Indonesia’s infrastructure boom is driving a 50% surge in demand for crushed stone, but traditional crushing methods can’t keep up. That’s why leading contractors and miners trust stone crusher Indonesia solutions from reliable manufacturers, like AIMIX Group: efficient, and built for the toughest tropical conditions.

With proven performance in major cities(Jakarta, Surabaya, Sukabumi, Medan, Balikpapan) and over 30 active projects nationwide, including limestone quarries, volcanic rocks processing, and recycling operations, our stone crusher machines in Indonesia have delivered an increase in production efficiency while reducing operational costs. Fisrt, you can have a browse how AIMIX stone crusher machine power these projects.

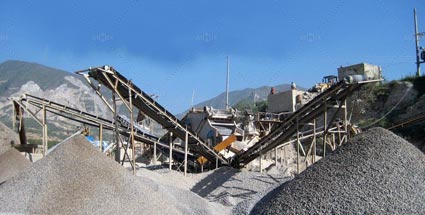

Real Cases: Stone Crusher Plant Opertion Across Indonesia

Operating Wheeled 4-in-1 Mobile Crusher Plant in Indonesia

- Raw materials: granite

- Capacity: 100tph

- Location: Sukabumi

- Configuration: feeder, jaw crusher, cone crusher, screen

- Project: aggregate production for road construction

Customer reviews: “The mobile crushers combine feeding, crushing, and screening, which has really reduced our costs and simplified our operations. I highly recommend AIMIX!”

Stationary Stone Crusher Machine Plant Operation in Indonesia

- Raw materials: limestone

- Capacity: 200tph

- Location: Tuban

- Configuration: feeder, primary jaw crusher, secondary impact crusher

- Output size: 5-10mm, 10-20mm, 20-40mm

- Project: Papermaking industry, expanding production and operations

Customer reviews: “AIMIX’s customer support has been outstanding. Their local service team guided us through the installation and were quick to respond to our questions.”

Running of Small Mobile Jaw Crushing Plant in Indonesia

- Raw materials: basalt

- Capacity: 30-50tph

- Location: Medan

- Configuration: feeder, jaw crusher, screen

- Project: For paving roadbed

Customer reviews: “Using this small mobile jaw crusher, we’re able to process more material in a shorter time, making our road base project run smoothly!”

Stationary Crusher Plant Operation Well in Indonesia

- Raw materials: Andesite

- Capacity: 80 tph

- Location: Padang

- Configuration: jaw crusher, cone crusher and screen

- Project: aggregates production for construction industry

Customer reviews: “The IoT remote monitoring technology in the crushing plant is truly cutting-edge. It allows us to track performance and troubleshoot issues in real-time, enhancing our operational efficiency.”

Different Types of Stone Crushers In Indonesia

According to the working principle of crushers, we can provide you with jaw crusher, impact crusher, cone crusher, and VSI crusher, etc. Different crushers have different working methods, so the materials produced are also different. Take a closer look at the details of various crushers.

APJ Series Jaw Crusher: The Cornerstone of Indonesia’s Mining and Construction Industry

Types: APJ-EAPJ-VAPJ-X

- Capacity: 50 – 800 t/h

- Feeding Size: ≤ 1000mm

- Output Size: 15 – 300mm

Main Application Areas/Scenarios:

- Primary crushing in large quarries/open-pit mines (especially when high production capacity is required and feed size is high);

- Commonly used in mines, construction aggregate production lines, and temporary construction sites (such as temporary crushing near road infrastructure).

