Crushers for sale in Australia can be used to mine and produce various ore aggregates or to process construction waste. AIMIX sold crushers to Australia is committed to the development of large-scale, intelligent, high mobility, high performance, low maintenance and other directions.

Different configuration options will produce different crushing results. If you want to buy any crushers for Australia, tell us your requirement, we have engineers to provide you the ideal crushing solution for your project.

However, to find the most suitable stone crusher Australia, you need to provide us with the following information, so that we can accurately determine which solution is the most suitable for your project. If you are not very clear, next, we will show you some previous solutions for other customers to do for your reference. Let’s take a closer look.

Solutions we customized for clients

- Solution: 1000 ton crawler mobile crusher

- Configurations: crawler mobile jaw crusher + mobile cone crusher + mobile screening plant

- Raw materials: high hardness of river pebbles

- Advantages: powerful crushing capacity and efficient crushing effect

- Our support: Once the equipment was delivered, AIMIX’s engineering team dispatched skilled technicians to Malaysia to aid in the installation and fine-tuning of the machinery. We also offer comprehensive instructions on operating the equipment and provide maintenance training to ensure customers can use and maintain it properly, allowing for optimal performance. Below is the installation site and a video showcasing the equipment in operation.

This solution uses a 150tph mobile crusher plant in Australia to break down mountain rocks of various origins. The finished product can be used as aggregate for many projects, such as the construction of road, building, railway, etc.

Raw materials used: ≤600mm

Production capacity: 150 tph

Finished particle size: 0-25 mm

The Specific Configuration Is As Follows:

APG-4211W vibrating feeder + APJ-7510E jaw crusher + APC-200C-M compound cone crusher + APS-2160Y4 vibrating screen

Due to its strong mobility, crawler mobile crusher has become an ideal equipment for processing construction waste in recent years. This is a large crawler crushing production line customized by our professional engineers for a customer in Manila, Philippines.

Raw materials used: construction waste

Production capacity: 200 tph

The Specific Configuration Is As Follows:

APYL-106J crawler mobile jaw crusher + APYL-300CS crawler mobile cone crusher + APYL-3618S crawler mobile screening machine

- Solution: 250 t/h

- Configurations: mobile jaw and cone crusher

- Project: road construction

- Advantages: save transportation costs and high crushing ratio

- Customer feedback: I am extremely satisfied with the equipment, it has exceeded my expectations in terms of efficiency and performance.Overall, I highly recommend your mobile crusher plant for its outstanding capabilities and the positive impact it has had on our rock processing operations.

- Solution: 100-120 ton

- Configurations: APJ-6090E jaw crusher + APC-110C cone crusher

- Project: asphalt road and concrete road paving

- Introduction: The client currently possesses an asphalt mixing plant with a capacity of 50-60 tons and a coal mining crushing machine. Presently, they are considering acquiring a comprehensive crushing production line to fulfill their stone production requirements and supply raw materials for asphalt mixtures and road bases.

After reading these programs, are there any you need? In addition to these, our stone crushing plants can also be used for crushing the following raw materials, the particles can be applied to the field I also note clearly, I hope to help your project.

What other stones are commonly found in Australia that crushers can process?

- Sandstone: Known for its natural beauty and versatility, sandstone is widely used for building facades, retaining walls, paving, and landscaping projects.

- Granite: With its strength and aesthetic appeal, granite is a popular choice for countertops, cladding, and outdoor paving in residential and commercial settings.

- Bluestone: Bluestone is a type of basalt that is highly regarded for its durability and attractive appearance. It is commonly used for paving, steps, and walling.

- Quartzite: Quartzite is a metamorphic rock known for its hardness and durability. It is often used as a decorative stone for cladding, flooring, and landscaping.

- Marble: Marble, renowned for its elegance and timeless appeal, is used in applications such as countertops, flooring, and decorative accents.

