Strategic Partner of Fortune Global 500 Enterprises

One-click Start, Intelligent Operation, Efficient Production

IOT Remote Monitoring, Real-time Status tracking, Lower Failure Rates

Type: Mobile or Stationary

Capacity: 0-100 / 100-200/ 200-300/ 300-500/ 500-700/ 700-1000 TPH

Output Sizes: 0-5/ 5-10/ 10-20 / 20-40 mm, etc. Customized Output Size

Application: Aggregate Production / Mining / Mining Processing / Construction Waste Removal and Recycling

Your project’s foundation starts with the right aggregate. AIMIX stone crusher plants are engineered to be the powerful, reliable heart of your project operation, transforming raw materials—from tough granite and basalt to softer limestone and ores—into consistent, high-spec aggregate material for concrete, roads, and beyond. We provide tailored solutions, whether you need a permanent stationary plant or an agile mobile setup, ensuring efficiency and output that drives profitability. Discover AIMIX’s different kinds of stone crusher plants for sale first.

Different Types of Stone Crusher Plants

Stone crusher plants come in different types. Understanding the different types of stone crushers is crucial for optimizing construction and mining operations. Each type of plant is designed for specific tasks, catering to various requirements in terms of size, output, and material type. In terms of mobility, we can divide it into stationary and mobile stone crusher plant. Here are detailed introduction of them.

AIMIX Group offers a variety of mobile stone crusher plants to meet your diverse needs. They include 4-in-1, 3-in-1, and 2-in-1 series, offering flexibility and versatility to operate efficiently in various site environments. Whether for ore crushing, construction waste recycling, or earthmoving projects, these mobile crushers provide efficient solutions.

Hottest Wheeled 4 in 1 Mobile Crusher Plants – 30-200 tph

- Main Configuation: Feeder + Jaw Crusher + Cone Crusher + Screen

- Max. Feeder Size: <500mm

- Output Size: 5-10mm, 10-20mm, 20-40mm

- Advantages: 4-in-1 integrated design, streamline the process and reduce operating costs; 3-axle chassis design enables quick site transfers with minimal setup. Move between job sites effortlessly.

- Popular Application: aggregate production for construction, like roads and building construction.

APY3-F 3-in-1 Mobile Impact Crushing Plant – 70-500 tph

- Main Configuation: Feeder + Impact Crusher + Screen

- Max. Feeder Size: <300mm

- Output Size: 0–40 mm

- Applications: suitable for processing soft hardness materials, especially for limestone, asphalt wastes, and concrete wastes, as the recycled aggregates, base/surface course aggregates.

APY3-J 3-in-1 Mobile Jaw Crusher – 45–400 tph

- Capacity Range:

- Configuration : Feeder + Jaw Crusher

- Feed Size: >425 mm

- Finished Product Particle Size: 15–300 mm

- Applications: primary crushing in the quarry and mines, onn-site aggregate production for roadbed materials.

APY2-C 2-in-1 Mobile Cone Crusher Plant – 100-300 tph

- Configuration : Cone Crusher + Screen

- Feed Size: <300 mm

- Finished Product Particle Size: 0-5mm, 5-10mm, 10-20mm

- Applications: relatively uniform output particle size; usually used for medium and fine crushing

