The UK market demands high-performance, regulation-compliant, and flexible concrete production systems. Investing in the right concrete batching plant for sale UK is not just a cost—it’s a strategic decision that affects every part of your project. Aimix provides one-stop concrete plant solutions featuring: one-click start, smart operation, efficient and intelligent, flexible and reliable.

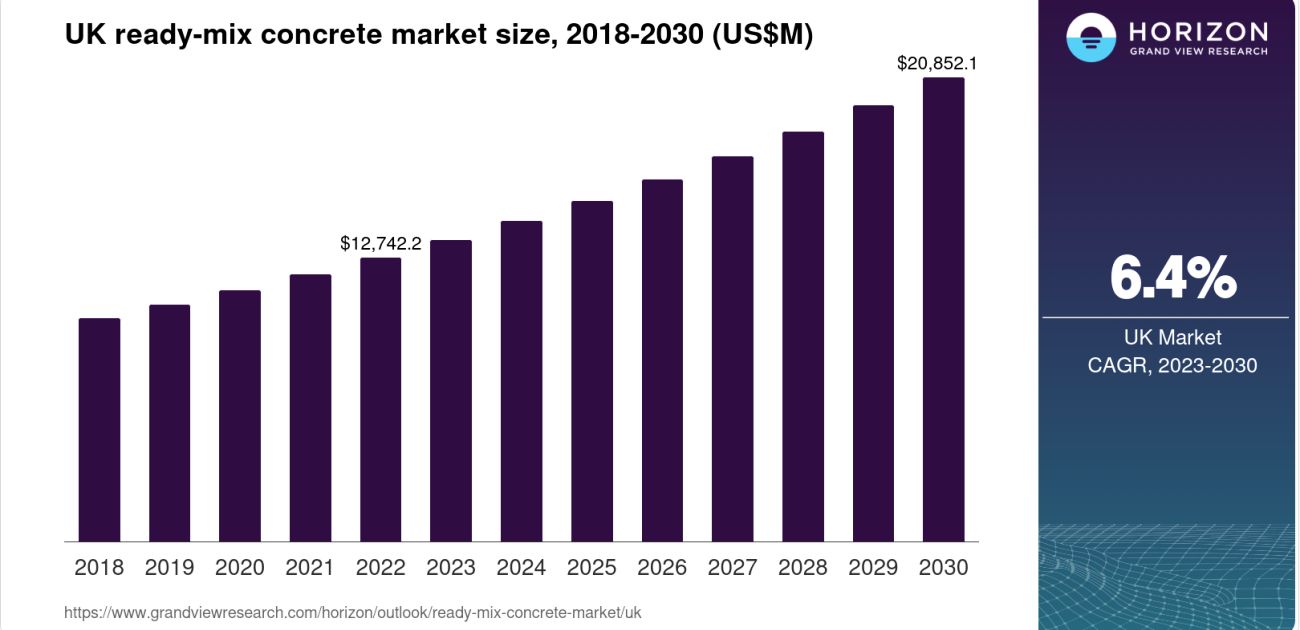

UK Concrete Batching Plant Market Overview

The United Kingdom is experiencing a resurgence in construction activity, fueled by major public infrastructure investments, housing development, and environmental sustainability goals. From high-profile projects to renew public housing and upgrade transportation networks, the demand for high-quality, on-time concrete delivery has never been greater.

Growth Drivers

- Major Government Infrastructure Projects – Large-scale national projects like HS2, Crossrail, and the Thames Tideway Tunnel require thousands of cubic meters of concrete daily—delivered with pinpoint timing and composition. These projects rely heavily on stationary and mobile concrete batching plants located close to the worksite to reduce transportation delays and mix inconsistencies.

- Housing Shortages and Urbanization – The UK’s ongoing housing crisis has sparked increased construction of residential units, particularly in urban centers such as London, Manchester, and Birmingham. Urban development favors compact or mobile concrete plants that fit within limited space while offering rapid batch delivery for smaller but frequent pours.

- Sustainability and Infrastructure Renewal – With much of the UK’s infrastructure reaching the end of its lifecycle, there’s strong demand for sustainable reconstruction. Concrete batching plants that support low-carbon concrete production and recycled materials are gaining traction. Additionally, the push for green building certifications (e.g., BREEAM) further emphasizes the role of eco-efficient concrete batching technology.

Main Challenges

- High Initial Investment and Volatile Economy – One of the most cited barriers to entry is the concrete batch plant cost. A high-quality, fully automated plant typically demands a substantial upfront investment. Economic uncertainty—driven by factors such as inflation, Brexit-related trade changes, and fluctuating construction demand—can delay purchasing decisions.

- Supply Chain Disruptions – The global shortage of microchips and mechanical components has affected construction equipment imports, including batching plant parts and accessories. This makes after-sales service, local stocking, and reliable manufacturers more critical than ever.