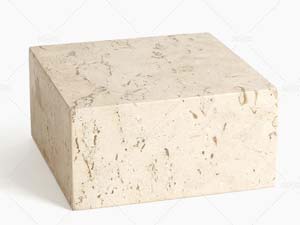

- Travertine: Travertine is a sedimentary rock that is popular for its unique texture and warm color variations. It is commonly used for indoor and outdoor flooring, pool surrounds, and wall cladding.

These are just a few examples of popular stones and materials in Australia. The choice of stone or material may vary depending on the specific project requirements and functional characteristics needed for each application.

Next, let’s take a look at the types of crushing equipment that AIMIX can provide for you and see what advantages they offer!

Hot Selling Mobile Crushing Plants For Sale Australia

According to the way of movement, we divide the mobile crushing equipment Australia into two types: tire-mounted type and crawler type. Below I will introduce our mobile crushing plants to you and list some professional scheme configurations.

Tire-mounted Type – Easy To Move, Flexible On Site

According to different application fields, AIMIX tire-mounted type mobile crushers for sale Australia can be divided into APY2-J primary mobile jaw crusher plant, APY2 series secondary mobile crusher plant, APY3-F construction waste mobile crusher plant and APY4-S mobile crushing and screening plant. The following are some detailed parameters of these mobile crushing plants for sale Australia, you can choose according to your needs.

APY2-69J mobile jaw crusher plantCapacity: 60-160(t/h)

- Feeder model: APG-3896W

- Maximum feed size(mm): 500

- Crusher model: APJ-6090E

- Silo volume(m3): 5.3

- Iron separator model(optional): RCYD(C)-6.5

- Side Out Belt Conveyor Model(Optional): B500×4m

- Main belt conveyor model: B800×8.5m

- Production capacity(t/h): 60-160

- Generator power(kW) (optional): 160

- Weight(t): 39

APY4-4660S Mobile Crushing And Screening PlantCapacity: 16-40(t/h)

- Feeder model: APG-3090W

- Tire configuration: Parallel three shafts

- Primary crusher model: APJ-4060E

- Production capacity(t/h): 16-40

- Secondary crusher model: APC-600Y

- Transport Length(mm): 15500

- Vibrating screen model: APS-1237Y

- Transport width(mm): 2800

- Return belt conveyor model: B500

- Transport height(mm): 4200

- Feeder belt conveyor model: B500

- Weight(t): 41

- Under-sieve belt conveyor model: B650

Crawler Type- Suitable For Complex Terrain And Can Climb Slopes

Generally speaking, we frequently classify the available crawler mobile crushers into four categories. It consists of a crawler-mounted jaw crusher plant, a crawler-mounted cone crusher plant, a crawler-mounted impact crusher plant, and a crawler-mounted screening plant.

APYL-300CS Crawler Mobile Cone CrusherCapacity: 290-495 (t/h)

- Volume (m³): 6.5

- Crusher Type: Single Cylinder Cone Crusher

- Feeding height (mm): 2870

- Processing capacity (t/h): 290-495

- Feeding capacity (t/h): 500

- Walking speed (kw/h): 0.6-1

- Discharge range (mm): 25-54

- Dimensions L×W×H (mm): 13850×3200×3800

- Machine power (kw): 308.7

- Main belt conveyor width (mm): 1200

- Host power (kw): 250

- Finished material belt conveyor width (mm): 500

- Machine weight (t): 52

- Finished material belt conveyor stacking height (mm): 3419

APYL-260R Crawler Mobile Impact CrusherCapacity: 160-350 (t/h)

- Volume (m³): 7

- Crusher Type: APF Impact Crusher

- Feeding height (mm): 4250

- Processing capacity (t/h): 160-350

- Feeding capacity (t/h): 300

- Walking speed (kw/h): 0.6-1

- Discharge range (mm): 25-100

- Dimensions L×W×H (mm): 18127×3626×3909

- Machine power (kw): 265.6

- Main belt conveyor width (mm): 1200

- Host power (kw): 200

- Return belt width (mm): 500

- Machine weight (t): 55

- Finished material belt conveyor stacking height (mm): 3471

Leave me a message if you’re interested in receiving a quote for a mobile type crushing equipment Australia, and our sales consultants will contact you within 24 hours. Let me introduce to you some of our hot-selling crusher products below.

