Stationary Asphalt Batch Plant – Trusted by Global Fortune 500 Partners

High-Precision Weighing System – Asphalt mix quality you can trust: ±0.5% for aggregates, ±0.25% for bitumen

Built for Heavy-Duty Use – Wear-resistant parts & predictive maintenance for over 1 million tons of output

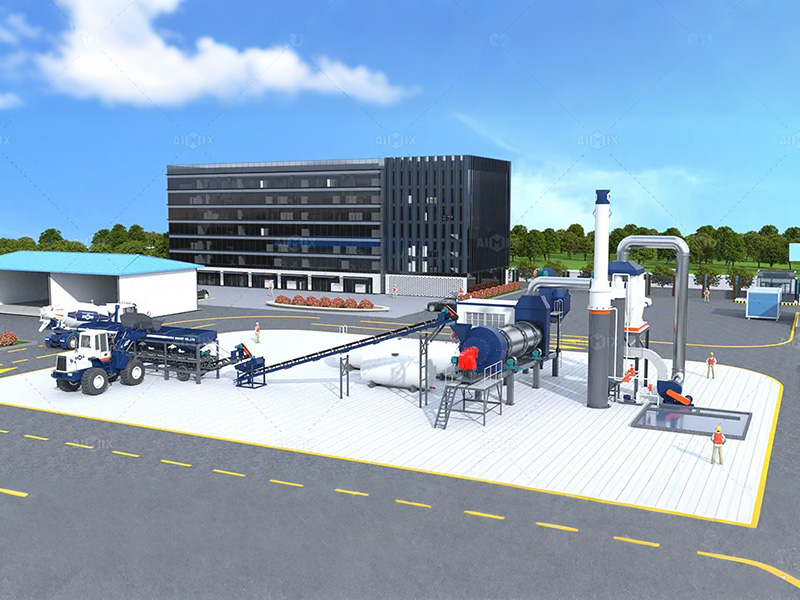

Stationary Asphalt Drum Mix Plant — Simple Setup. Stable Output. Solid Returns

Proven performance in rural highways, low-volume roads, and remote area infrastructure

Supporting sustainable road development from Southeast Asia to Africa and Latin America

Stationary asphalt plants are the go-to choice for contractors seeking reliable, high-volume asphalt production at fixed job sites. From national highways to regional road networks, they ensure consistent mix quality, stable output, and lower operational risks. Whether your project demands high-precision batching or simplified continuous mixing, our stationary asphalt mixing plants offer tailored solutions to match your goals, budget, and timeline.

How Our Asphalt Plants Help Contractors Get the Job Done

Our stationary asphalt plants are trusted by contractors all over the world to build strong, lasting roads. These global cases show how our ALQ and ALT series stationary asphalt mixing plants help solve real challenges — from meeting tight schedules to saving costs — so you can see the results for yourself and find the right asphalt mixing solution for your project.

Stationary Asphalt Batch Plant in Malaysia

Capacity: 120 tons/hour

Model: ALQ-120

Project Location: Malaysia

Project: Road Built and Construction

Application Scenario: Self-Use and Aggregate Selling

Customer Review: “After starting the use, the 120 ton asphalt batch plant runs smoothly with minimal maintenance. Its precise mixing and stable output have helped us deliver quality asphalt for both our own roads and local clients.”

Stationary Asphalt Batch Plant in Uzbekistan

Capacity: 120 tons/hour

Model: ALQ-120

Project Location: Uzbekistan

Project: Local Highway Construction

Application Scenario: Urban Road Construction and Maintenance

Customer Review: “The one-touch control system really saves us time, and the remote monitoring gave us peace of mind by catching issues early. The asphalt mix quality is stable, which is critical for our highway project.”

Stationary Asphalt Batch Plant in the Philippines

Capacity: 80 tons/hour

Model: ALQ-80

Project Location: Philippines

Project: Road Infrastructure Construction

Application Scenario: Maintenance of Urban and Rural Roads

Customer Review: “The ALQ-80 stationary asphalt batch plant’s easy control and precise mixing help us keep road repairs on schedule. Its durable build handles daily use without issues, making our job much smoother.”

