Asphalt plant is extremely essential in construction projects. Then what is asphalt plant? In short, an asphalt mixing plant is a key road construction equipment that mixes asphalt, crushed stone, mineral powder, and other materials in specific proportions and temperature to produce asphalt concrete for different road projects. What does an asphalt plant do? It is designed for the production of asphalt concrete, and has important engineering application value. Let me explore asphalt plant in detail next!

What Are The Different Types Of Asphalt Plants And Application Areas

Asphalt plants vary based on working principles and structures, with main types categorized by application areas. Here are these types in the following.

Mobile Asphalt Plant

- Discontinuous Portable Asphalt Mixing Plant: It’s commonly used in highways, airports and ports and other projects that require large quantities of asphalt concrete, as well as for projects that require frequent transfers.

- Mobile Asphalt Drum Mix Plant: It’s applicable to rural road construction and small road repair, temporary road maintenance, emergency road repair and other projects.

Stationary Asphalt Plant

- Sationary Asphalt Drum Mix Plant: It’s used for long-term stability of large-scale projects, such as highway construction, airport runway construction.

- Discontinuous Stationary Asphalt Plant: This type is for smaller demand but continuous and stable projects, such as urban road maintenance, urban trunk roads and industrial parks within the road construction.

In summary, mobile asphalt plant is suitable for temporary works and small-scale projects, while stationary asphalt mixing plant is more suitable for long-term large-scale projects. These classifications of asphalt plant in different fields can meet the needs of various engineering projects and provide reliable technical support for road construction. Then let’s delve into its specific components.

What Are The Components Of Asphalt Mixing Plant?

Asphalt plant burner is a complex engineering equipment, composed of several components, each of which plays a key role. The following are the main components of an asphalt burner.

Cold Aggeregate Supply System

Used to transport aggregates (e.g. stone, sand, etc.) to the mix production line. This system usually consists of conveyor belts, silos, hoppers, etc. to ensure that the aggregates are accurately proportioned for the subsequent mix production process.

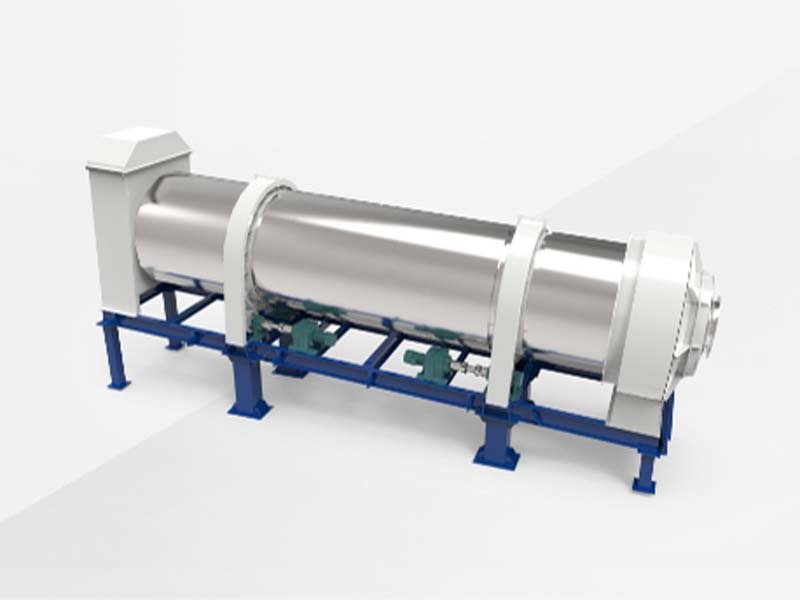

Drum Dryer

Also known as a drying screen, this is the equipment that dries the aggregate. The aggregates are heated in the drum to remove moisture and ensure the quality of the subsequent mix.

Coal Burner

Used to provide the heat energy required in the drum drying process. Usually oil, coal, natural gas etc. are used as fuels and the heat generated by combustion is used to heat the aggregates in the drum.

Cyclone Dust Collector System

Used to collect the dust and exhaust gases generated during the drum drying process. The cyclone dust collector separates the dust and exhaust gases by rotating in order to purify the discharged gases and protect the environment.

Dedust Collector

Further purifies the exhaust gases from the combustion system to ensure that the emissions meet environmental standards. Dedusting systems use filters and dust collectors to capture solid particles and harmful substances from exhaust gases.

