Are rising project costs, strict environmental regulations, and remote job sites making asphalt production more difficult across Australia? From mining roads in Western Australia to flood recovery in Queensland and city resurfacing in NSW, people often faces tight schedules and rising expenses. Choosing the right asphalt plant for sale in Australia is no longer just about capacity — it is about mobility, efficiency, and a solution tailored to local project conditions. Keep reading to see which asphalt plant solution fits your project best.

No two projects in Australia are the same, and the right asphalt plant can make all the difference. Whether you need flexibility for remote sites or high-capacity output for major highways, understanding the types of asphalt plants available is the first step toward the perfect solution.

Which Asphalt Plant Fits Your Australian Project Best?

What kind of asphalt plant is right for your project in Australia? There are four main types: mobile drum, mobile batch, stationary drum, and stationary batch asphalt plants. Each type is designed to meet different project conditions across the country — from remote regional roads in Queensland and Western Australia to urban resurfacing in New South Wales and airport projects in Victoria. With Australia investing over AUD 110 billion in infrastructure in 2025, understanding these options is key to choosing the right asphalt plant for efficiency, compliance, and cost control.

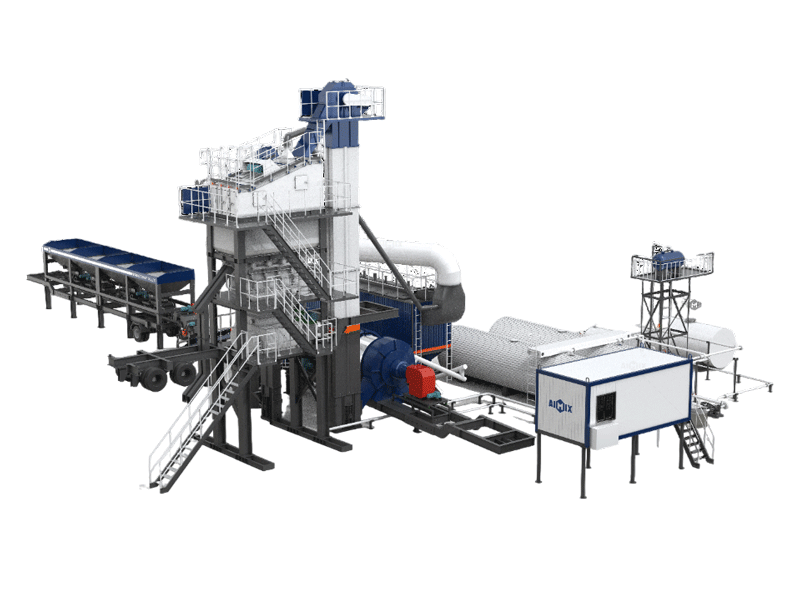

Mobile Asphalt Batch Mix Plant in Australia

- Capacity: 60-160TPH

- Mixing Cycle: 45s

- Best Selling Models: ALYQ-90

- Dust Filter: Bag Dust Filter / Water Dust Filter

ALYQ Series Mobile Asphalt Plant Features

- Fast Setup & Mobility: Modular design, plug-and-play connections, ready in 24 hours for remote QLD and WA projects.

- Smart Operation: AI system with remote monitoring, one-touch mix switching, and 50% labor savings.

- High-Efficiency Mixer: Boosts production by 15%, extra 10 tons/hour, easy blade replacement.

- Advanced Screen: Large patented screen, 100% higher throughput, motor maintenance every 2,000 hours.

- Precise Weighing & Dust Control: Weight error ≤1%, saves up to 80 tons/day, gravity + bag dust collector for EPA compliance.

