Is your operation struggling to turn bulky stone materials into profitable opportunities through a crusher machine for sale? The right crusher for sale could be the best solution you’ve been searching for! Whether you’re pulverizing rugged quarry rocks, recycling construction waste, or transforming chemical compounds into powders, these powerhouse tools do more than just break down materials; they optimize your workflow, enhance efficiency, and boost your ROI.

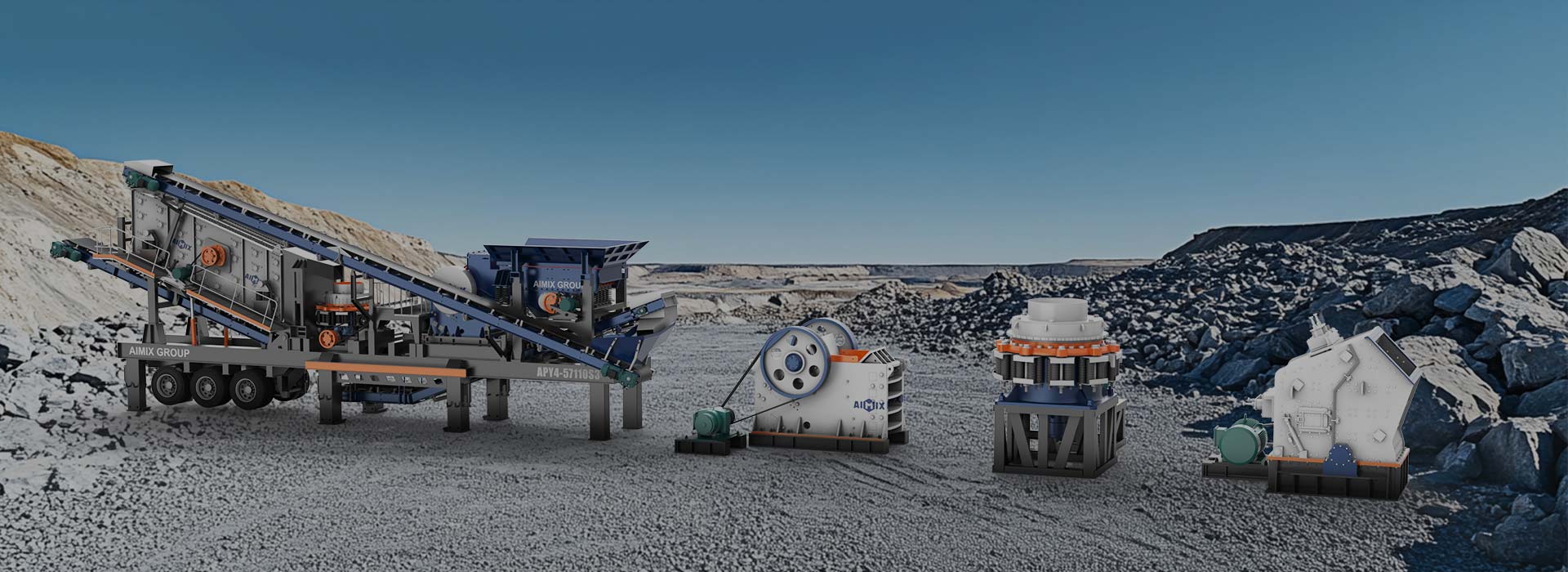

At AIMIX, we’ve engineered a variety of crusher machines for sale that do more than reduce particle size; the crushing equipment is engineered to boost your ROI through energy-smart operation, customizable configurations, and industry-leading durability. But with distinct crusher machine types for sale, which one will be your perfect match? Explore its types first.

Jaw, Cone, Impact & More: Explore the Types of Crusher Machines for Your Needs

Choosing the right crushing machine can make your project’s efficiency and profitability. In AIMIX Group, we offer different types of crushers in mining: jaw crusher, cone crusher, impact crusher, even movable crusher – each tailored to tackle specific materials, site conditions, and output goals. Whether you’re crushing hard granite for road construction, recycling concrete debris, or shaping aggregates for concrete production, our crusher batu prioritize durability, low operating costs, and results you can measure. Below, I would introduce you each types of crusher and why it might be your project’s perfect match.

APJ Jaw Crusher Machine – 50 – 800T/H

Feed size: ≤ 1000mmOutput size: 15 – 300mm

How it works:

Two metal jaws (one fixed, one moving) compress materials like a vise, breaking large rocks into smaller pieces.

Key Features:

- Large Crushing Ratio: Crushing ratio is about 6:1 to 10:1; Efficiently reduces large rocks (up to 1,000mm) into smaller, uniform sizes (as low as 15 mm).

- For Tough materials: Crushes hard materials like granite, basalt, quartz and pebbles effortlessly

Best for:

First-stage crushing in quarries or mining.

