Take control of Nigerian asphalt roads — save up to 30% project cost.

Finish Lagos and Kano projects 25% faster with flexible asphalt plants.

Durable, reliable asphalt solutions — thrive in Nigeria’s heat and rain.

Tired of Asphalt Delays and High Costs Across Nigeria’s Roads and Projects? From Lagos’ busy streets to rural feeder roads in Kano, everyone involved in road construction faces unpredictable weather, long transport distances, and high operating costs. We understand these challenges — that’s why our asphalt plant for sale in Nigeria is designed for local conditions, offering mobile flexibility, reliable output, and cost-effective solutions that keep your projects moving smoothly.

With so many different projects across Nigeria—from the busy streets of Abuja to rural roads in Enugu—choosing the right asphalt plant in Nigeria can make all the difference. Let’s explore which types of asphalt plants best suit Nigeria’s diverse road construction needs.

What Types of Asphalt Plants Fit Nigeria?

Struggling to find an asphalt plant that keeps your Nigerian projects on time and under budget? Project owners, road developers, and asphalt suppliers across Nigeria often ask the same question: which asphalt plant is right for my project? With scattered rural roads, busy city highways, short construction windows, and fluctuating fuel costs, selecting the wrong type can slow progress and increase expenses. That’s why we offer 5 types of asphalt plants designed to meet the diverse needs of road projects and asphalt supply across Nigeria.

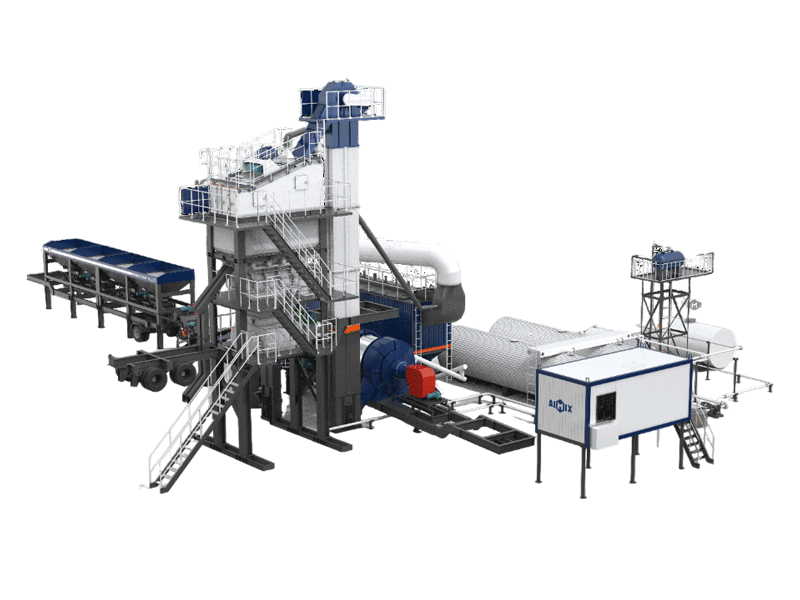

Stationary Asphalt Batch Plants (ALQ Series)

| Type | Capacity | Mixing Cycle | Dust Filter |

| ALQ Series | 40-400TPH | 45s | Gravity/Baghouse |

- Ideal for: Long-term, high-volume urban road construction and highway projects.

- Modular tower structure → Clear production planning → Installation efficiency up 30%, project ahead of schedule

- High-precision weighing, ±0.5% aggregate, ±0.25% asphalt → Uniform mix per cubic → Site rework reduced by 30%

- Automated mixing and discharge → Smooth continuous operation → Stable daily output, ideal for large projects

- AI maintenance alerts → Real-time fault monitoring → Downtime reduced 20%, project progresses faster

- Multi-stage dust control & heat recycling → Improved environment and stable temperature → Asphalt loss down 15%, safer site