ALYQ Series Mobile Asphalt Batch Mix Plant Specification

| Model | ALYQ60 | ALYQ80 | ALYQ100 | ALYQ120 | ALYQ160 | |

|---|---|---|---|---|---|---|

| Capacity | t / h | 60 | 80 | 100 | 120 | 160 |

| Mixer capacity | kg | 800 | 1200 | 1300 | 1700 | 2200 |

| Mixing cycle | s | 45 | 45 | 45 | 45 | 45 |

| Total power | Gasoline(kW) | 54 | 63.5 | 104.5 | 125 | 157.5 |

| Coal(kW) | 75 | 86.5 | 127.5 | 169 | 205 | |

| filter area | m2 | 370 | 420 | 480 | 510 | 620 |

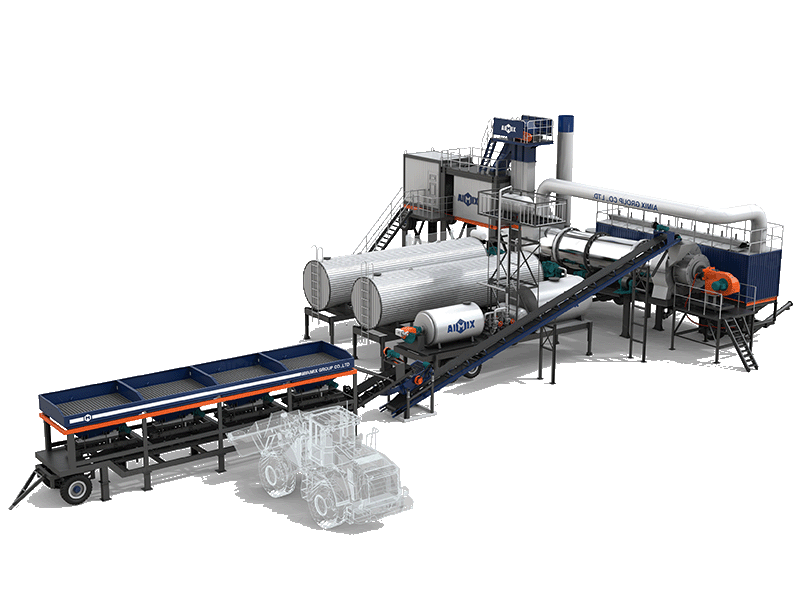

ALYT Series Mobile Drum Mix Plant

- Capacity: 20-120TPH

- Best Selling Models: ALYT-80, ALYT-100

- Fuel Consumption: Fuel Oil (5-7.5 kg/t) / Coal (13-15 kg/t)

- Dust Filter: Bag Dust Filter / Water Dust Filter

ALYT Series Mobile Asphalt Drum Mix Plant Features

- Quick Setup & Transfer: Modular design allows setup in 3–5 days, helping teams start regional or hilly road projects faster.

- Safe Low-Profile Design: Towerless, low center of gravity reduces risk on uneven or steep terrain in VIC and QLD.

- Adaptable to Complex Terrain: Easily crosses hills, mountains, and river bridge lines, avoiding obstacles and downtime.

- Continuous High Output: Drum mix ensures stable asphalt supply, keeping highway and urban resurfacing projects on schedule.

- Cost-Effective Mobility: High initial investment but low relocation cost, ideal for temporary works or seasonal projects.

ALYT Series Mobile Asphalt Drum Mix Plant Specification

| Model | ALYT20 | ALYT40 | ALYT60 | ALYT80 | ALYT100 | ALYT120 |

|---|---|---|---|---|---|---|

| Output | 20t/h | 45t/h | 60t/h | 80t/h | 100t/h | 120t/h |

| Power | 34kw | 65kw | 105kw | 135kw | 170kw | 200KW |

| Cold Aggregate Feeding System | 3.5m³×1 | 4m³×4 | 4m³×4 | 6.5m³×4 | 6.5m³×4 | 6.5m³×4 |

| Finihsed Asphalt Storage Bin | 2m³ | 2.5m³ | 4.5m³ | 5m³ | 7m³ | 7m³ |

| Asphalt Temperature | 120-180℃ | 120-180℃ | 120-180℃ | 120-180℃ | 120-180℃ | 120-180℃ |

| Fuel Consumption(Fuel Oil) | 5-7.5kg/t | 5-7.5kg/t | 5-7.5kg/t | 5-7.5kg/t | 5-7.5kg/t | 5-7.5kg/t |

| Fuel Consumption(Burning Coal) | 13-15kg/t | 13-15kg/t | 13-15kg/t | 13-15kg/t | 13-15kg/t | 13-15kg/t |

| Asphalt Tank | 10t | 20t | 30t | 30t | 35t | 35t |

| Option | bag dust collector / water dust collector | bag dust collector / water dust collector | bag dust collector / water dust collector | bag dust collector / water dust collector | bag dust collector / water dust collector | bag dust collector / water dust collector |

| Whole Plant Option | whole mobile / semi-mobile / fixed | whole mobile / semi-mobile / fixed | whole mobile / semi-mobile / fixed | whole mobile / semi-mobile / fixed | whole mobile / semi-mobile / fixed | whole mobile / semi-mobile / fixed |