Projects needing consistent, coarse output, like road base materials.

APC Cone Crusher Machine – 20 – 1000T/H

Feed size: ≤ 350mmOutput size: 3-60mm

How it works:

A rotating cone grinds materials against a steel bowl, producing precise, uniform shapes.

Key Features:

- High-Quality Output: Produces uniform, medium-fine aggregates (5-20mm) for asphalt or concrete production.

- Adjustable Settings: Self-adjusting settings reduce labor and downtime.

Suitable for:

Secondary crushing after a jaw crusher. Projects requires exact material sizes (e.g., railway ballast or decorative stone).

APF Impact Crushing Machine – 40 – 400T/H

Feed size ≤500mmOutput size 5 – 20mm

How it works:

The high-speed rotor hammers materials against impact plates, shattering rocks into smaller, angular pieces.

Key Features:

- Shape Control: Creates cubical end products ideal for asphalt, landscaping, and recycled materials.

- Fast Operation: High throughput for time-sensitive projects.

Appropriate for:

Recycling demolition waste into reusable materials or processing soft rocks, like limestone. Projects need precisely shaped aggregates production.

Mobile Crushing Equipment – 30 – 400TPH

Crawler TypeWheeled Type

Main Features:

- All-in-One System: Integrates crusher screener and conveyors on the mobile chassis for smooth operation.

- IoT Remote Monitoring: Real-time performance tracking; Auto-maintenance alerts; Fewer breakdowns.

- Smart Control System: One-button start; PLC & touchscreen operation; Boosts efficiency.

Appropriate for:

Projects requiring frequent relocation (e.g., road construction across multiple sites); Temporary jobs or limited workspace (urban demolition, small quarries); Recycling materials on-site to save transportation costs.

Every mining crusher machine, whether a jaw, cone, or impact typ, excels at crushing materials, but the real power lies in strategic combinations. When combined strategically, these crusher mining equipment form a custom crushing plant that operates efficiently on your site.

Whether it’s granite crushing in remote quarries or concrete recycling across demolition sites, AIMIX Group can provide you with the customized stone crushing plant solutions tailored to your material type, production goals, and operational workflo. Discover how our smartly configured mining crusher machines can optimize the productivity!

Custom Crushing Solutions: Optimized Crusher Systems for Every Project

By combining multiple construction crusher types into an integrated circuit, operators can optimize the comminution process through a multi-stage approach. In general, according to the requirements of projects, a crusher machine plant can be designed to stationary crusher plant and mobile crusher plant. Next, I will introduce you some cases about theese crushing plants, showinging their unique configurations below.

200tph Stationary Crushing Plant for Limestone Crushing

- Feeding size: < 500mm 150tph

- Output size: 5-10mm, 10-15mm, 15-20mm and 20-35mm

- Applications: crushing limestone rocks for paper industry

Configurations: vibrating feeder + APJ-6090E jaw crusher + APJ-1012E fine jaw crusher + belt

200tph Crawler Cone Crusher Equipment for Processing Cobblestones

- Feeding size: 200mm 150tph

- Output size: 5-40mm

- Applications: crushing cobblestones in the quarry for espressway construction

Configurations: vibrating feeder + APJ-6090E jaw crusher + APJ-1012E fine jaw crusher + belt

150tph Mobile Impact Crusher For Construction Waste Recycling

- Processing capacity: 150tph

- Output size: 0-1/4’-3/4′-1′-2′(0-5-19-25-50mm)

- Applications: crushing construction waste for subway construction

Configurations: vibrating feeder + impact crusher + vibrating screen + belt

80tph Crusher Plant for Aggregate Production and Sale Business

- Processing capacity: 80tph

- Output size: 5-20mm

- Applications: crushing volcanic stone for aggregate sale business

Configurations: vibrating feeder + cone crusher + mobile vibrating screen + belt

600tph Stationary Crusher Plant Processing Cobblestone

- Processing capacity: 600tph

- Finished Product: 0-5-10-20mm

- Applications: aggregate production used for construction industry

Configurations: vibration feeder + jaw crusher + cone crusher + vibrating screen

200tph Mobile Jaw Crushers for Granite Crushing

- Processing capacity: 200tph

- Finished Product: 10-40mm

- Applications: producing aggregate for road construction

Configurations: vibration feeder + jaw crusher + cone crusher + vibrating screen

1000 tph Mobile Crawler Crushers for Cobblestone Processing

- Maximun feeding: 380mm

- Finished Product: 5-35mm

- Applications: road construction

Configurations: crawler jaw crusher + crawler cone crusher + crawler screener

How to Choose A Suitable Crusher Machine – Ultimate Guide

Selecting the perfect crusher machine for mining isn’t just about power, it’s about finding the right fit for your materials, production goals, and site conditions. With so many options available, it’s easy to feel unsure where to start. But here’s the good news: by focusing on a few key factors, like crushing stages, mobility needs, and material hardness. You can narrow down your choices and find a solution that delivers real results.