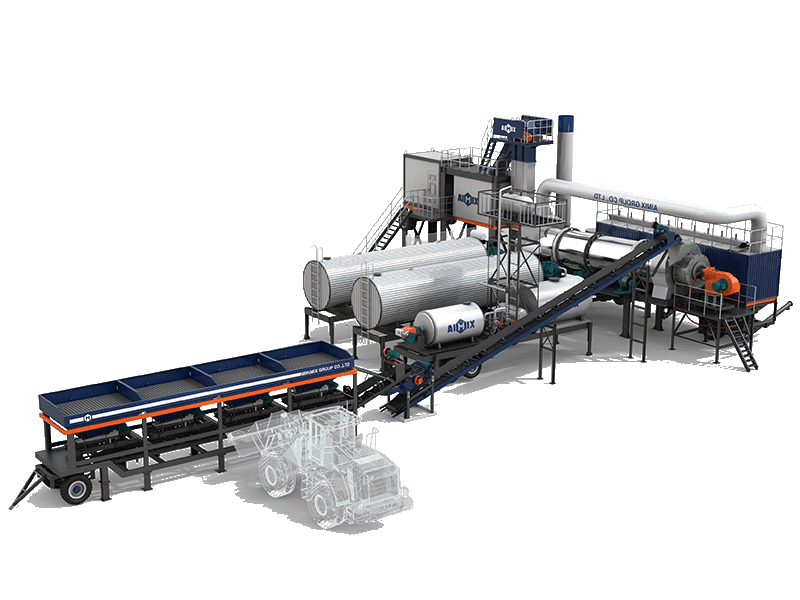

Batch Type Mobile Asphalt Plants (ALYQ Series)

| Type | Capacity | Mixing Cycle | Dust Filter |

| ALYQ Series | 40-160TPH | 45s | Gravity/Baghouse |

- Ideal for: Emergency repairs, multiple scattered sites, short-term urban and rural projects.

- Modular magnetic block design → Fast assembly and relocation → Production within 24h, cover multiple sites

- AI smart control → Quick formula change, auto compensation → Material waste reduced, save ~80 tons/day

- Power mixer system → 15%+ Higher mixing efficiency, output increased → 10 tons more per hour, 100 tons per day

- QuickDraw vibrating screen → Large screen area, high efficiency → Screening output doubled, easy operation

- Gravity + bag dust removal → Controlled emission, cleaner air → Improved site environment, neighbor satisfaction up

Drum Type Stationary Asphalt Plants (ALT Series)

| Type | Capacity | Fuel Use | Dust Filter |

| ALT Series | 20-100TPH | 13-15kg/t | Water/Baghouse |

- Ideal for: Long-term rural or regional road projects with stable terrain.

- Compact tower design → Clear production layout → Efficient installation, shorter project duration

- Intelligent temperature control → Consistent asphalt temperature → Rework reduced 25%, quality stable

- Optimized drying drum → Less heat loss → Fuel consumption down 10–15%, lower cost

- Continuous drum production → Stable output → Meets large-scale project demands, higher client satisfaction

- Multi-stage dust modules → Visible environmental control → Dust emission down 30%, safer worksite

Mobile Asphalt Drum Mix Plants (ALYT Series)

| Type | Capacity | Mixing Cycle | Dust Filter |

| ALYT Series | 20-120TPH | 10-15 min/batch | Water |

- Ideal for: Mountainous, hilly, or bridge connection roads needing fast deployment.

- Modular low-center design → Quick setup and dismantling → Relocation 3–5 days, multiple projects covered

- Tower-free layout → Compact footprint, adapts to rough terrain → Easy construction in remote areas

- Intelligent temperature control → Even asphalt temperature → Rework reduced 25%, mix stable

- Modular cold & finished bins → Clear capacity, simple operation → Higher efficiency, faster schedule

- Energy-saving burner → Lower fuel use, stable heating → Project cost down 10–15%

Mini Portable Asphalt Mixers (ALB Series)

| Type | Capacity | Fuel Use | Dust Filter |

| ALB Series | 2-20TPH | 13-15kg/t | Water/Baghouse |

- Small Portable Asphalt Mixer Price Range: $20,000-$35,000

- Ideal for: Small contractors, pothole repair teams, and courtyard paving.

