Concrete batching plant Singapore empowers the construction industry with unparalleled precision and efficiency. With strict regulations and limited space, choosing the right batching plant is crucial. Aimix offers smart, space-saving, and eco-friendly solutions tailored to Singapore’s needs, ensuring seamless operations for residential, commercial, and infrastructure projects.

Singapore’s Construction Demand for Batching Plants

Changi Airport Terminal 5A $10 billion mega-project requiring millions of cubic meters of precision-mixed concrete.

HDB HousingOver 100,000 new flats planned by 2030, emphasizing fast, eco-friendly construction.

MRT ExpansionsNew lines like the Cross Island MRT demand durable materials for underground tunnels.

Singapore’s construction pipeline is packed with the above landmark projects. Sustainability is no longer optional. The Building and Construction Authority (BCA) mandates Green Mark certifications, pushing contractors to adopt low-carbon materials and energy-efficient practices.

Key Requirements for Concrete Batching Plant Singapore

Regulatory Compliance

Singapore’s strict regulations ensure environmental and structural safety:

NEA Guidelines:

Noise levels below 65 dB during daytime.

Dust emissions controlled via enclosed systems.

Waste recycling protocols for excess concrete.

BCA Standards:

Mandatory use of certified materials (e.g., SS EN 206 for concrete strength).

Regular audits for batch plant calibration and mix consistency.

Technical Specifications

Automation & IoT:

Real-time monitoring of water-cement ratios and mix consistency.

Predictive maintenance alerts to minimize downtime of the batching plant in Singapore.

Weather Resistance:

Stainless steel components to combat humidity and corrosion.

Sealed control panels for rain protection.

Modular Designs:

Plug-and-play setups for fast concrete plant deployment in tight urban sites.

Scalability to upgrade capacity as projects expand.

Operational Efficiency

- Low Downtime: Dual mixer systems ensure continuous production during maintenance.

- Local Supplier Integration: Compatibility with Singapore’s ready-mix sand and aggregates.

Types of Batching Plant Suited for Singapore

As an experienced and reputable concrete batching plant supplier, Aimix is professional in tailoring different plants to meet Singapore’s unique projects needs, and the batching plant types for the local market include: AJ stationary type, AJY mobile type, AJSY and AJZY compact type, and eco-friendly type.

AJ Stationary Concrete Batching Plant for Singapore

Best for: Large-scale, long-term projects like HDB housing estates or Changi Terminal 5.

Key Features:

- High Capacity: Outputs up to 240 m³/h or more (e.g., AJ-180 or AJ-240 stationary batching plant models) to meet massive concrete demands.

- Advanced Automation: Integrated IoT systems for real-time mix adjustments, reducing human error.

- Durability: Corrosion-resistant materials to withstand Singapore’s humid climate.

Reasons to choose:

Ideal for multi-year projects requiring consistent, high-volume output.

Complies with BCA’s strict quality standards through precision mixing.

AJY Mobile Concrete Plant for Singapore

Best for: Urgent repairs, small-scale projects, or sites with limited access (e.g., Marina Bay roadworks).

Key Features:

- Portability: Mounted on trailers for rapid deployment at site.

- Compact Footprint: Fits into tight urban spaces(e.g., our AJY35 mobile concrete plant requires approximately 25-30% less space compared to AJ35 plant).

- Flexible Output: Adjustable from 25–100 m³/h based on project needs.

Reasons to choose:

Minimizes disruption in high-traffic areas like Orchard Road.

Cost-effective for short-term projects like drain upgrades or MRT station repairs.

Compact Concrete Mixing Plants for Singapore

Best for: Urban redevelopments or infill projects (e.g., shophouse restorations in Joo Chiat).

Key Features:

- Space-Saving Design: Modular layouts for cramped sites.

- Quick Assembly: Pre-fabricated components reduce setup time.

Reasons to choose:

- Avoids costly land leases for large plants in prime districts.

