Are you having a hard time choosing what kind of crushing plant to better process limestone? In fact, according to the efficacy of the combination of crushing plant, you have many options. Today I would like to recommend you a set of mobile tire crushing plant, equipped with impact crushing plant. This is a set of programs we have done for our customers before, and now we share it with you, hoping that it will be helpful to you!

First of all, let’s take a look at what equipment is included in this program to jointly complete the work of crushing limestone!

What equipment is equipped with this impact mobile crushing plant?

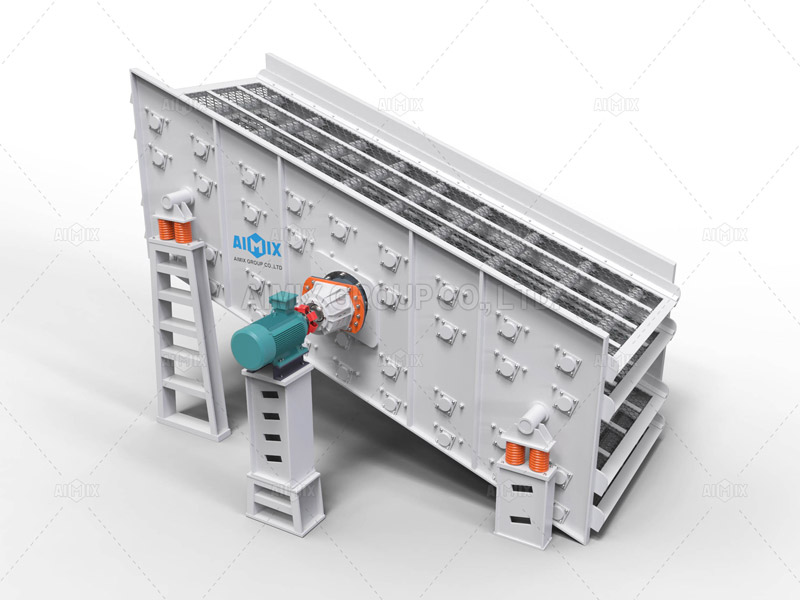

The APY3-1210 mobile impact crushing plant features an APG-3896W vibrating feeder, an APF-1210H crusher impact, and an APS-1848Y4 vibrating screen.

In addition, this mobile crushing production line is equipped with five belt conveyors as seen in the 3D workflow below.

What requirements can this solution meet?

- Processing materials: mainly limestone, with some broken stones and pebbles mixed in

- Production capacity: 70-100tph

- Maximum feeding size: 180mm

- Finished particle size: 0-5-13-19-25mm

why choose this configuration?

Good particle size: The European hydraulic impact crusher has a unique crushing cavity design. It can effectively crush the materials into the required particle size and improve the quality of the finished products.

Flexible movement: The equipment is mobile and can be flexibly moved according to production needs, which greatly reduces the transportation cost of the crushed materials and improves production efficiency.

Low maintenance cost: This mobile crushing plant is equipped with advanced hydraulic technology, which can effectively reduce maintenance costs and improve the service life of the crusher plant mobile.

How This Mobile Crusher Plant Works?

- Raw material feeding: The raw materials, which are quarry crushed materials with a size of 180mm and below, are fed into the vibrating feeder through the wheel loader equipment.

- Crushing: The vibrating feeder feeds the raw materials into the European hydraulic impact crusher, which crushes the materials into the required size range of 0-1/4”-1/2”-3/4”-1’.

- Screening: The crushed materials are then sent to the vibrating screen, which screens out the materials with the required particle size and separates them into four different sizes.

- Conveying: The finished products are then transported to the storage yard or directly loaded onto trucks for transportation.

Besides, because the tire-mounted mobile crusher plant is flexible in configuration, our professional technicians can design unique solutions for your own needs. Now send me a message if you are interested.