Investing in a concrete batching plant requires a long-term perspective, as total ownership cost goes far beyond the initial purchase. Life Cycle Cost (LCC) management helps evaluate the full economic impact across CAPEX, OPEX, maintenance, downtime, environmental compliance, and decommissioning. This article outlines core LCC principles, compares plant types, highlights key cost drivers, and offers strategies to reduce overall lifecycle expenses.

Why LCC Management Matters in Concrete Plant Investment

The concrete industry faces rising project complexity, stricter quality requirements, and increasing cost pressure. Selecting batching plants solely on purchase price can lead to unexpected expenses in energy, maintenance, and downtime.

Life Cycle Cost (LCC) analysis allows concrete suppliers, EPC contractors, and project owners to understand total ownership costs, optimize operational efficiency, and improve long-term profitability and equipment availability.

What Makes Up the Life Cycle Cost (LCC) of a Concrete Batching Plant?

Initial Investment (CAPEX)

The initial capital expenditure covers all upfront investments needed to get the batching plant operational. Key components include:

- Equipment procurement: Mixers, aggregate batching systems, cement silos, weighing systems, control units, and supporting structures. High-quality equipment may cost 15–30% more initially but delivers superior reliability and reduced downtime over its lifespan.

- Transportation, installation, and commissioning: Delivering heavy machinery to the site, assembling, and testing requires specialized labor and equipment. For mobile plants, relocation capabilities can slightly increase initial cost but reduce future transport expenses.

- Civil works and site preparation: Ground leveling, foundation construction, and access roads. Depending on site conditions, civil works can account for 10–20% of CAPEX and are critical for long-term equipment stability.

- Environmental and safety compliance: Dust collection units, wastewater recycling systems, noise barriers, and safety enclosures may add to upfront cost but are essential for regulatory approval and sustainable operation.

Operating Costs (OPEX)

Operating costs are recurring expenses incurred during daily plant operation. They often constitute the largest portion of total LCC.

- Energy consumption: Mixers, conveyors, screw feeders, and air compressors consume significant electricity. Energy-efficient motors and variable frequency drives can reduce energy costs by 10–20%.

- Labor costs: Skilled operators, quality control staff, and maintenance teams are necessary for continuous, high-quality production. Labor costs vary by region but often represent 15–25% of OPEX.

- Raw material losses: Inaccurate batching, material spillage, or poor yard management leads to wasted cement, aggregates, and admixtures. Given that materials constitute 60-70% of production cost, even minor improvements here significantly impact profitability.

- Consumables and utilities: Lubricants, wear parts (liners, blades, belts), water, and plant utilities contribute to operational expenses and require proactive tracking to avoid cost overruns.

Maintenance and Repair Costs

Regular maintenance ensures plant longevity and consistent concrete quality:

- Scheduled maintenance: Routine inspections, lubrication, and minor replacements prevent sudden breakdowns. Effective maintenance can extend equipment life by 20–30% and is the most cost-effective way to manage assets.

- Major overhauls: Periodic replacement of mixer blades, bearings, and electronic control systems. Major overhauls can be planned to minimize downtime and typically occur every 5–7 years.

- Replacement planning: Understanding equipment depreciation cycles helps in budgeting for eventual replacements and technology upgrades.

Downtime Costs (The Hidden Profit Killer)

Downtime often represents the most overlooked component of LCC:

- Production interruptions: Equipment failure, power outages, or material shortages can halt production, delaying deliveries and increasing project risk.

- Wasted materials: Partially processed concrete, aggregates, or admixtures may be lost during unplanned stops.

- Contractual penalties and reputation damage: Inconsistent supply may trigger liquidated damages, client dissatisfaction, or loss of future contracts. Investing in reliability is essentially insurance against these hidden costs.

Environmental Costs

Modern plants face strict environmental regulations, requiring dedicated investment:

- Dust collection systems and filters: Essential for compliance with local air quality regulations, especially for urban plants.

- Wastewater treatment and recycling: Wet production or washout water must be treated to prevent soil and water contamination.

- Noise mitigation and certification: Barriers, silencers, and monitoring systems ensure compliance with occupational and municipal standards, protecting worker health and avoiding fines.

End-of-Life and Transition Costs

Even at the end of a plant’s service life, costs remain:

- Dismantling and disposal: Safely removing equipment and disposing of or recycling materials incurs labor and transport costs.

- Residual asset value: Well-maintained, brand-name equipment can be resold or repurposed, partially offsetting decommissioning costs.

- Relocation or upgrade investments: For mobile plants or those being upgraded for higher capacity, moving or retrofitting equipment adds additional capital expenditure.

LCC Differences Across Batching Plant Types

Understanding how Life Cycle Cost (LCC) varies between different types of batching plants is crucial for investors, operators, and project managers. Plant type, design, and automation level all influence both upfront investment and ongoing costs.

Stationary vs. Mobile Batching Plants

Stationary Batching Plants

- Higher initial cost due to permanent foundations, larger structures, and robust equipment.