- Trailer/mounted design → Quick deployment on small sites → Minor repairs done same day

- Adjustable heating → Temperature controllable → Uniform mix, rework down 20–30%

- Small mixing tank → Capacity clear → Stable output for yards or narrow roads

- Simple control panel → Easy operation → Labor cost cut 50%, work lighter

- Diesel engine → Easy mobility → Covers multiple small projects, client satisfaction up

Whether you’re upgrading Lagos’ busy highways or repairing Kaduna’s rural roads, the right asphalt plant for sale in Nigeria can cut fuel use by up to 15%, reduce rework by 25–30%, and keep multiple projects on schedule. Explore specifications below to see how each model performs on real Nigerian sites and choose the solution that fits your needs perfectly.

Asphalt Plant Technical Specifications for Nigeria

Every asphalt road construction project in Nigeria has unique challenges—from busy urban streets to remote rural roads. Explore the technical specifications below to understand each asphalt plant’s capacity, mixing system, and operational features; Therefore, you can choose the model that fits your site, workflow, and project needs perfectly.

ALQ Series – Stationary Batch Asphalt Mixing Plant Specification

| Model | ALQ40 | ALQ60 | ALQ80 | ALQ100 | ALQ120 | ALQ160 | ALQ200 | ALQ240 | ALQ320 |

|---|---|---|---|---|---|---|---|---|---|

| Capacity | 40 t/h | 60 t/h | 80 t/h | 100 t/h | 120 t/h | 160 t/h | 200 t/h | 240 t/h | 320 t/h |

| Cold Aggregate Hoppers | 4×4.5m³ | 4×6.5m³ | 4×7.5m³ | 4×7.5m³ | 5×7.5m³ | 5×12m³ | 5×12m³ | 5×12m³ | 6×15m³ |

| Dryer Size | φ1.2m×5.2m | φ1.5m×6m | φ1.5m×6.7m | φ1.65m×7m | φ1.8m×8m | φ2.2m×9m | φ2.6m×9m | φ2.6m×9.5m | φ2.8m×10.2m |

| Fuel consumption | 70-300kg / h | 100-400kg / h | 120-600kg / h | 150-1000kg / h | 150-1000kg / h | 150-1400kg / h | 180-1800kg / h | 180-1800kg / h | 260-2500kg / h |

| Vibrating Screen (Layer) | 4 layers | 4 layers | 4 layers | 4 layers | 5 layers | 5 layers | 5 layers | 5 layers | 6 layers |

| Mixer Capacity | 500kg | 800kg | 1000kg | 1250kg | 1500kg | 2000kg | 2500kg | 3000kg | 4000kg |

| Cycle Time | 45s | 45s | 45s | 45s | 45s | 45s | 45s | 45s | 45s |

| Filter Area | 230m² | 300m² | 420m² | 480m² | 550m² | 650m² | 700m² | 1050m² | 1350m² |

| Asphalt Temperature | 140-180 ℃ | 140-180 ℃ | 140-180 ℃ | 140-180 ℃ | 140-180 ℃ | 140-180 ℃ | 140-180 ℃ | 140-180 ℃ | 140-180 ℃ |

| Total Power | 170kw | 200kw | 300kw | 350kw | 380kw | 490kw | 550kw | 670kw | 865kw |