Stationary Asphalt Batch Plant in Indonesia

Capacity: 80 tons/hour

Model: ALQ-80

Project Location: Indonesia

Project: Urban Road Construction

Application Scenario: Road Construction and Repairment

Customer Review: “The one-button start makes operating the stationary asphalt mix plant simple and efficient, saving us valuable time every day. With remote monitoring, we’re alerted early to any issues, helping us avoid costly downtime.”

Stationary Asphalt Drum Mix Plant in Guatemala

Capacity: 120 tons/hour

Model: ALT-120

Project Location: Guatemala

Project: Guatemala National Highway Project

Position: Guatemala City to Southern Ports

Customer Review: “Our team finds the ALT-120 easy to operate and highly reliable, which helps us stay on schedule for the national highway project. The efficient drum mixing ensures the asphalt quality remains consistent despite heavy daily use.”

Stationary Asphalt Batch Plant in Kazakhstan

Capacity: 80 tons/hour

Model: ALQ-80

Project Location: Kazakhstan

Project: Urban/Rural Road Construction

Application Scenario: Local Road Construction and Maintenance

Customer Review: “The ALT-120 stationary asphalt drum mix plant’s simple operation and reliable design have kept our national highway project on schedule. Its efficient drum mixing ensures consistent asphalt quality, even under heavy daily use.”

Get to Know the Two Types of Stationary Asphalt Plants: Batch & Drum Type

Stationary asphalt plants are mainly divided into two types: batch mix and drum mix. While both are designed for long-term asphalt production, they differ in structure, mixing method, and performance features. Below, we’ll walk you through the key parameters and core features of each type—so you can see which suits your construction needs best.

Stationary Batch Type – ALQ Series

Models: ALQ40ALQ60ALQ80ALQ100ALQ120ALQ160ALQ320

- Production Capacity: 40-400 t/h

- Mixing Cycle: 45s

- Asphalt Temperature: 140-180 ℃

- Dust filter: Gravity/Cyclone/Bag/Water dust filter

Stationary Asphalt Batch Plant Features

- High mixing accuracy for premium asphalt quality

- Automated control + one-button start = efficient operation

- Remote monitoring reduces downtime and improves reliability

- Ideal for large-scale, high-standard road projects

Stationary Drum Type – ALT Series

Models: ALT20ALT40ALT60ALT80ALT100ALT120

- Production Capacity: 20-100 t/h

- Asphalt Temperature: 120-180 ℃

- Finished Asphalt Storage Bin: 3-9 tons

- Dust filter: Bag/Water dust filter

Stationary Asphalt Drum Mix Plant Features

- Simple structure, low maintenance cost

- Efficient drying and stable continuous mixing

- Suitable for long-term use in flat, rural job sites

- Great for county roads, small-to-mid volume paving

Stationary Asphalt Plant Specifications

After learning about the two main types of stationary asphalt plants for sale, let’s take a look at their key technical details. This includes things like capacity, mixing style, fuel use, and control options — all important to help you understand what each type can do and which fits your project best.

ALQ Series Stationary Batch Asphalt Plants Specification

| Model | ALQ40 | ALQ60 | ALQ80 | ALQ100 | ALQ120 | ALQ160 | ALQ200 | ALQ240 | ALQ320 |

|---|---|---|---|---|---|---|---|---|---|

| Capacity | 40 t/h | 60 t/h | 80 t/h | 100 t/h | 120 t/h | 160 t/h | 200 t/h | 240 t/h | 320 t/h |

| Cold Aggregate Hoppers | 4×4.5m³ | 4×6.5m³ | 4×7.5m³ | 4×7.5m³ | 5×7.5m³ | 5×12m³ | 5×12m³ | 5×12m³ | 6×15m³ |

| Dryer Size | φ1.2m×5.2m | φ1.5m×6m | φ1.5m×6.7m | φ1.65m×7m | φ1.8m×8m | φ2.2m×9m | φ2.6m×9m | φ2.6m×9.5m | φ2.8m×10.2m |

