Ready mix concrete plant manufacturer selection determines how efficiently your operations run. Equipment breakdowns, inconsistent batching, and poor service can slow production and increase costs. Choosing the right manufacturer ensures high-speed, reliable performance, consistent concrete quality, and minimal downtime, enabling projects—from commercial RMC to infrastructure and precast—to meet deadlines and stay profitable.

Define Your Needs: Laying the Groundwork for a Successful Plant

Before selecting a ready mix concrete plant manufacturer, clearly defining your operational needs is essential. A plant that aligns with your production goals, project types, and future scalability ensures smooth operations and long-term profitability.

Assess Production Capacity and Project Scope

Determine daily and peak-hour outputKnowing your maximum concrete volume requirements per day and during peak hours helps decide plant capacity, mixer type, and material handling system.

Identify your market typeAre you supplying commercial RMC projects, precast factories, infrastructure developments, or internal construction needs? Each market has distinct requirements for batching accuracy, delivery speed, and quality.

Clarify concrete mix specificationsStandard, high-strength, self-compacting (SCC), or mixes using recycled aggregates all have different handling and mixing requirements. Clear understanding ensures your plant can meet both current and future production demands.

Select the Right Batching Plant Model

Stationary Ready Mix Concrete Batch Plant

- Popular Models:AJ-90, AJ-120, AJ-180

- Production Capacity:up to 270 m³/h

- Installation:Fixed on a concrete foundation, the structure offers high overall integrity and balanced load distribution, reducing vibration and wear.Requires fixed installation with a foundation. Installation typically takes 3–4 weeks or longer, depending on specific conditions.

- Automation Level:Full-process control enables more efficient operation and maintenance. The fully computerized system monitors material levels, mix ratios, and equipment status in real time, supporting data tracking and fault alerts. Coordinated batching, weighing, and mixing ensure high precision (≤ ±1%) and, combined with full automation, deliver highly consistent product quality.

- Applications:Stationary concrete plants are suitable for large-scale infrastructure projects, such as highways, large commercial and residential developments, and long-term industrial projects.

Mobile Ready Mix Concrete Plant

- Popular Models:AJY-60, AJY-90

- Production Capacity:up to 100m³/h or more

- Installation:The mobile batching plant integrates the main mixer, batching machine, belt conveyor, and other core components on a single movable chassis, using a modular, assembled structure. On-site installation requires no complex foundation and can be quickly disassembled for relocation, allowing operation within 1–3 days.

- Automation Level:Features an intelligent control system that automates batching, weighing, mixing, and discharging, with aggregate ±2% and cement/water ±1% accuracy. Some models support remote monitoring and fault diagnostics, reducing manual work and simplifying operation.

- Applications:Mobile concrete mixing plants are suitable for temporary construction projects, such as road maintenance, rural road construction, temporary construction sites, and small building projects.

Evaluate Site Infrastructure and Resources

Land layout

Ensure sufficient space for plant installation, material storage, and truck movement.

Power supply

Verify that local electricity capacity meets plant requirements. Consider backup power for regions with unstable supply.

Water and aggregates

Reliable access to quality water and aggregates is critical for consistent concrete production.

Environmental compliance

Dust control, noise reduction, and wastewater management systems must meet local regulations.

Identify Special Process and Future Requirements

Recycled aggregates

Screening, washing, and handling systems are needed if using construction waste or recycled materials.

Supplementary cementitious materials

Fly ash, slag, or GGBFS require precise dosing systems for consistent batching.

Moisture compensation and automated correction

Maintains consistent water-to-cement ratios and ensures batch uniformity.

Digital readiness

Industry 4.0 compatibility, remote monitoring, and predictive maintenance improve productivity and future-proof your investment.

Evaluate RMC Plant Manufacturer Reliability: Key Factors That Impact Your ROI

Choosing a ready mix concrete plant manufacturer is more than comparing prices. A reliable manufacturer ensures minimal downtime, high-quality output, and strong after-sales support, all of which are critical for business success.

Technical Expertise and Mixing Performance

The engineering capability of a ready mix plant manufacturer determines how effectively your plant performs. High-quality mixers, precise batching systems, and robust control technology are essential.

- Mixer technology: Twin-shaft or planetary mixers with high efficiency ensure uniform mixing across different concrete grades. According to the International Concrete Sustainability Conference (ICSC, 2024), mixers with high-performance blades can reduce concrete segregation by up to 15%, improving overall quality.