| 4 in 1 Mobile Crusher Plant - Wheeled Chassis Type | ||||

|---|---|---|---|---|

| Model | APY4-46J2512J-S3 | APY4-46J900C-S3 | APY4-57J110C-S3 | APY4-69J132C-S3 |

| Productivity(t/h) | 30 | 50 | 80 | 100-120 |

| Vibrating Feeder | ||||

| Model | APG-0824Z | APG-0824Z | APG-0930Z | APG-9538Z |

| Primary Stone Crusher | ||||

| Model | APJ-4060E | APJ-4060E | APJ-5075E | APJ-6090E |

| Type | Jaw crusher | Jaw crusher | Jaw crusher | Jaw crusher |

| Secondary Stone Crusher | ||||

| Type | Jaw crusher | Cone crusher | Cone crusher | Cone crusher |

| Model | APJ-2512X | APC-900Y | APC-110C | APC-132C |

| Vibrating Screen | ||||

| Model | APS-1548Y3 | APS-1548Y3 | APS-1848Y3 | APS-1848Y3 |

| Belt Conveyor | ||||

| Vehicle mounted belt conveyor | Yes | Yes | Yes | Yes |

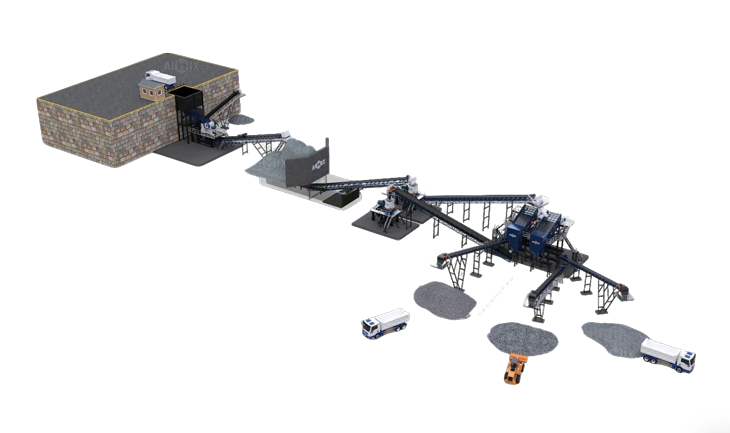

The stationary crushing plant is a high-capacity aggregate solution engineered for large-scale, long-term projects. It integrates specialized crushing equipment, such as jaw crushers for primary crushing and impact or cone crushers for secondary or tertiary processing, into a fully automated system. Designed for fixed locations, it provides continuous, high-volume production of quality aggregates, serving as a reliable core production unit for mining, major infrastructure, and large construction projects.

Stationary Crusher Plants – 50 ~ 1000 t/h Capacity

- Smart & Simple Operation: Centralized control enables easy monitoring, automated operation, and reduced manual dependency.

- Controlled Output Quality: Configurable crushing and screening stages deliver consistently graded aggregates that meet strict project specs.

- Eco-Conscious Design: Built with dust suppression, noise reduction, and sealed modules to meet environmental standards.

We also have manufactured crawler-type mobile stone crushing machine. The mobile or portable stone crusher plants, mounted on crawler chassis, are easy to maneuver and relocate across rough terrain. They are designed for easy transportation and on-site setup. Generally, the crawler crusher stone for sale is suitable for applications where the crushing location needs to be changed frequently, especially for demolition projects.

Tracked Stone Crusher Machine Plant – Under 400tph

- High adaptability: adapt to rugged mountain roads, muddy construction sites or narrow sites.

- Ready to Use: no need for complex installation and debugging, start production within 30 minutes.

- Quick response to demand: Suitable for short-term projects (such as urban building demolition) or decentralized operations (such as rotational mining in multiple quarries).

Whether you need a stationary crusher plant of stone or a stone crusher portable, we will customize the most suitable crushing solutions according to the projects. The following are the real cases of AIMIX movable stone crusher and stationary stone crushing plant all over the world. You can check them below.