- High demand is seen in locations near cities (Jakarta, Surabaya, Medan, Bali/Denpasar) and along major infrastructure projects.

| Model | Feed opening (mm) | Max feeding size(mm) | Output size(mm) | Capacity(t/h) | Power(kw) | Overal dimension(mm) | Weight(t) |

|---|---|---|---|---|---|---|---|

| APJ-1525E | 150×250 | 130 | 15-45 | 1-4 | 5.5 | 896×745×935 | 0.8 |

| APJ-2540E | 250×400 | 210 | 20-80 | 5-20 | 15 | 1450×1315×1296 | 2.8 |

| APJ-4060E | 400×600 | 340 | 40-100 | 16-60 | 30 | 1565×1732×1586 | 6.7 |

| APJ-5075E | 500×750 | 425 | 50-100 | 40-110 | 55 | 1890×1916×1870 | 11.7 |

| APJ-6090E | 600×900 | 500 | 65-180 | 80-180 | 55-75 | 2305×1840×2298 | 16 |

| APJ-7510E | 750×1060 | 630 | 80-180 | 110-320 | 90-110 | 2450×2472×2840 | 28 |

| APJ-8010E | 800×1060 | 680 | 100-200 | 140-340 | 90-110 | 2610×2556×2800 | 30 |

| APJ-8710E | 870×1060 | 720 | 170-270 | 180-360 | 90-110 | 2260×2556×2800 | 31.5 |

| APJ-9012E | 900×1200 | 750 | 95-225 | 220-450 | 110-132 | 3335×3182×3025 | 49 |

| APJ-1012E | 1000×1200 | 850 | 125-280 | 280-550 | 110-132 | 3435×3182×3025 | 52 |

| APJ-1215E | 1200×1500 | 1000 | 150-300 | 400-800 | 160-220 | 4200×3732×3843 | 101 |

APC Sreies Cone Crusher: Precision and Power in Indonesia’s Quarry Operations

Models: APC-DAPC-MAPC-CAPC-Y

- Capacity: 20 -1000 t/h

- Feeding Size: 65 – 300mm

- Output Size: 5 -10 mm; 10-40 mm

Main Application Areas/Scenarios:

- Hard bedrock quarries in Java, Sumatra, Kalimantan, and Sulawesi;

- Engineering fields requiring high fineness and controlled gradation, such as medium- to large-scale road and bridge construction, and gravel production for ports and railways;

| Model | Crushing cone diameter (mm) | Cavity | Max.feed size (mm) | Outlet adjustment range (mm) | Capacity (t/h) | Power (kW) | Dimensions L×W×H(mm) | Weight (t) |

|---|---|---|---|---|---|---|---|---|

| APC-30C | 600 (2'ft) | C | 95 | 10-38 | 20-75 | 30 | 2195×1158×1650 | 5.3 |

| F | 72 | 6-38 | 18-60 | 30 | 2195×1158×1650 | 5.3 | ||

| APC-75C | 900 (3'ft) | C | 150 | 25-38 | 59-129 | 75 | 2660×1640×2240 | 9.9 |

| M | 150 | 13-38 | 45-91 | 75 | 2660×1640×2240 | 9.9 | ||

| F | 85 | 45191 | 27-90 | 75 | 2660×1640×2240 | 9.9 | ||

| APC-110C | 1000 (3.3'ft) | C | 160 | 13-31 | 80-235 | 110 | 2760×1954×2255 | 10.8 |

| M | 115 | 45224 | 65-150 | 110 | 2760×1954×2255 | 10.8 | ||

| F | 80 | 45163 | 50-95 | 110 | 2760×1954×2255 | 10.8 | ||

| APC-132C | 1200 (3.75'ft) | C | 180 | 13-38 | 115-260 | 132 | 2850×2365×2340 | 15.5 |

| M | 130 | 45224 | 100-175 | 132 | 2850×2365×2340 | 15.5 | ||

| F | 90 | 45218 | 80-140 | 132 | 2850×2365×2340 | 15.5 | ||

| APC-160C | 1295 (4.25'ft) | C | 200 | 16-51 | 150-390 | 160 | 2960×2450×3155 | 23 |

| M | 150 | 13-25 | 115-210 | 160 | 2960×2450×3155 | 23 | ||

| F | 102 | 45218 | 90-160 | 160 | 2960×2450×3155 | 23 | ||

| APC-220C | 1400 (4.5'ft) | C | 215 | 19-51 | 200-420 | 220 | 3430×2690×3380 | 27 |