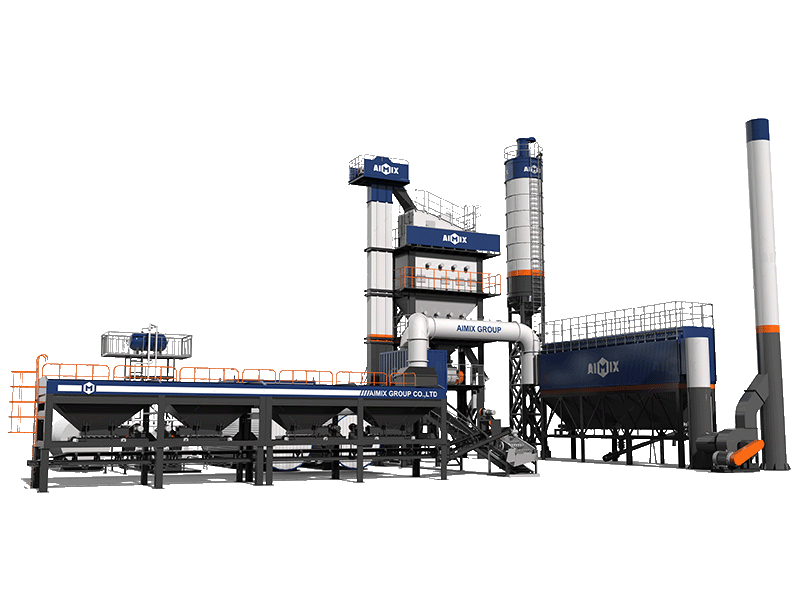

ALQ Series Batch Type Stationary Asphalt Plant

- Capacity: 60-400TPH

- Mixing Cycle: 45s

- Best Selling Models: ALQ-80, ALQ-100, ALQ-120

- Dust Filter: Bag Dust Filter / Water Dust Filter

Stationary Asphalt Batch Plant Features

- One-Touch Smart Control: Integrated system reduces multiple steps to one button, saving time on NSW and VIC highway projects.

- Flexible Operation Modes: PC, touchscreen, and button control adapt to teams while ensuring continuous asphalt production.

- IoT Remote Monitoring: Real-time tracking and maintenance alerts reduce downtime, supporting remote QLD projects.

- Automated Production: Automatic batching, mixing, and unloading improve efficiency, up to 500 tons/day for urban and airport works.

- High Precision & Durability: Aggregate ±0.5%, asphalt ±0.25%, wear-resistant parts handle millions of tons, ensuring stable quality.

ALQ Series Stationary Asphalt Batch Plant for Sale Australia Specification

| Model | ALQ40 | ALQ60 | ALQ80 | ALQ100 | ALQ120 | ALQ160 | ALQ200 | ALQ240 | ALQ320 |

|---|---|---|---|---|---|---|---|---|---|

| Capacity | 40 t/h | 60 t/h | 80 t/h | 100 t/h | 120 t/h | 160 t/h | 200 t/h | 240 t/h | 320 t/h |

| Cold Aggregate Hoppers | 4×4.5m³ | 4×6.5m³ | 4×7.5m³ | 4×7.5m³ | 5×7.5m³ | 5×12m³ | 5×12m³ | 5×12m³ | 6×15m³ |

| Dryer Size | φ1.2m×5.2m | φ1.5m×6m | φ1.5m×6.7m | φ1.65m×7m | φ1.8m×8m | φ2.2m×9m | φ2.6m×9m | φ2.6m×9.5m | φ2.8m×10.2m |

| Fuel consumption | 70-300kg / h | 100-400kg / h | 120-600kg / h | 150-1000kg / h | 150-1000kg / h | 150-1400kg / h | 180-1800kg / h | 180-1800kg / h | 260-2500kg / h |

| Vibrating Screen (Layer) | 4 layers | 4 layers | 4 layers | 4 layers | 5 layers | 5 layers | 5 layers | 5 layers | 6 layers |

| Mixer Capacity | 500kg | 800kg | 1000kg | 1250kg | 1500kg | 2000kg | 2500kg | 3000kg | 4000kg |

| Cycle Time | 45s | 45s | 45s | 45s | 45s | 45s | 45s | 45s | 45s |

| Filter Area | 230m² | 300m² | 420m² | 480m² | 550m² | 650m² | 700m² | 1050m² | 1350m² |

| Asphalt Temperature | 140-180 ℃ | 140-180 ℃ | 140-180 ℃ | 140-180 ℃ | 140-180 ℃ | 140-180 ℃ | 140-180 ℃ | 140-180 ℃ | 140-180 ℃ |

| Total Power | 170kw | 200kw | 300kw | 350kw | 380kw | 490kw | 550kw | 670kw | 865kw |

ALT Series Stationary Drum Mix Plant for Sale

- Capacity: 20-110TPH

- Best Selling Models: ALT-80, ALT-120

- Cold Aggregate Hopper: 3.5m³×1 – 6.5m³×4

- Dust Filter: Bag Dust Filter / Water Dust Filter

ALT Series Stationary Asphalt Drum Mix Plant Features

- Stable Long-Term Production: Fixed installation ensures reliable output for highway upgrades and village road networks in VIC.