ALYQ Series – Mobile Batch Asphalt Mixing Plant Specification

| Model | ALYQ60 | ALYQ80 | ALYQ100 | ALYQ120 | ALYQ160 | |

|---|---|---|---|---|---|---|

| Capacity | t / h | 60 | 80 | 100 | 120 | 160 |

| Mixer capacity | kg | 800 | 1200 | 1300 | 1700 | 2200 |

| Mixing cycle | s | 45 | 45 | 45 | 45 | 45 |

| Total power | Gasoline(kW) | 54 | 63.5 | 104.5 | 125 | 157.5 |

| Coal(kW) | 75 | 86.5 | 127.5 | 169 | 205 | |

| filter area | m2 | 370 | 420 | 480 | 510 | 620 |

ALT Series – Stationary Continuous Asphalt Mixing Plant Specification

| Courts Models | ALT20 | ALT40 | ALT60 | ALT80 | ALT100 |

|---|---|---|---|---|---|

| Capacity | 20 t/h | 45 t/h | 60 t/h | 80 t/h | 100 t/h |

| The ability to | 40kw | 75kw | 120kw | 165kw | 200kw |

| Cold Aggregate Hoppers | 3.5m³×1 | 4m³×4 | 4m³×4 | 6.5m³×4 | 6.5m³×4 |

| Finished Product Hopper | 3t | 3t | 7t | 7t | 9t |

| Asphalt Temperature | 120-180 ℃ | ||||

| Fuel consumption | 13-15kg/t | ||||

| Asphalt Tank | 10 t | 20 t | 30 t | 30 t | 35 t |

| Control room | 2.2m | 2.2m | 3m | 3m | 3.5m |

| Option | Bag dust filter | ||||

ALYT Series – Mobile Asphalt Drum Mix Plant Specification

| Model | ALYT20 | ALYT40 | ALYT60 | ALYT80 | ALYT100 | ALYT120 |

|---|---|---|---|---|---|---|

| Output | 20t/h | 45t/h | 60t/h | 80t/h | 100t/h | 120t/h |

| Power | 34kw | 65kw | 105kw | 135kw | 170kw | 200KW |

| Cold Aggregate Feeding System | 3.5m³×1 | 4m³×4 | 4m³×4 | 6.5m³×4 | 6.5m³×4 | 6.5m³×4 |

| Finihsed Asphalt Storage Bin | 2m³ | 2.5m³ | 4.5m³ | 5m³ | 7m³ | 7m³ |

| Asphalt Temperature | 120-180℃ | 120-180℃ | 120-180℃ | 120-180℃ | 120-180℃ | 120-180℃ |

| Fuel Consumption(Fuel Oil) | 5-7.5kg/t | 5-7.5kg/t | 5-7.5kg/t | 5-7.5kg/t | 5-7.5kg/t | 5-7.5kg/t |

| Fuel Consumption(Burning Coal) | 13-15kg/t | 13-15kg/t | 13-15kg/t | 13-15kg/t | 13-15kg/t | 13-15kg/t |

| Asphalt Tank | 10t | 20t | 30t | 30t | 35t | 35t |

| Option | bag dust collector / water dust collector | bag dust collector / water dust collector | bag dust collector / water dust collector | bag dust collector / water dust collector | bag dust collector / water dust collector | bag dust collector / water dust collector |

| Whole Plant Option | whole mobile / semi-mobile / fixed | whole mobile / semi-mobile / fixed | whole mobile / semi-mobile / fixed | whole mobile / semi-mobile / fixed | whole mobile / semi-mobile / fixed | whole mobile / semi-mobile / fixed |

ALB Series – Small Portable Asphalt Mixer Machine Specification

| Model | 0.38-0.4 m³ | 0.5 m³ | 0.7 m³ | 1 m³ | 1.5 m³ | 2 m³ | 3 m³ (Dual Tank) |

|---|---|---|---|---|---|---|---|

| Chassis Type | Mini Trailer Tricycle | Mini Trailer Tricycle | 4-Wheel | 6-Wheel | 6-Wheel | 6-Wheel | 6-Wheel |

| Diesel Generator | Changchai Diesel Engine | Changchai Diesel Engine | Weifang Diesel Engine | Weifang Diesel Engine | Weifang Diesel Engine | Weifang Diesel Engine | Weifang Diesel Engine |

| Power Output | 12 kW | 12 kW | 30 kW | 30 kW | 30 kW | 30 kW | 30 kW |

| Main Burner | 200,000 kcal | 200,000 kcal | 400,000 kcal | 440,000 kcal | 440,000 kcal | 440,000 kcal | 440,000 kcal (2 units) |

| Secondary Burner | 200,000 kcal | 200,000 kcal | 200,000 kcal | 200,000 kcal | 210,000 kcal | 220,000 kcal | 220,000 kcal |

| Mixing Tank Temperature | 120-165℃(Adjustable) | 160-210℃(Adjustable) | 160-210℃(Adjustable) | 160-210℃(Adjustable) | 160-210℃(Adjustable) | 160-210℃(Adjustable) | 160-210℃(Adjustable) |

