A small concrete batching plant, with capacities of 25–60 m³/h, helps construction companies, project developers, concrete suppliers, and precast manufacturers work more efficiently, save costs, and stay on schedule. Compact but powerful, these plants produce consistent, high-quality concrete and adapt easily to different project types. By reducing labor and transportation needs, they offer a practical, cost-effective solution for residential, commercial, and small infrastructure projects.

Exploring Different Types of Small Concrete Batching Plant

Aimix offers high-quality small concrete batching plants in both stationary and mobile types to suit a variety of project needs. Whether your project requires a fixed production site or flexible operation across multiple locations, there’s a solution for you. Let’s take a closer look at the different types of small concrete plants now.

AJSY Series Compact Concrete Batching Plant

- Hot-sale Models: AJSY-20, AJSY-40

- Productivity: 20-40 m³/h

- Mixer: Twin shaft mixer

- Mixing Principle: Uses blades for forced mixing

- Suitable Materials: Dry-hard concrete, high-strength concrete, and special materials requiring high uniformity

- Features: Compact Size, Massive Output

- Advantages: With engineering tires and lifting outrigger structures, the plant can be quickly transported between sites without the need for disassembly or reassembly.

AJZY Drum Type Small Concrete Mixing Plant

- Hot-sale Models: AJZY-40, AJZY-60

- Productivity: 40-60 m³/h

- Mixer: JZM750-JZM1500

- Mixing Principle: Uses drum rotation and gravity

- Suitable Materials: Plastic concrete, semi-dry concrete, lightweight concrete, mortar, and plaster

- Mixing Period: 90-120s

- Applications: Suitable for small-scale civilian building construction projects, remote and rural area construction, temporary or emergency construction.

AJ Stationary Type Small Batching Plant

- Hot-sale Models: AJ-25, AJ-35, AJ-50, AJ-60

- Productivity: 25-60 m³/h

- Mixer: Uses twin-shaft or planetary mixers

- Stable and Durable: Installed with a strong foundation for continuous operation.

- Automated Control System: Ensures precision and efficiency in concrete production.

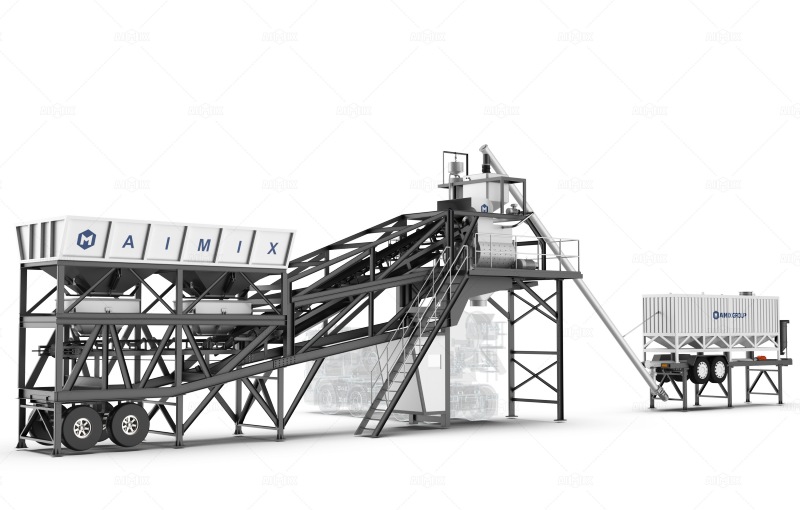

AJY Mobile Type Small Concrete Batch Plant

- Hot-sale Models: AJY-60

- Mixer: Twin shaft mixer, Planetary

- Aggregate Feeder: belt type

- Fast Setup: No heavy foundation required, reducing installation time. The plant can be disassembled in half a day and relocated to a new site within one day.

Small Concrete Plant Cases: Maximizing Efficiency in Projects

AJSY-35 Compact Batching Plant for Sale in Malaysia

- Delivery time: July 2025

- Application: For Roadbed Paving

- Customer needs: The client needed a small-scale batching plant that could be relocated quickly and start production in a short time frame.

- Our solution: We recommended our AJSY35 plant featuring compact design and fast installation capability.

