Mobile concrete batching plant solves the toughest construction challenges—rising transport costs, project delays, and hard-to-reach sites. By producing high-quality concrete directly on-site, it cuts hauling time, lowers expenses, and keeps projects on schedule. Ideal for remote, urban, or fast-moving works, a mobile batching plant delivers efficiency, flexibility, and reliability exactly where and when you need it.

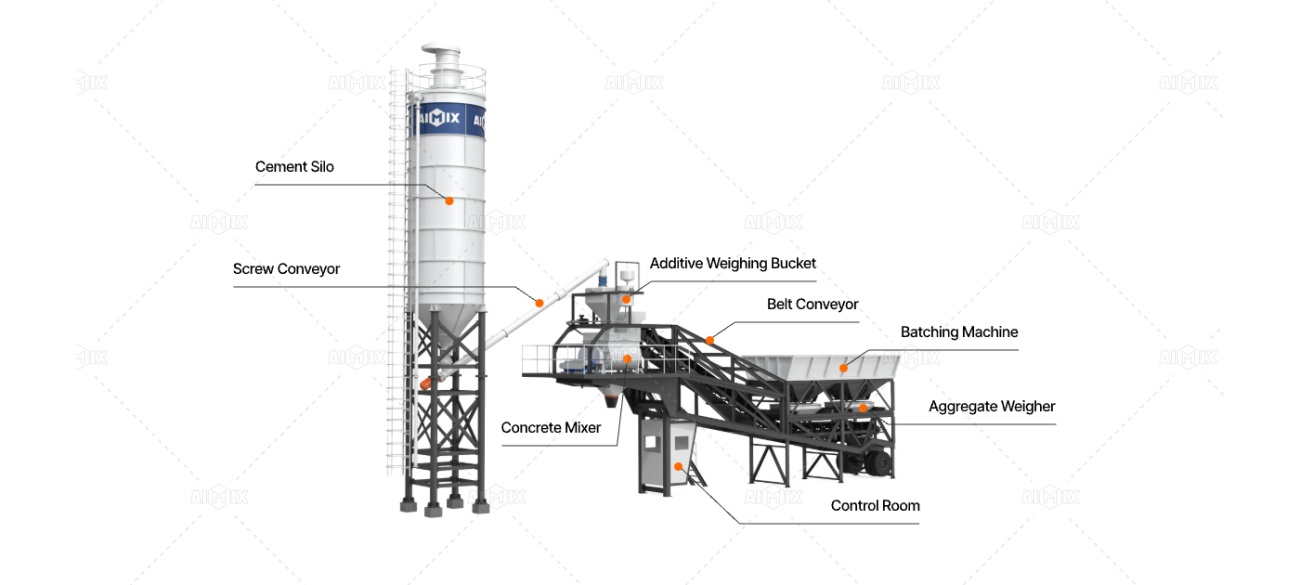

What is a Mobile Concrete Batching Plant? Full Definition and Key Components

A mobile concrete batching plant is designed for portability without compromising performance. Its modular structure allows for quick setup and relocation, making it suitable for projects that require frequent movement or temporary installations. Despite its compact size, it incorporates all essential systems for precise concrete production, ensuring consistent quality for every batch.

Main Components of a Mobile Concrete Batch Plant

Aggregate Bins / Storage Hoppers

Hold sand, gravel, and crushed stone separately for easy feeding.

Conveyor System

Transfers materials from the bins to the weighing and mixing units efficiently.

Weighing System

Ensures accurate measurement of aggregates, cement, water, and chemical additives.

Mixing Unit

Blends all ingredients uniformly to produce high-quality concrete.

Cement Silo

Stores cement and powder materials with dust control for environmental compliance.

Water and Additive System

Supplies water and chemical admixtures for desired concrete properties.

Control System

Automates batching, weighing, and mixing to maintain efficiency and consistency.

These components work together to provide a versatile, efficient, and reliable solution for producing concrete anywhere it’s needed.