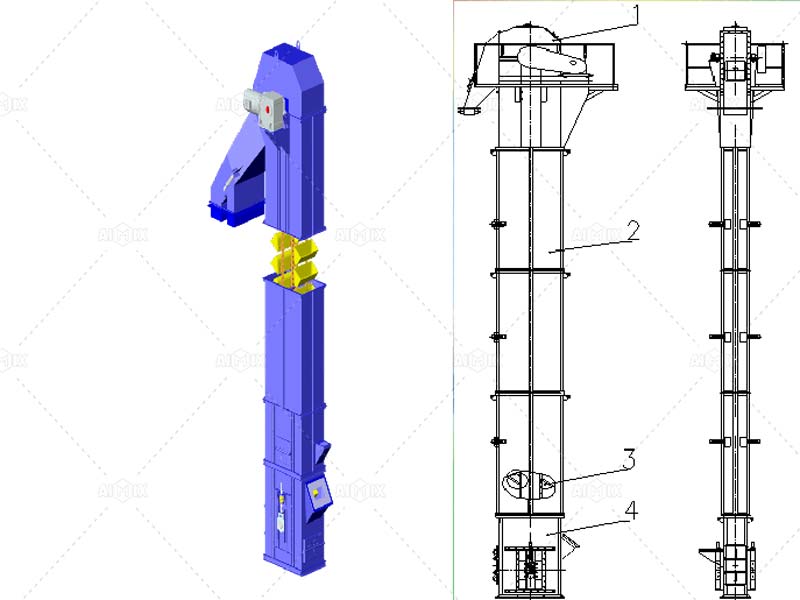

Hot Aggregate Elevator

conveys the dried aggregate to a screening system or weighing and mixing system. The system typically has equipment like lifting hoppers and conveyor belts to smoothly transport aggregates to the next production step.

Vibrating Screen

This can screen the hot-dried aggregate to remove impurities and rejected particles from it. The screening system includes a vibrating screen, mesh, and other equipment to maintain aggregate quality standards.

Filler supply system

It is used for conveying fillers (e.g. mineral powder, slag, etc.) to the mix production line in order to adjust the formula and performance of the mix.

Weighing and Mixing Systems

To weigh, mix and blend asphalt, aggregates and other additives. This system typically includes weighers, mixers, conveyor belts and other equipment to ensure that the mix is formulated and of the required quality.

Finished Asphalt Storage

Store the finished asphalt mixture for use in road construction and other projects. Finished asphalt storage equipment usually includes silos, hoppers, etc., to ensure the quality and preservation of finished asphalt.

Bitumen Supply System

Delivers asphalt to the weighing and mixing system for the production of the mix. This system usually includes equipment such as asphalt storage tanks, delivery pipes, pumps, etc. to make sure to deliver and use the asphalt accurately.

The components of an asphalt plant work in tandem to ensure the quality and efficiency of asphalt concrete production. Next, let’s explore how it works and its advantages.

What Are The Common Operations Of A Asphalt Mixing Plant?

Asphalt plant achieves the production of asphalt concrete through the synergy of several components. Its working principle can be briefly described as follows.

- Raw material preparation: The bitumen mixing plant firstly puts raw materials such as asphalt, crushed stone and mineral powder into the batching system according to the designed proportion.

- Drying: Crushed stone and other raw materials need to be dried to remove the moisture, in order to improve the quality and stability of asphalt concrete. The drying system heats and dries the raw materials.

- Heating and mixing: The combustion system provides heating energy to heat the asphalt to the appropriate mixing temperature. At the same time, a hot material lifting system transports the heated aggregates to the mixer.

- Mixing: In the mixing machine, asphalt, aggregate, mineral powder and other raw materials are fully mixed under the action of mixing blades to form uniform asphalt concrete.

- Control: The control system oversees the production process, adjusting component parameters to ensure stability and reliability.

- Finished product processing: Finished product silo have an important part in storing the produced asphalt concrete for subsequent use. The asphalt concrete that has passed the quality inspection will be stored or transported to the project site for construction.

Through the above steps, the asphalt plant is able to achieve efficient production of asphalt concrete, ensuring production quality and production efficiency. Its working principle is simple and straightforward, but requires the precise cooperation and synergy of each component. For more video, you can see the workflow of asphalt mixing plant, installation video on YouTube. So, what are the advantages of asphalt mixing plant for sale as a machine recognized to help road construction?