| Fuel consumption | 70-300kg / h | 100-400kg / h | 120-600kg / h | 150-1000kg / h | 150-1000kg / h | 150-1400kg / h | 180-1800kg / h | 180-1800kg / h | 260-2500kg / h |

| Vibrating Screen (Layer) | 4 layers | 4 layers | 4 layers | 4 layers | 5 layers | 5 layers | 5 layers | 5 layers | 6 layers |

| Mixer Capacity | 500kg | 800kg | 1000kg | 1250kg | 1500kg | 2000kg | 2500kg | 3000kg | 4000kg |

| Cycle Time | 45s | 45s | 45s | 45s | 45s | 45s | 45s | 45s | 45s |

| Filter Area | 230m² | 300m² | 420m² | 480m² | 550m² | 650m² | 700m² | 1050m² | 1350m² |

| Asphalt Temperature | 140-180 ℃ | 140-180 ℃ | 140-180 ℃ | 140-180 ℃ | 140-180 ℃ | 140-180 ℃ | 140-180 ℃ | 140-180 ℃ | 140-180 ℃ |

| Total Power | 170kw | 200kw | 300kw | 350kw | 380kw | 490kw | 550kw | 670kw | 865kw |

ALT Series Stationary Drum Mix Asphalt Plant Specification

| Courts Models | ALT20 | ALT40 | ALT60 | ALT80 | ALT100 |

|---|---|---|---|---|---|

| Capacity | 20 t/h | 45 t/h | 60 t/h | 80 t/h | 100 t/h |

| The ability to | 40kw | 75kw | 120kw | 165kw | 200kw |

| Cold Aggregate Hoppers | 3.5m³×1 | 4m³×4 | 4m³×4 | 6.5m³×4 | 6.5m³×4 |

| Finished Product Hopper | 3t | 3t | 7t | 7t | 9t |

| Asphalt Temperature | 120-180 ℃ | ||||

| Fuel consumption | 13-15kg/t | ||||

| Asphalt Tank | 10 t | 20 t | 30 t | 30 t | 35 t |

| Control room | 2.2m | 2.2m | 3m | 3m | 3.5m |

| Option | Bag dust filter | ||||

What is the Price Range for a Stationary Asphalt Mixing Plant?

Understanding the price range of stationary asphalt plants is essential for budgeting your project effectively. Whether you’re looking for a cost-efficient option or a high-capacity solution, the price varies significantly based on plant type and features. Below is a clear breakdown to help you choose the best fit within your budget. Let’s see the specific stationary asphalt plant price together!

Key Differences Between Stationary Asphalt Plant and Mobile One?

If you’re planning an asphalt project, understanding the key differences between stationary and mobile asphalt plants can help you make the right investment. Whether you’re building long-term highways or managing short-term site work, each type offers unique benefits in capacity, mobility, setup time, and cost. Let’s compare them side by side to find out which asphalt plant fits your project needs best.

|

|

|

|---|---|---|

| Fixed installation | Installation Type | Movable structure with trailer or chassis |

| Batch mixing or drum mixing | Mixing Technology | Mostly drum or simplified batch |

| High (up to 320 t/h for ALQ series) | Production Capacity | Medium to low (typically up to 100 t/h) |

| Requires foundation and long setup (≥1 month) | Mobility | Quick setup and transfer (a few days) |

| Long-term projects, highways, national roads | Best For | Short-term or remote projects, small/medium roads |

| Full automation, IOT monitoring, multi-mode control | Automation & Control | Basic to moderate automation |

| Multiple: gravity, bag, water, cyclone, etc. | Dust Collection Options | Mostly bag or cyclone filters |

| Low-frequency, predictive maintenance supported | Maintenance | More frequent maintenance due to transport/movement |

| Higher infrastructure cost | Initial Investment | Lower setup cost, but higher per-use transport cost |

| High stability and precision | Overall Efficiency | High flexibility, suitable for diverse job sites |

How To Choose The Right Stationary Asphalt Mixing Plant For Sale

Buying a stationary asphalt plant is a big decision — and choosing the right one can save you time, money, and trouble. Here’s a simple guide to help you select the best stationary asphalt mixing plant for sale from China suppliers for your project:

Understand Your Project Needs

Every construction project is different — identify what fits yours:

🛣️ Project type: Highway, urban road, or rural paving?

