Quartz crusher plays a crucial role in transforming one of the hardest natural minerals into usable materials for construction, glass, electronics, and silica production. Due to its exceptional hardness, wear resistance, and chemical stability, quartz crushing demands specialized equipment and customized solutions to ensure efficiency and product quality.

In this article, we’ll dive into the unique properties of quartz, the key crushing challenges it presents, and the innovative, customized solutions, and how AIMIX delivers efficient, reliable quartz processing plants ensures optimal performance and maximum returns.

Understanding Quartz Rocks and Its Industrial Applications

Quartz rock is one of the most abundant and versatile minerals on Earth. Its unique properties make it invaluable across numerous industries. Whether you are in construction, technology, or manufacturing, understanding quartz and its applications can help you make informed decisions for your business.

- Hardness & Durability: Ranking 7 on the Mohs scale, quartz is harder than most common construction rocks, ensuring resistance to wear and abrasion.

- Structural Stability:Its conchoidal fracture and resistance to chemical weathering allow it to maintain integrity in diverse environmental conditions.

- Crystalline Advantage:The ordered crystal structure provides transparency and stability, making it ideal for high-precision applications.

- Construction Industry: Use crushed quartz in countertops, tiles, and flooring due to its beauty and scratch-resistant surface. Engineered quartz stone is a popular choice for modern kitchens and bathrooms.

- Glass manufacturing: Quartz is a primary raw material in glass production. Its high silica content allows manufacturers to create clear, strong glass for windows, containers, and optical devices.

- Electronics: Thanks to its piezoelectric properties, it serves as a critical component in oscillators, filters, and sensors. You’ll find it in devices like smartphones, computers, and watches.

- Metallurgy and Foundries:Industries use quartz as a flux in metal smelting. It helps remove impurities and enhances the quality of the final metal product.

Having explored the remarkable properties and vast applications of quartz rock, a crucial question arises for you: how can you efficiently transform raw, rugged quartz into the specific, high-quality material that these industries demand? The answer lies squarely in selecting the quartz crushing machine. The type of rock quartz crusher you choose directly impacts your product’s size, shape, efficiency, and profitability. In the next section, we introduce a type of crusher to crush quartz rock.

Types of Crushers To Crush Quartz Rock

Crushing quartz rock requires crushers specifically designed to handle these challenges. Below are the most effective crusher types, each selected based on quartz’s physical properties and the desired output.

Jaw Crushers: Primary Crushing for Tough Quartz

Best For: Initial size reduction of large quartz chunks from mines or quarries.

Why It Works for Quartz:

- High Crushing Force: handling compressive strength above 300 MPa, making it suitable for quartz.

- Feeding Size Considerations: Quartz rock often exceeds 600 mm in diameter. It can ensure smooth feeding and prevents blockages.

- Output Particle Size: Primary jaw crushing can reduce quartz into 50–150 mm fragments, ready for secondary crushing.

Cone Crushers: Precision Secondary/Tertiary Crushing

Best For: Further reducing quartz to medium/fine sizes, used for for glass or ceramics.

Why It Works for Quartz:

- Layered Crushing Action: Interparticle crushing minimizes liner wear and produces uniform particle shapes.

- Adjustable Settings: Quartz particle size can be customized (about 5–20 mm) to meet specific industrial requirements.

- Output: Consistent, well-shaped quartz particles for downstream processes.

Impact Crushers: Producing Cubical Quartz Aggregates

Best For: When cubical-shaped quartz is needed, like used for decorative aggregates and construction.

Why It Works for Quartz:

- Effective Impact Force: Uses high-speed impact to break quartz, reducing excessive fines.

- Minimal Dust & Fines:Lower heat generation minimizes micro-cracking, preserving quartz purity.

- Versatile Feed Size: Can handle quartz hard materials with proper liner selection.

VSI Crushers: For Fine Quartz or Silica Sand (Controlled Shape & Size)

Best For: Producing precisely shaped fine quartz or silica sand, ideal for construction, water filtration, or industrial abrasives.

Why It Works for Quartz:

- Rock-on-Rock Impact:Uses a high-speed rotor to throw quartz against a wear-resistant anvil or bedrock, creating cubic or well-graded fine particles.

- Adjustable Fineness: Produces uniform fine aggregates, like 0–5 mm, with consistent shape, critical for applications requiring specific gradations.

