Concrete batching plant for sale in South Africa plays a vital role in supporting the local construction industry by offering a cost-effective and efficient way to produce high-quality concrete. With a rapidly evolving market driven by infrastructure projects, urban regeneration, and housing developments, the demand for the plants has grown significantly. Aimix provides customized concrete plant solutions to meet the unique needs of construction projects across South Africa.

Market Overview in South Africa

Construction Industry Landscape

South Africa’s construction sector has shown signs of steady recovery, supported by government infrastructure investments and private real estate projects. From roads and highways to renewable energy facilities and residential communities, the scope of development is broad and geographically widespread.

As more construction companies take on diverse projects, they require consistent concrete supply that traditional off-site mixing facilities cannot always guarantee. This is where having a concrete batching plant becomes not just useful—but critical to project success.

Market Needs and Challenges

One of the main challenges in South Africa is the logistics of transporting concrete over long distances. Delays can compromise the quality of the mix, leading to weaker structures or costly project setbacks. There is also a growing push toward sustainable construction and environmentally responsible practices.

Therefore, there’s a strong market need for mobile and stationary batching plants that can be customized for urban or remote job sites, support eco-friendly operation, and improve efficiency.

Economic Considerations

While budget is always a factor, many contractors now recognize that the long-term savings from owning a concrete batching plant South Africa—through reduced concrete procurement costs, better mix control, and operational efficiency—far outweigh the initial investment.

Typical Applications of Concrete Batching Plants in South Africa

Infrastructure Development

Government projects such as the Strategic Integrated Projects (SIPs) prioritize roads, rail, energy, and water infrastructure—each requiring a massive and consistent supply of concrete. Stationary concrete plants serve as permanent setups for these high-volume needs, ensuring that large-scale mixes are delivered continuously.

Urban and Rural Housing

Housing projects, especially RDP housing and private developments, are growing. Here, mobile batching plants South Africa are invaluable. They allow builders to produce fresh concrete on-site, reducing delays and improving the speed of construction.

Remote and Industrial Projects

Mining operations, wind farms, and agricultural infrastructure located far from urban centers also rely on portable or mobile concrete batching plants. These can be set up close to the action, reducing the need for long-haul transport.

Ready-Mix Production

Some contractors even use plants to start their own ready mix concrete plant for sale operations, selling concrete to local builders and becoming small-scale manufacturers.

Suitable Types of Concrete Batching Plant for Sale in South African Market

Stationary Batching Plant – Ideal for Large-scale Projects in South Africa

Best suited for large-scale and long-term projects, stationary concrete batching plants for sale in South Africa are known for their high output capacity (production up to 240 m³/h or more). These plants typically feature silos, twin-shaft mixers, and robust automation systems. Our AJ series stationary plants are available in two types based on the aggregate feeding method: hopper type and belt type.

Advantages:

- Precision feeding system: production continuity increased by 20%, and raw material waste reduced by 10%.

- Professional customized design, full coverage of scenarios: can quickly adapt to different scenarios such as mining, infrastructure, commercial concrete, etc., and improve equipment utilization by 35%.

- High volume production, ideal for commercial RMC plant business.

Mobile Batch Plant – For Easy Transportation between Sites

Mobile concrete batching plants for South Africa are the go-to solution for contractors needing fast setup, portability, and flexibility. Popular models like Aimix’s AJY series offer compact designs with capacities from 25 m³/h to 100 m³/h.

Advantages:

Mini and Compact Concrete Plant – Best Choice for Projects with Limited Space

Mini and compact concrete plants are cost-effective options ideal for startups or projects with limited space. They come in both stationary and mobile forms (including AJZY drum type and AJSY compact form) according to specific project needs. Aimix offers customized compact batching plant solutions tailored to meet the specific needs of each project.