- Supports niche projects like heritage building conservation with precise, small-batch mixes.

Eco-Friendly Batching Plant for Singapore

Best for: Green-certified projects (e.g., BCA Green Mark Platinum buildings).

Key Features:

- De-dusting for Feeding, weighing, discharging of powders.

- Enclosed storage and transportation of sand and gravel aggregates.

- Zero discharge – A complete sewage recycling and utilization.

- Disposal of waste sludge by concrete washing and gravel separation.

- Fully enclosed design greatly reduces operating noise.

Reasons to choose:

The eco-friendly batching plant meets carbon tax requirements and BCA’s sustainability benchmarks.

Concrete Plant Specifications

| Model | AJ-25 | AJ-35 | AJ-50 | AJ-75 | AJ-60 | AJ-90 | AJ-120 | AJ-180 |

|---|---|---|---|---|---|---|---|---|

| Theoretical Productivity (m³/h) | 25 | 35 | 50 | 75 | 60 | 90 | 120 | 180 |

| Mixer Model (Mixer Output L) | JS500 | JS750 | JS1000 | JS1500 | JS1000 | JS1500 | MAO3000/2000(SICOMA) | MAO4500/3000(SICOMA) |

| Mixer Power (kW) | 18.5 | 30 | 2×18.5 | 2×30 | 2×18.5 | 2×30 | 2×37 | 2×55 |

| Mixing Cycle Period (s) | 72 | 72 | 72 | 72 | 60 | 60 | 65 | 65 |

| Max.Aggregate Size (mm) | Φ60 | Φ60 | Φ60 | Φ80 | Φ60 | Φ80 | Φ80 | Φ80 |

| Standard Aggregate Bin Capacity (m³) | 3×3 | 3×5 | 3×8 | 3×12 | 4×7 | 4×15 | 4×15 | 4×20 |

| Kind of Aggregate | 2/3 | 2/3/4 | 3/4 | 3/4 | 4/5 | 4/5 | 4/5/6 | 4/5/6 |

| Max. Discharging Height (m) | 3.8 | 4.1 | 4.1 | 4.1 | 4.1 | 4.1 | 4.3 | 4.3 |

| Overall Weight (ton) | ≈15 | ≈18 | ≈23 | ≈30 | ≈40 | ≈68 | ≈93 | ≈101 |

| Installation Power (kW) | ≈65 | ≈75 | ≈100 | ≈140 | ≈110 | ≈160 | ≈220 | ≈290 |

| Model | AJY25 | AJY35 | AJY50 | AJY75 | AJY100 |

|---|---|---|---|---|---|

| Theoretical Productivity (m³/h) | 25 | 35 | 50 | 75 | 100 |

| Mixer Model (Mixer Output L) | JS500 | JS750 | JS1000 | JS1500 | JS2000 |

| Mixer Power (kW) | 18.5 | 30 | 2x18.5 | 2x30 | 2x37 |

| Mixing Cycle Period (s) | 72 | 72 | 72 | 72 | 72 |

| Max.Aggregate Size (mm) | Φ60 | Φ60 | Φ60 | Φ60 | Φ60 |

| Aggregate Bin Capacity (m³) | 4x4m³ | 4x4m³ | 4x5m³ | 4x6m³ | 4x8m³ |

| Powder Storage Silo (ton) | 1x50 | 1x100 | 1x100 | 2x100 | 3x100 |

| Max. Discharging Height (m) | 3.8 | 3.8 | 4.2 | 4.2 | 4.2 |

| Weighing Range & Accuracy of Aggregate (kg) | 2x900kg±2% | 2x900kg±2% | 2x1200kg±2% | 2x1800kg±2% | 2x2400kg±2% |

| Weighing Range & Accuracy of Cement (kg) | 350kg±1% | 500kg±1% | 600kg±1% | 1000kg±1% | 1200kg±1% |

| Weighing Range & Accuracy of Water (kg) | 200kg±1% | 200kg±1% | 350kg±1% | 450kg±1% | 550kg±1% |