Mobile Batching Plant Types for Various Requirements

AJY Series Mobile Concrete Batching Plant

Aimix AJY series mobile concrete batching plant allows direct discharge into a concrete mixer truck. It ensures higher mixing efficiency and consistency, making it well-suited for projects requiring ready-mixed concrete with stable quality and quick delivery. The plant’s production capacity can reach up to 100 m³/h, or even higher depending on project requirements.

Highly Integrated & Modular DesignCore components mounted on a mobile chassis; quick assembly and disassembly. Setup typically takes 1–3 days, far faster than fixed plants which require 3–4 weeks.

Strong MobilityTire-mounted chassis can be towed across roads and construction sites. Supports non-paved or rough terrain, solving the “fixed location” limitation.

Automated Control SystemIntelligent batching, mixing, and discharge; high precision (aggregates ±2%, cement/water ±1%). Reduces human error and ensures consistent concrete quality.

Low Site RequirementsOnly a level surface (≤3°) is needed, occupying 300–500㎡. Ideal for temporary sites, urban spaces, and remote areas.

Environmentally Friendly & SafeDust collection system and safety guards included. Minimizes environmental impact and ensures worker safety.

Easy Maintenance & Cost-EffectiveModular components for simple servicing. Lower maintenance and transport costs than comparable stationary batching plants.

AJSY Series Mini Mobile Concrete Plant

Designed for maximum flexibility, our AJSY mobile compact batching plant can be quickly installed and relocated between job sites. It is ideal for “small-batch, high-frequency” production scenarios such as maintenance works, small infrastructure projects, and temporary construction sites, providing fast setup and efficient operation. The most popular models are the AJSY-20 and AJSY-40.

Ultra-Low Cost & Micro-Scale Adaptability

Perfect for rural houses, thin-layer road paving (5–10 cm), and small irrigation works, avoiding oversized equipment waste.

Extremely Lightweight & Easy Relocation

Whole unit weight of 3–8 tons, towable by standard trucks. Road-adaptable for rural dirt roads, narrow alleys, and even directly to the construction site.

Highly Integrated & Quick Installation

Core components (mixer, micro batching machine, water tank, simplified control) on a single chassis. 1–2 people can install and start production within 1–3 hours, enabling same-day operation.

Low Investment & Easy Maintenance

Affordable for individual contractors, small construction teams, or village builders. Simplified structure with minimal wear parts (blades, liners), low energy consumption, easy self-maintenance.

Simple Operation & Fast Learning Curve

Manual or semi-automatic control; some models feature a basic PLC. Remote control and touch screen operation make it intuitive for non-professional operators.

Small Footprint & Site Flexibility

Occupies only 200㎡; can be placed in courtyards, fields, or narrow site corners. Close placement to work areas reduces concrete transport distance and minimizes segregation.

Complete Basic Functionality

Supports standard concrete grades C15–C30 for small buildings or components. Ensures reliable slump and workability, meeting basic construction quality standards.

AJZY Series Drum-Type Mobile Concrete Plant – Continuous, Efficient, and Flexible

Our AJZY drum-type mobile concrete plant is equipped with a rotating drum mixer, making it ideal for producing plastic and semi-dry concrete. It offers a cost-effective solution with simple operation and easy mobility, perfectly suited for small-scale construction projects where concrete quality requirements are moderate.

Compact Structure & Efficient Mobility

- Integrated design: Mixer drum, batching system, and control system on a single trailer or mobile frame.

- Quick relocation: Towable to site, adaptable to dirt roads, narrow alleys, and other complex terrains.

- Fast setup: Only a level surface (≤3°) required; 1–3 hours to complete installation and start production.

Capacity Suited for Small to Medium Projects & Energy Efficient

- Production capacity: uo to 75 m³/h, ideal for small-scale housing, village roads, or minor water conservancy projects.

- Low power demand: Drum-based self-fall mixing relies on gravity, minimizing energy consumption.

Unique Mixing Principle & Material Adaptability

- Self-fall mixing: Materials lifted by drum blades then fall freely, achieving uniform mixing.

- Suitable for plastic or semi-dry concrete (C15–C30) and asphalt mixtures.