| Fuel Type | Diesel | Diesel | Diesel | Diesel | Diesel | Diesel | Diesel |

| Fuel Consumption | 2.5-5L per batch | 4-5L per batch | 4-5L per batch | 5-6L per batch | 6-7L per batch | 6-7L per batch | 8-10L per batch |

| Mixing Motor | 2.2 kW | 5.5 kW | 5.5 kW | 5.5 kW | 5.5 kW | 5.5 kW | 5.5 kW |

| Dust Removal System | / | Water Dust Removal | Water Dust Removal | Water Dust Removal | Water Dust Removal | Water Dust Removal | Water Dust Removal |

| Tank Capacity (m³) | 1 m³ | 1.75 m³ | 2.35 m³ | 3.25 m³ | 4.25 m³ | 5 m³ | 4.25 m³ * 2 |

| Mixing Volume (tons/m³) | 0.25 m³ / 0.5 tons | 0.5 m³ / 1 ton | 0.7 m³ / 1.4 tons | 1 m³ / 2 tons | 1.5 m³ / 3 tons | 2 m³ / 3 tons | 1.5 m³ / 3 tons (Dual Tank) |

| Production Time Per Batch | 10-15 min/batch | 10-15 min/batch | 10-15 min/batch | 10-15 min/batch | 10-15 min/batch | 10-15 min/batch | 10-15 min/batch (Dual Tank) |

| Production Capacity (T/h) | 2-3 T/h | 4-6 T/h | 5.6-8.4 T/h | 8-12 T/h | 12-15 T/h | 15-18 T/h | 18-20 T/h |

| Applications | Small road repairs, manhole repairs | Road repairs, courtyard paving | Road repairs, courtyard paving | Road repairs, courtyard paving | Road repairs, courtyard paving | Road repairs, courtyard paving | Road repairs, courtyard paving |

| Inverter | 380V-24V | 380V-24V | 380V-24V | 380V-24V | 380V-24V | 380V-24V | 380V-24V |

| Hot Melt Kettle Capacity | 200L | 400L | 400L | 500L | 500L | 500L | 500L |

| Vibration System / Air Pump (Slag Removal Device) | / | 0.1/8 type air pump (0.1 m³ flow) | 0.1/8 type air pump (0.1 m³ flow) | 0.1/8 type air pump (0.1 m³ flow) | 0.1/8 type air pump (0.1 m³ flow) | 0.1/8 type air pump (0.1 m³ flow) | 0.1/8 type air pump (0.1 m³ flow) |

| Material Ratio | 3%-5% oil-stone ratio (new material) | 3%-5% oil-stone ratio (new material) | 3%-5% oil-stone ratio (new material) | 3%-5% oil-stone ratio (new material) | 3%-5% oil-stone ratio (new material) | 3%-5% oil-stone ratio (new material) | 3%-5% oil-stone ratio (new material) |

| Automatic Loading Hopper | / | Hoist Bottom Discharge | Hoist Bottom Discharge | Hoist Bottom Discharge | Hoist Bottom Discharge | Hoist Bottom Discharge | / |

| Weight (Tons) | 1.8 T | 3.8 T | 4.2 T | 4.8 T | 5.6 T | 5.6 T | 6.5 T |

| Starting Method | Electric Control | Electric Control / Electric Start | Electric Control / Electric Start | Electric Control / Electric Start | Electric Control / Electric Start | Electric Control / Electric Start | Electric Control / Electric Start |

| Dimensions (LWH, mm) | 5200*1600*2000 | 5200*1600*2000 | 6000*2000*2750 | 6200*2300*2950 | 6600*2300*2950 | 6900*2300*3250 | 6600*3300*2950 |

| Material | Double-layer manganese plate (single layer thickness 5.75mm), rock wool insulation layer 5cm*6 | Double-layer manganese plate (single layer thickness 5.75mm), rock wool insulation layer 5cm*6 | Double-layer manganese plate (single layer thickness 5.75mm), rock wool insulation layer 5cm*6 | Double-layer manganese plate (single layer thickness 5.75mm), rock wool insulation layer 5cm*6 | Double-layer manganese plate (single layer thickness 5.75mm), rock wool insulation layer 5cm*6 | Double-layer manganese plate (single layer thickness 5.75mm), rock wool insulation layer 5cm*6 | Double-layer manganese plate (single layer thickness 5.75mm), rock wool insulation layer 5cm*6 |

What Is the Price of Asphalt Plant in Nigeria?

