In the concrete industry, maintaining efficient and reliable batching plant operations is essential for consistent production and meeting project timelines. Traditional scheduled maintenance, while standard, can result in unnecessary downtime or missed maintenance needs, impacting both efficiency and costs.

The transition to smart monitoring and predictive maintenance marks a new era in lifecycle management. By leveraging real-time data and advanced analytics, plants can move from reactive or fixed-schedule maintenance to proactive, condition-based strategies—improving reliability, reducing costs, and extending equipment lifespan.

Understanding Equipment Lifecycle in a Batching Plant

The lifecycle of batching plant equipment consists of several key stages, each requiring focused management and careful monitoring. Each stage has specific management priorities and potential risks that can significantly impact overall performance and long-term cost efficiency.

Procurement

- Focus: Select equipment that precisely matches production capacity, system compatibility, energy efficiency, and local regulatory standards.

- Risks: Poor or inappropriate selection may lead to early mechanical failures, operational inefficiency, and substantially higher lifecycle costs.

Installation

- Focus: Ensure correct setup, precise alignment, and accurate calibration during commissioning to achieve optimal performance.

- Risks: Misalignment, improper configuration, or inadequate commissioning can compromise production quality and accelerate mechanical wear.

Operation

- Focus: Monitor daily usage, track load patterns, and check all performance parameters consistently for reliable operation.

- Risks: Overloading, improper use, or lack of continuous monitoring can significantly shorten batching plant lifespan and productivity.

Maintenance

- Focus: Conduct preventive and corrective servicing to maintain equipment reliability and reduce unexpected downtime.

- Risks: Traditional fixed-schedule maintenance may result in over-maintenance or unexpected breakdowns, causing increased downtime and higher operating costs.

Upgrade / Decommissioning

- Focus: Implement retrofitting, technology upgrades, or equipment replacement to maintain or improve productivity levels.

- Risks: Delayed upgrades or replacements may cause inefficiency, compatibility issues, and misalignment with new concrete production requirements.

Common Lifecycle Challenges

- Equipment aging and gradual wear affecting overall plant performance

- Unplanned downtime significantly disrupting production schedules and timelines

- Escalating maintenance and operational costs over the equipment’s life cycle

A structured understanding of each stage allows users to adopt proactive strategies, optimize performance, and extend equipment longevity.