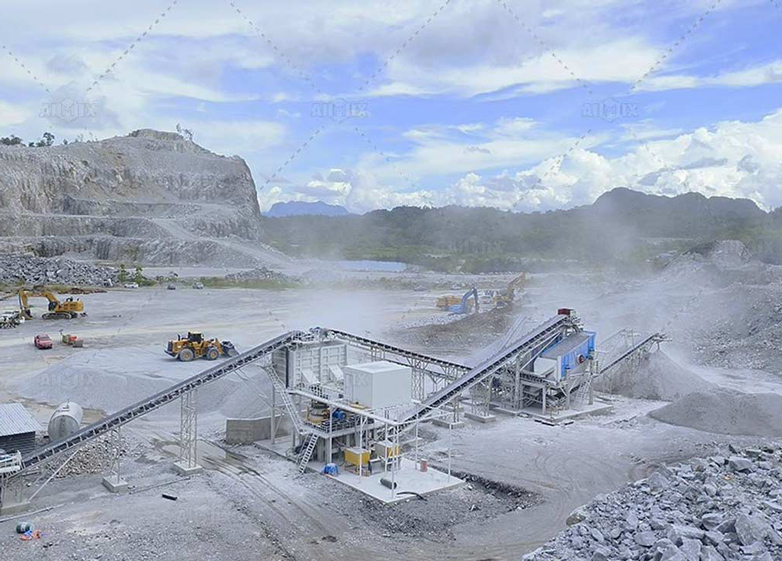

Exploring Diverse Case Studies of Stone Crushing Plants

AIMIX Group has successfully established a strong presence in the global market, with its crusher plants being sold in over 80 countries, like Malaysia, Indonesia, Philippines, Russia, Mongolia, Tanzania, Honduras, Ecuador, Peru, Colombia, El Salvador, Uzbekistan, etc. Here are a series of case studies showcasing AIMIX stone crusher plants, illustrating the effectiveness of our crushing solutions.

4-in-1 Wheeled Mobile Stone Crushers Operation On-site

- Processing capacity: 50tph

- Output size: 10-30mm

- Applications: crushing granite rocks on-site for aggregate-sale business expansion

- Configurations: feeder, jaw crusher, cone crusher, and vibrating screen

- Customer reviews: “Having collaborated with AIMIX for seven years, when it came to this business expansion, AIMIX was still our first choice. They would provide customized solutions for me!”

4-in-1 Wheeled Mobile Stone Crusher Plant For Aggregate Sale Business

- Processing capacity: 15-120 tph

- Output size: 0-5mm, 5-10mm, 10-20mm, and 20-30mm

- Applications: limestone crushing, supplying aggregate for his contracted projects.

- Configurations: Vibrating Feeder + Jaw Crusher + Impact Crusher + Vibrating Screen

- Customer reviews: “Our project expenses have reduced dramatically since we adopted the AIMIX crushing plant. We no longer stress about high aggregate prices. It’s a dependable and lasting solution for our requirements.”

4-in-1 Wheeled Mobile Stone Crusher Plant For Aggregate Sale Business

- Processing capacity: 150tph

- Output size: 5-10; 10-20mm

- Applications: crushing granite materials for sale of aggregate materials

- Configurations: vibrating feeder + mobile jaw crusher + mobile cone stone crusher + vibrating screen+ belt

- Customer reviews: “In my aggregates business, operational efficiency and cost control are critical to the project. The AIMIX 4-in-1 combined mobile crushers simplify the crushing process and lower the operating costs. This significantly boosts our ROI.”

600 tph Crawler Stone Crusher and Screener For Road Construction

- Processing capacity: 600 tph

- Finished Product: 5-40mm

- Applications: crushing cobblestones for road construction

- Configurations: vibration feeder, crawler jaw crusher, crawler cone crusher, crawler screener, etc

- Customer reviews: “Our road project had special needs for aggregate size and site layout. AIMIX tailored a solution with 5 units of crawler crushers. The setup runs efficiently and is easy to move, saving us time and costs. It’s great to work with a team that really understands on-site demands.”

Tire-mounted Mobile Crusher For Aggregate Production

- Processing capacity: 100tph

- Finished Product: 10-30mm

- Applications: processing river stone for aggregate production

- Configurations: vibration feeder, jaw crusher, cone crusher, screen

- Customer reviews: “In the rugged terrain of my granite quarry, the AIMIX crawler mobile crusher performs exceptionally. Its track system easily adapts to uneven ground, remains stable, climbs efficiently, and eliminates the need for additional road construction.”

350tph Stationary Stone Crushing Plant Processing Cobblestone On-site

- Processing capacity: 350tph

- Finished Product: 0-5-10-20-30mm

- Applications: crushing cobblestone on-site for aggregate for construction industry

- Configurations: vibration feeder, jaw crusher, cone crusher, vibrating screen, etc

- Customer reviews: “We chose the crushing line primarily for its user-friendly integrated control system. Both the PLC touchscreen and physical buttons make operation intuitive for workers, with smooth shift changes between day and night crews. The one-touch start/stop feature significantly improves efficiency.”

The success of customer projects is largely attributed to our customized crushing solutions. These tailored solutions not only meet the unique needs of each client but also enhance operational efficiency and productivity. By addressing specific challenges faced in various industries, our customized solutions ensure optimal performance and results. Here I have listed other customized solutions we have made for clients. Check them below.