- Skilled Labor Shortages – Modern batching concrete plants rely on PLC control systems, automated feeding, and quality management software. However, the UK’s construction sector has struggled with a shortage of skilled operators and maintenance technicians who can run and troubleshoot these systems efficiently.

Popular Types of Concrete Plant for Sale in the UK Market

Concrete plants play a vital role in supplying the essential material for construction projects, ranging from residential buildings to large-scale infrastructure developments. If you’re looking for a concrete batching plant for sale in the UK, understanding the different types available can help you choose the best option for your needs. Below, we introduce the most popular types of batching plants, each designed to meet specific project requirements.

Stationary Batching Plants: Power for Long-Term Infrastructure Projects

Best suited for: Major infrastructure schemes such as HS2, Thames Tideway, motorway expansions, and large-scale commercial developments.

Stationary batching plants are the backbone of high-volume concrete supply. Installed with solid foundations and custom site layouts, the stationary plants can produce up to 180 m³/hour or more, ensuring continuous supply for projects that require massive pours or consistent mix designs over months or years. Aimix stationary plants can adopt belt-type or hopper-type according to specific needs.

Key Advantages:

High CapacityAble to sustain long pours and multiple simultaneous supply lines for large-scale construction.

AutomationIntegrated PLC systems and digital batching controls enhance precision and repeatability, minimizing human error.

DurabilityBuilt for years of reliable operation, these stationary concrete plants offer the lowest long-term cost per cubic meter produced.

Mobile Concrete Batching Plants: Flexibility for Remote and Temporary Sites

Best suited for: Rural housing projects, infrastructure upgrades in remote areas, wind farm or solar power construction sites.

Mobile concrete batching plants offer a plug-and-play solution that can be quickly deployed, operated, and relocated across various job sites. These plants are mounted on trailer chassis or steel frames, allowing rapid transport and setup without major foundation works. For example, Aimix AJY series mobile batching plant with wheeled design is easy to relocate — disassembly can be completed in half a day, and the entire site transfer can be finished within one day.

Key Advantages:

- Location Flexibility: Perfect for off-grid or rural environments with limited access to ready mix concrete delivery.

- Reduced Transport Costs: By producing concrete on-site, mobile plants significantly cut the cost of hauling material from central plants. According to UK project data, this can lead to up to a 36% reduction in HGV (heavy goods vehicle) traffic, lowering carbon emissions and improving traffic safety.

- Time-Saving: Quick commissioning allows contractors to start operations within days, crucial for short project windows.

- Regulatory Simplicity: Mobile batch plants often bypass full planning permission if used temporarily, streamlining project logistics.

Popular models in the UK range from 25 to 75 m³/hour capacity, with advanced options offering automatic controls, moisture sensors, and admixture dosing.

Compact and Modular Concrete Plants: Space-Saving Urban Solutions

Best suited for: City-based developments, brownfield regeneration sites, or contractors working with limited available space.

With real estate at a premium in cities like London, Manchester, and Birmingham, compact or modular batching plants offer a smart alternative. For example, Aimix drum-type compact batching plant is equipped with a drum mixer that is ideal for mixing highly flowable plastic concrete. The plant features a compact, integrated design that requires no foundation and no installation when relocating — ready to use anytime, anywhere. In addition to AJZY drum type compact plant, we also offer AJSY type portable compact plant.

Key Advantages:

Minimal Site RequirementsTheir small size and modular nature allow setup in basements, side streets, or rooftops.

Quick InstallationNo concrete foundation is necessary—compact batching plants are shipped with pre-engineered steel supports for fast erection.

Eco-FriendlinessEnclosed designs reduce dust, sound, and emissions, meeting stricter urban environmental controls.

UK contractors increasingly deploy compact concrete batching plants for inner-city commercial builds, parking structures, and infill residential developments. Capacities typically range from 25 to 60 m³/hour, with flexible configurations and full digital control panels.

Concrete Plant Specifications

| Model | AJ-25 | AJ-35 | AJ-50 | AJ-75 | AJ-60 | AJ-90 | AJ-120 | AJ-180 |

|---|---|---|---|---|---|---|---|---|

| Theoretical Productivity (m³/h) | 25 | 35 | 50 | 75 | 60 | 90 | 120 | 180 |

| Mixer Model (Mixer Output L) | JS500 | JS750 | JS1000 | JS1500 | JS1000 | JS1500 | MAO3000/2000(SICOMA) | MAO4500/3000(SICOMA) |

| Mixer Power (kW) | 18.5 | 30 | 2×18.5 | 2×30 | 2×18.5 | 2×30 | 2×37 | 2×55 |

| Mixing Cycle Period (s) | 72 | 72 | 72 | 72 | 60 | 60 | 65 | 65 |

| Max.Aggregate Size (mm) | Φ60 | Φ60 | Φ60 | Φ80 | Φ60 | Φ80 | Φ80 | Φ80 |

| Standard Aggregate Bin Capacity (m³) | 3×3 | 3×5 | 3×8 | 3×12 | 4×7 | 4×15 | 4×15 | 4×20 |