Associated Equipment In The Crushing Plant For Sale Australia: Crusher Machines

Above I introduced the mobile crushing plant in Australia, in addition, we also sell stationary crushing plants. The stationary crushing plant for sale Australia is composed of several pieces of equipment, which can be equipped with vibrating feeders, jaw crushers, cone crushers, impact crushers, vsi crushers, vibrating screens and multiple belt conveyors. Here, I will introduce several common rock crushers for sale Australia for you.

Crush Various Rocks- Jaw Type

The jaw crushers for sale Australia are often used for coarse crushing and is usually responsible for the first crushing process. The jaw crusher Australia is suitable for various ores with a compressive strength not higher than 320MPa, such as granite, basalt, etc. We also have APJ-E, APJ-V, and APJ-X three series of AIMIX jaw crushers for sale in Australia on sale. Among them, the APJ-X series is also often called mini jaw crusher for sale Australia. For specific parameters, please check the relevant pages.

APJ-5075E jaw granite crusherCapacity: 40-110 (t/h)

- Model:APJ-5075E

- Feed opening size (mm):500×750

- Max Feeding size (mm):425

- Output size (mm):50-100

- Processing capacity (t/h):40-110

- Mixing power (kw):55

- Total weight (t):11.7

- Dimension (L×W×H) (mm):1890×1916×1870

| Model | Crushing cone diameter (mm) | Cavity type | Maximum feed size (mm) | Adjustment range of discharge port (mm) | Processing capacity (t/h) | Mixing power (km) | Dimension (L×W×H) (mm) | Weight (t) |

|---|---|---|---|---|---|---|---|---|

| APC-600Y | 600 (2’ft) | B | 65 | 12-25 | 12-25 | 30 | 1740×1225×1940 | 5.5 |

| D | 35 | 3-13 | 5-23 | |||||

| APC-900Y | 900 (2’ft) | B | 115 | 15-50 | 50-90 | 55 | 1990×1640×2380 | 10.2 |

| Z | 60 | 5-20 | 20-65 | |||||

| D | 40 | 3-13 | 15-50 | |||||

| APC-1200Y | 1200 (2’ft) | B | 145 | 20-50 | 110-200 | 110 | 2805×2300×2980 | 25.5 |

| Z | 100 | 8-26 | 50-150 | |||||

| D | 50 | 3-15 | 18-105 | |||||

| APC-1750Y | 1750 (2’ft) | B | 215 | 25-60 | 280-480 | 160 | 3610×2950×4185 | 50.5 |

| Z | 185 | 10-30 | 115-320 | 51 | ||||

| D | 85 | 5-15 | 75-230 | 52 | ||||

| APC-2200Y | 2200 (2’ft) | B | 300 | 30-60 | 590-1000 | 260-280 | 4790×3430×5080 | 84 |

| Z | 235 | 10-30 | 200-580 | 85 | ||||

| D | 110 | 5-16 | 120-340 | 85 |

| Model | Crushing cone diameter (mm) | Cavity type | Open edge feed port size (mm) | Maximum feed size (mm) | Outlet adjustment range (mm) | Processing capacity (t/h) | Power (kW) | Dimension (L×W×H) (mm) | Weight (t) |

|---|---|---|---|---|---|---|---|---|---|

| APC-600S | 600 (2’ft) | BF | 70 | 60 | 6-38 | 16-50 | 30 | 2195×1158×1651 | 4.5 |

| BM | 95 | 80 | 10-38 | 18-65 | |||||

| BC | 110 | 90 | 13-38 | 22-70 | |||||

| DF | 35 | 30 | 3-13 | 9-35 | |||||

| DC | 50 | 40 | 5-16 | 22-70 | |||||

| APC-900S | 900 (3’ft) | BF | 102 | 85 | 9-22 | 45-91 | 75 | 2656×1636×2241 | 10 |

