timber

- Plastic

- Packing materials

Demolition Waste

Waste generated during the process of building demolition (including remodeling of historical buildings) usually includes:

Large quantities of structural materials such as concrete, masonry, steel, etc.

- Gypsum board

- Roofing materials, etc.

Road Demolition Waste

This includes waste generated during the construction and maintenance of roads and bridges, such as:

- Old asphalt

- Crushed stone

- Concrete

- Road signs and guardrails, etc.

Opportunities And Challenges For The Industry

The construction waste industry plays an important role in promoting sustainable development and realizing a circular economy. With the increasing global emphasis on environmental protection and resource conservation, this industry faces unprecedented opportunities and challenges.

- Policy support and increased market demand: Many countries and regions have implemented policy measures to encourage the c and d waste recycling, providing policy support and market momentum for the industry.

- Technological innovation: Technological advances provide more possibilities for effective treatment, sorting and reuse of construction waste, such as the application of efficient technologies like mobile crushing plants and intelligent sorting systems.

- Increased environmental awareness: Increasing public awareness of environmental protection and increased demand for sustainable products and services from enterprises and individuals have brought a broader market for the resource utilization of construction waste.

- Incomplete policies and regulations: Although many places already have relevant policy support, overall, the policy and regulation system for construction waste management is still incomplete, and there are deficiencies in implementation and supervision.

- Outdated technology: Although the technology has developed, there is still the problem of outdated technology, which is unable to efficiently classify, treat and resource utilization of construction waste.

- Immature industry chain: The construction demolition waste recycling involves a long industry chain with many links that need to be coordinated, and faces its own challenges from the initial sorting to the final sale of reused products.

The construction waste industry plays an important role in promoting environmental protection and resource recycling, but also faces challenges in various aspects such as cost, technology, policy and market. Through scientific and technological innovation, policy guidance and market cultivation, the healthy development of the construction waste industry can be effectively promoted, realizing a win-win situation in terms of economic benefits and environmental protection.

What AIMIX Can Do To Support You

As a leading company in the construction machinery industry, AIMIX Group can provide customers with a full range of construction waste treatment solutions. Our services include:

-

Equipment supply:

AIMIX provides a complete set of construction waste treatment equipment, including crushing equipment, screening equipment, conveying equipment, separating equipment and molding equipment, which guarantees the high efficiency and durability of the equipment.

-

Technical support:

Our professional team can provide customers with a full range of technical support such as equipment selection, installation and commissioning, operation training, etc., to ensure the smooth operation of customers.

-

Solution Design:

According to the specific needs and site conditions of customers, we provide customized solutions for construction waste treatment to maximize the treatment efficiency and resource utilization.

-

After-sales service:

perfect after-sales service system, provide equipment maintenance, accessories supply and technical consultation, ensure the long-term stable operation of customer’s equipment.

By cooperating with AIMIX, customers can not only get high-quality equipment and professional technical support, but also get significant economic and environmental benefits in the construction waste reclcying industry. We are committed to helping our customers realize the goal of sustainable development and jointly promote the progress of green building industry.