- Results: Despite the limited working area and complex terrain, the AJSY35 was successfully set up and made ready for production in just 10 days. It works efficiently at job site now and the customer is very satisfied with its performance.

AJY-60 Mobile Batching Plant for Ethiopia

- Delivery time: March 2025

- Application: For Housing Projects

- Customer needs: The client needed a reliable solution to speed up batching, ensure a steady concrete supply, and keep multiple real estate projects on schedule.

- Our solution: We provided the AJY60 mobile concrete plant equipped with 1m³ Sicoma Mixer, ensuring rapid mixing cycles and consistent output quality. Its compact and modular design allow quick relocation between job sites.

- Results: Faster batching, no material shortages, on-time project completion.

AJZY-30 Small Concrete Plant for Sale in the Philippines

- Delivery time: November 2023

- Application: For residential construction project

- Customer feedback: We appreciate Aimix’s profession and timing after-sales service. This small concrete plant is easy to operate and works efficiently. We wish cooperate with Aimix again.

AJG-35 Dry Mix Small Batching Plant for Sale in Fiji

- Delivery time: November 2024

- Application:For concrete selling and construction projects

- Customer feedback: This small dry mix batching plant works well and all in good conditions. It met our project needs and help us save operational cost. Aimix’s service is good.

Small Mobile Concrete Plant: Solving Your Construction Challenges

Construction projects often struggle with equipment breakdowns, inconsistent concrete quality, low efficiency, and complicated operations. The small mobile concrete plant is built to overcome these issues, making on-site production simpler and more reliable. In this section, we will introduce our AJSY-40 compact mobile plant and explain how it helps solve these construction challenges.

Upgraded Mixing System – Higher Capacity and Stable Quality

The improved mixer structure increases mixing volume by 30%, ensuring consistent, high-quality concrete for residential, commercial, and infrastructure projects. Even under demanding conditions, the plant maintains stable performance.

Intelligent Operation System – One Person Can Operate

Equipped with a smart wireless remote control, the AJSY40 plant allows a single operator to manage the entire plant. This reduces labor requirements, simplifies training, and makes operation easy even for first-time users.

Efficient Feeding System – Save Time and Boost Productivity

The single-belt feeding system cuts loading time by 50% and improves overall efficiency by 50%, ensuring projects stay on schedule while reducing manual labor.

Precision Batching System – Accurate and Continuous Production

With weighing errors controlled within 1%, our AJSY-40 compact batching plant allows simultaneous batching and mixing. This ensures continuous production of quality concrete with minimal waste, outperforming competitors.

Smart Maintenance – Reduce Downtime and Manual Work

Automatic calibration, smart fault detection, and maintenance reminders reduce the need for manual checks. Problems are quickly spotted and fixed, helping prevent costly downtime. The AJSY40 small mobile concrete plant combines efficiency, accuracy, and intelligent operation, giving contractors reliable, high-quality concrete with minimal effort.

Maximize Efficiency and Investment Value

A small mobile batching plant cuts transportation and labor costs while delivering consistent concrete. It helps contractors run projects more efficiently and save money. For those looking for a practical, cost-effective solution, this compact concrete plant solution is a smart investment that maximizes both productivity and value.

Which Projects Benefit Most from Small Concrete Batching Plants

Small concrete batching plants offer flexibility, moderate production, and low investment. They are ideal for projects with limited space, dispersed locations, or moderate concrete demand. Here are the construction projects that benefit most.

Residential Construction: Fresh Concrete for Homes and Villas

Small concrete plants are ideal for residential projects like single-family homes, villas, and small apartments. Onsite mixing ensures fresh and quality concrete, fits limited spaces, and helps contractors maintain schedules efficiently.

Small Commercial Buildings: Efficient On-Demand Concrete Production

Small commercial projects such as offices, shops, and warehouses benefit from portable small batching plants. On-demand mixing reduces waste, ensures consistent quality, matches project schedules, and provides cost-effective solutions for smaller-scale commercial construction.

Road and Bridge Maintenance: Flexible Solutions for Infrastructure Repairs

For rural roads, minor bridges, and small highway repairs, mobile compact concrete batching plants provide flexible onsite concrete production. They reduce transport distances, save time and costs, and ensure sufficient concrete while offering mobility for dispersed or ongoing maintenance projects.