Customized Crushing Solutions Tailored for Different Stones

Stationary 100 tph Stone Crusher for Concrete Production

- Raw material size: basalt rocks ≤500mm

- Finished product specifications: 0-5mm / 5-12mm / 12-25mm / 25-38mm

- Processing capacity 100 tons/hour

- Application scenarios: Commercial concrete batching plant, road infrastructure construction

- Configured Solution: vibrating feeder + jaw crusher + compound cone crusher + fine crushing compound cone crusher + vibrating screen

- Technical highlights of Solution: Double cone crusher tandem process – improve crushing efficiency by 30%

- “I am extremely satisfied with the stone crushing and screening plant project that was carried out by the team. Their expertise in crushing basalt on the mountain and producing high-quality sand and gravel aggregates for ordinary concrete exceeded my expectations. The resulting materials were precisely what we needed for our construction project. The team’s professionalism, attention to detail, and commitment to delivering excellent results were commendable. I highly recommend their services to anyone seeking a reliable and efficient stone crushing solution.”

Mobile type Stone Crushing Plant for Aggregate Production

- Raw materials and its sizes: hard rocks and mountain rocks ≤ 600mm

- Finished particle size: sand and gravel between 0-24mm

- Processing capacity: 200 tons/hour

- Application: aggregates for building construction

- Configured Solution: feeder + jaw crusher + compound cone crusher + vibrating screen

- Core advantages of the solution: 4 in 1 unique design, save landing space; no foundation installation required

- “I cannot express my satisfaction enough with the solution – 200 tph stone crusher. It can proecss 2,400 tons of stone materials per day. The mobile stone crusher plant has moved to 3 operating areas and continuously supplies 200,000 cubic meters of high-quality sand and gravel for my building projects!”

150tph Mobile Sand Making Plant to Make Quartz Sand

- Raw materials and its sizes: high-siliceous quartz ≤400mm

- Finished particle size: medium-fine sand 0.1-0.6mm / fine sand 0.6-3mm

- Processing capacity: 150 ton per hour

- Application: crush quartz produce quartz sand as raw material for glass and ceramics.

- Configured Solution: vibrating feeder + jaw crusher + compound cone crusher + vibrating screen + sand making machine + sand washing machine

- Core advantages of the solution: 1. Rock-on-rock mode of VSI crusher can achieve more than 95% sphericity. 2. Sand washing machine Three-stage scrubbing: spiral blade + high-pressure spray + ultrasonic vibration triple impurity removal

- “In the photovoltaic glass sand supply project, this mobile sand production line has made a difference. It keeps 4000 hours of trouble-free continuous operation. The high-quality sand produced ensured smooth glass and ceramics production.”

Besides, all of the above scenarios are aimed at producing the materials needed for construction, but with different raw materials. We also have many other programs for the production of other raw materials, such as the use of granite for the production of concrete, limestone crushing for the production of aggregates, and volcanic rocks for the production of sand. If you want to customized a crushing solution for you, welcome to contact us without hesitation.

After looking at so many crushing options in the market, have you been clear about the one you need? It is important to choose the right stone crushing solution, but in the face of expensive stone crusher plants, it is also crucial to choose the right one for ensuring profitability and operational efficiency.

Core Planning for Your Stone Crushing Line: From Requirements to Technical Design

The foundation of a profitable and efficient stone crushing operation is not laid with the first pile of aggregate, but in the meticulous planning that precedes it. This crucial phase involves transforming your unique business goals, material characteristics, and site constraints into a coherent and optimized technical blueprint. A well-executed plan, which systematically bridges operational requirements with practical engineering design, is the essential first step toward ensuring your plant delivers the desired productivity, product quality, and return on investment. Here’s a comprehensive guide that provides actionable insights to assist you in planning stone crushing plant tailored to your business needs.

Raw Material Characteristics Analysis

- Type and Hardness: Is it limestone, granite, river pebbles, or quartz? The hardness (Mohs hardness), abrasion resistance, soil content, and moisture content of different materials vary greatly, which is crucial in determining the selection of the primary crusher, like jaw crusher, gyratory crusher.