Simple Operation & Low Maintenance

- User-friendly control: Manual or semi-automatic operation; PLC-equipped models offer one-touch start/stop and fault diagnostics.

- Low maintenance: Simplified structure; main wear parts are blades and liners, easily replaceable on-site.

Strong Site Adaptability

- Minimal site requirements: Footprint only 100–300㎡ (compared with 300–500㎡ for forced-type mobile plants).

- Can be deployed in courtyards, fields, or narrow site edges, minimizing concrete transport distance and preventing segregation.

On-Site Efficiency: Mobile Concrete Plants Powering Diverse Projects

AJY-75 Mobile Concrete Batch Plant for Government Project in Ethiopia

The client needed a concrete production solution that could fully comply with strict government standards. The project required high-quality concrete, reliable output, and strict adherence to regulatory specifications, with minimal reliance on external suppliers.

- Provided AJY-75 mobile batching plant with a production capacity of 75 m³/h.

- Equipped with JS1500 twin-shaft mixer for fast, uniform mixing.

- Designed as a cost-effective, high-capacity mobile solution, capable of producing consistent concrete on-site.

- Successfully met all technical and governmental quality standards.

- Enabled efficient on-site batching, reducing delays and dependency on external ready-mix suppliers.

- Maintained consistent concrete quality throughout the project, supporting timely and reliable completion.

- Provided the client with flexibility to adjust production according to project progress, enhancing overall operational control.

AJSY-35 Small Mobile Concrete Batching Plant for Roadbed Paving in Malaysia

The Malaysian client required a small-scale mobile batching plant suitable for limited space, complex terrain, and a tight project timeline. Quick relocation and rapid setup were critical to ensure production could start immediately upon arrival.

- Recommended AJSY-35 portable batching plant, designed for compact installation and fast assembly.

- Modular design allowed swift transportation and on-site setup.

- Ensured full operational capability in constrained areas with challenging site conditions.

- The plant was fully installed and operational in just 10 days, demonstrating rapid deployment capability.

- Enabled on-demand concrete production, eliminating delays from third-party suppliers.

- Improved project flexibility, allowing the client to efficiently manage paving schedules in limited working areas.

- The customer reported high satisfaction with the plant’s performance, reliability, and ease of operation.

AJZY-50 Mobile Concrete Mixing Plant – Warehouse Construction in Indonesia

The customer needed a one-stop mobile concrete production solution for their warehouse project to reduce costs, ensure quality control, and avoid dependency on external concrete suppliers.

- Provided the AJZY-50 drum-type mobile mixing plant for concrete production

- Together with self-loading mixer, excavator, and wheel loader.

- Ensured all essential equipment was available for efficient on-site production.

- Enabled customized production schedules to meet project-specific demands.

- Streamlined workflow and cut transportation costs significantly.

- Delivered consistent concrete quality, meeting the customer’s project standards.

- Improved control over production and delivery schedules, optimizing efficiency.

- Minimized operational risks and enhanced on-site flexibility, allowing the customer to manage multiple tasks efficiently.

Why a Mobile Concrete Mixing Plant is the Smart Choice: 5 Key Advantages

Investing in a mobile concrete mixing plant brings a powerful combination of operational efficiency, cost savings, and project flexibility. Here are the five key advantages:

Unmatched Flexibility and Mobility

Mobility is the cornerstone advantage. A mobile batch plant allows you to “follow the work.” Whether you’re working on a 50-kilometer highway stretch or multiple housing developments across a county, your concrete production moves with the project. This capability eliminates the distance barrier, enabling contractors or companies to take on projects that were previously logistically impossible or financially unviable due to transport costs.

Rapid Setup and Dismantling

Time is money in construction. While a stationary concrete plant can take weeks to install, a mobile plant usually can be setup within 1-3 days. Quick deployment allows you to start generating revenue almost immediately, and fast dismantling ensures you can move to the next project without costly delays.

Significant Cost Reduction

- Transportation Savings: On-site production greatly reduces or eliminates ready-mix delivery fees, which can be substantial for distant sites.