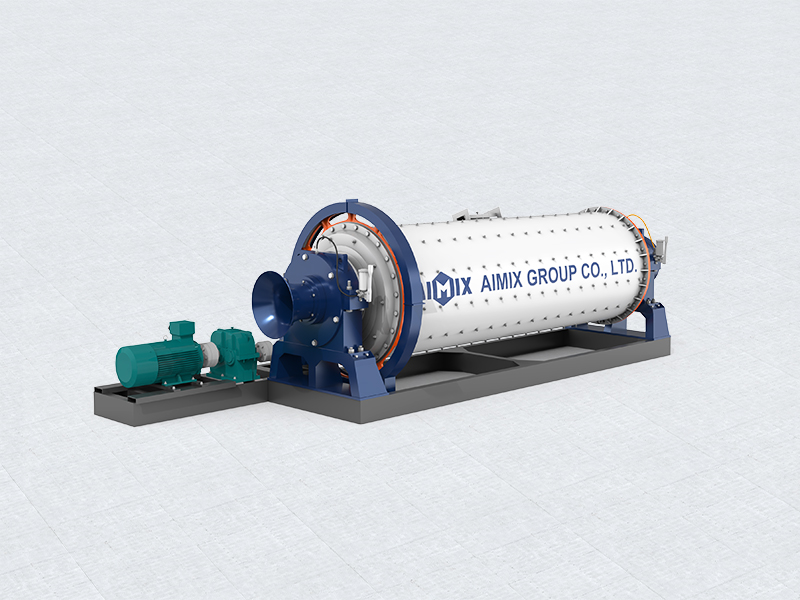

Ball Mills: For Ultrafine Quartz or Silica Powder

Best For: Producing precisely shaped fine quartz or silica sand, ideal for construction, water filtration, or industrial abrasives.

Why It Works for Quartz:

- High-Precision Grinding: Utilizes grinding media (balls) inside a rotating cylindrical chamber to reduce quartz to extremely fine particles (down to 5–100 microns or finer).

- Customizable Grind Size: Adjustable rotation speed, ball size, and milling time control final fineness for specialized uses.

Specifications

| Model | Feed opening (mm) | Max feeding size(mm) | Output size(mm) | Capacity(t/h) | Power(kw) | Overal dimension(mm) | Weight(t) |

|---|---|---|---|---|---|---|---|

| APJ-1525E | 150×250 | 130 | 15-45 | 1-4 | 5.5 | 896×745×935 | 0.8 |

| APJ-2540E | 250×400 | 210 | 20-80 | 5-20 | 15 | 1450×1315×1296 | 2.8 |

| APJ-4060E | 400×600 | 340 | 40-100 | 16-60 | 30 | 1565×1732×1586 | 6.7 |

| APJ-5075E | 500×750 | 425 | 50-100 | 40-110 | 55 | 1890×1916×1870 | 11.7 |

| APJ-6090E | 600×900 | 500 | 65-180 | 80-180 | 55-75 | 2305×1840×2298 | 16 |

| APJ-7510E | 750×1060 | 630 | 80-180 | 110-320 | 90-110 | 2450×2472×2840 | 28 |

| APJ-8010E | 800×1060 | 680 | 100-200 | 140-340 | 90-110 | 2610×2556×2800 | 30 |

| APJ-8710E | 870×1060 | 720 | 170-270 | 180-360 | 90-110 | 2260×2556×2800 | 31.5 |

| APJ-9012E | 900×1200 | 750 | 95-225 | 220-450 | 110-132 | 3335×3182×3025 | 49 |

| APJ-1012E | 1000×1200 | 850 | 125-280 | 280-550 | 110-132 | 3435×3182×3025 | 52 |

| APJ-1215E | 1200×1500 | 1000 | 150-300 | 400-800 | 160-220 | 4200×3732×3843 | 101 |

| Model | Rotor diameter × length (mm) | Feed opening size (mm) | Feed particle size (Max,mm) | Production capacity (t) | Power (kW) | Weight (t) | Dimensions L×W×H (mm) |

|---|---|---|---|---|---|---|---|

| APF1007V | Φ1000×700 | 400×730 | 200 | 20-50 | 45-55 | 9.5 | 2400×1550×2660 |

| APF1010V | Φ1000×1050 | 400×1080 | 200 | 35-80 | 55-75 | 12.2 | 2400×2250×2620 |

| APF1210V | Φ1250×1050 | 570×1030 | 250 | 70-120 | 90-110 | 15 | 2690×2338×2890 |

| APF1214V | Φ1250×1400 | 570×1430 | 250 | 90-180 | 132-160 | 18.5 | 2690×2688×2890 |

| APF1315V | Φ1320×1500 | 625×1530 | 350 | 150-250 | 160-200 | 19.5 | 3096×3273×2667 |

| APF1320V | Φ1320×2000 | 625×2030 | 350 | 160-350 | 200-280 | 28 | 3096×3560×3185 |

| APF1415V | Φ1400×1500 | 800×1530 | 400 | 280-350 | 250-315 | 33 | 3220×3473×2960 |

| APF1520V | Φ1500×2000 | 1315×2040 | 500 | 300-500 | 315-400 | 43 | 3890×3564×3220 |

| Model | Crushing cone diameter (mm) | Cavity type | Maximum feed size (mm) | Adjustment range of discharge port (mm) | Processing capacity (t/h) | Mixing power (km) | Dimension (L×W×H) (mm) | Weight (t) |