| M | 160 | 16-38 | 155-220 | 220 | 3430×2690×3380 | 27 | ||

| F | 115 | 13-22 | 150-230 | 220 | 3430×2690×3380 | 27 | ||

| APC-250C | 1650 (5'ft) | C | 235 | 22-64 | 240-570 | 250 | 3940×2954×3770 | 37.8 |

| M | 175 | 19-38 | 215-320 | 250 | 3940×2954×3770 | 37.8 | ||

| F | 130 | 13-25 | 180-275 | 250 | 3940×2954×3770 | 37.8 | ||

| APC-315C | 1800 (5.5'ft) | C | 267 | 22-64 | 330-655 | 315 | 4310×3250×4530 | 44.3 |

| M | 203 | 16-25 | 230-330 | 315 | 4310×3250×4530 | 44.3 | ||

| F | 140 | 13-22 | 185-340 | 315 | 4310×3250×4530 | 44.3 | ||

| *Note: Technical parameters are subject to change without notice. C type: coarse crushing cavity; M type: medium crushing cavity; F Type: fine crushing cavity; 1. The output is calculated based on medium-hard materials and a bulk density of 1.6t/m3. 2. The power is calculated based on medium-hard materials and an altitude below 1000 meters. 3. It can be made into an assembly module structure to meet the requirements of tunnels and transportation. |

||||||||

APF Series Impact Crusher: Transforming Waste into Resources in Urban Development

Types: APFAPF-V

- Capacity: 40 – 400 t/h

- Feeding Size: ≤500mm

- Output Size: 5 -200 mm

- Sand and gravel plants in coastal/nearshore sandstone and limestone areas (such as western/eastern Java, Madura, and parts of Sumatra)

- Mobile impact crushers for urban construction sites and demolition and regeneration projects

Main Application Areas:

| Model | Rotor diameter × length (mm) | Feed opening size (mm) | Feed particle size (Max,mm) | Production capacity (t) | Power (kW) | Weight (t) | Dimensions L×W×H (mm) |

|---|---|---|---|---|---|---|---|

| APF1007V | Φ1000×700 | 400×730 | 200 | 20-50 | 45-55 | 9.5 | 2400×1550×2660 |

| APF1010V | Φ1000×1050 | 400×1080 | 200 | 35-80 | 55-75 | 12.2 | 2400×2250×2620 |

| APF1210V | Φ1250×1050 | 570×1030 | 250 | 70-120 | 90-110 | 15 | 2690×2338×2890 |

| APF1214V | Φ1250×1400 | 570×1430 | 250 | 90-180 | 132-160 | 18.5 | 2690×2688×2890 |

| APF1315V | Φ1320×1500 | 625×1530 | 350 | 150-250 | 160-200 | 19.5 | 3096×3273×2667 |

| APF1320V | Φ1320×2000 | 625×2030 | 350 | 160-350 | 200-280 | 28 | 3096×3560×3185 |

| APF1415V | Φ1400×1500 | 800×1530 | 400 | 280-350 | 250-315 | 33 | 3220×3473×2960 |

| APF1520V | Φ1500×2000 | 1315×2040 | 500 | 300-500 | 315-400 | 43 | 3890×3564×3220 |

VSI Crusher: Crafting High-Quality Sand for Indonesia’s Growing Infrastructure

- Feeding Size: 30-55mm

- Output Size: 0-5 mm

Main Application Areas:

- Common application in areas like Java and Bali/Nusa Tenggara, where there’s a high concentration of construction projects or natural sand shortages.

- Sand making factories near large ports or cities often use VSI to replace river sand

After reading the above introduction, you may still not know much about the selection of pabrik stone crusher di indonesia. In general, the above Indonesia stone crusher does not work alone. Because a whloe crushing production line does not rely solely on a single mesin crusher, but is composed of a variety of crusher equipment and processes to achieve efficient crushing, screening and transportation of raw materials. Besides, AIMIX technical engineers would create a tailor-made crushing solution for your project! Next, you can check several customimzed crushing solutions we have offered.

