Frustrated with mobile crusher plant that is difficult to operate and maintain? Traditional models often demand specialized skills, constant manual adjustments, and lead to costly downtime. Now, AIMIX optimizes the mobile crushing operation with smarter, user-friendly solutions for maximum efficiency and simplicity.

Crush Smarter with AIMIX: Mobile Crusher Plants That Boost Output and Cut Downtime

Intelligent Integrated Control

- Dual control: PLC touchscreen + physical buttons for easy, mistake-proof operation

- Real-time, visualized production data boosts efficiency by 30%+

IOT Remote Monitor

- 24/7 live equipment health and performance tracking

- Smart diagnostics push maintenance alerts to cut failures by up to 60% and extend service life

Intelligent Feed

- Remote-controlled feed rate adapts instantly to your production needs

- Keeps material flow stable for continuous, efficient crushing

Hot-sale Wheeled Type Mobile Crushing Plant – All-in-One Crushing Solutions

AIMIX brings you the ultimate flexibility in mobile crushing with our 4-in-1, 3-in-1, and 2-in-1 wheel-mounted mobile crushing plants. The mobile crushing solution has combined advanced technology with compact design, making it ideal for various applications in construction and mining. With its mobility and high productivity, the APY series wheeled mobile crusher for sale ensures that you can easily transport and set up the plant at different job sites, while maintaining optimal performance.

APY4 Wheeled Mobile Crushing Plant – ①Feed & ②Primary Crush & ③Secondary Crush & ④Screen

Capacity: 50, 80, 100, 120tph

Crusher Configuration: Primary jaw crusher + Adjustable Secondary Crusher(cone crusher, impact crusher, or fine jaw crusher), suitable for various working conditions

Finial Particle Size: 0-5mm, 5-10mm, 10-20mm, 20-40mm etc

Applicable Materials: granite, marble, basalt, iron ore, river pebbles

Main Application: supply aggregate for construction industry, especially for infrastructure construction, like roads and buildings.

| 4 in 1 Mobile Crusher Plant - Wheeled Chassis Type | ||||

|---|---|---|---|---|

| Model | APY4-46J2512J-S3 | APY4-46J900C-S3 | APY4-57J110C-S3 | APY4-69J132C-S3 |

| Productivity(t/h) | 30 | 50 | 80 | 100-120 |

| Vibrating Feeder | ||||

| Model | APG-0824Z | APG-0824Z | APG-0930Z | APG-9538Z |

| Primary Stone Crusher | ||||

| Model | APJ-4060E | APJ-4060E | APJ-5075E | APJ-6090E |

| Type | Jaw crusher | Jaw crusher | Jaw crusher | Jaw crusher |

| Secondary Stone Crusher | ||||

| Type | Jaw crusher | Cone crusher | Cone crusher | Cone crusher |

| Model | APJ-2512X | APC-900Y | APC-110C | APC-132C |

| Vibrating Screen | ||||

| Model | APS-1548Y3 | APS-1548Y3 | APS-1848Y3 | APS-1848Y3 |

| Belt Conveyor | ||||

| Vehicle mounted belt conveyor | Yes | Yes | Yes | Yes |

APY3 Impact Type Mobile Crusher Plants – Low Production Cost

1. Capacity and Configuration:

- Production Capacity Range: 70–500 T/H

- Typical Configuration: Feeder + Impact Crusher + Vibrating Screen

2. Material and Operating Condition Suitability

- Material Hardness Range: Medium-soft to medium hardness, like construction waste, concrete, asphalt blocks, limestone, dolomite, etc.

- Maximum Feed Size: ≤300mm

- Finished Product Requirements: 0–40 mm, high cubic content, low flaky and elongated particle content

3. Output Quality

- Excellent Particle Shape: The impact crushing principle results in better cubic particles, suitable for recycled aggregates, base/surface course aggregates.

- Adjustable Particle Size: Adjustable discharge grate gap and rotation speed allow for precise control of 0–40 mm output.

4. Application Scenarios

- Construction demolition and solid waste resource utilization (C&D waste)

- Road renovation and asphalt recycling

- Secondary/tertiary crushing in quarries, especially for limestone

APY3 Jaw-Type Mobile Crusher Plant – Primary Crushing

1. Capacity and Configuration

- Capacity Range: 45–400 T/H

- Configuration: Feeder + Jaw Crusher + Vibrating Screen

2. Material and Working Condition Adaptability

- Applicable Materials: Medium to high-hardness rocks, such as granite, basalt, limestone, river pebbles, large concrete blocks from building demolition, etc.

- Feed Size: Large feed opening, supporting raw materials >425 mm

- Working Conditions: Primary crushing in quarries, pre-crushing of mine overburden, coarse crushing of large concrete blocks from building demolition

3. Output and Subsequent Processes

- Finished Product Particle Size: 15–300 mm can be obtained through screening; in most scenarios, it serves as coarse material before secondary crushing

- Particle Shape Characteristics: Jaw crusher output has distinct edges, making it more economical as raw material for subsequent shaping/secondary crushing

Cost and Mobility

4. Typical Application Scenarios

- Primary crushing in quarries and mines

- Building demolition/solid waste – pre-crushing of large concrete blocks + magnetic separation

- Temporary construction material yards, on-site sand/stone production for road construction

APY2 Cone-Type Mobile Crusher Plant – Secondary Or Tertiary Crushing

Feeding Size: 160-215mm

Capacity: 50-420T/H

Configuration: Cone Crusher + Screen

Precise particle size control: multiple cavity types to choose (standard/medium/short head type), finished product 0-38mm

Introduction: Cone type mobile crushing plant for sale is specially designed for medium and fine crushing of high hardness materials. It is suitable for secondary crushing of sand and gravel aggregate. The finished products are mostly cubic.