|---|---|---|---|---|---|---|---|---|

| APC-600Y | 600 (2’ft) | B | 65 | 12-25 | 12-25 | 30 | 1740×1225×1940 | 5.5 |

| D | 35 | 3-13 | 5-23 | |||||

| APC-900Y | 900 (2’ft) | B | 115 | 15-50 | 50-90 | 55 | 1990×1640×2380 | 10.2 |

| Z | 60 | 5-20 | 20-65 | |||||

| D | 40 | 3-13 | 15-50 | |||||

| APC-1200Y | 1200 (2’ft) | B | 145 | 20-50 | 110-200 | 110 | 2805×2300×2980 | 25.5 |

| Z | 100 | 8-26 | 50-150 | |||||

| D | 50 | 3-15 | 18-105 | |||||

| APC-1750Y | 1750 (2’ft) | B | 215 | 25-60 | 280-480 | 160 | 3610×2950×4185 | 50.5 |

| Z | 185 | 10-30 | 115-320 | 51 | ||||

| D | 85 | 5-15 | 75-230 | 52 | ||||

| APC-2200Y | 2200 (2’ft) | B | 300 | 30-60 | 590-1000 | 260-280 | 4790×3430×5080 | 84 |

| Z | 235 | 10-30 | 200-580 | 85 | ||||

| D | 110 | 5-16 | 120-340 | 85 | ||||

| *Note: Technical parameters are subject to change without prior notice. 1.Standard B type is generally used in medium crushing. 2.Medium Z type is generally used for medium and fine crushing. 3.Short head D type is generally used for fine crushing. |

||||||||

Key Considerations for Your Quartz Crusher Selection

When selecting a quartz crusher, it’s essential to consider the entire quartz crushing process as a complete system rather than just individual quartz stone crusher. This comprehensive approach ensures that all stages, like primary crushing, secondary or fine crushing, screening, and layout customization, work harmoniously together. Here are some key considerations to guide your selection:

Desired Output Size

-

Tailor your choice of quartz rock crusher to achieve the target granularity.

- For coarse aggregates, jaw or cone crushers are effective, while for finer outputs, impact crushers or VSI crushers are more suitable.

- For ultra-fine powder, a ball mill is the best option, ensuring precise control over particle size.

Production Scale

-

The scale of your operation will significantly influence your quartz crusher plant choice.

- Large mining operations may benefit from a combination of jaw, cone, and VSI crushers to handle varying sizes and volumes efficiently.

- In contrast, smaller labs or specialized operations may find that small capacity crusher or ball mills suffice for producing specific powders.

Downstream Use

-

The end use of the crushed quartz is critical.

- For instance, electronics-grade quartz requires ultrafine, contamination-free grinding, which is best achieved with ball mills.

- Conversely, if the goal is to produce construction sand, a sand making machine will deliver durable, well-shaped aggregates suitable for construction applications.

System Integration

-

Integrating all stages of the crushing process ensures optimal performance. Each stage should be designed to complement the others, from primary crushing through to final dust collection, to maintain a smooth workflow and minimize operational disruptions.

Flexibility of Crushing Solutions

-

Consider whether a mobile or stationary quartz crushing plant is best for your operation.

- Mobile quartz crusher for sale offers flexibility and the ability to quickly relocate to different sites, making them ideal for projects with varying locations or smaller-scale operations.

- On the other hand, stationary crushing plants are typically more robust and can handle larger volumes of material, making them suitable for large-scale mining operations where a fixed setup is advantageous.

Assess your site requirements, production needs, and logistical considerations to determine the most effective solution.

Hardness & Abrasiveness

-

Given the hardness of quartz, prioritize quartz crusher equipped with wear-resistant components. Materials such as manganese steel, tungsten carbide, or ceramic liners are ideal for enduring the abrasive nature of quartz, thus prolonging the lifespan of your equipment.

Customization and Layout

-

Customizing the layout of your crushing system allows for a more efficient operation. This includes considering the flow of materials, the positioning of equipment, and the overall space available, which can significantly impact performance and efficiency.