Customized Crushing Solutions for Diverse Projects

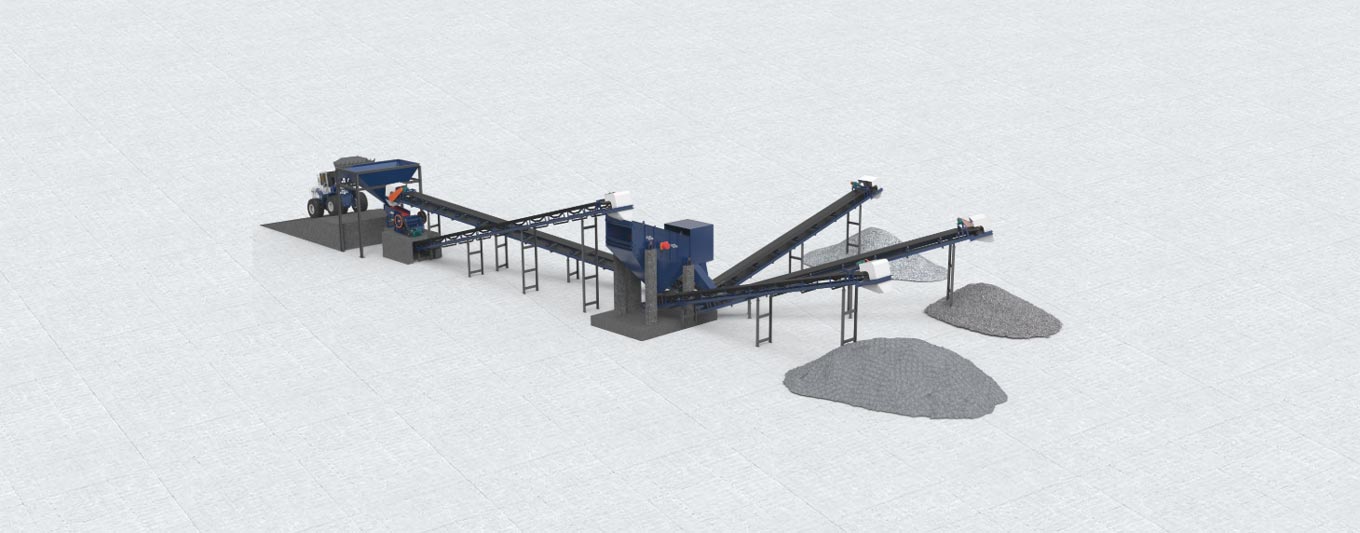

100tph Portable Stone Crusher For Aggregate Production

- Processing capacity: 100tph

- Output size: 10-15; 15-25mm

- Applications: crushing granite for aggregate production used in concrete batching plant