How much is asphalt plant in Nigeria? The price of an asphalt plant in Nigeria can vary widely based on factors such as the type of asphalt plant, its capacity, brand, configuration, and additional features. In Nigeria, the asphalt plant price range is approximately $50,000 to $1,220,000. Below is a detailed price list of asphalt mixing plant in Nigeria to help you better make a decision.

After reviewing asphalt plant prices in Nigeria, see how our machines perform on real projects from busy highways in Europe to rural roads in Asia. Explore these global cases to see how similar asphalt mixing solutions could work for your Nigerian projects.

See Our Asphalt Plants in Action Around the World

Every road project has its own challenges—tight schedules, rough terrain, and quality demands. Our asphalt plants have tackled these conditions in various countries, delivering smooth mixes, fast setup, and reliable performance. Browse these projects to see how the right asphalt plant makes construction easier, even on challenging sites like those across Nigeria.

Batch Type Asphalt Plant in Malaysia

- Capacity: 120 TPH

- Model: ALQ-120

- Mobility: Stationary Type

- Application Scenario: Urban Road Construction and Maintenance

- Customer Review: “During a highway project in Johor, we needed reliable asphalt fast. Traditional asphalt plants would have delayed us. Using the 120 TPH asphalt batch plant from AIMIX, we started asphalt production at right. The project stayed on schedule, costs were controlled, and the client was very satisfied.”

Batch Type Asphalt Plant in the Philippines

Batch Type Asphalt Plant in Indonesia

Drum Mix Asphalt Plant in Guatemala

Drum Mix Asphalt Plant in Ecuador

After seeing how our asphalt plants perform across the world, the next question is simple: what impact can owning an asphalt plant create in Nigeria? Let’s dive into why it matters for fast-growing cities, highway upgrades, and community roadworks across the coun

Why Asphalt Plants Matter in Nigeria

Facing Road Construction Challenges Across Nigeria? From urban highways to rural villages, contractors often struggle with delays, high costs, and limited asphalt supply. With a vast network of nearly 195,000 km, much of it still unpaved, efficient and reliable asphalt production has never been more critical. Read on to learn why asphalt plants are essential in Nigeria and how they can transform your road projects.

High Road Demand – Most Roads Remain Unpaved

Nigeria has a road network of approximately 195,000 km, but only around 60,000 km are paved with asphalt. That means nearly 70% of roads are unpaved or consist of gravel and earth surfaces. For construction, maintenance, and upgrading, reliable asphalt supply and stable production capacity are essential.

Critical for Transportation & Economy

Over 90% of passenger and freight transport in Nigeria relies on roads. Poor road conditions increase transport costs, delay deliveries, and damage goods, affecting commerce, agriculture, and logistics.

Speed & Flexibility – Quick Maintenance & Repair

With a high volume of roads requiring repair, rural access, and urban maintenance, traditional construction methods are slow and inefficient. High-capacity, fast-deploying asphalt plants allow contractors to respond quickly, reduce construction time, and maintain continuity in projects.

Cost-Efficient Asphalt Road Building Solution

Asphalt paving generally has lower initial costs and faster application compared to concrete roads. For dispersed, budget-limited projects across Nigeria, asphalt plants provide efficient, cost-effective solutions for both urban and rural road projects.

Support Rural Access & Economic Growth

Many rural and remote areas still lack paved roads, limiting access to schools, hospitals, markets, and economic opportunities. Asphalt plant Nigeria can accelerate road construction and rehabilitation, improving mobility, connecting communities, and boosting local economies.