What Are The Advantages Of Asphalt Plant?

As a specialized machine for producing asphalt concrete, the asphalt mixer plant has many advantages that make it widely used in road construction and maintenance. Here are the main advantages below.

High Production Efficiency

Firstly, advanced production equipment and automated control system at the asphalt mix plant enable efficient production, enhancing construction efficiency. Compared with manual mixing, it can achieve continuous production, saving a lot of manpower and time costs.

Stable Production Quality

Asphalt batch mix plant can also ensure the stable quality of asphalt concrete production through accurate batching and control system. Of course, the precise proportioning and efficient mixing of raw materials ensure the uniformity and stability of asphalt concrete, which improves the durability and service life of the road surface.

Strong Adaptability

The asphalt mixing machine is able to customize the production according to the needs of different projects with strong adaptability. Whether it is the construction of highways, city roads, airport runways, or rural roads, industrial parks, asphalt batching plants can meet their production requirements, providing reliable support for a variety of projects.

High Resource Utilization

Furthermore, asphalt plant can make full use of raw material resources, reduce waste and improve the efficiency of resource utilization. Through precise batching and recycling technology, the asphalt equipment can minimize the waste of raw materials and reduce production costs.

Environmental Protection And Energy Saving

The asphalt plant uses advanced tech for cleaner emissions, reducing waste gas and dust to protect the environment. At the same time, the asphalt batch plant efficiently uses energy, saving resources and reducing environmental impact.

Short Construction Period

The asphalt concrete produced by the bitumen plant has the characteristic of fast hardening, which can shorten the construction period. The construction of asphalt pavement usually takes only a few days to put into use, especially improving the construction efficiency and shortening the project cycle.

Long Service Life

At last, asphalt concrete pavement is highly durable and resistant to aging, allowing for long-term use. The asphalt concrete from asphalt plants is high quality and stable, leading to durable surfaces with lower maintenance costs.

Next we will discuss why you should choose an asphalt plant when building a road.

Why Should You Choose Asphalt Plant For Building Roads?

Constructing roads is crucial for city development; selecting proper equipment is vital for quality and efficiency. Here are a few important reasons to choose an asphalt plant for pavement construction.

- Reliable Road Quality: The plant produce high-quality asphalt concrete for smooth and durable roads. Besides, asphalt concrete pavements are highly durable and can withstand vehicle pressure and harsh weather, ensuring road safety.

- Short Construction Period: Asphalt concrete hardens quickly and has a short construction period. Building asphalt pavement only takes a few days, leading to a quicker construction cycle, less traffic disruption, and improved efficiency.

- Low Maintenance Costs: Asphalt concrete pavement maintenance costs are low. Asphalt’s seamless surface minimizes cracks and potholes, cutting maintenance and repair costs. Furthermore, asphalt pavement is easy to clean and maintain, extending its lifespan and lowering maintenance costs.

- Environmentally Friendly: The asphalt mixing machine uses advanced tech to cut waste gas and dust emissions, safeguarding the environment. What’s more, asphalt concrete is renewable, reducing raw material consumption, environmental impact, and meeting sustainable development needs.

- Strong Adaptability: They are customizable for diverse project requirements, making them adaptable. Besides, asphalt batch plants support projects such as highways, urban roads, and airports, meeting production needs reliably.

- High Resource Utilization: This machine can make full use of raw material resources, reduce waste and improve the efficiency of resource utilization through accurate batching and recycling technology.

Based on the above reasons, it is a wise choice to choose this powerful machine for pavement construction. It guarantees quality pavements, quick construction, affordable maintenance, and offers urban traffic development support. Thus, choosing the asphalt batching plant lays the foundation for your road construction success!

AIMIX Professional Asphalt Plant Equipment Manufacturer

For high-quality equipment, choose AIMIX, the professional asphalt plant manufacturer. We offer reliable, durable equipment for road construction projects. All in all, we offer customized solutions for both mobile and stationary asphalt plants to ensure smooth project operation.

By understanding the asphalt batch mix plant’s characteristics thoroughly, you gain a comprehensive insight into it. In conclusion, please feel free to contact us with any asphalt mixing plant needs or related questions. We are here to serve you!