| Kind of Aggregate | 2/3 | 2/3/4 | 3/4 | 3/4 | 4/5 | 4/5 | 4/5/6 | 4/5/6 |

| Max. Discharging Height (m) | 3.8 | 4.1 | 4.1 | 4.1 | 4.1 | 4.1 | 4.3 | 4.3 |

| Overall Weight (ton) | ≈15 | ≈18 | ≈23 | ≈30 | ≈40 | ≈68 | ≈93 | ≈101 |

| Installation Power (kW) | ≈65 | ≈75 | ≈100 | ≈140 | ≈110 | ≈160 | ≈220 | ≈290 |

| Model | AJY25 | AJY35 | AJY50 | AJY75 | AJY100 |

|---|---|---|---|---|---|

| Theoretical Productivity (m³/h) | 25 | 35 | 50 | 75 | 100 |

| Mixer Model (Mixer Output L) | JS500 | JS750 | JS1000 | JS1500 | JS2000 |

| Mixer Power (kW) | 18.5 | 30 | 2x18.5 | 2x30 | 2x37 |

| Mixing Cycle Period (s) | 72 | 72 | 72 | 72 | 72 |

| Max.Aggregate Size (mm) | Φ60 | Φ60 | Φ60 | Φ60 | Φ60 |

| Aggregate Bin Capacity (m³) | 4x4m³ | 4x4m³ | 4x5m³ | 4x6m³ | 4x8m³ |

| Powder Storage Silo (ton) | 1x50 | 1x100 | 1x100 | 2x100 | 3x100 |

| Max. Discharging Height (m) | 3.8 | 3.8 | 4.2 | 4.2 | 4.2 |

| Weighing Range & Accuracy of Aggregate (kg) | 2x900kg±2% | 2x900kg±2% | 2x1200kg±2% | 2x1800kg±2% | 2x2400kg±2% |

| Weighing Range & Accuracy of Cement (kg) | 350kg±1% | 500kg±1% | 600kg±1% | 1000kg±1% | 1200kg±1% |

| Weighing Range & Accuracy of Water (kg) | 200kg±1% | 200kg±1% | 350kg±1% | 450kg±1% | 550kg±1% |

| Weighing Range & Accuracy of Additive (kg) | 30kg±1% | 30kg±1% | 30kg±1% | 30kg±1% | 50kg±1% |

| Overall Weight (ton) | ≈15 | ≈20 | ≈25 | ≈31 | ≈37 |

| Installation Power (kW) | ≈65 | ≈75 | ≈90 | ≈125 | ≈180 |

Versatile Applications and Projects of Concrete Mixing Plants

Concrete mixing plants are essential for a wide range of construction projects thanks to their efficiency, reliability, and adaptability. Whether it’s residential housing, commercial developments, or major infrastructure like highways, bridges, airports, and railways, these plants deliver a steady supply of high-quality concrete.

As a trusted and experienced supplier, Aimix has successfully provided batching plants for diverse applications around the world. To help you make an informed decision, we invite you to check the following project cases about how our plants have supported various construction needs.

Local Regulatory Framework for Concrete Plant

Concrete batching plant for sale in the UK isn’t just about technology and pricing—it also involves meeting strict regulatory requirements. Here are the key legal and environmental frameworks:

Environmental Agency (EA) Permits

Any concrete batch plant should comply with EA permitting requirements. These permits help reduce pollution, ensure waste management, and regulate emissions. Plants need to control dust, water runoff, and noise levels to minimize impact on nearby communities.

Planning Permission

For stationary plants, planning permission from the local council is typically required. Temporary or mobile batch plants may qualify for exemptions or require only simplified notices depending on the project duration and location.

BS EN 206 and BS 8500 Compliance

These standards govern the quality of concrete produced in the UK. Your plant should be capable of batching concrete in line with these regulations—especially for public infrastructure and structural applications.

Health & Safety Executive (HSE)

Concrete batching sites need to follow HSE safety guidelines, which include employee training, operational safety, material handling protocols, and emergency response plans.

What Influences Concrete Batch Plant Price in the UK?

The concrete batch plant price in the UK varies widely depending on:

- Plant Type – Mobile plants tend to cost less (due to foundation-free or minimal groundwork needs or other reasons) than stationary setups but offer more flexibility.

- Production Capacity – Ranging from 25 m³/h to over 240 m³/h, higher capacities typically come with a higher price tag.

- Automation Level – Options range from basic manual control to fully automated systems.