Remote and Rural Projects: Overcoming Site Challenges with Mobile Plants

Remote or rural infrastructure projects like irrigation channels and small community facilities benefit from mobile small plants. Onsite concrete production overcomes access issues, ensuring continuous construction and improving efficiency in challenging locations.

Essential Factors for Selecting the Right Small Concrete Batching Plant Manufacturer

Choosing a reliable manufacturing for a small concrete batching plant is essential for achieving smooth operations, long-lasting performance, and cost efficiency. To make an informed decision, it is important to consider several major factors that ensure you select a supplier capable of meeting your project’s specific needs.

Reputation and Experience

Choose a supplier with a proven track record in manufacturing and supplying concrete batching plants. Aimix has over 15 years of experience in the industry, is a strategic partner of Global 500 companies, and exports to 100+ countries. With 6 global branches and more than 100 service outlets worldwide, we demonstrate strong credibility and global reach.

![]()

Product Quality and Advanced Technology

High-quality equipment ensures consistent concrete quality and long-lasting performance. Look for batching plant suppliers offering durable plants with robust structures, efficient mixers, and user-friendly automated control systems. Aimix’s batching plants integrate advanced technology to improve production efficiency and simplify operations, catering to diverse project needs.

![]()

Customization and Flexibility

A capable manufacturer should provide options tailored to your project requirements, including various capacities, mixer types, and mobility features. We supports customization, ensuring each plant aligns with the specific scale and nature of your construction projects.

![]()

After-Sales Support and Warranty

Reliable after-sales service is crucial for minimizing downtime and operational issues. Check for warranty terms, availability of spare parts, technical support, and on-site training. Aimix’s extensive global service network ensures prompt support and maintenance assistance anywhere your project is located.

![]()

Price and Long-Term Cost-Effectiveness

While initial investment matters, consider long-term operational costs, durability, and efficiency. We deliver cost-effective solutions that reduce maintenance expenses and increase productivity, offering real value beyond the initial purchase price of concrete batching plants.

5 Ways to Extend the Lifespan of Your Small Batching Plant

Proper care and operation can greatly increase the durability and efficiency of your small batching plant. Here are five key strategies to follow:

Regular Maintenance

- Inspect concrete mixers, belts, bearings, and motors regularly.

- Follow the manufacturer’s maintenance schedule for lubrication, part replacement, and system checks.

- Prevent unexpected breakdowns and ensure smooth operation.

Proper Cleaning

- Remove dust, debris, and leftover concrete from mixers, hoppers, and conveyors daily.

- Prevent abrasion, corrosion, and blockages.

- Maintain accurate functioning of sensors and automation systems.

Use High-Quality Materials

- Choose clean aggregates and cement to reduce wear on plant equipment.

- Remove oversized stones or foreign objects that could damage components.

- Maintain proper water-cement ratios to avoid concrete hardening inside the plant.

Optimize Operation Procedures

- Operate within recommended capacity limits to avoid overloading motors and mixers.

- Train operators on proper loading, mixing, and discharge processes.

- Balance material feeding to reduce mechanical stress and improve concrete quality.

Protect Against Harsh Conditions

- Use protective covers for mixers, control panels, and motors.

- Install dust collection systems and ensure proper ventilation.

- Shield the plant from extreme weather, moisture, and dust to prevent corrosion or electrical issues.

Future Trends: Smart, Flexible, and Eco-Friendly

The evolution of small concrete batch plants is closely following industry trends in automation, sustainability, and adaptability:

Smart AutomationModern small concrete plants are increasingly equipped with user-friendly control panels, IoT connectivity, and AI-assisted monitoring. These features enhance batching accuracy, reduce human error, and simplify operation, making small plants easier to manage even with limited staff.

FlexibilityCompact, modular designs allow quick setup and relocation, enabling contractors to adapt to changing project sites and schedules. This flexibility makes small batching plants ideal for residential, commercial, and rural projects where mobility and space efficiency are key.

Eco-Friendly DesignEnergy-efficient motors, water recycling systems, and dust suppression technologies are becoming standard, helping contractors reduce environmental impact while meeting low-carbon construction standards.