| BC | 175 | 150 | 13-38 | 59-163 | |||||

| BEC | 178 | 150 | 25-38 | 118-163 | |||||

| DF | 41 | 35 | 3-13 | 27-90 | 10.5 | ||||

| DM | 76 | 65 | 3-16 | 27-100 | |||||

| DC | 102 | 85 | 6-19 | 59-129 | |||||

| APC-1300S | 1295 (4.25’ft) | BF | 137 | 115 | 13-31 | 109-181 | 160 | 2983×1866×3156 | 22.5 |

| BM | 210 | 178 | 16-38 | 132-253 | |||||

| BC | 241 | 205 | 19-51 | 172-349 | |||||

| BEC | 259 | 220 | 25-51 | 236-358 | |||||

| DF | 64 | 54 | 3-16 | 36-163 | |||||

| DM | 89 | 76 | 6-16 | 82-163 | |||||

| DC | 105 | 89 | 8-25 | 109-227 | |||||

| DEC | 133 | 113 | 16-25 | 118-236 | |||||

| APC-1600S | 1676 (5.5’ft) | BF | 209 | 178 | 16-38 | 181-327 | 250 | 3940×2954×3770 | 43 |

| BM | 241 | 205 | 22-51 | 258-417 | |||||

| BC | 269 | 228 | 25-64 | 299-635 | |||||

| BEC | 368 | 313 | 38-64 | 431-630 | |||||

| DF | 70 | 60 | 5-13 | 90-209 | 44 | ||||

| DM | 89 | 76 | 6-19 | 136-281 | |||||

| DC | 133 | 113 | 10-25 | 190-336 | |||||

| DEC | 133 | 113 | 13-25 | 253-336 |

| Model | Crushing cone diameter (mm) | Cavity type | Open edge feed port size (mm) | Maximum feed size (mm) | Outlet adjustment range (mm) | Processing capacity (t/h) | Power (kW) | Dimension (L×W×H) (mm) | Weight (t) |

|---|---|---|---|---|---|---|---|---|---|

| APC-600S | 600 (2’ft) | BF | 70 | 60 | 6-38 | 16-50 | 30 | 2195×1158×1651 | 4.5 |

| BM | 95 | 80 | 10-38 | 18-65 | |||||

| BC | 110 | 90 | 13-38 | 22-70 | |||||

| DF | 35 | 30 | 3-13 | 9-35 | |||||

| DC | 50 | 40 | 5-16 | 22-70 | |||||

| APC-900S | 900 (3’ft) | BF | 102 | 85 | 9-22 | 45-91 | 75 | 2656×1636×2241 | 10 |

| BC | 175 | 150 | 13-38 | 59-163 | |||||

| BEC | 178 | 150 | 25-38 | 118-163 | |||||

| DF | 41 | 35 | 3-13 | 27-90 | 10.5 | ||||

| DM | 76 | 65 | 3-16 | 27-100 | |||||

| DC | 102 | 85 | 6-19 | 59-129 | |||||

| APC-1300S | 1295 (4.25’ft) | BF | 137 | 115 | 13-31 | 109-181 | 160 | 2983×1866×3156 | 22.5 |

| BM | 210 | 178 | 16-38 | 132-253 | |||||

| BC | 241 | 205 | 19-51 | 172-349 | |||||

| BEC | 259 | 220 | 25-51 | 236-358 | |||||

| DF | 64 | 54 | 3-16 | 36-163 | |||||

| DM | 89 | 76 | 6-16 | 82-163 | |||||

| DC | 105 | 89 | 8-25 | 109-227 | |||||

| DEC | 133 | 113 | 16-25 | 118-236 | |||||

| APC-1600S | 1676 (5.5’ft) | BF | 209 | 178 | 16-38 | 181-327 | 250 | 3940×2954×3770 | 43 |

| BM | 241 | 205 | 22-51 | 258-417 | |||||

| BC | 269 | 228 | 25-64 | 299-635 | |||||

| BEC | 368 | 313 | 38-64 | 431-630 | |||||

| DF | 70 | 60 | 5-13 | 90-209 | 44 | ||||

| DM | 89 | 76 | 6-19 | 136-281 | |||||

| DC | 133 | 113 | 10-25 | 190-336 | |||||

| DEC | 133 | 113 | 13-25 | 253-336 |

Crush Rocks With High-hardness – Cone Type

Cone crusher for sale Australia is suitable for processing medium to high hardness materials, such as basalt, granite, etc. The cone crusher produced by AIMIX can process materials with a maximum particle size of 300mm. We have various types of cone crusher Australia, including spring cone crushers, hydraulic cone crushers, compound cone crushers, mobile cone crusher for sale Australia, etc. If you are interested in this, please click the inquiry button below.