Main crushers: mobile jaw crusher and mobile cone crusher machine

100-200 tph Stone Crusher Machine in Indonesia For Processing Construction Waste

- Processing capacity: 100-200tph

- Finished Product: 5-15mm

- Applications: crushing construction waste bricks for recycling

Configurations: jaw crusher and impact crusher

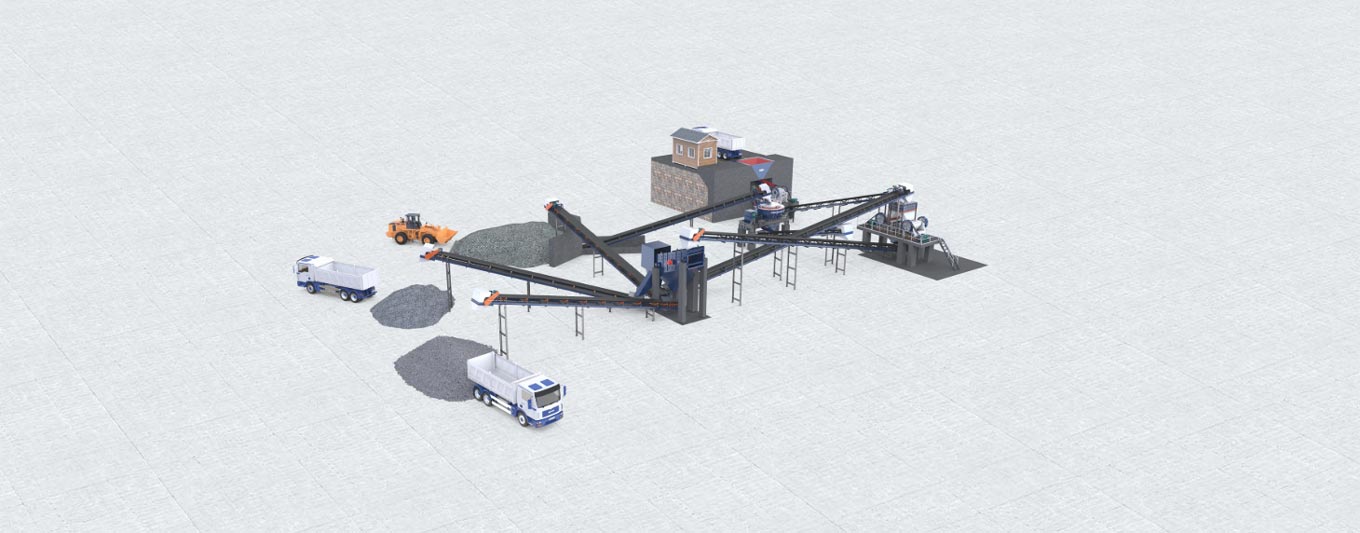

200-300tph Stationary Stone Crusher Plant for Large-sized Construction Project

- Processing capacity: 200-300tph

- Finished Product: 0-5-10-15-20mm

- Applications: processing granite for road paving

Configurations: Jaw crusher, cone crusher, and VSI crusher

30-50tph Crusher Batu Mini for Small Scale of Mining

- Processing capacity: 30-50tph

- Finished Product: 10-25mm

- Applications: small scale of mining or construction waste processing

Main configuration: 1 unit of mobile mini jaw crusher for sale Indonesia

As the solutions show, AIMIX can customized different capacities of crushing plants, both stationary and mobile stone crusher plant. And these stone crushing plants in Indonesia can use for various industries, especially for aggregate production used in construction industry, road industry, and construction waste recycling. Next, let’s learn more about its applications in these industries.

Indonesia’s Crushing Plant Market: From Construction Projects to Waste Recycling

Construction Industry

In the construction industry, stone crusher plant in Indonesia plays a vital role in producing high-quality aggregate materials. These materials are essential for:

- Concrete Production: Crushed stone and gravel serve as key components in concrete mixture production, providing strength and durability to structures.

- Foundation Construction: Aggregates are used for creating stable foundations for buildings, bridges, and other infrastructure, ensuring longevity and safety.

Widely Applied Regions:

The demand is particularly high in rapidly urbanizing areas such as Jakarta (and its surrounding satellite cities like Bekasi and Tangerang), Surabaya (East Java), and Medan (North Sumatra). These regions are experiencing significant growth in residential, commercial, and industrial construction projects, driving the need for locally sourced, cost-effective aggregates.

Road Construction Industry

The road construction industry heavily relies on stone crusher plant for sale to provide materials for:

- Base and Subbase Layers: Crushed aggregates form the foundation layers of roads, offering stability and load-bearing capacity.

- Asphalt Production: Crushed stone and gravel are crucial for asphalt mixture production, which are used in paving roads, parking lots, and driveways.

Where to Apply it:

Key regions include Sumatra (especially along the Trans-Sumatra Toll Road corridor), Java (North Coast Road and Jakarta-Cikampek Toll Road expansions), and Sulawesi (infrastructure projects connecting major ports). These areas are prioritized in Indonesia’s national infrastructure roadmap (Masterplan Percepatan dan Perluasan Pembangunan Ekonomi Indonesia 2025), making them hotspots for crushing plant deployment.