Enable Large-Scale Infrastructure Projects

Nigeria continues to require extensive road upgrades and new durable surfaces. Asphalt mixing plant Nigeria can allow simultaneous production and paving across multiple regions, supporting nationwide infrastructure development and modern road network expansion.

Understanding the importance of asphalt plant for sale in Nigeria is just step one. The key is finding a solution that keeps production running smoothly despite heat, rain, and remote sites. See why choosing a locally adapted asphalt mixing plant in Nigeria can save time, cut costs, and ensure superior road quality.

Why Localized Adaptation Matters for Asphalt Plants in Nigeria?

Have you ever noticed that asphalt plant performing well globally still struggles on Nigerian construction sites? Local factors—climate, transport, materials, energy, regulations, and construction practices—can greatly affect asphalt plant efficiency and paving quality. Choosing an asphalt plant truly adapted to Nigerian conditions impacts not just productivity, but also project cost, quality, and schedule. The following seven dimensions highlight why localized adaptation is crucial:

Climate Adaptability: Stable Production in Hot and Rainy Conditions

- Nigeria’s Climate: Tropical, with average annual temperatures of 30–40°C, rainy season rainfall 200–300 mm/month, and humidity over 80%.

- Construction Challenges: High temperatures soften asphalt, increasing flow; wet aggregates dry slowly, reducing mix uniformity. Rainy season may introduce mud and water into bins, delaying production.

- Localized Solutions: ALQ/ALYQ/ALYT series asphalt plant for sale in Nigeria features high-efficiency burners, smart temperature control maintaining 140–180°C during drying and mixing, multi-layer dust and water protection, and automated inspection with fault prediction.

- Impact: Rainy-season efficiency increases ~40%, mix uniformity improves to ±0.5%, annual continuous production reaches ~320 days, saving ~USD 50,000 in climate-related costs, reducing rework by 15–20%, and improving road durability.

Transportation & Logistics: Reducing Waste and Cost from Long Haul

- Geography: Construction sites are widely distributed, especially along Lagos–Ibadan, Abuja–Kaduna, and rural networks. Urban roads are dense, rural roads often unpaved or uneven.

- Challenges: Stationary asphalt mixing plants shipped from ports to remote sites take 7–10+ days; asphalt cools and separates, causing 10–15% waste; transport costs account for 20–30% of total project expenses.(Independent Newspaper)

- Localized Solutions: Modular or mobile ALYQ/ALYT asphalt plant for sale in Nigeria allows fast assembly and production within 24 hours, producing asphalt on-site and reducing transport distances by 50–70%.

- Impact: Daily transport cost savings USD 500–1,000, extra daily output 50–100 tons, project schedule advanced 5–10 days, particularly beneficial for remote or rural sites.

Terrain Adaptability: Flexible Deployment in Complex Environments

- Terrain: Nigeria features coastal wetlands and marshes in the south, hills and semi-deserts in the north; road construction often crosses rivers, wetlands, or hilly terrain. Fixed plants require leveled sites and foundations.

- Challenges: Traditional asphalt mixing plants cannot be quickly installed on rugged sites; rivers and valleys require extra lifting or support, increasing labor and equipment costs.

- Localized Solutions: Mobile ALYQ modular Nigeria asphalt plants can start production within 24 hours, allow quick disassembly, and flexibly deploy across hills and rivers; capacity can be adjusted according to project scale.

- Impact: Preparation time reduced 70%, emergency road repair completed in 48 hours; mechanical handling and installation costs saved USD 10,000–15,000.

Power & Energy: Solving Unstable Grid Problems in Remote Areas

- Power Situation: Nigeria’s grid is unstable; remote areas face frequent outages averaging 120+ hours annually; some villages lack reliable electricity.

- Challenges: Stationary asphalt batch mix plant Nigeria depends on stable grid power; outages interrupt production, extend project schedules, increase mix waste, and raise maintenance costs.

- Localized Solutions: Dual-fuel systems (diesel + coal) ensure continuous energy supply; smart remote monitoring provides alerts and maintenance reminders; automatic fuel switching or diesel generator backup ensures uninterrupted production.