- Reduced Waste: Controlled on-demand batching minimizes costly unused concrete, often 10–15% of deliveries.

- Lower Initial Investment: Mobile concrete mixer plants generally require a smaller capital outlay than stationary plants, as they avoid expensive foundations, permanent structures, or complex installation.

Ideal for Diverse Project Sites

Mobile plants thrive in challenging environments. They are suitable for remote areas with no infrastructure, constrained urban sites, and environmentally sensitive locations where minimizing the footprint is critical. Their versatility expands the range of potential projects users can undertake.

Enhanced Environmental Compliance

Modern mobile batching plants are built for sustainability. Many include advanced dust collection systems at the cement silo and loading points, and closed-loop water recycling systems to reuse process water and slurry. This reduces water consumption and prevents contaminated water from leaving the site, helping comply with strict environmental regulations.

How to Choose the Right Mobile Concrete Batching Plant: A Practical Buyer’s Guide

Selecting the ideal mobile concrete batching plant is crucial for ensuring your project runs efficiently and cost-effectively. This guide helps you evaluate production needs, equipment features, and supplier reliability. If you are looking to buy a mobile plant, these considerations will guide your decision.

Determine Your Production Capacity (m³/h)

Production capacity is the first and most critical consideration. Mobile plants are classified by their maximum theoretical output, often indicated in model numbers like Aimix AJY60 (60 cubic meters per hour). Carefully analyze your project’s peak daily concrete requirements to select a concrete plant that meets demand without oversizing, which could unnecessarily increase costs.

Evaluate Key Components and Specifications

- Mixer Type: Twin-shaft mixers offer powerful, high-intensity mixing action, ideal for producing large volumes of durable, high-strength concrete efficiently and consistently. Planetary mixers ensure superior homogeneity and precision, perfect for fine-grained, semi-dry, or precast concrete requiring excellent surface quality.

- Control System: Choose a fully automated PLC system to ensure precise measurement of aggregates, cement, water, and additives. Automation guarantees consistent batch-to-batch quality and reduces reliance on skilled operators.

- Weighing System Accuracy: High-precision load cells for aggregates and powders are essential to meet strict engineering specifications.

- Cement Silo Capacity: Silos typically range from 50–200 tons. Larger silos reduce the frequency of deliveries, especially critical for remote sites.

Consider Logistical and Site Factors

- Site Access & Ground Conditions: Ensure roads allow safe towing, and the site is stable enough to support plant operation.

- Transport Regulations: Check local weight and dimension limits. This may affect your choice between single-trailer units or modular setups.

Evaluate the Manufacturer and Supplier

A mobile concrete batching plant is a long-term investment that depends heavily on the manufacturer’s expertise and service quality. When evaluating potential suppliers, focus not only on price but also on their technical capabilities and project experience. Check their:

- After-sales service network and spare parts availability: Ensure fast delivery of critical components to minimize downtime.

- Technical support and installation supervision: Confirm that the supplier provides on-site guidance or remote commissioning assistance.

- Operator training and maintenance programs: Proper training ensures efficient plant operation and prolongs equipment lifespan.

- Response and communication efficiency: A supplier who responds quickly to technical inquiries helps maintain continuous productivity.

Partnering with a reliable and experienced manufacturer ensures smooth installation, stable operation, and consistent technical support—making your investment in a mobile batching plant for sale secure and worthwile.

Maximizing Value When Investing in a Mobile Concrete Batch Plant

Investing in a mobile concrete batch plant involves more than the initial purchase—it’s about balancing cost, performance, and long-term value. For example, the AJY series mobile concrete batching plant price from Aimix typically starts at $38000, depending on production capacity, automation level, and configuration. Smaller, compact models suit short-term or low-volume projects, while larger, fully automated units are better for continuous, high-volume concrete production.

Beyond the purchase price, the total mobile batching plant cost includes setup, transportation, raw materials, maintenance, fuel, and labor. Efficient planning and operation can reduce unnecessary expenses and extend the plant’s service life, ensuring a higher return on investment.