- Typically more durable and stable, suitable for high-volume commercial concrete production.

- Lower maintenance frequency for core equipment due to stable installation and controlled environment.

Mobile Batching Plants

- Lower relocation and setup costs, modular design enables deployment across multiple short-term projects.

- May have slightly higher operating costs if frequently relocated or exposed to variable site conditions.

- Ideal for construction sites with intermittent demand or remote locations where building permanent infrastructure is impractical.

Dry vs. Wet Mix Plants

Dry Mix Plants

- Simple design, minimal moving parts, lower maintenance costs.

- Mixing occurs during transportation, which can reduce energy use at the plant but may compromise concrete uniformity.

- Often chosen for smaller projects or regions with limited labor availability.

Wet Mix Plants

- Concrete is mixed at the plant before discharge.

- Slightly higher operating costs due to additional mixers and water management.

- Provides more consistent concrete quality, reducing variability and potential rework.

High Automation vs. Basic Control Systems

Automated Concrete Plants

- Reduce labor requirements, improve batching accuracy, and minimize downtime.

- Smart data analytics enable predictive maintenance, energy optimization, and real-time production monitoring.

- Higher upfront investment but potential for lower LCC per cubic meter over the plant’s lifecycle.

Basic Control Systems

- Lower purchase cost, simpler operation.

- May increase labor and material waste due to less precise batching.

- Suitable for smaller-scale operations where automation ROI may be limited.

Key Factors That Influence Batching Plant LCC

The Life Cycle Cost of a concrete batching plant is not only determined by its type but also by specific operational and technical factors. Optimizing these factors can significantly reduce LCC and improve long-term profitability.

Durability of Mixer and Batching Components

- Mixer parts such as liners, arms, and shafts must withstand abrasion and high loads.

- Accurate and reliable aggregate and cement batching systems reduce waste and improve consistency.

- Investing in high-quality components increases upfront costs but reduces frequent replacements and downtime.

Batching Accuracy and Its Impact on Material Cost

- Even a 1% deviation in batching accuracy can translate into significant material loss over a year.

- Precision depends on load cells, sensors, calibration, and proper maintenance.

- High batching accuracy improves concrete quality and minimizes rework, positively impacting both operational efficiency and LCC.

Maintenance Practices

- Preventive maintenance: reduces unexpected failures, prolongs equipment lifespan, and maintains consistent production.

- Emergency repairs: costly both in downtime and replacement parts.

- Local service support and OEM availability are critical, especially for automated or high-capacity plants.

Energy Efficiency

- Energy consumption is a major OPEX driver, often accounting for 15–25% of operating costs.

- High-efficiency motors, sealed powder handling systems, and optimized air compressors can significantly reduce energy usage.

- Continuous monitoring and process optimization further enhance energy efficiency and reduce costs per cubic meter.

Production Intensity and Application Scenario

- Commercial Ready Mix Concrete Plants: operate continuously with high volume, benefiting from stationary, automated systems to maximize efficiency.

- Project-based or intermittent plants: may favor mobile or simpler designs to minimize idle capacity and relocation costs.

- Matching batching plant type to project requirements and production schedules is key to minimizing LCC.

How to Evaluate LCC: Practical Methods

Evaluating the Life Cycle Cost (LCC) of a concrete batching plant is crucial to make informed investment decisions. LCC provides a holistic view of all costs, helping investors, plant operators, and project managers plan for long-term efficiency and profitability.

Basic LCC Formula

A simple yet effective way to calculate LCC is:

LCC = CAPEX + OPEX + Maintenance Costs + Downtime Costs − Residual Value

- CAPEX: Equipment purchase, installation, civil works, and compliance costs.

- OPEX: Labor, energy, consumables, and material losses.

- Maintenance Costs: Preventive and corrective maintenance, component replacements.

- Downtime Costs: Lost production, delayed deliveries, and contractual penalties.

- Residual Value: Remaining value of the plant or components at the end of life.

This formula ensures all major cost drivers are accounted for in a transparent manner.

Comparative LCC Model for Batching Plants

Evaluating multiple plant options can highlight long-term cost advantages:

Low-cost plant:

- Lower CAPEX, but may incur higher energy consumption, frequent maintenance, and greater downtime.

- Potentially higher LCC per cubic meter over the plant’s lifecycle.

High-spec, energy-saving plant:

- Higher upfront investment, but features such as high-efficiency motors, automated batching, and durable mixers reduce OPEX, maintenance, and downtime.

- Often results in lower LCC per cubic meter despite higher CAPEX.

Choosing a plant solely on purchase price can be misleading. LCC analysis ensures a clear picture of total cost of ownership.

Digital Tools for LCC Monitoring

Modern batching plants increasingly rely on digital technologies to track and reduce LCC:

- Energy monitoring systems: Track real-time energy consumption of mixers, conveyors, and air compressors.

- Equipment health diagnostics: Sensors monitor wear, vibration, and motor loads to predict failures.

- Automated reporting and predictive maintenance: Software alerts operators before breakdowns occur, minimizing downtime and extending component lifespan.