- Impact: Continuous 24-hour operation in remote areas, near-zero downtime; energy cost reduced 15–20%; production capacity increased 30%; outages no longer delay projects by 7–10 days, saving USD 20,000–30,000 per project.

Raw Material Adaptability: Efficient Handling of Diverse Aggregates

- Material Conditions: Aggregate types vary widely—high-moisture sands in southern coasts, hard gravel in the north, uneven sizes in certain regions.

- Challenges: Stationary asphalt plants perform poorly with high-moisture or uneven aggregates, reducing output 15–25% and causing inconsistent quality.

- Localized Solutions: Our asphalt plant for sale in Nigeria has wear-resistant blades and liners last 5 years; high-precision weighing (±0.5% aggregates, ±0.25% powder/asphalt); smart drying and mixing automatically compensate for moisture.

- Impact: Asphalt mix uniformity improves 20–30%; pavement durability improves 20–30%; rework rate falls below 5%, ensuring stable quality and extended road lifespan.

Environmental & Safety Compliance: Meeting Urban and Rural Standards in Nigeria

- Current Situation: Dust, emissions, and noise are major concerns; some regions enforce strict local standards.

- Challenges: Excessive dust, smoke, or noise can halt construction, delay projects, and strain community relations.

- Localized Solutions: Our asphalt plant for sale in Nigeria has Gravity + bag + water spray dust control; low-noise fans reduce sound by 20–30 dB; fully compliant with Nigerian environmental standards.

- Impact: Dust emissions cut 90%, exhaust emissions 30–40%; compliant operations reduce fines, improve corporate image, and maintain good community relations.

Versatile Applications: Urban, Rural, and Special Project Readiness

- Road Network: Nigeria has 200,000+ km of roads; 15% urban, 85% rural, often complex terrain with gravel surfaces; bridges, ports, airports, and industrial parks require diverse construction capabilities.

- Challenges: Single-type asphalt plants struggle to meet high-output urban roads, low-capacity rural roads, and special projects simultaneously, leading to inefficiency, high transport costs, and extended timelines.

- Localized Solutions: ALQ/ALYQ/ALT/ALYT/ALB Series Modular hot mix asphalt plants adjust capacity flexibly; support fixed, mobile, or semi-mobile modes.

- Impact: Average output increases 15–25%, project duration reduced 10–20%, improving overall profitability, especially in remote or multi-site projects.

Understanding why localized adaptation is crucial for asphalt plants in Nigeria helps you see how the right equipment can save time, cut costs, and ensure quality on every project. Curious to see how these solutions perform in real installations around the world? Explore more pictures of asphalt plant setups in other countries below.

See More Pictures of Asphalt Plant Installation in Other Countries

Aside from our asphalt mixing plant installed in Nigeria, we have also completed numerous stationary or portable asphalt plant installed in various other countries, demonstrating our global reach and expertise. Here are some asphalt plant pictures in the following.

How We Ensure Your Asphalt Plant Runs Smoothly

As a trusted asphalt plant manufacturer, we have a proven track record of delivering reliable solutions worldwide among the list of Nigeria asphalt plant companies. Here’s how we make sure your asphalt plant operates efficiently from day one:

Global Expertise: Over 2,000 successful projects across diverse environments ensure we understand local challenges and best practices.

Wide Reach: Our products and services cover 150+ sales regions and countries, so wherever your project is, we’re close by.

Benchmark Facilities: 50+ benchmark sites demonstrate equipment performance under real conditions, giving you confidence in what you buy.

Spare Parts Availability: 50+ accessories outlets worldwide ensure rapid delivery of replacement parts, minimizing downtime.

On-Site Support: 30+ overseas engineers provide installation guidance, commissioning, and ongoing technical assistance.

Ready to Start Your Asphalt Project in Nigeria?

Don’t let delays, high costs, or unpredictable site conditions slow you down. Choose a turnkey asphalt plant for sale in Nigeria built for reliability, efficiency, and adaptability — backed by global experience and local support. Get in touch today to request a quote and let our experts help you find the perfect solution for your project. Your smooth, high-quality asphalt production starts here!