- Feed Size: What is the maximum particle size of the raw material? This determines the model of the feeder and the feed inlet size of the primary crusher.

- Raw Material Shape: Is there a predominance of flaky and needle-like materials? These materials may require pre-screening or the selection of a special crushing chamber type.

Know Finished Product Requirements

- Specifications and Grading: How many types of finished products do you need to produce? What are the particle size and proportion requirements for each type of finished product? like 0-5mm manufactured sand, 5-10mm, 10-20mm crushed gravel. It determines the process design of the stone crushing line (e.g., the number of crushing stages) and the number of screening layers and apertures.

- Finished Product Shape: Are there requirements for the content of needle-like and flaky particles? If used for high-grade highway surface courses or concrete aggregates, high particle shape requirements may be necessary, potentially requiring the configuration of a cone crusher or impact crusher or sand making machine for shaping.

- Production Target: What are your expected hourly and annual production capacities? (e.g., 50 tph, 100tph, 150 tph, 200 tph, 300 tph, etc. ) This is the fundamental basis for all equipment selection. Please set a reasonable target with a moderate margin based on market forecasts.

Estimate Site and Investment Budget

- Site Conditions: Is the production line fixed or mobile? Site topography, area, power supply capacity, environmental restrictions, and transportation conditions will all affect the layout and equipment selection. Mountainous sites may be suitable for a stepped layout.

- Investment Budget: Determine the total budget range and allocate it reasonably among equipment purchase, infrastructure, installation, and subsequent operation and maintenance. Avoid choosing low-quality equipment to reduce initial investment, which can lead to a surge in later maintenance costs.

Choose the Right Process flow and Equipment Selection

While a planned process flow is the technical blueprint for success, the reliability and longevity of your operation depend on the automatic stone crusher plant manufacturer who brings that blueprint to life. Selecting the right manufacturer is a strategic choice that affects your crushing plant’s performance, operational costs, and long-term profitability. Therefore, after solidifying your technical requirements, the next critical step is to identify and evaluate a reliable and competent stone crushing plant manufacturer. The following practical guidelines are designed to assist you in navigating this crucial selection process and finding a true partner for your stone crushing business.

Notes For Choosing a Stone Crusher Plant Manufacturer

A reputable crusher plant manufacturer will provide dependable machine for crushing stone, excellent customer support, and innovative solutions tailored to your specific needs, ultimately maximizing productivity and minimizing downtime for your operations. Therefore, here are some guidance on choosing stone crusher manufacturers:

Reliability and Reputation

Research the stone crushing machine suppliers’ reputation and reliability in the industry. Look for established companies with a track record of producing high-quality and durable new stone crusher plant machinery.

Quality and Performance

Examine the quality of materials used in the construction of the stone crusher plants and their components. Ensure that it meets your specific requirements in terms of capacity, efficiency, and output size.

Global After-sales Service Network

A reliable manufacturer should offer a robust global after-sales service network to ensure timely support, spare parts supply, and technical assistance—especially for overseas projects. This minimizes downtime and keeps your operations running smoothly, no matter where the plant is installed. AIMIX Group has over 100+ service networks and 6 branch offices all over the world, and customers can get timely and effective support and services no matter where they are located, including parts supply, fault repair, technical consultation, etc.

Technology and Innovation

Look for stone crusher plant manufacturers that incorporate advanced technology and innovative features in their crusher plants. This can improve overall performance, reduce maintenance, and enhance productivity.

Environmental Protection and Sustainable Development

Check if the manufacturer offers customization options to adapt the stone crushing plant for sale to your specific needs. This includes the ability to adjust the configuration, add or remove components, or integrate additional equipment.

After-Sales Support

Evaluate the after-sales support provided by the stone crusher machine manufacturer. Ensure they offer comprehensive technical assistance, spare parts availability, and maintenance services to keep your plant running smoothly.

Cost and Value

Consider the stone crushing plant cost and compare it with the features, quality, and performance offered. Strive for a balance between cost-effectiveness and long-term value.

Environmental Impact

Pay attention to the environmental impact of the stone crusher plant for sale. Look for manufacturers who prioritize sustainability by incorporating eco-friendly designs and technologies.

