What is a gravel crusher? Think of it as your ultimate productivity partner on site – a high-performance gravel crusher machine engineered to transform raw, natural rock into premium, specification-ready aggregate for roads, concrete foundations, and various building applications. In today’s fast-paced construction and mining sectors, it’s the very backbone of your profitability. The right crusher doesn’t just process material; it supercharges your entire operation, slashing downtime and maximizing the value of every ton. But with great opportunity comes a critical choice: a perfectly matched gravel crusher plant is your ticket to unmatched efficiency, while the wrong setup can burn through budgets and stall your progress.

Ready to discover which type of gravel crushing plant will become your most valuable asset and propel your next project to success? Let’s dive in.

Choose the Right Gravel Crusher: Stationary or Mobile Solutions?

When selecting a gravel crushing plant, the first decision is simple: do you need mobility or maximum output? AIMIX offers two types of crushing plants: stationary crushing plants for high-volume, long-term projects, and mobile crushers for flexible, multi-site operations. Below, we break down their strengths, ideal use cases, and unique advantages to help you pick the perfect fit.

Mobile Gravel Crushers: Crush Anywhere, Anytime

Forget rigid setups—mobile crushers bring the crushing line directly to your material. Mounted on trailers or tracks, these mobile gravel crushers can be relocated in hours, eliminating costly transport of pre-crushed stone or delays from site changes. Whether you’re working in urban areas or rugged terrain, AIMIX offers two mobile options:

- Tire-Mounted Mobile Crushers: Ideal for paved surfaces, like city projects, with quick setup and easy highway transport.

- Crawler-Mounted Mobile Crushers: Built for off-road toughness, crawling over rough ground without needing roads.

Combined Tire-Mounted Mobile Crushers

Types: 4-in-1 (feeder, two crusher, screen); 3-in-1 (feeder, one crusher, screen); 2-in-1 (feeder, one crusher, screen)

Main crushers: jaw crusher, cone crusher, and impact crusher

Capacity: 50-350 tph

Output size: 5-40mm crushed gravel

Why Go Wheeled Type?

- Integrated design: Combines feeding, crushing, and screening in one unit, streamlining the process and reducing operating costs.

- Tri-axle chassis: Three-axle design enables rapid relocation and easy site transfers.

- Skid-plate supports: Larger ground contact area improves stability on uneven or soft terrain.

- Modular configuration: Secondary crusher modules are easily swappable (impact crusher or sand maker), allowing flexible setup combinations for diverse applications.

Tracked Gravel Crushers

Capacity: 50-400 tph

Crushers: jaw crusher, cone crusher, and impact crusher

Why Go Crawler Type?

- Superior off-road capability: Track chassis handles mud, slopes, and rough terrain with low ground pressure and strong climbing ability, reducing site preparation needs.

- In-place operation: Work close to the material source to cut secondary handling and loading, significantly lowering fuel and transport costs.

- Multi-machine collaboration: Connect with feeders, screens, and stackers via wired/wireless links to form flexible lines and scale capacity.

- Environmental compliance options: Spray dust suppression, enclosed belt covers, noise-reduction kits, and diesel-electric hybrid choices for strict urban and environmental standards.

Stationary Gravel Crushing Plants: Built for Heavy-Duty, Long-Term Production

Stationary crusher plants are the powerhouse of aggregate production. Installed on a fixed foundation, they combine multiple machines (like jaw crushers, cone crushers, and screens) into a single, optimized stone crusher plant capable of processing thousands of tons daily. Their robust design handles everything from hard granite to soft limestone, ensuring consistent gravel sizes for roads, foundations, or drainage systems.

50-1000 tph Stationary Gravel Crushing Plants

Best for: Large-scale quarries, mines, or permanent construction sites requiring continuous, high-capacity gravel output.

Why Stationary type?

- Massive Output: Engineered for high-volume needs, models available for 50-500+ tons/hour.