Tips for Maximizing Investment Value

Prioritize High-Quality Components

Choose robust mixers, accurate weighing systems, and advanced control units to guarantee steady concrete output and reduce unplanned maintenance costs.

Evaluate Total Cost of Ownership (TCO)

Consider the complete financial picture—including maintenance, power usage, spare parts, and labor—to understand the true long-term mobile concrete plant price.

Adopt Modular or Custom Designs

Select a plant layout that meets your immediate production targets but allows flexible upgrades or relocation for future projects.

Build Long-Term Supplier Partnerships

Work with mobile concrete batching plant manufacturers who offer continuous product updates, reliable technical assistance, and easy access to genuine spare parts—ensuring the best lifecycle performance of your investment.

Maximizing value isn’t about choosing the cheapest plant—it’s about securing durability, efficiency, and consistent performance, reducing downtime, and achieving long-term profitability while managing the mobile concrete plant cost effectively.

Your End-to-End Partnership: From Investment to Long-Term Success

At Aimix, we do more than sell equipment—we become your strategic partner. Our comprehensive service is designed to reduce investment risks, streamline project execution, and maximize profitability throughout the lifecycle of your concrete plants. Here’s how our seamless, value-driven service works across all project phases:

| Phase | Core Service | Key Highlights & Commitment | Value to You |

|---|---|---|---|

| Pre-Sales | Consulting & Planning | In-depth project consultation and overall layout planning. | Reduces Investment Risk & Optimizes Budget – Provides clarity for a safe, informed investment decision. |

| Dedicated Integrated Support Team | Specialized team (Sales, Technical, Project) aligns your needs with the optimal solution. | Ensures Project Success – Guarantees solution-fit, reduces communication overhead, and ensures smooth final acceptance. | |

| Profitability Analysis | Data-driven financial models projecting ROI and payback period. | Safer Decision-Making – Lowers investment risk with a clear financial outlook. | |

| Sales | Real-Time Information Service | Proactive updates and sharing of project milestones and documents. | Saves Time & Cost – Reduces installation time and prevents costly project delays. |

| Strict Quality Control | Pre-delivery checks including no-load testing and detailed inspection reports. | Ensures Reliability & Longevity – Minimizes early failures, shortens commissioning, and extends equipment lifespan. | |

| Professional Transport Service | Customized packaging, strategic crating, reinforced protection. | Guarantees Safe & On-Time Delivery – Protects your asset and ensures timely arrival. | |

| After-Sales | Comprehensive Training | Operational and maintenance training for your team. | Reduces Operational Errors – Lowers installation difficulty and future repair costs. |

| Flexible Installation Support | Remote guidance, on-site service, or support from local service points. | Smooth Project Handover – Reduces complexity and saves on labor costs. | |

| Rapid Troubleshooting | 24-hour resolution for operational faults. | Minimizes Downtime Loss – Keeps operations running and revenue flowing. | |

| Proactive Health Check-Ups | Regular follow-ups to monitor equipment status and provide preventative guidance. | Boosts Productivity & Safety – Enhances efficiency, prevents hazards, and extends service life. |

Why Aimix Service is Your Competitive Advantage

Holistic Support

We are with you every step of the way — from initial planning to daily operations.

Risk Reduction

We help minimize investment risks through careful planning, strict quality control, and reliable support.

Efficiency and Cost Savings

Streamlined processes, preventive measures, and expert guidance save you both time and money.

True Partnership

Our dedicated Integrated Support Team ensures your goals come first, delivering practical solutions tailored to your project.