- Batching precision: Advanced load cells and automated dosing minimize material waste. Even a 2% error in cement or aggregate measurement can increase operational costs by thousands annually.

- Control system stability: Reliable PLC or SCADA systems reduce human errors, enable continuous production, and facilitate real-time monitoring. Remote monitoring and automated alerts can reduce downtime by 20–30%, according to a 2023 report by Global Cement Technology Insights.

Superior technical performance ensures consistent concrete quality, reduces waste, and protects your project deadlines and reputation.

Build Quality and Component Reliability

The plant’s structural integrity and component quality determine lifespan and maintenance costs.

- Steel structure and welding quality: High-grade steel and precise fabrication reduce wear and extend operational life, often exceeding 15–20 years with proper maintenance.

- Corrosion protection: Anti-corrosion coatings, galvanization, or weatherproof treatments prevent early rusting, especially in humid or coastal regions.

- Component quality: Motors, reducers, sensors, and valves from reputable brands ensure fewer breakdowns and reduce downtime. Industry studies show branded components can cut repair frequency by 25–40% compared to generic alternatives.

Strong build quality lowers maintenance costs, minimizes unplanned downtime, and extends service life, providing better ROI over the rmc plant’s lifetime.

Customization and Project Execution Expertise

Every site has unique challenges, from land layout to climate conditions. A manufacturer’s ability to provide tailored solutions is crucial.

- Custom plant layouts: Optimize workflow, truck circulation, and material storage.

- Climate-specific adaptations: Insulation, heating, dust control, and corrosion protection ensure stable performance in extreme weather.

- Turnkey solutions: A manufacturer who handles installation, commissioning, and operator training accelerates project startup and reduces risks.

Customization reduces operational bottlenecks, prevents costly retrofits, and ensures the plant performs efficiently from day one.

Proven Track Record and Certifications

Trustworthy ready mix concrete plant manufacturers demonstrate their capabilities through real-world projects and verified standards.

- Certifications: CE, ISO, and local compliance approvals ensure quality management systems are in place.

- Customer references: Case studies, installation videos, and feedback from operators provide tangible proof of performance.

- Global service network: Availability of spare parts and local support reduces downtime, even in remote regions.

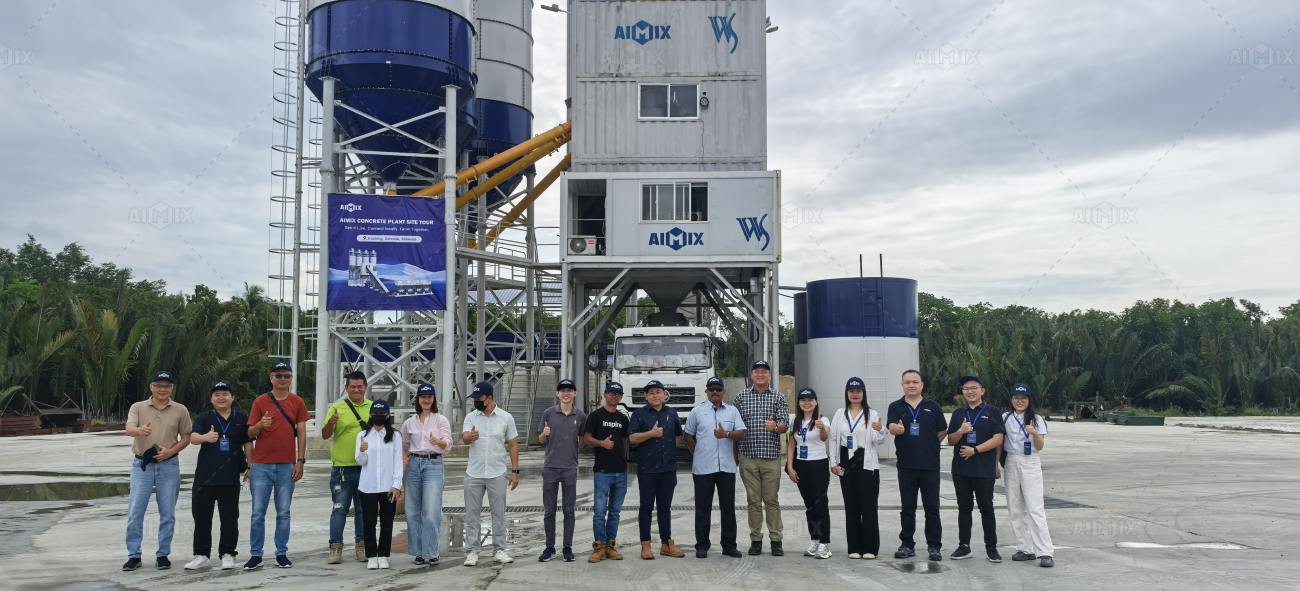

A manufacturer with a strong track record and certifications lowers risk, increases confidence in operational reliability, and supports your long-term business growth. Aimix has 6 global branch offices and more than 100 service outlets to provide rapid support for overseas clients.