- Compact Tower Design: Integrated tower with smart temperature control reduces heat loss and improves efficiency.

- Optimized Drying Drum: High thermal exchange efficiency lowers fuel consumption by 10–15%, cutting operational costs.

- Suitable Terrain: Ideal for flat, large-scale projects such as regional roads and connected rural networks.

- Cost-Effective Operation: Low initial investment for long-term projects; fixed site reduces downtime and save costs.

ALT Series Stationary Drum Mix Plant Technical Specification

| Courts Models | ALT20 | ALT40 | ALT60 | ALT80 | ALT100 |

|---|---|---|---|---|---|

| Capacity | 20 t/h | 45 t/h | 60 t/h | 80 t/h | 100 t/h |

| The ability to | 40kw | 75kw | 120kw | 165kw | 200kw |

| Cold Aggregate Hoppers | 3.5m³×1 | 4m³×4 | 4m³×4 | 6.5m³×4 | 6.5m³×4 |

| Finished Product Hopper | 3t | 3t | 7t | 7t | 9t |

| Asphalt Temperature | 120-180 ℃ | ||||

| Fuel consumption | 13-15kg/t | ||||

| Asphalt Tank | 10 t | 20 t | 30 t | 30 t | 35 t |

| Control room | 2.2m | 2.2m | 3m | 3m | 3.5m |

| Option | Bag dust filter | ||||

Now that you understand the different types, the next question is simple — how much does an asphalt plant cost in Australia? Asphalt plant price Australia varies based on capacity, configuration, mobility, and environmental requirements. Let’s break down what really affects your investment and how to plan your budget wisely.

How About the Asphalt Plant Price in Australia?

How much should you budget for an asphalt plant in Australia? The asphalt plant equipment price alone typically ranges from $50,000 to $1,000,000, depending on plant type, capacity, and configuration. (This figure refers to the plant itself and does not include transportation, civil foundation work, installation, or local compliance upgrades.) Understanding what drives this price range is essential before making an investment decision.

What Factors Affect Asphalt Plant Prices in Australia?

Plant Type and Structure

Mobile plants usually cost less and offer relocation flexibility, while stationary plants require larger structures and precision systems, resulting in higher prices.

![]()

Production Capacity (TPH)

Higher output requires larger dryers, mixers, and dust collectors, which increases cost significantly, especially for 160–240 TPH highway-grade systems.

![]()

Environmental Compliance

Meeting Australian EPA standards often requires baghouse asphalt plant australia with dust collector compliance, low-NOx burners, and noise control systems.

![]()

Automation and Control System

AI control systems, IoT remote monitoring, and automatic weighing improve efficiency and reduce labor costs, but increase upfront equipment pricing.

![]()

Customization and Optional Configurations

Extra asphalt tanks, RAP systems, fiber feeders, or upgraded burners raise the total equipment cost depending on project needs.

But remember, the price tag on the plant itself is just the beginning. Shipping, installation, site preparation, permits, and initial working capital can add a significant amount to your total investment. Let’s break down these additional costs so you know exactly what to plan for in Australia.

How Much Will Your Asphalt Plant Cost Beyond the Equipment?

Buying the asphalt plant itself is only part of the investment. Shipping from China to Australia, site preparation, installation, permits, and initial working capital can add hundreds of thousands of AUD. This table shows reference costs for a 100 TPH asphalt plant, helping you plan your budget realistically while considering local Australian conditions.

⚠️ All figures are reference values. Actual costs may vary depending on shipping port, customs duties, site conditions, and local regulations.