Advantages:

Low investment, high return

Simple operation

Ideal for private developers, small-scale precast operations

Specifications of Batching Concrete Plants

| Model | AJ-25 | AJ-35 | AJ-50 | AJ-75 | AJ-60 | AJ-90 | AJ-120 | AJ-180 |

|---|---|---|---|---|---|---|---|---|

| Theoretical Productivity (m³/h) | 25 | 35 | 50 | 75 | 60 | 90 | 120 | 180 |

| Mixer Model (Mixer Output L) | JS500 | JS750 | JS1000 | JS1500 | JS1000 | JS1500 | MAO3000/2000(SICOMA) | MAO4500/3000(SICOMA) |

| Mixer Power (kW) | 18.5 | 30 | 2×18.5 | 2×30 | 2×18.5 | 2×30 | 2×37 | 2×55 |

| Mixing Cycle Period (s) | 72 | 72 | 72 | 72 | 60 | 60 | 65 | 65 |

| Max.Aggregate Size (mm) | Φ60 | Φ60 | Φ60 | Φ80 | Φ60 | Φ80 | Φ80 | Φ80 |

| Standard Aggregate Bin Capacity (m³) | 3×3 | 3×5 | 3×8 | 3×12 | 4×7 | 4×15 | 4×15 | 4×20 |

| Kind of Aggregate | 2/3 | 2/3/4 | 3/4 | 3/4 | 4/5 | 4/5 | 4/5/6 | 4/5/6 |

| Max. Discharging Height (m) | 3.8 | 4.1 | 4.1 | 4.1 | 4.1 | 4.1 | 4.3 | 4.3 |

| Overall Weight (ton) | ≈15 | ≈18 | ≈23 | ≈30 | ≈40 | ≈68 | ≈93 | ≈101 |

| Installation Power (kW) | ≈65 | ≈75 | ≈100 | ≈140 | ≈110 | ≈160 | ≈220 | ≈290 |

| Model | AJY25 | AJY35 | AJY50 | AJY75 | AJY100 |

|---|---|---|---|---|---|

| Theoretical Productivity (m³/h) | 25 | 35 | 50 | 75 | 100 |

| Mixer Model (Mixer Output L) | JS500 | JS750 | JS1000 | JS1500 | JS2000 |

| Mixer Power (kW) | 18.5 | 30 | 2x18.5 | 2x30 | 2x37 |

| Mixing Cycle Period (s) | 72 | 72 | 72 | 72 | 72 |

| Max.Aggregate Size (mm) | Φ60 | Φ60 | Φ60 | Φ60 | Φ60 |

| Aggregate Bin Capacity (m³) | 4x4m³ | 4x4m³ | 4x5m³ | 4x6m³ | 4x8m³ |

| Powder Storage Silo (ton) | 1x50 | 1x100 | 1x100 | 2x100 | 3x100 |

| Max. Discharging Height (m) | 3.8 | 3.8 | 4.2 | 4.2 | 4.2 |

| Weighing Range & Accuracy of Aggregate (kg) | 2x900kg±2% | 2x900kg±2% | 2x1200kg±2% | 2x1800kg±2% | 2x2400kg±2% |

| Weighing Range & Accuracy of Cement (kg) | 350kg±1% | 500kg±1% | 600kg±1% | 1000kg±1% | 1200kg±1% |

| Weighing Range & Accuracy of Water (kg) | 200kg±1% | 200kg±1% | 350kg±1% | 450kg±1% | 550kg±1% |

| Weighing Range & Accuracy of Additive (kg) | 30kg±1% | 30kg±1% | 30kg±1% | 30kg±1% | 50kg±1% |

| Overall Weight (ton) | ≈15 | ≈20 | ≈25 | ≈31 | ≈37 |

| Installation Power (kW) | ≈65 | ≈75 | ≈90 | ≈125 | ≈180 |

What to Consider Before Buying a Concrete Batch Plant

Capacity Needs

Start by assessing the daily concrete volume you’ll need. Larger projects may demand stationary type batch plants, while smaller or short-term projects might only require mobile or mini batch plants.

Automation and Technology

Modern batching plants come with automated systems (like PLC control systems for real-time operation monitoring) that handle batching, weighing, mixing, and discharge. This not only ensures precision and consistency but also reduces labor costs.

Environmental Compliance

South Africa enforces regulations on dust control and noise. Ensure the concrete plant has proper filtering systems and enclosures to comply with environmental laws.

Budget and Lifecycle Costs

Compare not just the initial purchase price but the total cost of ownership—maintenance, spare parts, operator training, fuel consumption, and productivity.

After-Sales Support

It matters a lot to opt for a reputable and relabile concrete batch plant supplier that offers installation guidance, operator training, spare parts availability and 24/7 customer support, ensuring the good performance of the plant and reducing downtime.

Regional Challenges for Concrete Plant Installation & Maintenance

Installing and maintaining a concrete batching plant in South Africa requires addressing unique regional challenges:

Power Reliability

- Frequent load-shedding demands backup solutions like diesel generators or hybrid systems (solar/diesel). Solar-powered plants are increasingly viable, reducing reliance on Eskom’s unstable grid.