Proof in Performance: Real-World Project Cases

AJ-180 Concrete Batching Plant for Commercial RMC Operations in Malaysia

Customer Need

A commercial construction company in Malaysia required a high-capacity ready mix concrete plant to achieve faster batching cycles and provide consistent, high-quality concrete, especially during peak construction seasons.

Our Solution

Supplied AJ-180 stationary batching plant with a 3m³ Sicoma twin-shaft mixer.

High batching efficiency and precise material dosing ensure reliable output.

Robust design minimizes downtime and maintenance needs.

Outcome & Value

Successfully met peak-season production demand.

Delivered consistent concrete quality for multiple commercial projects.

Model project demonstrating Aimix’s capability in large-scale RMC plant manufacturing.

Customer Feedback

“This large-scale batching plant meets our concrete production needs. We would gladly recommend Aimix to others requiring concrete plants.”

AJY-75 Mobile Batching Plant Powering Government Construction Works in Ethiopia

Customer Need

The client required a mobile concrete plant that could meet strict government project standards while being flexible and cost-effective.

Our Solution

Supplied AJY-75 mobile concrete plant with JS1500 mixer, designed for fast setup and high-quality output.

Compact, modular design allows easy relocation and adaptation to multiple sites.

Automated batching ensures compliance with strict specifications.

Outcome & Value

Fully met government project quality and efficiency requirements.

Cost-effective solution with reliable performance and minimal downtime.

Highlights Aimix’s expertise in mobile RMC plant solutions for public and regulatory projects.

Customer Feedback

“The mobile plant met all our standards and was easy to operate. Aimix’s rapid and professional support ensured smooth project execution.”

AJ-60 Concrete Batching Plant Supporting Production Upgrade in Laos

Customer Need

A leading mining company in Laos required a reliable, high-capacity concrete plant to replace aging equipment, improve batching efficiency, and support expanding operations.

Our Solution

Supplied AJ60 stationary concrete plant with a customized layout for the client’s site.

Robust design ensures stable operation, consistent batch quality, and low maintenance.

Provided pre-sales consultation, on-site installation, and operator training for seamless transition.

Outcome & Value

Production efficiency improved significantly, meeting project demands without delays.

Maintenance costs reduced due to modern components and durable design.

Achieved smooth operation and long-term operational reliability.

Customer Feedback

“This AJ60 plant runs efficiently, delivers consistent concrete quality, and AIMIX’s support made the transition effortless. We are confident in this long-term partnership.”

Operational Efficiency & Management: Maximizing Plant Performance

Operational efficiency defines how effectively a ready mix concrete plant converts resources into high-quality concrete. By focusing on workflow optimization, material management, energy use, and workforce productivity, a plant can maximize throughput, reduce waste, and maintain consistent product quality.

Streamlined Workflow and Scheduling

Modern batching plants feature automated production planning and dispatch tools. Intelligent scheduling of mixing cycles, truck loading, and batching sequences minimizes idle time and ensures smooth site operations.

Benefit: Higher daily output, better truck coordination, and improved equipment utilization.

Material Flow Optimization

Optimized hoppers, conveyors, and mixing systems maintain a continuous, balanced material flow. Real-time monitoring and precise calibration prevent bottlenecks and allow stable concrete batching, even when handling variable aggregates.

Benefit: Reduced material waste, lower energy consumption, and enhanced overall plant productivity.

Integrated Monitoring Systems

Sensors and advanced control software track moisture content, aggregate grading, and mix ratios in real time. This ensures consistent concrete quality and reduces overuse of cement or water.

Benefit: Stable product quality, fewer rejected batches, and predictable performance across all project types.

Energy and Resource Management

Optimizing energy use in mixers, conveyors, and auxiliary systems lowers operational costs. Efficient water, power, and fuel management ensures sustainable operation without sacrificing output.