| Category | Item | Mobile Plant (AUD) | Stationary Plant (AUD) | Notes (Australia Context) |

|---|---|---|---|---|

| 1. Transportation | Sea freight | 25,000 – 45,000 | 50,000 – 90,000 | Shanghai → Sydney/Brisbane/Perth; container quantity affects cost |

| Inland transport | 8,000 – 20,000 | 20,000 – 40,000 | Heavy haulage permits required for oversized components | |

| 2. Civil Works | Concrete foundation | 15,000 – 40,000 | 120,000 – 250,000 | Stationary plants require full foundation; site leveling included |

| Electrical & transformer | 10,000 – 30,000 | 40,000 – 80,000 | Grid connection, switchgear; may vary by state regulations | |

| Site leveling & drainage | 8,000 – 25,000 | 50,000 – 100,000 | Important in flood-prone regions (QLD) | |

| 3. Installation & Commissioning | Mechanical installation | 15,000 – 35,000 | 60,000 – 120,000 | Includes crane rental and local labor |

| Commissioning & training | 8,000 – 20,000 | 20,000 – 40,000 | On-site engineer support recommended | |

| 4. Compliance & Licensing | EPA permits | 10,000 – 30,000 | 20,000 – 60,000 | Environmental approvals in NSW, VIC, QLD |

| Noise & safety measures | 8,000 – 20,000 | 15,000 – 40,000 | Especially near residential areas or schools | |

| 5. Initial Working Capital | Raw materials (1 month) | 80,000 – 150,000 | 120,000 – 250,000 | Bitumen + aggregates; depends on production volume |

| Fuel reserve | 20,000 – 40,000 | 35,000 – 70,000 | Diesel or gas for heating & mixing | |

| Spare parts stock | 15,000 – 40,000 | 25,000 – 60,000 | Critical wear parts and emergency replacements |

Key Insight

Portable Asphalt Plant Australia Total Other Costs: ~AUD 200,000 – 400,000

Stationary Asphalt Plant Australia Total Other Costs: ~AUD 400,000 – 800,000

⚠️ Reference only: Actual costs may vary depending on shipping port, customs duties, local site conditions, and compliance requirements. Australian buyers should consult local engineers or logistics providers for precise estimates.

Cost planning is only half of the equation. To make a smart investment, you also need to understand where the Australian asphalt market is heading. Are infrastructure projects expanding? Is regional demand increasing? Let’s take a closer look at the latest market trends shaping asphalt plant opportunities across Australia.

Latest Australia Asphalt Market & Demand Trends

How is the demand for asphalt evolving across Australia in 2026 and beyond? With governments investing heavily in highways, regional roads, and urban resurfacing, the need for reliable asphalt production is rising. Contractors and local councils face tight schedules, strict environmental standards, and regional project challenges — making efficient, flexible asphalt plants more critical than ever. Below, we break down the latest market trends, regional demands, and equipment growth to help you plan your next asphalt plant investment.

| Driver | Trend | Impact on Asphalt Plant Demand |

|---|---|---|

| Public Infrastructure Investment | Transport investment > AUD 129 billion | More highway & regional projects needing asphalt production |

| Construction Activity | Road works ~ AUD 39.7 billion (FY26) | Consistent production & plant deployment |

| Equipment Market Growth | Asphalt paving equip. CAGR ~5.8% | Higher demand for efficient paving and mixing equipment |

| Regional & Remote Projects | Continued demand in QLD, WA & NT | Mobile plant preferences for relocation efficiency |

Strong Government Infrastructure Investment

Elevated Road Construction & Maintenance Activity

Expanding Asphalt Equipment Market

Regional & Remote Project Demands

Implications for Asphalt Plant Buyers

Growing asphalt demand is only one side of the story. As projects expand and regulations tighten, the real question becomes: how is the asphalt mixing plant market itself responding? Let’s look at what the 2026–2030 outlook means for equipment investment across Australia.

What Is the Outlook for the Asphalt Mixing Plant Market in Australia?

Is the Australian asphalt mixing plant market entering a new growth phase after 2026? With sustained infrastructure investment, tightening environmental standards, and rising demand for regional flexibility, buyers are rethinking how and when to invest in new hot mix asphalt plants. Understanding where the market is heading can help contractors, councils, and investors make smarter, future-proof decisions.

Market Size & Growth Momentum

Mobile vs. Stationary Plant Demand

Mobile asphalt plants are increasingly adopted for regional roads, flood recovery works, and temporary projects, especially in QLD, WA, and NT, where relocation speed and site flexibility are critical.

Stationary asphalt plants continue to dominate large-scale highway, airport, and long-term urban projects in NSW and Victoria, where high output and continuous production are required.

By 2026+, mobile asphalt mix plants are expected to account for over 40% of new plant installations, reflecting Australia’s geographically dispersed project distribution.

Environmental & Compliance Impact

Technology & Automation Trends

What This Means for Buyers

The market outlook shows where Australia is heading — but what does that mean for your specific project? Growth forecasts and investment figures are only part of the picture. The real question is: which asphalt plant configuration fits the conditions in your state? Let’s break it down by region and match plant types to actual project demand.

How to Select the Right Asphalt Plant by Australian State?