These tools provide actionable data that directly supports cost-efficient operations and LCC reduction.

Strategies to Reduce the Life Cycle Cost of a Concrete Batch Plant

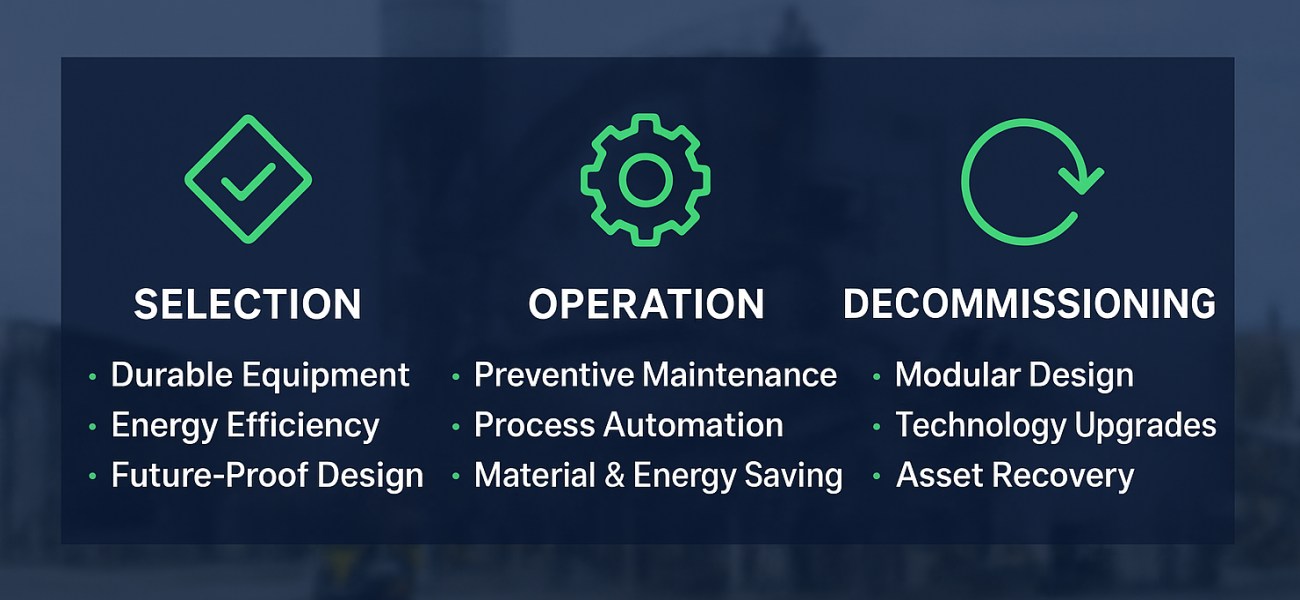

Reducing LCC requires a holistic approach throughout the plant’s lifecycle—from selection to operation, and eventually, decommissioning.

Reduce LCC During the Selection Phase

Investing wisely upfront is key:

- Prioritize durability: High-quality mixers, load cells, and conveyors reduce maintenance and replacement costs.

- Focus on energy efficiency: High-efficiency motors, variable frequency drives, and sealed powder handling systems reduce energy consumption by up to 20% or more, a major OPEX contributor.

- Supplier network: Choosing vendors with strong regional service coverage reduces downtime and spare parts delays.

- Future-proof design: Modular, upgradable control systems allow automation and capacity expansion without major reinvestment.

Reduce LCC During Operation

Efficient operational practices significantly impact OPEX:

- Preventive maintenance: Scheduled inspections, lubrication, and minor part replacements reduce emergency repairs. Industry experience shows preventive strategies can reduce downtime by 20–30%.

- Intelligent plant control: Automated batching improves mix accuracy, reducing material waste and improving consistency.

- Raw material yard optimization: Proper storage and handling minimize spillage, moisture-related losses, and batching errors.

- Minimizing idle operation and energy waste: Adjusting production schedules to actual demand and shutting down unused equipment reduces energy costs.

Reduce LCC During Replacement/Decommissioning

Planning for the plant’s end-of-life reduces residual costs:

- Modular and reusable designs: Enable plant relocation or redeployment without major disassembly costs.

- Upgradable control systems: Avoid full replacement of automation when technology improves.

- Asset recovery planning: Salvaging or selling components can offset decommissioning expenses, improving LCC balance.

The True Cost Lies Beyond the Sticker Price

The purchase price of a concrete batching plant reflects only part of its cost profile. LCC analysis highlights drivers such as energy use, maintenance, downtime, and component replacements that determine total ownership costs.

Companies that prioritize durable equipment, automation, energy efficiency, and proactive maintenance can reduce total cost per cubic meter, maintain consistent production quality, and gain a competitive edge in the market. In today’s concrete production industry, Life Cycle Cost will become the new standard for decision-making, guiding investors, EPC contractors, and plant owners toward smarter, long-term profitability rather than short-term savings.