- Durability: Heavy-duty steel frames and wear-resistant parts minimize downtime.

- Customizable: Mix and match crushers/screens to match your exact gravel specs,like precise 5mm or 20mm crushed gravel aggregates.

- Cost-Effective for Volume: Lower per-ton processing costs over time vs. mobile alternatives.

Ultimately, the choice between a stationary or mobile gravel crusher hinges on a careful evaluation of your project’s scale, duration, and budget. By selecting the appropriate crushing solution, you lay the foundation for producing the specific type and size of gravel required. With your equipment strategy in place, the next step is to understand where these machines deliver the greatest value. Let’s explore the key applications of gravel crushers across different industries and project types.

Where Gravel Crushers Shine: Real-World Applications Across Industries

Gravel crushers prove their value in diverse fields, delivering reliable performance and tailored solutions for different material demands. Below are several real-world scenarios showing how AIMIX equipment helps clients overcome practical challenges.

200–250 TPH Limestone Gravel Crushing for Aggregate Production

Output Size: 0–5 mm, 5–10 mm, 10–20 mm

Applications: aggregate production for enlarging business

Client requirements: Needed stable, high-volume production with uniform particle size; strict construction deadline;

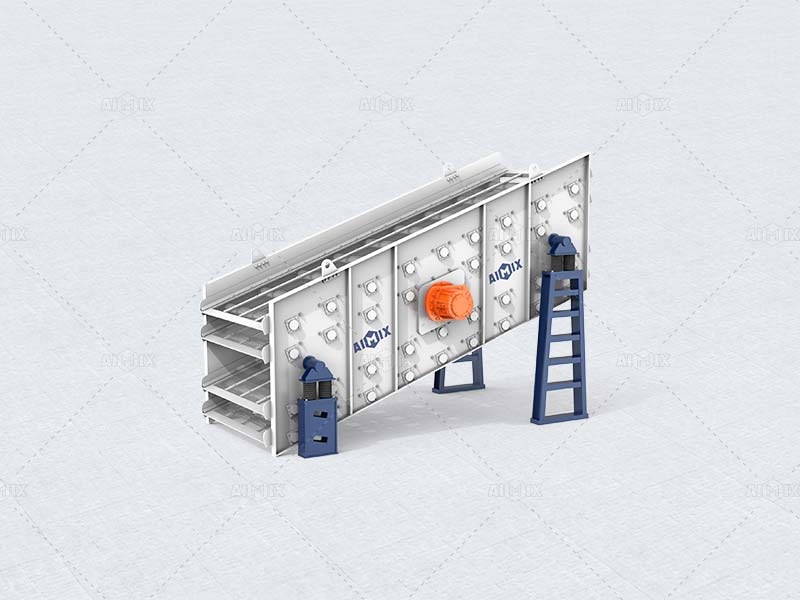

Solution: Configured a stationary crushing plant with a jaw crusher (primary), cone crusher (secondary), and vibrating screening system to ensure consistent gradation.

Customer Feedback: “AIMIX helped us achieve continuous, high-quality output. The reliability of the line significantly reduced downtime and kept our project on schedule.”