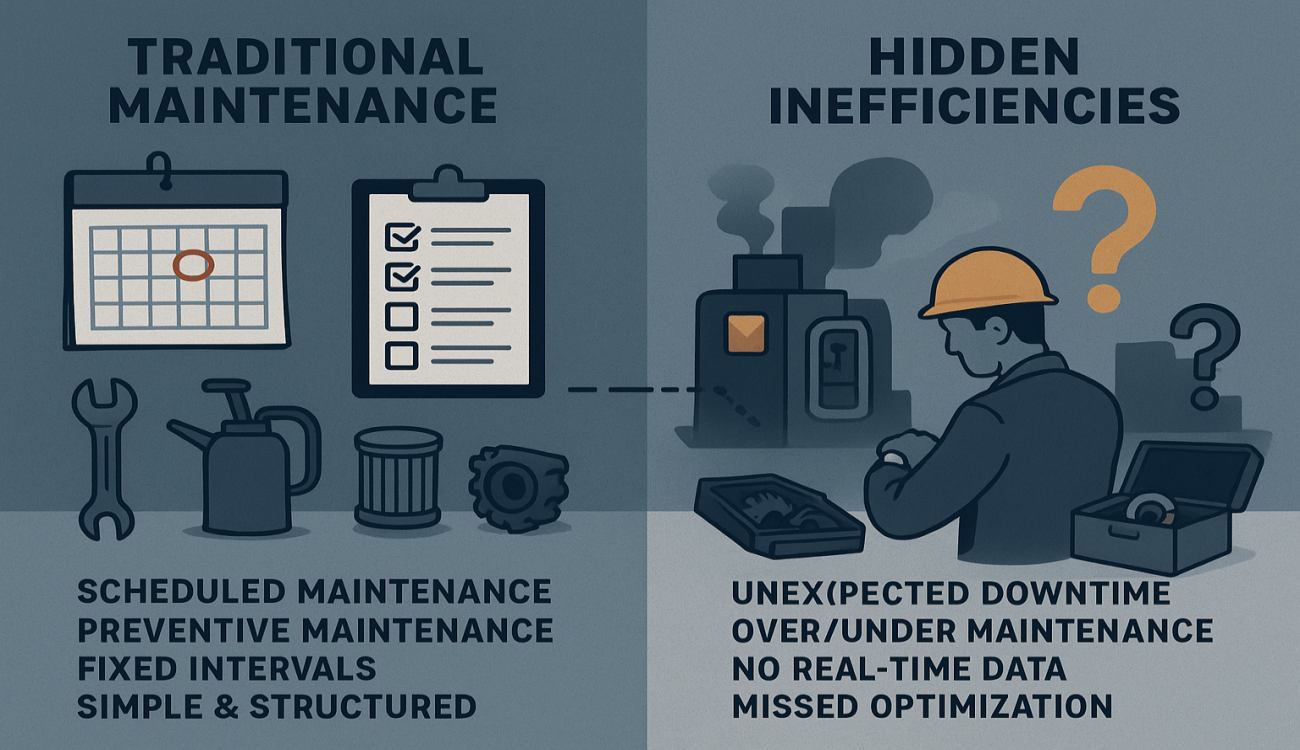

Traditional Maintenance Plans in Concrete Plants: Simple but Inefficient

Traditional maintenance plans have long been the standard approach in concrete plants, focusing primarily on scheduled maintenance and preventive maintenance.

Scheduled Maintenance

Scheduled maintenance involves performing maintenance tasks at fixed, predetermined intervals, regardless of the actual condition or performance of the equipment.

Typical examples include routine lubrication of moving parts, timely replacement of filters, and comprehensive system inspections conducted on a weekly, monthly, or annual basis to ensure basic operational reliability.

Preventive Maintenance

Preventive maintenance is based on manufacturer recommendations or historical operational data and is designed to minimize the likelihood of unexpected equipment failure.

Common tasks include periodic calibration of critical components, timely replacement of worn parts, and thorough visual inspections to identify early signs of wear or potential issues before they impact production.

Advantages

- Simple and straightforward to implement: The approach is easy to understand and follow, allowing operators to maintain consistent routines without complex procedures.

- Requires minimal technical expertise: Maintenance tasks can be performed even by staff with limited training, making it accessible across different skill levels.

- Provides a structured schedule for maintenance activities: Ensures equipment is serviced regularly, helping maintain reliability and reducing the risk of unexpected breakdowns.

Limitations

- Lack of real-time monitoring: Equipment may fail between scheduled maintenance cycles, leading to unexpected downtime.

- Over-maintenance or under-maintenance: Maintenance may be performed unnecessarily or insufficiently, wasting resources or increasing the risk of breakdowns.

- Limited efficiency improvement: Since maintenance is not based on actual equipment conditions, opportunities for optimizing production uptime and reducing costs are often missed.

Case Example

A medium-sized batching plant relying solely on scheduled maintenance experienced frequent unplanned downtime due to motor and mixer failures. Despite adhering to the maintenance schedule, operators found that some components were over-serviced while others failed prematurely, causing production delays and additional repair costs. This example illustrates the inherent inefficiencies of traditional maintenance approaches and underscores the need for more proactive, condition-based strategies.

Transitioning to Smart Monitoring: Unlocking Predictive Maintenance for Concrete Batching Plants