APC-900S cone granite crusherCapacity: 59-163 (t/h)

- Model:APC-900S

- Crushing cone diameter (mm):900 (3’ft)

- Maximum feed size (mm):150

- Adjustment range of discharge port (mm):13-38

- Processing capacity (t/h):59-163

- Mixing power (kw):75

- Total weight (T):10-10.5

- Dimension (L×W×H) (mm):2656×1636×2241

| Model | Rotor diameter × length (mm) | Feed opening size (mm) | Feed particle size (Max,mm) | Production capacity (t) | Power (kW) | Weight (t) | Dimensions L×W×H (mm) |

|---|---|---|---|---|---|---|---|

| APF1007V | Φ1000×700 | 400×730 | 200 | 20-50 | 45-55 | 9.5 | 2400×1550×2660 |

| APF1010V | Φ1000×1050 | 400×1080 | 200 | 35-80 | 55-75 | 12.2 | 2400×2250×2620 |

| APF1210V | Φ1250×1050 | 570×1030 | 250 | 70-120 | 90-110 | 15 | 2690×2338×2890 |

| APF1214V | Φ1250×1400 | 570×1430 | 250 | 90-180 | 132-160 | 18.5 | 2690×2688×2890 |

| APF1315V | Φ1320×1500 | 625×1530 | 350 | 150-250 | 160-200 | 19.5 | 3096×3273×2667 |

| APF1320V | Φ1320×2000 | 625×2030 | 350 | 160-350 | 200-280 | 28 | 3096×3560×3185 |

| APF1415V | Φ1400×1500 | 800×1530 | 400 | 280-350 | 250-315 | 33 | 3220×3473×2960 |

| APF1520V | Φ1500×2000 | 1315×2040 | 500 | 300-500 | 315-400 | 43 | 3890×3564×3220 |

Crush Brittle Rocks – Impact Type

Both impact crusher and cone crusher for sale Australia are often used for secondary crushing. The difference is that impact crusher for sale Australia is suitable for processing brittle materials with low hardness, such as limestone and concrete blocks. The maximum feed particle size of the impact crushers Australia provided by AIMIX is 500mm. We have the following three series of impact crushers for sale: APF series, APF-H and APF-V series. Besides, we also have mobile impact crushers for sale Australia, for more information, please contact me or check the impact crusher page.

APF1210 impact granite crusherCapacity: 100-160 (t/h)

- Model:APF1210

- Rotor diameter (mm):Φ1200×1000

- Feed opening size (mm):450×1060

- Max Feeding size (mm):350

- Processing capacity (t/h):100-160

- Mixing power (kw):90-110

- Total weight (t):17

- Dimension (L×W×H) (mm):2550×1940×2110

The above are three commonly used crushers for sale Australia. In addition, AIMIX GROUP also has vibrating feeders, vibrating screens, belt conveyors, and vertical shaft impact crusher for sale Australia for perfect configurations. If you are interested in stationary crushing plant for sale Australia, please contact us, our professional engineers will build a set of exclusive stationary crushing plant for your project as below.

Stationary type crushing plants available

150TPH Stationary Crusher Plant For Concrete Production

200TPH Stationary Crusher Plant For Crushing Granite

60TPH Stationary Crushing Plant For Producing Construction Materials

In a word, if you want to customize your own crushing plant for sale Australia, please do not hesitate to contact us now. AIMIX GROUP has a complete service system, which can provide you with the most professional after-sales service while providing you with high-quality products.