Benefit: Reduced operating costs and environmental impact, contributing to long-term project sustainability.

Workforce Productivity

Clear production workflows, standardized operating procedures, and task-specific allocations enhance team efficiency. Cross-training ensures smooth operation even during personnel changes.

Benefit: Consistent production rates, fewer operational errors, and effective utilization of workforce capacity.

Comprehensive Service and Support from a Reliable Ready Mix Concrete Plant Manufacturer

A reliable ready mix concrete plant manufacturer and supplier doesn’t just supply equipment—it provides end-to-end support to ensure every project is successful, efficient, and profitable. Aimix services are structured into three key stages: pre-sale, during-sale, and after-sale, each designed to deliver measurable value to our clients.

Pre-Sale Services: Reducing Investment Risk and Optimizing Planning

- Professional Consultation and Project Planning: We offer detailed pre-sale consultation and overall project planning to help optimize budgets, minimize investment risk, and shorten project cycles.

- Dedicated Service Team: Our team analyzes, confirms, and refines your requirements, ensuring the proposed solution aligns perfectly with your project needs, reducing communication overhead and ensuring smooth implementation.

- Investment Profitability Analysis: We provide models for financial and ROI evaluation, enabling safer, data-driven investment decisions.

During-Sale Services: Ensuring Quality and Efficiency

- Information Synchronization: We maintain real-time updates and shared project information, reducing installation time and overall costs while preventing delays.

- Quality Control: Comprehensive checks, including empty-load testing and inspection reports, ensure reliable operation, shorten construction time, and extend equipment lifespan.

- Professional Transport Services: Customized packing, reinforced protection, and smart logistics guarantee equipment safety and timely delivery, meeting client expectations for transport efficiency and reliability.

After-Sale Services: Supporting Long-Term Success

- Training Programs: Operator training reduces installation and commissioning challenges, minimizes operational errors, and lowers maintenance costs, preventing downtime.

- Installation Support: From online guidance to on-site assistance and local service network support, we ensure smooth installation and project handover, saving labor costs and management effort.

- 24-Hour Troubleshooting: Rapid response to technical issues minimizes downtime, protecting your project schedule and operational efficiency.

- Follow-Up Services: Regular equipment reviews monitor performance, enhance productivity, prolong equipment life, and reduce safety risks.

From start to finish, we provide complete support to ensure you receive high-quality ready mix concrete plants and dependable, efficient operations. We look forward to working with you and supporting your business success.

Ready Mix Plant Cost vs Value: Understanding Total Cost of Ownership

When investing in a ready mix concrete plant, the initial purchase price is just part of the equation. Lifetime costs—including energy, maintenance, downtime, and spare parts—often exceed the upfront investment. Considering the total cost of ownership (TCO) helps buyers make smarter decisions and maximize their ROI.

Understanding Initial Investment

Beyond the quoted ready mix plant price, buyers should consider all components that impact upfront costs:

- Core equipment: Mixers, batching systems, aggregate handling equipment.

- Automation and control systems: PLC, sensors, and weighing modules.

- Steel structure and conveyors: Platforms, supports, and material transfer systems.

- Logistics and installation: Shipping, taxes, customs, assembly, and commissioning.

A low initial price quote for an RMC plant may not include installation, software, or essential spare parts, which can lead to higher costs later. Always request a detailed line-item breakdown to understand the full scope of expenses before making a purchase.

Calculating Long-Term Costs

The TCO approach accounts for recurring operational costs:

TCO = Purchase Price + Energy Costs + Maintenance & Spare Parts + Downtime Loss – Residual Value

- Energy consumption: Efficient motors and conveyors reduce monthly operating costs.

- Maintenance and spare parts: Regular upkeep prevents unplanned breakdowns and extends plant life.

- Downtime impact: Even short stoppages can cause significant losses, particularly during peak production.

A plant with slightly higher upfront cost may have lower operational expenses and better longevity, resulting in a lower cost per cubic meter of concrete over its lifecycle.

Choosing the Right Manufacturer for Value

Manufacturers from different regions offer distinct strengths:

- European suppliers: Known for high precision, consistent quality, and long-term reliability, often with a higher upfront investment.

- Chinese suppliers: Offer competitive pricing, flexible customization, and faster production and delivery, providing strong overall value for a wide range of projects.

Hidden Costs to Watch For

Failing to account for hidden costs can undermine long-term returns.