Asphalt plant selection in Australia goes beyond production capacity. Each state differs in infrastructure priorities, regulatory requirements, geographic conditions, and project scale. A plant suited for a long-term motorway project in New South Wales may not fit remote regional works in Western Australia. Find the right asphalt plant configuration for your state in the guide below.

| State | Typical Project Focus | Recommended Capacity | Recommended Plant Type | Representative Projects (2026–2028) | Why It Works |

|---|---|---|---|---|---|

| New South Wales (NSW) | Major highway upgrades, metro expansions, airport resurfacing | 160–240 TPH | Stationary Batch / Stationary Drum | M1 Pacific Motorway Upgrade, Western Harbour Tunnel | Large corridor projects often exceed 30–50 km paving sections, requiring >1,500 tons/day stable output with strict EPA emission compliance |

| Victoria (VIC) | Urban road renewal, regional transport links, sustainability requirements | 140–200 TPH | Stationary Batch | North East Link Project, Melbourne Airport Rail | Metropolitan resurfacing and link upgrades demand high mix precision and consistent 1,200–1,800 tons/day production |

| Queensland (QLD) | Regional highways, flood recovery works, rural road networks | 100–160 TPH | Mobile Batch / Mobile Drum | Bruce Highway Upgrades, Flood Recovery Works | Dispersed regional works across hundreds of kilometers favor mobile units producing 800–1,300 tons/day with fast relocation |

| Western Australia (WA) | Mining access roads, remote infrastructure, long regional connections | 120–200 TPH | Mobile Batch / Mobile Drum | Great Northern Highway Works, Pilbara Regional Roads | Remote projects spanning long haul distances require modular relocation and fuel-efficient continuous production above 1,000 tons/day |

| South Australia (SA) | Council & regional maintenance, mid-scale resurfacing | 80–140 TPH | Mobile Drum / Mobile Batch | South Road Upgrade, Rural Road Resealing | Mid-scale resurfacing programs typically require 600–1,100 tons/day with cost-balanced setup |

| Northern Territory (NT) | Community access roads, smaller localized projects | 60–120 TPH | Mobile Drum | Stuart Highway maintenance, Remote community access roads | Lower-volume projects under 800 tons/day benefit from transportable, simplified configurations |

Choosing the right asphalt plant is only part of the equation. Before production begins, every asphalt facility in Australia must pass through environmental, planning, and safety approvals. Understanding these requirements early can save months of delays and unexpected costs. Let’s look at what certifications and permits you’ll need before breaking ground.

What Certifications and Approvals Are Required to Set Up an Asphalt Plant in Australia?

Establishing an asphalt plant in Australia requires compliance with environmental, safety, and local planning regulations. Requirements vary by state, but most projects must obtain approvals across environmental protection, construction planning, workplace safety, and equipment standards before operation. Below is an overview of the key certifications typically required.

Environmental Protection Approval (EPA)

Environmental approval is the most critical requirement. Depending on the state (NSW EPA, EPA Victoria, etc.), operators typically need:

Air emission permit (dust, particulate matter, NOx control)

Noise impact assessment

Waste management plan

Water discharge approval (if applicable)

Modern asphalt plants must meet strict dust filtration and burner emission standards, often requiring high-efficiency baghouse systems and low-NOx burners.

Local Council & Development Approval

Before construction, approval from the local council is generally required, including:

Land zoning compliance

Development application (DA)

Site layout and environmental impact documentation

Traffic impact assessment (for heavy vehicle movement)

Approval timelines can range from several weeks to several months depending on location.

Workplace Health & Safety (WHS) Compliance

All asphalt plants must comply with Australian Work Health and Safety regulations, including:

Risk assessments

Emergency response plans

Machinery guarding standards

Safe operation procedures

Operators must align with Safe Work Australia guidelines.

Electrical & Mechanical Standards

Imported or locally manufactured equipment must comply with relevant Australian Standards (AS / AS/NZS), including:

Electrical system certification

Pressure vessel compliance (bitumen tanks)

Burner and fuel system safety standards

Third-party inspection may be required prior to commissioning.

Import & Customs Compliance (For Overseas Equipment)

If the asphalt plant is shipped from overseas:

Equipment documentation must meet Australian customs requirements

Electrical systems may require local certification adaptation

Installation and commissioning must align with Australian compliance standards

How We Support Compliance

While regulatory approval ultimately rests with the asphalt plant owner, experienced asphalt plant suppliers Australia can assist by:

Meeting regulatory requirements ensures your plant can operate — but performance and efficiency determine how competitively it runs. Beyond compliance, engineering innovation plays a decisive role in fuel savings, production stability, and long-term reliability. Here’s how our patented technologies enhance asphalt plant performance in real operating conditions.