150 TPH 4-in-i Mobile Granite Crushers for Commercial Concrete Production

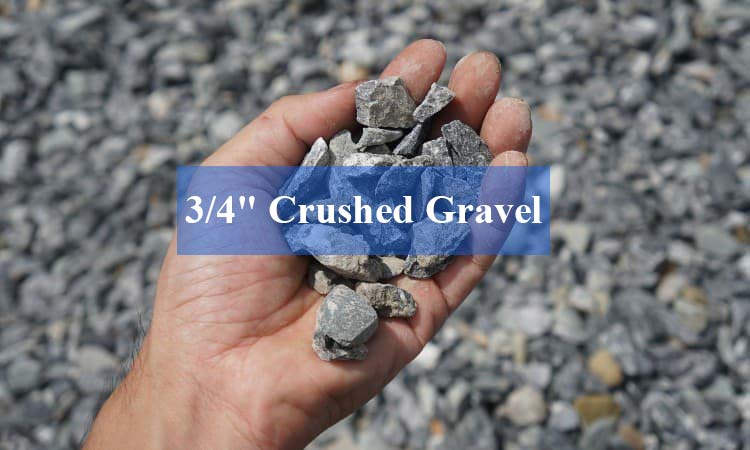

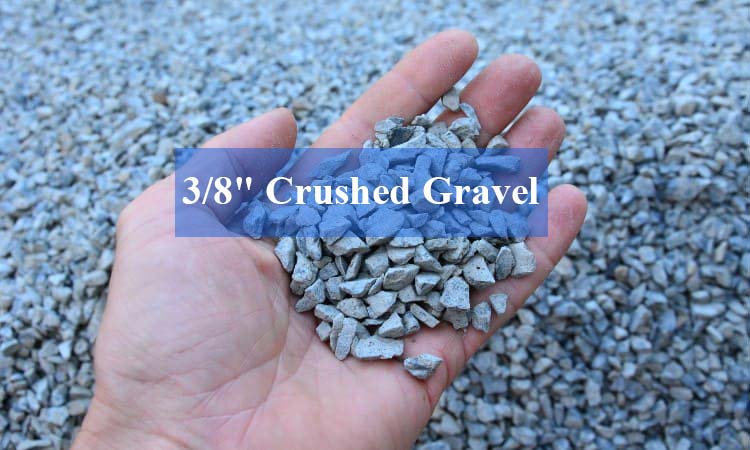

Output Size: 3/4″ and 3/8″ crushed gravel

Applications: quality aggregate production as the raw materials for concrete mixing plant, then for commercial concrete business

Client requirements: Granite hardness caused excessive wear on previous equipment; required clean, precisely sized gravel for high-strength concrete.

Solution: Delivered a mobile jaw crusher + mobile cone crusher combination equipped with wear-resistant liners and intelligent control to optimize particle shape.

Customer Feedback: “The mobile setup handles basalt incredibly well. We get stable cubic aggregates and lower maintenance costs.”

600 TPH Track Mounted Crushers for Railway Ballast

Output Size: 10–30 mm

Applications: Railway ballast manufacturing

Client requirements: Required extremely durable, angular stones; high-strength crushing capabilities; long-term operational stability.

Solution: Installed a crawler jaw crusher + cone + screening system designed for continuous, high-hardness material processing.

Customer Feedback: “AIMIX provided a robust, efficient line. The ballast meets all railway standards, and the system runs with minimal downtime.”

What Are the Typical Uses of Crushed Gravel?

Crushed gravel is produced from natural sources such as river gravel (pebbles, cobblestones) and quarried stone including limestone, granite, basalt, sandstone, and gypsum. After crushing and screening, these materials are sorted into different sizes, each designed for specific construction, landscaping, or engineering applications. Here are some common crushed gravel sizes and their applications for reference:

| Nominal Size (Inch) | Metric Size Range | Key Characteristics & Material | Primary Applications & Project Examples |

|---|---|---|---|

| 3/4″ | 5 – 19 mm | Coarse aggregate, well-graded. Often crushed limestone or basalt for high strength and durability. | Concrete Mixes: Standard aggregate for ready-mix concrete. Base Layers: Excellent for driveway, patio, and sidewalk foundations. Drainage: Used in drain fields and backfill. |

| 3/8″ | 5 – 9.5 mm | Clean, consistent chips. Can be angular crushed stone or smooth, rounded river gravel for aesthetics. | Asphalt Pavement: Top-layer aggregate for a smooth finish. Decorative Landscaping: As a loose topcoat for gardens, walkways, and driveways. |

| 1/4″ | 2.5 – 6.5 mm | Fine, compactable chips. When made from crushed river pebbles, it provides a firm yet comfortable walking surface. | Pathways & Garden Trails: Creates a stable, well-draining surface that is easy to walk on. Driveway Topping: Binds well to create a semi-solid surface. |