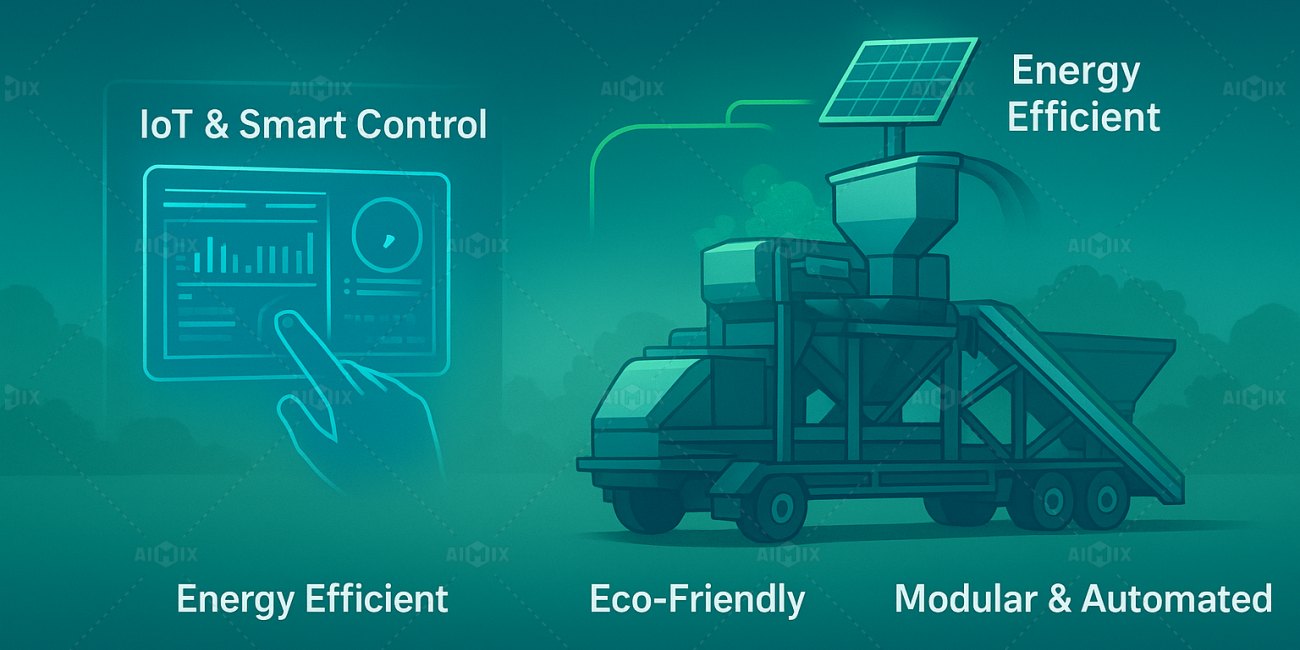

Future Trends in Mobile Batch Plants: Smarter, Greener, and More Efficient

Smart Technologies for Real-Time Control

Modern plants increasingly incorporate IoT-enabled systems for real-time monitoring, remote control, and predictive maintenance. These features allow users to optimize production, detect issues before they escalate, and maximize uptime.

Energy-Efficient Operations

New-generation mobile batching plants focus on reducing energy consumption through optimized mixing processes, efficient motors, and power management systems. This not only lowers operational costs but also minimizes the environmental footprint.

Eco-Friendly Construction Solutions

Advanced plants are equipped with dust collection systems, low-noise mixers, and precise material dosing. These innovations reduce cement waste, protect local air quality, and support environmentally responsible construction practices.

Modular Design and Advanced Automation

Modular layouts allow rapid assembly and relocation, while automation systems ensure consistent output, reduce labor requirements, and improve overall operational efficiency.

Partner with Aimix for Reliable Mobile Batching Plants or Become a Distributor

Elevate your business with Aimix’s high-quality mobile concrete batching plants. Designed for fast, efficient, and cost-effective concrete production, our mobile plants are perfect for a wide range of construction projects—from residential buildings to large-scale infrastructure.

Whether you need a mobile batching plant for your own operations or want to become a distributor, Aimix offers:

Competitive PricingGet the best value without compromising quality.

Comprehensive SupportFrom installation and training to after-sales service.

Proven ReliabilityTrusted by customers worldwide for consistent performance.

Join Aimix as a distributor and enjoy exclusive benefits, access to a growing customer base, and long-term business success in the concrete industry. Contact us today to explore partnership opportunities and deliver premium, reliable concrete solutions to your market.