Maintenance and Support

-

Choose equipment from reputable quartz crusher manufacturers that provide robust support and maintenance services. This ensures that your crushing system remains operational and effective over the long term.

By viewing quartz crushing as a complete system, you can make informed decisions that enhance efficiency, effectiveness, and sustainability.

Understanding the key factors is the first step. Now, let’s see how these principles come together in a real-world scenario. At AIMIX, we engineer tailored solutions that maximize your profitability. The following quartz crusher case shows how we designed a complete crushing plant to overcome specific challenges for a quartz processing project.

Tailored Solutions: 150 tph Quartz Stone Crushing Plant Case

Challenge:

- Produce high-purity quartz sand for glass/ceramics across multiple sites. Needed flexible mobile solution with washing capability.

- A precise output of medium and fine sand between 0-3mm.

AIMIX Mobile Solution:

- APG-3895W (vibrating feeder) + APJ-6090E (jaw crusher) + APC-160C (middle crushing compound cone crusher) + APS-1860Y2 (primary vibrating screen) + APV-9532 (vsi sand making machine) + APW-2816D (sand washing machine)

Results Delivered:

- Capacity: Exceeded yield requirements with a capacity of 150 TPH.

- Product Quality: Delivered clean, well-shaped quartz sand (0-3mm) ideal for glass and ceramics.

- Flexibility: Mobile crusher plant configuration enabled easy relocation of the production line for operational adaptability.

Challenges and Solutions in Crushing Quartz Rock

Crushing quartz, known for its extreme hardness and abrasiveness, presents unique challenges that can impact your operational costs and productivity. Understanding these challenges and their modern solutions is key to running a profitable operation.

Challenge 1: Severe Wear on Parts

Quartz’s high silica content quickly wears jaws, mantles, and liners.

Solutions: Use wear-resistant alloys, rotate parts regularly, and keep critical spares on-site to reduce downtime.

Challenge 2: Excessive Dust Generation

Fine silica dust threatens worker health and regulatory compliance.

Solutions: Apply water spray systems, seal transfer points, and use baghouse collectors for effective dust control.

Challenge 3: Product Shape and Yield

Producing cubical particles for sand or is difficult; flaky particles reduce product value.

Solutions: Use VSI quartz sand crusher for better shaping, optimize rotor speed and feed, and run closed-circuit systems with screens for consistency.

Challenge 4: High Energy Demand

Quartz requires significant power to crush, raising energy costs.

Solutions: Invest in efficient motors and variable frequency drives, and size the whole circuit correctly to avoid bottlenecks.

Overcoming quartz crushing challenges also demands smart strategies. Partnering with an experienced quartz rock crusher machine supplier, like AIMIX Group, ensures the right equipment and solutions to maximize efficiency and ROI.

Why AIMIX is Your Partner for Quartz Crushing Solution

You understand the challenges of quartz crushing. You’ve seen the solutions. Now, the most critical decision remains: choosing the right partner to implement them. Beyond just machinery, you need a collaborator with the expertise, technology, and commitment to ensure your operation’s long-term profitability. Here’s why AIMIX is that partner.

Deep-Dive Expertise, Not Just Equipment

-

Our engineering team begins with a thorough analysis of your specific quartz composition and production goals. This allows us to recommend a perfectly tailored circuit flow—whether it’s a stationary plant for high-volume output or a mobile setup for multi-site flexibility—ensuring every piece of equipment works in harmony for maximum efficiency.

Engineered for Quartz’s Extreme Abrasion

-

Standard crushers wear down. AIMIX crushers are built to endure.

- Premium Wear Components: We use ultra-high manganese steel and custom-developed alloys for liners, rotors, and impact tips, significantly extending service life in high-silica environments.

- Crusher-Specific Designs: Our VSI crushers feature optimal rotor designs for superior rock-on-rock action, producing perfectly shaped cubical sand while minimizing wear on parts.

End-to-End Support: From Blueprint to Production

-

Your success continues long after installation. Our comprehensive support system ensures it.

- Free Process Flow Design: Our experts provide a detailed plant layout and flow chart tailored to your site and capacity.

- On-Site Installation & Training: We dispatch engineers to oversee commissioning and train your crew on operation and maintenance best practices.

Proven ROI Through Reliability and Efficiency

-

Your success continues long after installation. Our comprehensive support system ensures it.

The AIMIX crushing solution is an investment in lower operating costs. Our plants are designed for high energy efficiency, reducing your cost per ton. Combined with our durable components and remote monitoring capabilities, we help you achieve the highest possible return on investment by maximizing uptime and output.

Choose AIMIX for a more reliable, efficient, and profitable quartz crushing operation. Partner with us today to discover how to elevate your business and take the next step toward success!