| Weighing Range & Accuracy of Additive (kg) | 30kg±1% | 30kg±1% | 30kg±1% | 30kg±1% | 50kg±1% |

| Overall Weight (ton) | ≈15 | ≈20 | ≈25 | ≈31 | ≈37 |

| Installation Power (kW) | ≈65 | ≈75 | ≈90 | ≈125 | ≈180 |

| Model | AJ-180 | AJ-240 | AJ-270 | AJ-300 | |

|---|---|---|---|---|---|

| Theoretical productivity(m3/h) | 180 | 240 | 270 | 300 | |

| Mixer | JS3000 | JS4000 | JS4500 | JS5000 | |

| Power of mixing machine(kw) | 2×55kw | 2×75kw | 2×75kw | 2×90kw | |

| Aggregate maximum particle | 80 | 80 | 80 | 80 | |

| Feeding capacity(L) | 4500 | 6000 | 6750 | 7500 | |

| Discharge capacity(L) | 3000 | 4000 | 4500 | 5000 | |

| Aggregate bin capacity(m3)(optional) | steel storage | 4×25 | 4×25 | 4×30 | 4×30 |

| barn | 4×6 | 4×6 | 4×6 | 4×6 | |

| Aggregate batching capacity(L) | 4800 | 6400 | 7200 | 7200 | |

| Belt conveying capacity(t/h) | 900 | 1200 | 1200 | 1400 | |

| Screw conveying capacity(t/h) | 80 | 110 | 170 | 170 | |

| Discharge height(m) | 4.2 | 4.2 | 4.2 | 4.2 | |

| Installed capacity(kw) | 220 | 280 | 300 | 340 | |

| Weighing range | stone | (900-3600)±2% | (900-4800)±2% | (900-5000)±2% | (900-6000)±2% |

| sand | (900-3600)±2% | (900-4800)±2% | (900-5000)±2% | (900-6000)±2% | |

| cement | (300-1800)±1% | (400-2400)±1% | (400-2700)±1% | (400-3000)±1% | |

| fly ash | (200-600)±1% | (200-800)±1% | (200-1200)±1% | (200-1400)±1% | |

| water | (200-800)±1% | (200-1100)±1% | (200-1300)±1% | (300-1500)±1% | |

| additive | (15-70)±1% | (20-100)±1% | (20-110)±1% | (20-120)±1% | |

Aimix Concrete Mixing Plants for Diverse Applications

Aimix concrete batching plants are engineered to support various construction projects, ensuring clients achieve substantial business success. Whether you’re working on residential, commercial, or infrastructure projects, our batch plant solutions offer flexibility and reliability. Check some of our project cases to see how these plants have been successfully applied across diverse construction scenarios, helping you choose the best solution tailored to your specific project requirements.