Customer Reviews and References

Read customer reviews and seek references from other buyers who have purchased from the manufacturer. Their feedback can provide valuable insights into the company’s reliability and customer satisfaction.

Compliance with Regulations

Ensure that the manufacturer and the stone crusher plants comply with relevant safety and environmental regulations in your region.

Delivery and Installation

Clarify the delivery timeline and installation process with the manufacturer. Make sure they can deliver the stone screening plant within your required timeframe and assist with its proper installation.

You can choose the AIMIX Group manufacturer as your primary choice. AIMIX, in line with the concept of customer first, spends a lot of money to invite professional crushing technology engineers, set up a production team, sales team, after-sales team, and technology research and development team. We have successfully helped more than 100 customers to solve their problems with crushing plant of stone. We will continue to help more customers expand their industry chain and become bigger and stronger.

Advanced Features on Stone Crusher Plants That Maximize Productivity and Minimize Downtime

In today’s competitive landscape, modern stone crushing plants rely heavily on intelligent technologies to enhance their operations. Beyond basic functions, advanced features are crucial for achieving higher efficiency, consistent product quality, and uninterrupted service. These innovations transform a simple processing line into a highly connected and self-optimizing operation.

Intelligent Automation & Process Control

An automatic stone crusher plant uses a centralized control system based on PLC (Programmable Logic Controller). This system does more than just start and stop equipment; it continuously monitors key parameters like crusher load, power draw, and chamber pressure. By making real-time adjustments to feed rates and crusher settings, it optimizes throughput and ensures consistent product quality—all with minimal manual intervention. This direct link between automation and productivity gains is significant.

Predictive Health Monitoring

Unplanned downtime can be costly. Advanced stone plants now use smart sensor technology to monitor critical components such as crusher liners, mantles, and bearings. By analyzing wear rates and performance data, the system provides timely maintenance alerts, allowing for parts replacement during planned pauses. This proactive approach helps prevent unexpected failures and extends the life of the equipment.

Integrated Eco-Efficiency Systems

Today’s productivity goals must go hand-in-hand with environmental responsibility. Modern designs feature closed-loop dust suppression that activates spray nozzles based on material flow rather than timers. This ensures effective dust control while conserving water. Additionally, hybrid power options in mobile stone crusher plants allow operators to switch seamlessly between diesel and external electric power, significantly reducing fuel costs and enabling quieter operations in urban areas. This flexibility helps keep your site running longer and in more locations.

Unified Data & Connectivity

The true potential of these advanced features is realized through integrated data platforms. Performance metrics, production reports, and maintenance alerts can all be accessed remotely. This connectivity provides a comprehensive view of operations, allowing for data-driven decisions related to crsuhing plant optimization, shift planning, and long-term capital strategies. In this way, operational data becomes a strategic asset.

What Are The Main Components of Stone Crushing Plants?

Modern stone crushing plants integrate a complete processing system from feeding to final product output, offering flexible solutions that precisely match customer requirements. The essential components work together to handle the entire production process, including material feeding, primary/secondary crushing, precise screening, sand making (when needed), forming a fully customizable stone crushing solution. Here’s an overview of the primary components:

Feeder

Feeders, like vibrating feeders, regulate the flow of raw material into the stone crushing machine. They ensure a consistent feed rate, which helps in smooth and continuous crushing operations.

Jaw Crusher

The primary jaw crusher machine stone handles large rocks and reduces them to smaller, manageable sizes for secondary crushing. It’s the first stage in the crushing process.

Cone Crusher

Secondary crusher, like cone crushers, further reduce the size of materials processed by the primary crusher. These are ideal for achieving finer materials.

Impact Crusher

The impact crusher machine for stone is crucial for producing finely crushed materials by using high-speed impact forces, ideal for creating uniform-sized aggregates for construction.