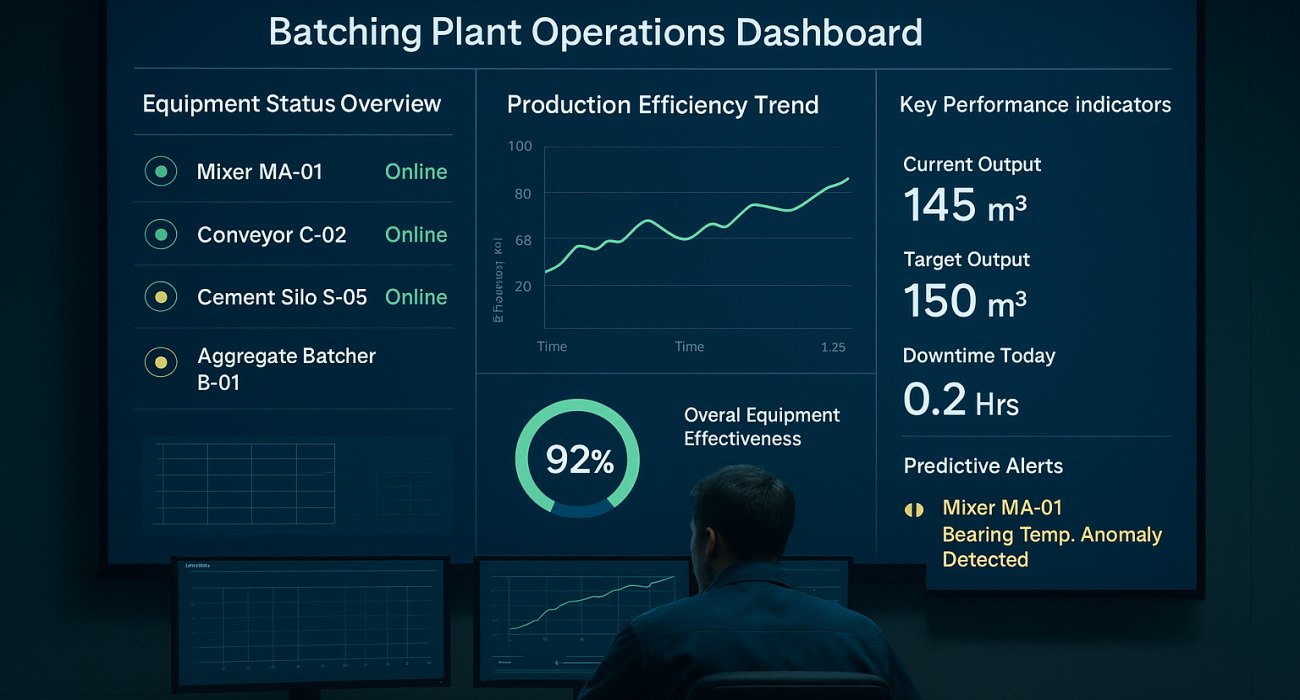

As concrete batching plants scale up and production demands grow, traditional maintenance methods often struggle to maintain continuous, efficient operation. Smart monitoring, also known as predictive maintenance, offers a transformative approach by leveraging real-time sensor data, advanced analytics, and automated alerts to proactively manage equipment health, reduce downtime, and optimize operational costs.

How Smart Monitoring Works

Smart monitoring continuously tracks critical equipment parameters to identify early signs of wear, predict potential failures, and optimize maintenance schedules. Unlike fixed-interval or preventive maintenance, this condition-based approach ensures interventions are performed only when necessary, avoiding unnecessary service while preventing unexpected breakdowns.

Core Technologies

- Sensor Monitoring: Modern batching plants are equipped with sensors that measure temperature, vibration, motor current, hydraulic pressure, and other essential parameters. These sensors provide real-time insights, allowing early detection of anomalies before they develop into severe equipment failures.

- Data Analytics Platforms: Collected data is processed using AI-powered analytics software, which identifies trends, patterns, and deviations. This enables accurate forecasting of component degradation, helping users schedule maintenance at the most effective time.

- Remote Control and Alert Systems: Smart monitoring systems allow operators to access equipment data remotely via dashboards or mobile devices. Instant alerts notify staff of potential issues, enabling rapid response and minimizing production interruptions.

Advantages Compared to Traditional Maintenance

- Reduced Unplanned Downtime: Early detection of faults keeps production processes running smoothly, minimizing interruptions and lost output.

- Optimized Operational Costs: Maintenance is performed only when required, reducing labor, parts, and energy expenses.

- Extended Equipment Lifespan: Timely intervention prevents severe wear and reduces the frequency of replacements.

- Data-Driven Decision Making: Historical and real-time insights support informed choices regarding upgrades, spare parts inventory, and production planning.

Case Example

Aimix stationary batching plant implemented an IoT-based remote monitoring system to track critical equipment in real time. Parameters such as motor temperature, vibration, and current are continuously monitored, with automatic alarms and diagnostic reports generated for anomalies. The system also provides predictive maintenance based on runtime and component wear data, reducing the risk of unexpected downtime. Since implementation, the plant’s failure rate dropped 40%, maintenance costs decreased 25%, and equipment lifespan increased over 15%, significantly improving reliability and operational efficiency.