| 1/2″ | 5 – 13 mm | Free-draining, angular particles. The size and shape create void spaces that allow water to pass through easily. | Drainage Solutions: Ideal for French drains, pipe bedding, and septic systems. Base Stabilization: Provides a solid, well-draining sub-base for concrete slabs. |

| 1″ | 13 – 25 mm | Larger, structural aggregate. Provides solid, stable load distribution. | Sub-base Preparation: The standard for road sub-base, building pads, and parking lot foundations. General Construction Fill. |

| 2″ and Larger | 50 mm + | Very large, high-mass rock. Typically high-strength granite or basalt to withstand extreme loads. | Heavy-Duty Base: For highways, industrial sites, and heavily trafficked driveways. Erosion Control: Riprap for slopes, shorelines, and drainage ditches. |

Complete Gravel Crushing Process: From Raw Material to Final Product

Building a high-efficiency gravel crushing plant requires understanding how raw materials are transformed step by step into well-graded, market-ready aggregates. Whether the material comes from river gravel, mountain rock, or quarry stone, the production flow generally follows the same core stages: Feeding → Primary Crushing → Secondary Crushing → Screening → Sand Making → Washing. Below is a detailed breakdown of each stage and how it contributes to the final output.

Feeding

The process begins with delivering raw stones or gravel into the aggregate crusher through a vibrating feeder. Through the process, it can ensures steady, uniform feeding for stable production.

Primary Crushing

Primary crushing reduces large rocks (300–800 mm) into manageable sizes (100–200 mm). This stage determines the overall capacity and efficiency of the entire line.

- Jaw Crusher: Best for high-capacity, strong primary crushing

- Gyratory Crusher: Suitable for very large, continuous operations

Secondary Crushing

Secondary crushing further reduces stone sizes to 20–60 mm, depending on final product requirements.

- Cone Crusher: Best for hard rock like granite, basalt

- Impact Crusher: Suitable for medium-hard materials and for producing better-shaped aggregates

Screening

After secondary crushing, materials pass through vibrating screens to sort aggregates into different size categories (e.g., 0–5 mm, 5–10 mm, 10–20 mm, 20–30 mm).

Sand Making (Optional)

For production lines requiring 0–5 mm sand, the screened fine materials enter a VSI sand maker or impact sand-making machine.

Washing (Optional)

Sand and some gravels require washing to remove dust, clay, and impurities. This improves the quality and adherence of aggregates in concrete or asphalt.

Final Output

After crushing, screening, sand making, and washing, the final products may include: 0–5 mm manufactured sand; 5–10 mm fine gravel; 10–20 mm standard aggregate; 20–40 mm coarse gravel; 40+ mm ballast or base material.

Choose AIMIX – for the Safe Operation!

Crusher with High Production Efficiency

-

AIMIX gravel crushers are equipped with advanced production technologies and machinery, ensuring high efficiency in the stone crushing process. This increases overall productivity and makes operations more efficient.

Reliable Quality

-

We are a reputable gravel crusher manufacturer. We are committed to providing reliable quality products. The durability of our rock crushers ensures longevity and consistent performance, resulting in high-quality crushed stone.

Cost Effectiveness

-

While improving production efficiency, our crusher plant can also reduce production costs and improve return on investment.

Customer Service

-

We are customer-centric and provide one-to-one service to meet customer needs. We also support customized production plans and production lines, provide 3D renderings, CAD drawings, etc.

Technical Support

-

Choose AIMIX, you will get professional after-sales technical support and service. This means that customers have access to the expertise they need to maintain and resolve equipment issues, helping them run for long, trouble-free hours.

In conclusion, AIMIX crusher adopts advanced technology, reliable design and provides high-quality crusher fine gravel. We also provide professional after-sales to reduces your costs, personalized service and customized solutions. Choose us to help you achieve greater success!