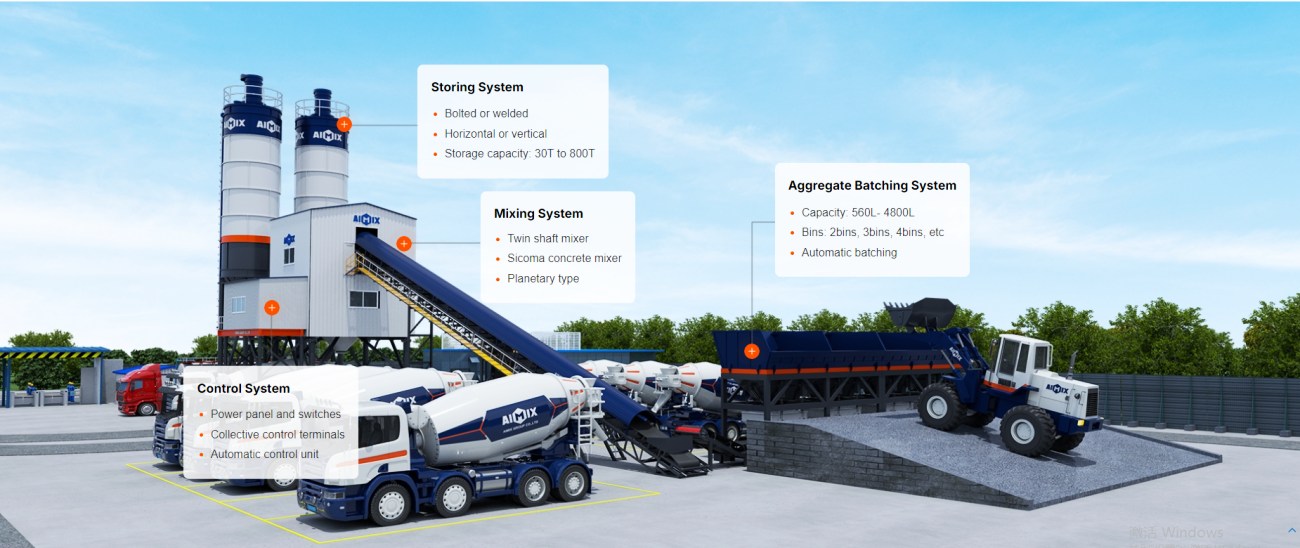

Critical Components and Benefits of Concrete Batch Plant

Concrete batching plant in Singapore integrates storage silos, precise weighing systems, conveyors, mixer, automated control system and other components. These components ensure accurate material measurement, consistent mixing, and efficient handling, vital for high-quality concrete production.

Automation minimizes human error and material waste, ensuring adherence to Singapore’s stringent quality and environmental regulations. This efficiency supports rapid, reliable output for infrastructure projects while aligning with sustainability goals.

Steps to Start a Concrete Plant Business in Singapore

Starting a concrete plant business in Singapore involves several critical steps that require careful planning, adherence to regulations, and a strategic approach to operations. Let’s take a look at the general guide now.

Conduct Market Research

Starting a concrete plant begins by analyzing the local construction market. Identify potential clients, study competitors, and understand the demand for ready-mix concrete. This research will help you determine the best location for your plant and the optimal production capacity.

Develop a Comprehensive Business Plan

Draft a detailed business plan that outlines your company’s objectives, production capacity, target market, financial projections, and operational strategy. A robust business plan is essential not only for guiding your operations but also for securing funding and attracting investors.

Secure Capital and Financing

Determine the initial investment required for batching plant setup, including land acquisition or lease, equipment purchase, and installation. Explore financing options such as bank loans, government grants, or partnerships to fund your venture.

Obtain Necessary Licenses and Permits

Navigating Singapore’s regulatory environment is crucial. Apply for the required permits from local authorities, such as environmental clearances, construction licenses, and business registration with the Accounting and Corporate Regulatory Authority (ACRA). Ensure that your plant complies with safety, emission, and zoning regulations.

Choose the Right Equipment and Technology

Invest in modern, efficient equipment like automated batching systems and eco-friendly machinery. Consider sustainable practices, including the use of recycled aggregates, to align with Singapore’s green construction initiatives.

Establish a Skilled Team and Operational Procedures

Hire experienced professionals for concrete mixing plant operations, quality control, and maintenance. Develop standardized operating procedures to ensure consistent concrete quality and optimal production efficiency.

Launch Marketing and Networking Efforts

Finally, promote your business by building relationships with construction firms and local developers. Utilize digital marketing strategies, attend industry events, and leverage government incentives to boost your market presence.

Analyzing the Cost Components of a Concrete Batching Plant

Initial Capital Costs

Investment begins with significant upfront expenses. This includes land acquisition, procurement of batch plant, and installation. Incorporating advanced automation technology and eco-friendly features (such as dust collectors and wastewater systems) further increases initial costs. Our batching plant price typically starts at $33000, and you can contact us for detailed price according to your specific requirements.