Water Scarcity

- Drought-prone regions like the Western Cape necessitate closed-loop water recycling systems to minimize freshwater use by up to 30%.

Regulatory Compliance

- Concrete batching plant for sale in South Africa should meet NRCS safety certifications and adhere to Occupational Health and Safety Act (OHSA) standards for dust (≤10 mg/m³) and noise (≤85 dB). Coastal installations require corrosion-resistant materials to withstand salty air.

Terrain & Climate

- Rocky or uneven sites (e.g., mining areas in Limpopo) need reinforced foundations, while arid regions like the Northern Cape require dust suppression systems to protect equipment.

Maintenance Practices

- Local Expertise: Partner with certified technicians for professional and prompt repairs.

- Spare Parts Availability: Stock critical components (e.g., mixer blades, conveyor belts) to avoid delays.

- Seasonal Adjustments: Winterize concrete mixing plants in high-altitude regions (e.g., Drakensberg) with antifreeze and insulated pipes.

Transport & Logistics

- Mobile concrete plants with all-terrain capabilities are ideal for remote projects, but ensure accessible routes for raw material delivery.

Future Trends in South Africa’s Concrete Batching Plant Market

Automation & Smart TechIoT-enabled batch plants with real-time monitoring will surge, driven by a 24% annual growth in construction IoT adoption. These systems reduce errors by 15–20% through automated adjustments.

Solar & Hybrid PowerTo combat load-shedding, solar-powered concrete plants will expand under South Africa’s goal to add 8.1 GW of solar PV by 2030. Hybrid models (e.g., solar-diesel) already cut fuel costs by 40–50% in pilot projects.

Green Infrastructure PushBacked by the R130 billion Just Energy Transition Partnership, 30% of public tenders will require eco-friendly batching plants by 2030. Demand for carbon-neutral and recycled-aggregate-compatible plants will rise 35% by 2028.

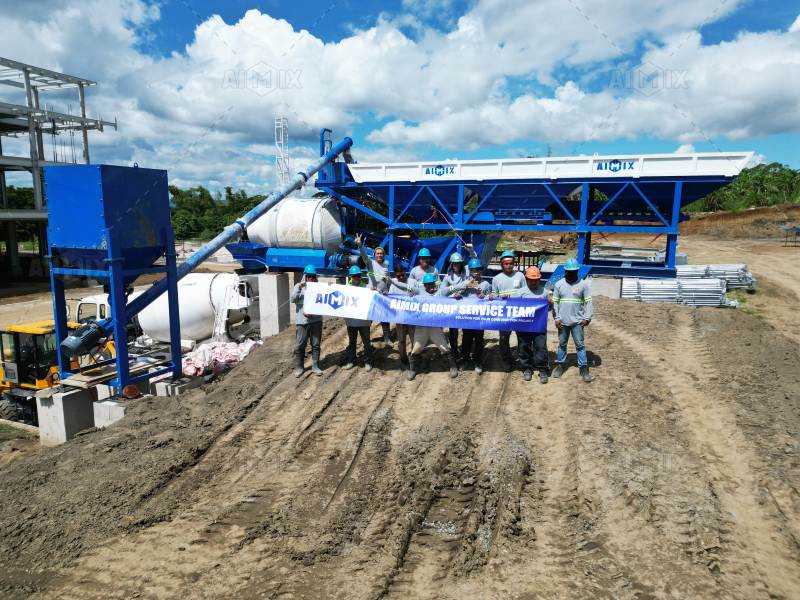

Become an Official Aimix Distributor in South Africa

Aimix is a trusted name in the construction machinery industry, known for delivering high-quality, reliable, and efficient concrete batching plants worldwide. With South Africa’s construction sector rapidly growing, now is the perfect time to expand your business by becoming an Aimix distributor.

What You’ll Gain

- Access to a full range of stationary, mobile, and compact concrete batching plants

- Competitive pricing and strong profit margins

- Marketing materials, technical training, and 24/7 support

- Partnership with a brand trusted by 10000+ global clients

Tailored for the South African Market

- Aimix provides custom batching plant solutions designed to meet the specific demands of South Africa’s infrastructure, housing, and commercial development projects.

Join the Aimix Network Today

- Don’t miss your chance to become part of a successful, growing global family. Contact us today to explore how you can become an Aimix distributor in South Africa!