- Technology Features – Advanced features like IoT integration and cloud-based control systems can increase cost but improve efficiency.

- Brand and Origin – Locally manufactured batching plants may differ in price compared to imported models.

Aimix concrete batching plant prices typically start at $33000 depending on configurations. Investing more upfront often leads to higher efficiency and lower long-term operating costs. Please see the table below for a reference on Aimix concrete plant price ranges.

| Model | Price |

|---|---|

| AJ-25-AJ-50 | $33000-$48000 |

| AJ-60-AJ-180 | $78000-$210000 |

| AJY-25-AJY-90 | $38000-$120000 |

Concrete Batching Plant for Sale UK: Key Buying Considerations

Assess Your Production Capacity

Start by determining your daily concrete output requirements. Choosing a concrete plant with the right production capacity (e.g., 90 m³/hour) ensures your project stays on schedule without overinvesting in unnecessary capacity.

Prioritize Batching Accuracy

Batching precision is vital for maintaining concrete quality and meeting UK construction standards. Look for plants with advanced weighing systems to deliver consistent mix proportions across every batch. Our plants equip with precise feeding system, boosting production continuity by 20% and cuts material waste by 10%.

Consider the Level of Automation

Fully automated batching plants reduce labor costs and increase operational efficiency. Take Aimix stationary batching plant for example, the one-click start/stop + dual operation modes—reduces startup preparation time by over 30%, cuts operational errors by 50%, and ensures production continuity. IoT remote-control system cuts failure rates by 40%, saves 25% in maintenance costs, and extends equipment life by over 15%.

Choose the Right Storage Configuration

Ensure your cement silos and aggregate bins are appropriately sized for your mix designs and production targets. Proper sizing prevents frequent refilling and supports continuous production. Aimix offers vertical cement silos (space-saving for compact sites) and horizontal ones (high capacity for continuous operations) to meet different needs.

Evaluate After-Sales Support

Reliable after-sales service is essential. Work with suppliers who offer operation and maintenance training, spare parts availability, and quick-response technical support to minimize downtime and extend your plant’s lifespan.

Why Choose a Trusted Concrete Batching Plant Manufacturer for Your Business?

Investing in a concrete batching plant is a significant decision for any construction-related business. Whether you’re starting a new concrete production line or upgrading your current setup, the manufacturer you choose plays a critical role in the long-term success of your operation.

Ensuring Compliance with UK Regulations

Choosing a trusted concrete batch plant manufacturer ensures your plant meets UK regulations, including environmental standards and quality control. Compliance helps avoid costly fines and project delays.

High-Performance, Durable Equipment

Reputable manufacturers supply high-quality, durable concrete plants tailored to meet the demands of various UK construction projects, from urban infrastructure to rural builds.

Comprehensive After-Sales Support

A trusted supplier offers maintenance services, spare parts, and operator training, reducing downtime and extending the lifespan of your batching plant.

Selecting the Right Plant Type

A reliable manufacturer helps guide you in choosing the right batching plant type—mobile, stationary, or compact—based on your specific production needs and site conditions.

Building Trust and Reputation

Partnering with a top-tier concrete batch plant manufacturer enhances your credibility in the UK market, improving relationships with clients and contractors, and supporting long-term business success.

Future Trends Shaping the UK Batching Plant Market

As the UK construction industry evolves, batching concrete plants are undergoing a significant transformation to align with future demands around sustainability, technology, and resilience.

Sustainability InnovationsDriven by the UK’s net-zero carbon targets, concrete producers are adopting carbon-neutral mixes, utilizing recycled aggregates and alternative binders like GGBS (ground granulated blast-furnace slag). Industry leaders such as Heidelberg Materials are pioneering closed-loop water recycling systems, further reducing the environmental impact of batching operations.

Digitalization and AutomationThe shift toward smart construction is accelerating. IoT-enabled batching systems now allow for real-time mix adjustments based on environmental data and project-specific needs. Remote-controlled operations and predictive maintenance powered by AI and sensors are minimizing downtime and optimizing performance—making modern batching plants more efficient and cost-effective.

Government-Led OpportunitiesPublic investment in green infrastructure—including transport electrification, flood defences, and renewable energy—creates opportunities for environmentally compliant plants. In parallel, local sourcing initiatives aim to reduce supply chain vulnerability, making UK-based batching plant companies increasingly competitive and attractive for long-term procurement.

Cooperate with Us for Reliable Concrete Batching Plants

Ready to boost your concrete production and drive project success? Partner with Aimix, a trusted supplier of high‑performance concrete batching plants. Our tailored solutions combine cutting‑edge technology, robust build quality, and responsive service, ensuring you get the best value for your investment. Whether you need a mobile unit for fast deployment or a stationary plant for long‑term operations, we offer competitive pricing and comprehensive support across the UK. Contact us today to discuss your requirements and get an ideal recommendation!