Construction Waste Recycling

- Material reuse: They crush and process concrete, bricks, and other materials from demolition sites, recycling construction waste into reusable aggregates.

Applied Regions:

Major urban centers with high construction activity and waste management challenges—such as Jakarta, Surabaya, and Bandung (West Java)—are leading adopters. For example, Jakarta’s initiatives to promote circular economy practices have driven the use of mobile crushing plants at construction sites to process waste on-site, reducing landfill dependency and transportation costs.

Let’s take a closer look at how AIMIX stone crushers are being used in 100+ construction, road building, and recycling projects across global areas.

Choose AIMIX Stone Crusher Manufacturer in Indonesia

To start stone crusher business in Indonesia, it is important for you to choose a reliable crusher machine manufacturer, like AIMIX Group. A good manufacturer not only can ensure quality and performance of products, but the best after-sales service and stone crusher harga. And AIMIX Group can provide you all. We stand out as a top choice. Our commitment to customer satisfaction and operational excellence makes us the go-to partner for your crushing needs.

Local Availability with a Branch Office and Warehouse

AIMIX is among the few Chinese manufacturers with a dedicated branch office and warehouse in Indonesia. This presence allows us to:

- Ready stock of quarry stone crusher in Indonesia, components, spare parts, allowing you to purchase locally and eliminate long wait times.

- Offer direct communication in both English and Bahasa Indonesia, ensuring smooth project coordination.

Proven Success Across Indonesia

We integrates advanced technologies into its stone crushers, ensuring higher efficiency, lower costs, and safer operations:

- Our stone crushers have already been applied successfully in different cities, like Jakarta urban construction, Sumatra quarry operations, and Sulawesi mining projects. Clients in these regions report high productivity and low maintenance issues, which highlights AIMIX’s adaptability to diverse raw materials and project conditions across the country.

Cutting-Edge Technology and Smart Features

- IoT-Enabled Monitoring: Real-time data collection and remote diagnostics to monitor machine health and predict maintenance needs.

- Integrated Control Systems: Centralized automation to adjust crushing parameters, reducing human error and optimizing throughput.

- Smart Feeding Technology: Intelligent feeding control that balances material flow, minimizes blockages, and extends wear part life.

These features make our crushing equipment not only reliable but also smarter and future-ready, ideal for Indonesia’s fast-developing infrastructure sector.

Customized Crushing Solutions for Your Project

- Recognizing the distinct nature of each project, we deliver customized crushing solutions perfectly aligned with your individual needs. Whether dealing with hard basalt in Sulawesi, limestone in Java, or recycled aggregates from urban demolition in Jakarta, our engineering team ensures you receive the most efficient stone crusher plant design, layout, and configuration for your specific needs.

Exceptional After-Sales Service

At AIMIX, we prioritize customer satisfaction through exceptional after-sales support. Our services include:

- On-Site Installation and Training: To ensure the safe operation of your mesin stone crusher, our team provides on-site installation and comprehensive training. We are committed to equipping you with the knowledge and skills necessary for effective operation, enabling you to maximize the performance of your stone crusher quarry in Indonesia.

- One-Year Warranty on Spare Parts: We offer a comprehensive one-year warranty on all spare parts. If any defective part arises within the warranty period, we will replace it at no cost to you. This commitment ensures your stone crusher operates efficiently without unexpected expenses.

- Timely After-Sales Support: We have engineers stationed overseas, ready to assist you with remote troubleshooting or on-site repairs. Our Indonesian team is committed to resolving any issues swiftly and efficiently, ensuring your peace of mind.

Backed by advanced technology and product quality, AIMIX crushing plants deliver reliable performance across Indonesia. Coupled with our responsive after-sales service, many local clients have already achieved stable and efficient operations in cities from Jakarta to Surabaya.

You are welcome to visit our running projects on-site with our guidance to see the results firsthand. Don’t hesitate to share your project requirements with us today, and our professional team will provide you with tailored solutions without delay.