Operational Expenses

Ongoing costs encompass skilled labor wages, utility rates (energy consumption), and raw materials such as cement and aggregates. Routine maintenance is essential to ensure optimal performance and quality.

Regulatory Compliance

Meeting Singapore’s strict environmental and safety regulations may require additional investments in emission controls or noise reduction technologies. Licensing, permits, and insurance also add to recurring expenses.

Long-Term Considerations

Over time, costs may include equipment upgrades, repairs, replacement of wear-prone parts and others. However, automation helps reduce labor and material waste, and government incentives for sustainable practices can offset some costs, making it crucial to balance these factors for profitability.

Future Outlook for Concrete Batching Plants in Singapore

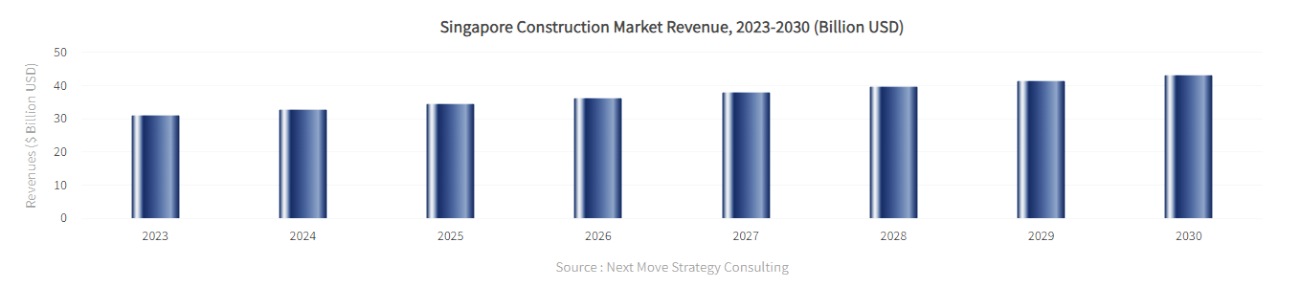

The Singapore Constrcution Market size was valued at USD 31.18 billion in 2023, and is predicted to reach USD 43.22 billion by 2030, at a CAGR of 4.2% from 2024 to 2030, according to the Next Move Strategy Consulting.

Emerging Trends in the Construction Industry

Singapore’s construction industry is constantly evolving, with emerging trends such as smart city initiatives, green building practices, and digital integration playing significant roles. These trends are driving the demand for innovative and efficient concrete production methods. As the city-state continues to push the boundaries of urban development, the role of concrete batching plant in Singapore is expected to grow in importance.

Technological Shifts and Innovation

Future technological advancements in concrete batch plant are likely to focus on even greater automation, enhanced digital integration, and improved sustainability features. Innovations such as artificial intelligence (AI) for predictive maintenance, blockchain for supply chain transparency, and further integration of IoT technologies will continue to transform the industry. These shifts are set to improve efficiency, reduce downtime, and further lower operational costs of the batch plant.

Policy and Regulatory Developments

Government policies in Singapore are increasingly favoring sustainable development and efficient resource use. As environmental standards become more stringent, the batching concrete plant market will need to adapt to these regulations by incorporating greener technologies and more energy-efficient operations. Future regulatory developments may also include incentives for adopting innovative technologies, further driving market growth.

Investment Opportunities and Market Expansion

The outlook for concrete batching plant in Singapore remains highly positive. As infrastructure projects continue to rise and the demand for high-quality concrete increases, there will be significant investment opportunities in upgrading or establishing new batching plants. Investors who prioritize technological advancements, sustainability, and operational efficiency will likely see substantial returns. Additionally, the trend towards modular and scalable plant designs means that even smaller players in the market can expand their operations as needed, creating a more dynamic and competitive market environment.

Looking to buy a batching plant or start a concrete plant business in Singapore? Aimix offers one-stop solutions designed for maximum efficiency and profitability. From expert guidance to high-performance equipment, we ensure seamless setup and long-term success. Partner with us today and take your business to the next level!