In AIMIX, we’ve helped countless clients across industries,from quarry operators to recycling specialists, designing crushing solutions that maximize efficiency, reduce costs, and meet their unique challenges. Whether you’re processing hard granite for construction or recycling concrete for urban projects, the right crusher equipment can make all the difference. In this guide, we’ll guide you through the essential steps to choose the best on site crusher for your needs.

1. Define Your Crushing Stage

Crushing is a multi-step process, and each stage requires a specific type of crusher to get the job done efficiently. Depending on your material and project goals, you might need to break down large rocks into smaller chunks, shape aggregates for construction, or produce ultra-fine particles for industrial use. Here’s the three main crushing stages and the crushing and screening machines that excel in each:

Primary Crushing (Coarse Crushing) Primary Jaw Crusher: Simple design, high reliability, and low maintenance. Perfect for hard, abrasive materials, like granite, basalt, or pebbles.

Primary Impact Crusher: Versatile and efficient, ideal for softer materials like limestone or recycled concrete.

Secondary Crushing (Medium Crushing) Secondary Cone Crusher: Further reducing materials to smaller, uniform sizes (20-100mm). Precision for high-quality aggregates. It can produces finely crushed, evenly shaped materials ideal for construction.

Secondary Impact Crusher: Great for shaping. It delivers cubical-shaped aggregates, perfect for projects requiring both crushing and shaping.

Tertiary Crushing (Fine Crushing) Tertiary Crushing (Fine Crushing): Producing finely crushed materials (0-10mm) like sand or industrial powders. Adjustable settings for consistent output size, ideal for high-quality aggregates.

Tertiary Vertical Shaft Impact (VSI) Crusher: It can ensure precise control over particle size and shape. And it creates ultra-fine, well-shaped sand for specialized applications like glass production or industrial use.

2. Consider Your Project Site Conditions

Your site conditions and relocation frequency play a critical role in choosing the right crusher setup. After all, a machine that works perfectly in a quarry might struggle on a crowded urban demolition site. Whether you’re working in a remote location, a tight city space, or need to move between multiple sites, there’s different crushers designed to fit your needs.

Fixed Crushing Line Cost-effective for high-volume production and can be customized for specific needs. Ideal for large-scale, long-term projects with stable site conditions, like quarries and mining operations.

Wheeled Mobile Crushers Easy to tow and set up, making them ideal for smooth roads and flat terrain. Appropriate for crushing jobs requiring moderate mobility and easy transport between sites, like road construction and small quarries.

Crawler Crushers Self-propelled and highly maneuverable, perfect for rough or uneven terrain. Generally, it applied for challenging terrains or frequent relocation needs, like remote mining sites and urban construction waste recycling.

3. Match the Crusher to Your Raw Material

The type of material you’re working with (whether it’s hard granite, medium-hard limestone, or soft recycled concrete) plays a huge role in determining the best crusher for your needs. Choosing the right machine for your material ensures higher efficiency, longer equipment life, and better-quality output.

Hard Materials (Granite, Basalt) Primary crushing generally use a jaw crushers and the secondary crusher adopts cone crusher machine.

Medium-Hard Materials (Dolomite) Primary crushing uses the jaw crusher machine, and secondary crushing ususally adopts cone crusher or impact crushers

Soft or Abrasive Materials (Limestone, Concrete, Asphalt) Primary or secondary crushing adopts the impact crushers or specialized VSI crushers.

4. Assess Production Capacity Requirements

Production targets and operational efficiency are key drivers in crusher selection. Balancing capacity with energy use ensures cost-effective operations.

Hourly Output Small quarries may need 50–100 tph; large mines require 500+ tph.

Energy Consumption Compare kW per ton rates, for example, jaw crushers are efficient for primary crushing but consume more power in finer stages.

Uptime Needs Automated crushers (like hydraulic cone models) reduce maintenance pauses vs. manual adjustments.

5. Evaluate Maintenance and Operational Costs

The true cost of ownership extends far beyond the initial purchase price. Smart buyers should consider long-term operational expenses.

Wear Part Replacement Impact crusher blow bars wear faster than jaw plates but are cheaper to replace.

Labor Skills Needed Cone crushers require trained operators; jaw crushers are simpler to maintain.

Long-Term ROI Higher upfront costs may pay off for a long time. But never mind, there is a large demand for crushed aggregates in the market.

6. Future-Proof Your Investment

A quality crusher equipment should adapt to your evolving business needs and technological advancements. Forward-thinking selection protects your investment.

Scalability Can the crusher machine for sale handle future production increases? Modular designs allow easy upgrades.