⏳ Duration: Will the asphalt plant stay in one place long-term?

🧱 Asphalt mix quality: Does your job need high-precision batching?

👉 Large-scale, long-term projects usually require asphalt batch plants (ALQ series). Smaller, continuous paving jobs may suit drum mix plants (ALT series).

Consider Equipment Output

Capacity matters — don’t let the plant slow down your progress.

🔢 Small/medium jobs: ALT20–ALT100 or ALQ40–ALQ100

🚛 Large-scale production: ALQ120–ALQ320 for continuous demand

🏗️ Avoid delays: Undersized asphalt plants slow down progress

Choose the output that fits your job size and schedule

Check Environmental Performance

More projects today demand clean, efficient operation:

🌬️ Dust control: Gravity dust, bag filter, water filter options

🔇 Noise reduction: Especially important in urban areas

♻️ Emission compliance: Meet local green standards

These features help meet regulations and protect your brand reputation.

Focus on Operation & Control

A smart system saves time and reduces errors:

💻 Multiple control modes: Touchscreen, computer, manual buttons

📲 IOT monitoring: Real-time fault alerts and maintenance reminders

⚙️ Automation: One-button start, consistent batching quality

This means fewer manual steps, safer production, and better efficiency.

Evaluate Service & Support

After-sales service is crucial to long-term success:

🧑🔧 Installation & training: Is on-site help provided?

📦 Spare parts supply: Can you get them quickly when needed?

📞 Remote & local support: Faster troubleshooting = less downtime

Reliable service saves downtime and keeps your project on track.

Plan Your Budget Wisely

The right budget choice balances cost and long-term value:

💰 Initial investment: ALT ($60K–$200K), ALQ ($130K–$1M)

🛠️ Maintenance & operation costs: Consider lifetime use, not just price

🔁 ROI over time: High-quality asphalt plants mean fewer breakdowns

⚠️ Don’t just look at the price — also consider output, automation, and lifetime cost.

📌 Final Tip: Think beyond the machine — think project fit, reliability, and future-proofing. Still unsure? Ask us for a tailored asphalt plant recommendation based on your jobsite.

How To Get The Most Reasonable Stationary Asphalt Plant Price?

Securing a reasonable asphalt plant price for a stationary asphalt batching plant is crucial. Here are some ways to help you find the best value while ensuring quality.

Understand Market Trends

Define Your Equipment Requirements

Choose a Reliable Manufacturer

Take Advantage of Manufacturer Promotions

Opt for Customized Solutions

Negotiate and Explore Long-Term Partnerships

Consider Total Life Cycle Costs

By following these methods, you can make a more informed decision and secure the right asphalt batching plant stationary at the most reasonable stationary asphalt mixing plant price. Remember to consider equipment quality, after-sales service, and long-term costs to ensure your investment in asphalt mixing plant is worthwhile.

Essential Tips for Choosing a Reliable Stationary Asphalt Plant Supplier

When looking to purchase a stationary asphalt mix plant, it’s important to carefully evaluate potential stationary asphalt mixing plant suppliers to ensure you make a well-informed decision. Here are key steps to guide you to choose a suitable asphalt plant supplier:

![]()

Targeted Search

Use precise search terms including your country or region to find experienced manufacturers, not just intermediaries.

![]()

Factory Verification

Ensure the stationary asphalt mixer manufacturer truly operates a factory so you can verify production strength and quality control firsthand.

![]()

Component Transparency

Ask about core components, material sources, and part brands to assess long-term performance and durability.