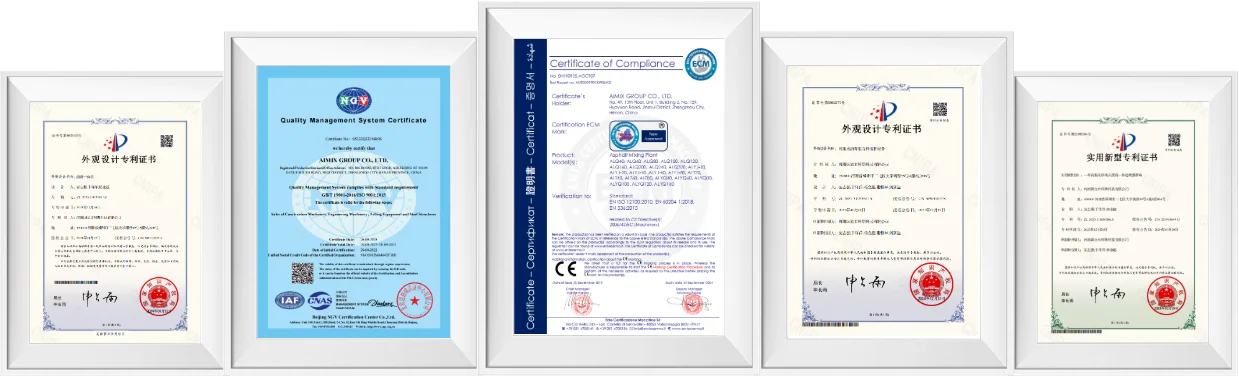

Certified Patented Technologies Behind Our Asphalt Plants

Reliable performance starts with engineering innovation. Our asphalt plants incorporate patented structural designs and proprietary technologies developed to improve mobility, integration, thermal efficiency, and operational stability. These certifications demonstrate measurable technical advancement rather than standard industry configurations.

Utility Model Patent – Mobile Drum Mixer

Improves heat transfer efficiency by up to 15% and reduces fuel consumption by 8–12%, while shortening installation time by approximately 20%.

Patent – Asphalt Plant Pipeline Expansion Technology

Enhances thermal stability and reduces pressure loss by up to 10%, ensuring consistent bitumen flow during high-capacity production above 160 TPH.

Design Patent Certificate

Optimized structural layout reduces footprint by 10–15% and improves maintenance accessibility, lowering routine service time by approximately 15%.

Patent – High-Integrated Asphalt Mixing Equipment

Modular high-integration design shortens commissioning time by up to 25% and improves overall system coordination efficiency under continuous operation.

See the innovation behind our asphalt plants come to life! Watch how AIMIX patented technologies perform on real projects across Australia and around the globe, delivering efficiency, quality, and reliability every step of the way.

Watch Our Asphalt Plants in Action – Australia & Around the World

See how our asphalt mixing plants are making projects easier and more efficient worldwide. From regional roads in Australia to large-scale infrastructure projects across Asia, Africa, and Europe, our exported plants deliver reliable performance, fast installation, and high-quality asphalt. Check out our YouTube videos to watch real project setups, equipment in operation, and satisfied customers sharing their experiences.

Watching our asphalt plants in action shows their power, but keeping them performing at their best requires regular care. Let’s dive into the key maintenance steps that make every project run smoothly.

Asphalt Mixing Plant Maintenance Guide for Efficient & Reliable Operation

Regular maintenance is critical to ensuring stable production, extended equipment lifespan, and safe plant operation. A well-planned maintenance program reduces unexpected downtime, lowers repair costs, and keeps output quality consistent. Below are the essential routine tasks that help your asphalt mixing plant Perth operate at peak performance.

Lubricate Equipment

Adhere strictly to the lubrication schedule specified by the manufacturer. Ensure all moving parts, including bearings, gears, and joints, are properly lubricated to minimize wear and tear. Use the recommended type and amount of lubricant to ensure maximum efficiency and longevity of the components.

Check Vibrating Screen

Regularly inspect the vibrating screen for any signs of wear, tear, or damage. Ensure that the screen mesh is not clogged and is in good condition to prevent any disruption in the screening process. Replace or repair any damaged parts to maintain the efficacy of the screening operation.

Inspect Gas Line

Conduct periodic inspections of the gas lines for any leaks or damages. Use soapy water or a gas detector to identify any leaks. Repair any identified leaks immediately to ensure safety and prevent any interruptions in the heating process.