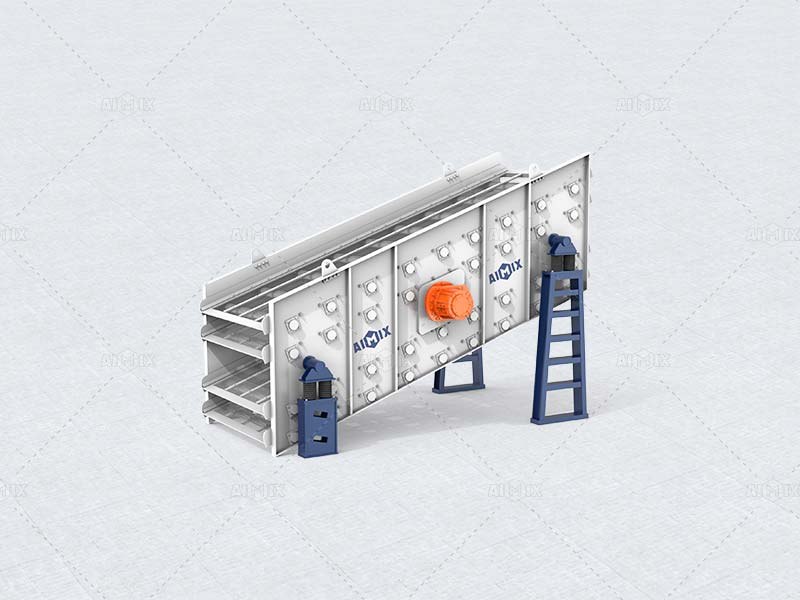

Screening Machine

After crushing, materials are screened to separate different sizes. Vibrating screens are often used to sort and classify crushed stone.

Belts

Conveyor belts transport materials between different stages, from feeding to crushing and screening. They connect the entire system, ensuring a smooth flow of materials.

How Does A Stone Crusher Plant Work?

After understanding the main components of a stone crushing plant above, now we can delve into the working principle of a stone crushing production line. The efficient operation of a stone crushing production line relies on the synergy of various components, which play an important role in the entire process. Next, we will introduce in detail how these components work together to achieve stone crushing and screening.

Large rocks are extracted from quarries or mines. This is typically done using heavy machinery, such as hammer and drill bit.

The extracted stones are fed into the jaw crusher via a feeder. The feeder regulates the flow of materials into the crusher.

The jaw crusher crushes the large stones into smaller, manageable sizes. This is the first step in size reduction.

The crushed stones are then fed into a cone or impact crusher for further reduction. These crushers refine the size and shape of the stones.

After crushing, the material is passed through vibrating screens to separate different sizes. Oversized materials may be sent back to the crusher for further processing.

The screened materials are sorted into various grades and sizes, suitable for different applications like construction, road building, or landscaping.

Maintenance Tips for Your Setup Stone Crusher Plants

Running your crusher plant at full capacity daily without proper maintenance accelerates wear and tear. To further enhance your crusher plant’s efficiency and extend its lifespan, regular manual maintenance remains essential. Here are key practices to keep operations smooth while minimizing costly repairs and downtime.

Regular Inspections

Check rock crusher wear parts frequently, like jaws, liners, blow bars, and mantles. Replace them when worn to maintain efficiency and prevent damage to other components. Besides, remember to examine bolts, frames, and supports for looseness caused by vibrations. Tighten or repair as needed.

Clean the Equipment

Regularly clean the stone crushing equipment, especially after processing materials like clay or sticky substances, which can build up and affect efficiency. Check for any material build-up inside the crushing chamber, which can reduce performance.

Check Electrical Systems

Inspect wiring, connections, and motors for damage. Monitor motor amp draw to prevent overload and ensure efficient operation.

Lubrication Management

Use stone crusher manufacturer-recommended grease/oil for bearings, shafts, and moving parts. Follow scheduled intervals to prevent overheating and friction. Monitor oil temperature and quality in hydraulic systems; replace fluids as specified.

Belt Maintenance

Ensure conveyor and drive belts are properly tensioned (neither too loose nor tight) and aligned to avoid slippage or uneven wear.

Check for Vibrations and Noise

Excessive vibrations or unusual noise may indicate issues with bearings, alignment, or balancing. Address these problems early to avoid major repairs.

By systematically addressing these areas, you can boost your stone crusher plant’s longevity, efficiency, and safety while reducing downtime. For additional support, AIMIX engineers are ready to assist. Contact us anytime for operational queries!