Technology Integration IoT-enabled crushers (real-time monitoring, predictive maintenance) reduce unplanned downtime.

Integrated Control A crushing machine with integrated control system can be operated by PLC touch screen or buttons to improve production efficiency.

By aligning your crushing stage, material type, and site conditiona, you can efficiently select a suitable crusher that maximizes productivity and minimizes downtime. Still unsure? Please contact AIMIX experts for a tailored recommendation right now!

Smart Investment: How Much Should You Budget for Your Ideal Crusher Machine for Sale?

When you are looking for a crushing and screening equipment for sale, the first thing you may concern about is the crusher machine price. In fact, the cost of crusher machine can be affected by many factors. Such as production technology, production materials, spare parts, shipping logistics, etc. So how about the prices in AIMIX aggregate crusher machine company? Here is a overview of AIMIX crusher machine price list for reference:

| Products | Model | Price Range |

|---|---|---|

| Jaw Crusher | APJ-E | $18000-$210000 |

| APJ-V | $27000-$175000 | |

| APJ-X | $9800-$23200 | |

| Cone Crusher | APC-Y | $26000-$124000 |

| APC-C | $46000-$232000 | |

| APC-M | $63000-$260000 | |

| APC-D | $60000-$450000 | |

| Impact Crusher | APF | $19000-$66000 |

| APF-V | $20000-$68000 | |

| APF-H | $35000-$140000 | |

| Sand Making Machine | APV | $27000-$65000 |

| APV-X | $28000-$105000 | |

| Primary Mobile Crushing Plant | APY2-57J-APY2-110J | $550000-$960000 |

| Secondary Mobile Crushing And Screening Plant | APY2-1010F-APY2-1214F | $620000-$940000 |

| APY2-110C-APY2-200C | $750000-$1350000 | |

| Construction Waste Mobile Crushing and Screening Plant | APY3-1010F-APY3-1315F | $910000-$1420000 |

| Integrated Mobile Crushing and Screening Plant | APY4-4660S-APY4-6912S | $730000-$1240000 |

| Crawler Crusher | APYL | $950000-$2300000 |

Taken together, crushers and crushing plants are a critical and indispensable part of the modern engineering landscape, bringing tremendous value and success to your projects. No matter what challenges you face, choosing the right crusher and screener will be the key to achieving outstanding results.

Now, do you know what is a crusher construction machine? When you choose a preferred model of the stone crusher plant for sale, our salesman and engineer will help you judge whether the type is suitable for your project. As long as you tell us your requirement in detail. If the standard types of crushers in mineral processing can’t meet your demand, we can customize crushing solutions for you.

Apart from the crusher machine plant price, you also need pay attention to the quality of products from crusher machine manufacturers. So, how to choose crusher machine suppliers in the market? Here are some suggestions for reference.

Advice on Choose A Best Crusher Manufacturers

Reputation and Track Record

Opt for a crusher company with a well-established reputation in the industry, backed by a proven track record of delivering high-quality, reliable, and durable rock crusher for sale near me. Look for crusher suppliers with a history of satisfied customers and positive industry feedback.

Customization and Flexibility

Choose crusher equipment manufacturers that offer a diverse range of crushing solutions and the ability to customize the crusher industry to meet your specific requirements. This ensures you can find the right crusher machine for sale that aligns with your processing needs, material characteristics, and production goals.

After-Sales Support

Select mining crusher manufacturers that provide comprehensive after-sales support, including maintenance, repair, and spare parts services. This ensures your crushing equipment for sale operates at peak efficiency throughout its lifecycle, minimizing downtime and maximizing your return on investment.

Manufacturing Standards & Certifications

Ensure the crusher machinke suppliers adheres to recognized manufacturing standards and holds relevant certifications. This not only guarantees quality but also compliance with safety and environmental regulations, providing peace of mind about the equipment you purchase.

Technology & Innovation

Look for companies that invest in the latest technology and innovations in crushing equipment. Advanced technology, like IoT monitoring and automated adjustment systems, can enhance efficiency, reduce operational costs, and improve overall performance, ensuring you stay competitive in your industry.

Client Testimonials and Cases

Examine client testimonials and case studies to gain insights into the experiences of other customers. These information can provide valuable context about the reliability, efficiency, and performance of the crushers offered by the crusher manufacturer.

After reading the above guidances, you are bound to find best crusher supplier, like AIMIX Group. AIMIX, as a leading crusher manufacturer, meets all of the above three crucial points. Customers can rest assured that by choosing to cooperate with AIMIX, we will offer high-quality crushing solutions, customized to your needs, backed by exceptional after-sales support. AIMIX’s reputation, flexibility, and customer-centric approach make us an excellent choice for your crushing equipment requirements. Contact us right now to learn more about our crushing solutions!