Clear Pipe Blockages

Regularly check for blockages in pipes, especially those that handle materials with large particle sizes. Remove any obstructions to ensure a smooth flow of materials through the system. Implement preventive measures such as screens or filters to minimize the risk of blockages.

Control Room Dust Management

Maintain a clean control room environment to prevent dust accumulation. Use dust extraction systems or air purifiers to minimize dust levels. Regularly clean electrical panels and equipment to prevent dust from affecting their operation and longevity.

Clean Mixing Tank

After each operation, thoroughly clean the feeding door and the interior of the mixing tank. Remove any residual material to prevent contamination of future batches and ensure consistent mixing quality. Inspect the tank for any signs of wear or damage and address them promptly.

Tighten Bolts and Nuts

Periodically check all bolts and nuts for tightness. Use the appropriate tools to tighten any loose bolts and nuts, ensuring all connections are secure. Pay special attention to critical areas that experience high vibrations or stress.

Screw Conveyor Maintenance

Regularly check the lubrication of the screw conveyor shaft seal. Ensure that the seal is in good condition to prevent leaks and maintain efficient operation. Calibrate the screw conveyor as necessary to ensure accurate material handling and distribution.

Stirred Drive Gear Lubrication

Use the observation hole to check the lubrication level of the stirred drive gear. Add the appropriate amount of lubricating oil if needed to ensure smooth operation. Inspect the gears for any signs of wear or damage and address any issues promptly to prevent breakdowns.

Maintenance keeps your plant running — but the right local support keeps your business moving. From emergency technical assistance to spare parts supply and on-site commissioning, service capability directly impacts uptime and profitability. So, what asphalt mixing plant services are actually available in Australia? Let’s explore the support network you can rely on.

What Asphalt Mixing Plant Services Can You Get in Australia?

As an established asphalt plant manufacturer with projects serving the Australian market, we understand that reliable local support is just as important as equipment quality. From installation and commissioning to spare parts supply and technical assistance, comprehensive service ensures stable production, reduced downtime, and long-term operational confidence. Here’s what you can expect from our asphalt mixing plant services in Australia:

Pre-Sales Consultation

Needs Assessment: Understanding the specific needs of the customer and recommending the suitable model of asphalt mobile batching plants for sale Perth.

Technical Advice: Giving detailed technical information and suggestions to help customers make informed decisions.

Product Quality Assurance

High-Quality Manufacturing: Using premium materials and advanced technology to ensure the equipment is durable and efficient.

Strict Quality Control: Conducting rigorous quality checks at various stages of production to ensure compliance with international standards.

Delivery and Installation

Timely Delivery: Ensuring that the asphalt mixing equipment is delivered safely and on time to the customer’s site.

Installation Support: Professional engineers for on-site installation support to ensure the equipment is installed correctly and efficiently.

Training Services

Operator Training: Offering comprehensive training for operators and maintenance personnel to ensure proper use and maintenance of the equipment.

Safety Training: Emphasizing safe operation procedures and best practices to reduce the risk of accidents.

After-Sales Support

Technical Support: Ongoing technical support through phone, email, or on-site visits to resolve operational issues.

Maintenance Services: Providing regular maintenance services to ensure the equipment operates efficiently and to prevent unexpected breakdowns.

Warranty and Repairs

1 Year+ Warranty Coverage: Offering comprehensive warranty services that cover manufacturing defects and major component failures.

Repair Services: Providing prompt and efficient repair services to ensure the equipment is quickly back in operation.

Want to make the most of your asphalt plant in Australia? Let’s dive into the key questions contractors and investors ask most about installation, operation, and local support.

Frequently Asked Questions About Asphalt Plants in Australia

What Is The Warranty Period For An Asphalt Plant In Australia?

How Long Does It Take To Produce And Ship An Asphalt Plant To Australia?

How Long Does It Take To Install An Asphalt Plant?

How Fast Can A Mobile Asphalt Plant Be Relocated Between Sites?

Are Spare Parts of Asphalt Plant Available Locally In Australia?

What Maintenance Is Required To Keep The Asphalt Plant Running Efficiently?

Can Australian Asphalt Plants Use Recycled Asphalt Pavement (RAP)?

How Quickly Can Technical Support Respond In Australia?

Ready to Upgrade Your Asphalt Operations in Australia?

Looking for a reliable asphalt mixing plant for your projects? We provide high-quality asphalt plants, local support, and practical guidance to make your work easier and faster. Contact us today for a free quote and see how our equipment can help you get the job done right. Don’t wait—start improving your asphalt operations with us now!