Operating an asphalt plant for the first time can be daunting. Our client in Ulaanbaatar, Mongolia faced tight deadlines and no prior experience. They needed to complete a road project before the cold season. With our ALQ80 stationary batch type asphalt plant, they quickly installed, commissioned, and started production, achieving high efficiency and quality from day one.

Understanding the Customer’s Goal and Challenges

- Our client aimed to complete a high-quality road paving project in a short timeframe.

- Their biggest challenge was lack of experience in handling a stationary asphalt plant.

- They were unsure how to install, calibrate, and operate the equipment efficiently.

- Additionally, the cold weather in Ulaanbaatar posed a tight deadline for the installation.

- Missing the optimal working period could significantly affect the project’s quality and timeline.

It was clear that achieving high productivity while avoiding operational mistakes required expert guidance and reliable equipment. The client needed not just a machine, but a full solution that could help them start from scratch and still reach professional standards.

How We Helped Overcome Barriers for the Customer in Mongolia

To address these challenges, AIMIX provided hands-on support and a turnkey solution. We specialize in guiding customers with little to no prior asphalt plant experience. Our team provided hands-on support throughout the entire process, from shipment, installation, and commissioning, to training operators and optimizing production.

Introducing the ALQ80 Stationary Batch Type Asphalt Plant

The ALQ80 stationary type asphalt batch plant was selected for its robust capacity and advanced features:

| Model | ALQ80 |

|---|---|

| Capacity | 80 t/h |

| Cold Aggregate Hoppers | 4×7.5m³ |

| Dryer Size | φ1.5m×6.7m |

| Fuel consumption | 120-600kg / h |

| Vibrating Screen (Layer) | 4 layers |

| Mixer Capacity | 1000kg |

| Cycle Time | 45s |

| Filter Area | 420m² |

| Asphalt Temperature | 140-180 ℃ |

| Total Power | 300kw |

With our integrated intelligent control system and automated production workflow, operators could manage multiple processes with ease. Even customers without prior experience found it intuitive and efficient.

Actions Taken for Efficient Project Completion

To meet the tight timeline, we implemented a structured action plan:

Pre-installation Consultation

Reviewing site conditions, power supply, and road paving requirements.

Professional Installation

Ensuring asphalt mixing equipment was fully operational by late September 2025.

Operator Training

Hands-on instruction on intelligent control systems, IOT monitoring, and automated production processes.

Production Optimization

Fine-tuning aggregate ratios, asphalt temperature, and cycle times for maximum efficiency.

Remote Monitoring

Utilizing our IOT systems for predictive maintenance and real-time operational guidance.

By introducing these systems, the client overcame the barrier of inexperience. Moreover, our installation team ensured that the asphalt plant was fully operational well ahead of the cold season. The cold aggregate hoppers, dryer, and mixer were set up and tested by late September 2025, leaving enough time for full-scale production.

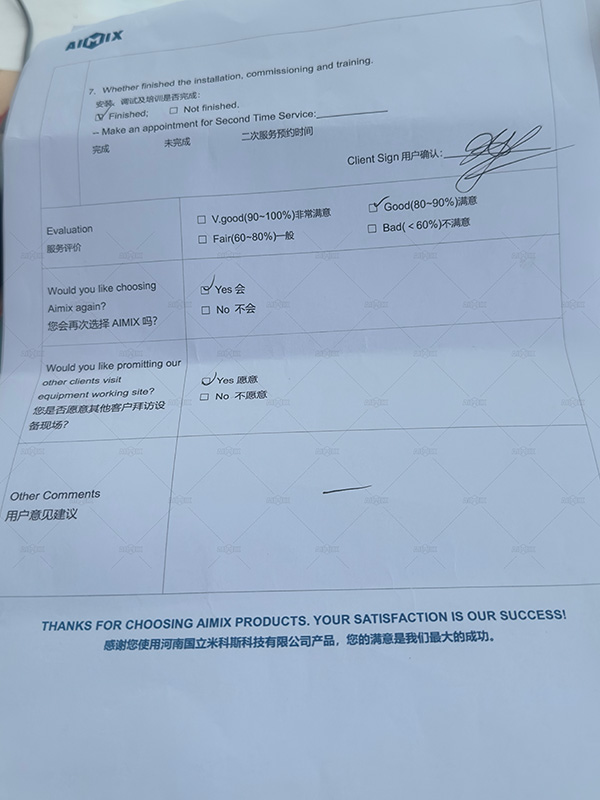

Project Results and Client Success

The ALQ80 asphalt batch mix plant delivered exceptional performance. Despite the client’s initial lack of experience, they successfully completed the road paving project before Mongolia’s cold season. Key results included:

- High production efficiency: The asphalt batching plant operated at enough capacity, meeting project deadlines.

- Excellent quality control: High-precision weighing ensured consistent asphalt mixtures, keeping errors within ±0.25% for asphalt and ±0.5% for aggregates.

- Reduced downtime: Enlarged cold aggregate hoppers minimized material shortage waiting times, improving overall efficiency.

- Reliability: Upgraded wear-resistant components and predictive maintenance minimized operational risks.

- Customer satisfaction: The client praised our comprehensive support, stating that the plant exceeded expectations and enabled rapid project completion.

Why the ALQ80 Stationary Asphalt Plant Stands Out

The ALQ80 stationary asphalt mixing plant offers unique features that make it ideal for contractors facing tight deadlines and challenging environments:

Integrated Intelligent Control: One-click start/stop simplifies operation and minimizes mistakes.

Flexible Operation Modes: Combines computer, touchscreen, and manual control to suit any operator.

IoT Remote Monitoring: Real-time updates on equipment status and maintenance reminders.

High Precision Weighing: Ensures accurate mix quality with minimal deviation.

Durable Components: Upgraded mixer blades and heated aggregate bins for longevity and high output.

Quick Installation: Modular design and adjustable piping speed up setup efficiently.

Thanks to these features, the ALQ80 batch asphalt plant not only meets production goals but also provides peace of mind for operators, even those without prior experience.

Why Choose Us for Asphalt Projects

We are not just an asphalt plant supplier, and we can provide full project support, especially for clients with no prior asphalt plant experience. Our ALQ80 Stationary Batch Type Asphalt Plant combines high efficiency, intelligent controls, and robust reliability to ensure every road project succeeds.

With us, clients gain:

- Expert guidance from planning to production

- Advanced, automated asphalt mixing technology

- High-precision material weighing and quality control

- Remote monitoring and predictive maintenance for ongoing reliability

- Fast installation and commissioning to meet tight deadlines

Achieve Road Construction Success with Us

Whether you are new to asphalt plant operations or an experienced contractor, we provides the tools, expertise, and support you need. The ALQ80 batch type hot mix plant in Ulaanbaatar is a clear example of how strategic planning, smart technology, and reliable guidance can overcome any challenge and achieve rapid, high-quality results.

Ready to take your road construction projects to the next level? Contact us today to explore how our asphalt plants can help you achieve timely, high-quality results, even if you are starting from scratch.