- Software instability causing batching delays.

- Low accuracy leading to cement waste.

- Weak structural components accelerating wear and downtime.

- Slow spare parts delivery increasing production interruptions.

Considering the total cost of an RMC plant beyond its purchase price ensures steady production, minimal interruptions, and lasting profitability.

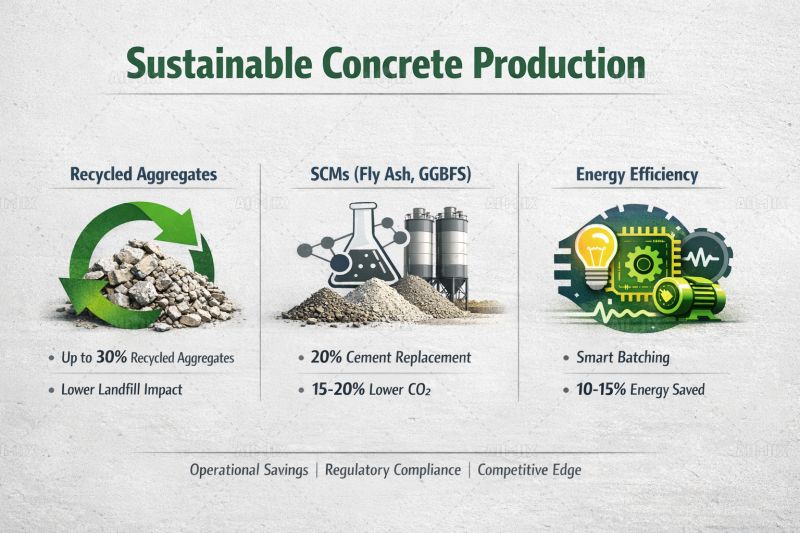

Sustainability and Market-Ready Design: Features Buyers Should Consider

When evaluating ready mix concrete batching plant manufacturers, buyers should prioritize both sustainability and future scalability. Modern plants are expected to support green construction, reduce operational costs, comply with regulations, and adapt to evolving market demands.

Sustainable Construction Features

Recycled Aggregates HandlingAdvanced RMC plants can process recycled concrete and construction waste, with proper screening, washing, and feeding systems. This allows the use of up to 30% recycled aggregates without compromising concrete quality. Benefits include reduced raw material costs and lower landfill impact.

Use of Supplementary Cementitious Materials (SCMs)Precision dosing of fly ash, slag, or GGBFS (Ground Granulated Blast Furnace Slag) enables partial cement replacement, lowering carbon emissions. Replacing 20% of cement with fly ash can cut CO₂ emissions by 15–20%, making environmentally conscious concrete both reliable and cost-effective.

Energy-Efficient EquipmentHigh-efficiency motors, variable-speed conveyors, LED lighting, and smart batching systems reduce electricity consumption by 10–15%. Selecting a manufacturer with integrated energy-saving features ensures compliance with ESG standards while lowering operational expenses.

A manufacturer who integrates sustainable capabilities delivers long-term operational savings, regulatory compliance, and a competitive edge in green construction markets.

Market Alignment and Scalability

Flexible Production for Diverse Projects

- Multiple concrete grades: Standard mixes, high-strength, SCC, or mixes with recycled aggregates.

- Modular batching systems: Quickly switch production modes to meet changing project requirements.

- Application versatility: Serve commercial RMC, infrastructure projects, and precast factories with a single plant.

Expandable Capacity for Business Growth

- Scalable design: Add mixers, silos, or conveyors as demand increases.

- Incremental upgrades: A 60 m³/h plant can grow to 90–120 m³/h with minimal downtime.

- Investment protection: Expand capacity without replacing the entire plant.

Digital and Smart Construction Readiness

- PLC/SCADA integration for automated monitoring and control.

- Remote diagnostics and predictive maintenance to minimize unplanned downtime.

- IoT sensors and cloud-based scheduling for future-ready operations aligned with Industry 4.0 trends.

Choose a rmc plant company who offers flexible, scalable, and digitally ready plants to ensure long-term profitability, adaptability, and alignment with evolving market demands.

Success in concrete production starts with the right partner. AIMIX provides cutting-edge, customizable ready mix plants, professional support, and long-term service, helping you deliver quality concrete consistently. Collaborate with us now to enhance productivity, streamline operations, and ensure your projects succeed from the first batch to the last.