![]()

Value Over Price

Don’t judge by price alone. Compare the total value, including service terms, warranty, and spare parts availability.

![]()

Reliable After-Sales Support

Choose a supplier with responsive support before and after delivery, especially if you’re managing remote operations.

Working with a reliable stationary asphalt mix plant supplier helps reduce risks, ensures smooth installation, and improves project outcomes in the long run. Need help comparing stationary asphalt mixing plant suppliers? Contact us—we’ll guide you step by step.

Stationary Asphalt Mixing Plant Market Outlook

The global market for stationary asphalt mixing plants for sale continues to expand steadily, driven by large-scale infrastructure development and the growing demand for consistent, high-quality asphalt production.

📊 Market Performance at a Glance

- 2024 Market Size: USD 3,570.3 million

- Projected 2030 Market Size: USD 4,324.7 million

- CAGR (2025–2030): 3.3%

- Market Share of Asia Pacific (2024): Over 45% of global revenue

- Top Growth Contributors: Southeast Asia, China, Middle East, Africa

🔍 Key Drivers & Trends

- Infrastructure Expansion: Over 65% of stationary asphalt plant demand comes from highway, airport, and municipal projects requiring continuous, high-output production.

- Environmental Compliance: More than 70% of newly purchased stationary asphalt mixing plants in 2024 included advanced dust collection and emission reduction systems.

- Technology Adoption: Roughly 60% of stationary asphalt batching plant suppliers now offer automated control and IoT-based monitoring for efficiency and uptime.

- Cost Efficiency: Compared to mobile asphalt plants, stationary discontinuous asphalt plants reduce long-term operating costs by 15–25%, especially in fixed-location projects.

🌍 Regional Market Insights

- Asia Pacific remains the largest and most dynamic market, led by Indonesia, China, and Vietnam.

- Southeast Asia alone is expected to contribute over USD 800 million to global market growth by 2030.

- Middle East & Africa are projected to grow above the global CAGR, driven by infrastructure diversification and oil-independent construction projects.

- Europe & North America focus on sustainable plant upgrades, with retrofit and environmental tech driving 40% of purchases in those regions.

📈 Future Outlook

- The demand for stationary asphalt batch plants (40–320 t/h) will continue to dominate due to their mixing precision and long-term durability.

- High-output models (ALQ160 and above) are projected to account for over 30% of new installations by 2030, reflecting growing project scales.

- Stationary asphalt mixer suppliers that offer customized solutions, strong after-sales service, and localized delivery support will hold a competitive edge.

What Services Can You Expect for Your Stationary Asphalt Plant?

Choosing a stationary asphalt plant near me is only the beginning — reliable service and support make all the difference in long-term performance and peace of mind. At AIMIX, we go beyond just supplying equipment. From pre-sales consultation to after-sales assistance, we provide full-cycle support to ensure your hot mix asphalt plant runs smoothly and delivers lasting value. Here’s what you can expect when working with us:

Professional Pre-Sales Support

You can get tailored recommendations based on your project size, location, and budget — making it easy to choose the right model.

Customization and Quotation

We provide flexible asphalt plant customization and send detailed quotations, helping you plan confidently without hidden costs.

On-Site Factory Visit Welcome

Visit our factory to check product quality, production process, and see real machines in operation — trust built with transparency.

Fast Installation & Staff Training

Our expert team handles installation and trains your operators to ensure smooth, efficient plant startup from day one.

Worry-Free After-Sales Service

Enjoy full lifecycle support — from spare parts to troubleshooting — with responsive help just a message or call away.

Ongoing Technical Guidance

Get expert advice anytime to improve plant performance, reduce downtime, and solve technical issues quickly.

👉 With AIMIX, you’re not just buying a stationary asphalt plant for sale — you’re getting a reliable partner every step of the way.

Reliable Stationary Asphalt Plant, Your Trusted Partner

We offers durable, high-performance stationary asphalt mix plants backed by expert service from start to finish. Whether you need a large or small solution, we ensure smooth operation and long-term value. Contact us today to get a tailored quote and start building with confidence!