Benefits of Smart Lifecycle Management

Implementing smart lifecycle management in concrete batching plants delivers strategic and operational advantages, transforming how users maintain, monitor, and optimize equipment.

Increased Equipment Utilization and Production Efficiency

By integrating real-time monitoring with predictive planning, plants can optimize production schedules and workflows. This ensures consistent output, higher utilization of machinery, and the ability to meet project deadlines without unnecessary interruptions.

Enhanced Resource Planning

Smart lifecycle management offers actionable insights for workforce allocation, maintenance scheduling, and spare parts inventory management. Plant managers can proactively plan resources, reducing overstocking, minimizing idle labor, and ensuring that critical components are available when needed.

Strategic Asset Management

Continuous monitoring and predictive analytics support long-term decision-making regarding equipment upgrades, retrofits, or replacements. This helps maximize the return on investment for critical assets while preventing premature capital expenditures.

Operational Predictability and Competitiveness

By combining data-driven insights with proactive maintenance strategies, plants can achieve more predictable operations, reduce unexpected disruptions, and strengthen their competitive position in the concrete industry.

Case Example

A batching plant in Southeast Asia implemented predictive monitoring on its AJ180 stationary batching plant. Within six months, equipment utilization increased by 20%, unplanned downtime decreased by 30%, and concrete production became more consistent. The system also improved maintenance planning, spare parts management, and workforce allocation, demonstrating how smart lifecycle management enhances both operational efficiency and strategic asset management.

Implementing Smart Monitoring: Step-by-Step Strategies for Batching Plants

After understanding the benefits of smart lifecycle management, batching plants can realize these advantages through a structured, phased implementation strategy. Proper planning ensures smooth deployment, measurable ROI, and sustained operational improvements.

Assess Current Equipment and Define Key Indicators

Evaluate the condition and performance of all critical equipment, including mixers, conveyors, pumps, and control systems. Identify key performance indicators (KPIs) such as vibration levels, motor current, temperature, and throughput efficiency to serve as benchmarks for monitoring and maintenance decisions.

Deploy Sensors and Monitoring Systems

Install IoT sensors on critical components to collect real-time operational data. Ensure seamless integration with existing plant control systems and reliable connectivity for continuous data flow.

Build Data Platforms and Train Personnel

Implement analytics platforms capable of processing large volumes of sensor data, generating alerts, and predicting maintenance needs. Train staff on system operation, data interpretation, and response protocols to maximize the effectiveness of smart monitoring.

Continuous Optimization and Feedback Loop

Regularly review performance metrics and refine predictive models to adjust maintenance schedules. Establish a feedback loop to learn from operational data, continuously improving monitoring accuracy and maintenance efficiency.

Collaborate with Vendors and Customize Solutions

Work closely with batching plant suppliers and technology partners to tailor monitoring systems to the plant’s specific needs, ensuring compatibility, long-term support, and adaptability to future production changes.

Cost and ROI Analysis

Analyze implementation costs alongside expected savings in maintenance, labor, and unplanned downtime. Track improvements in equipment utilization and production efficiency to measure ROI and demonstrate the value of a fully data-driven maintenance ecosystem.

By following these strategies, batching plants can maximize equipment reliability, reduce operational costs, and achieve measurable productivity gains, laying the foundation for a fully smart and proactive maintenance system.

Future-Ready and Sustainable Batching Plants

The concrete industry is evolving rapidly, and modern batching plants should adapt to stay competitive. Embracing smart lifecycle management allows plants to respond effectively to changing market demands, regulatory requirements, and sustainability goals, while ensuring reliable and efficient operations.

By adopting intelligent monitoring and predictive maintenance, batching plants can move from reactive practices to a proactive, strategic approach. This shift not only supports consistent, high-quality concrete production but also positions plants for long-term growth, operational resilience, and environmental responsibility.

Concrete batching plant professionals and stakeholders are encouraged to embrace digital tools, flexible solutions, and sustainable practices, ensuring their plants remain efficient today and future-ready for the challenges of a rapidly transforming industry.