Crawler Type Mobile Crushing Plant – Unstoppable Crushing Power Anywhere

Apart from wheeled type, we also have manufactured crawler type mobile crushers for you. The track crusher also can be equipped with various crusher hosts, like track jaw crusher, track cone crusher plant, track impact crusher plant, and track screener.

APYL Crawler-Type – Stable Crushing on Any Terrain

- Capacity: 70–500 T/H

- Feeding Size: 35–650 mm

- Discharging Size: 0–180 mm

- Crusher types: Crawler jaw crusher, crawler cone crusher, track impact crusher

- Key Scenarios Where You Need the Crawler Crusher: On-site demolition and recycling; Uneven, soft, or muddy ground conditions; Frequent relocation within the same project; Urban or space-limited job sites

Small Mobile Crushing Plant — The Smart Choice for 30–50 TPH Projects

- Capacity: 30–50 T/H

- Maximum Feeding Size: ≤380mm

- Discharging Size: 20-50mm

- Configuration: Jaw crusher, diesel engine, and feeding hopper

- Application: On-site crushing for small construction projects, recycling of concrete and demolition waste, road base preparation, and cost-sensitive projects requiring flexible and mobile crushing solutions

Global Mobile Crushing Projects — Real Solutions, Real Results

Our mobile crushing solutions are trusted by customers across multiple continents, serving a wide range of industries and on-site applications. From urban construction waste recycling to quarry and infrastructure projects, we have delivered over 1000+ customized mobile crushing solutions, each designed to match local materials, site conditions, capacity demands, and project budgets. Explore the following cases below to see how AIMIX solutions perform in real projects worldwide.

APY4 Tire-mounted Mobile Crushers Operation in El Salvador

- Processing capacity: 50 tph

- Output size: 10-30mm

- Configurations: feeder, jaw crusher, cone crusher, and vibrating screen

- Applications: crushing granite rocks on-site for aggregate-sale business expansion

APY4 Wheeled Mounted Mobile Crushers In Mexico

- Capacity: 80 tph

- Output size: 5-10mm, 10-15mm, 15-20mm

- Configurations: APG-0930Z vibrating feeder + APJ-5075E jaw crusher + APC-110C cone crusher + APS-1848Y3 Vibrating Screen

- Applications: finial aggregates, produced in Mexico using APY4 mobile crushing equipment, are exported to the United States

Mobile Crawler Cone Crusher and Screener In Malaysia

- Processing capacity: 100-200tph

- Output size: 5-10mm, 10-20mm, 20-40mm

- Configurations: track cone crusher + track vibrating screen

- Applications: crushing cobblestone for aggregate materials that used in the expressway construction

APY3 Mobile Impact Crushing Plant Working in Colombia

- Processing capacity: 150tph

- Output size: 10-25mm

- Applications: crushing concrete wastes to reuse in construction building project

- Configurations: vibrating feeder + impact type mobile crusher + screen + belt

APY4 Portable Crusher Working in Honduras

- Processing capacity: 150tph

- Output size: 5-10; 10-20mm

- Configurations: vibrating feeder + mobile jaw crusher + mobile cone crusher + screen + belt

- Applications: crushing granite materials as the aggregates for sale locally

Mobile Jaw Crusher Machine For Road Construction

- Processing capacity: 200tph

- Finished Product: 0-5, 10-20mm

- Configurations: vibration feeder, mobile jaw crusher, vibrating screen, etc

- Applications: crushing volcanic rocks for road construction

Crawler Mobile Concrete Crushing Plant In Singapore

- Processing capacity: 200tph

- Finished Product: 10-15, 20-25mm

- Configurations: vibration feeder, track jaw crusher, track impact crusher, vibrating screen, etc

- Applications: recycling construction waste as the raw materials for road paving

APYL Crawler Mobile Crushing Plant in the Philippines

- Processing capacity: 150tph

- Finished Product: 5-20mm

- Configurations: track impact crusher, vibrating screen, etc

- Applications: recycling construction waste as the aggregate for concrete production

Quicker Relocation, Start Crushing Faster

Fast relocation secures not only time for you, but also fleeting business opportunities and profits. Choosing our mobile crushing solution means every deployment is precise and swift, turning every minute into tangible output. Here’s how our two kinds of mobile crusher chassis help you succeed on every site:

Wheeled (Tri‑Axle) Chassis

- Tri‑axle stability: balanced load distribution reduces sway and braking distance. You roll faster and safer.

- Hook and go: standard fifth‑wheel coupling locks in seconds. No special permits in most regions.

- Highway speed: tow at road limits, then slip into tight sites with a compact turning radius.

- Quick setup: hydraulic legs level the unit in minutes. Connect power. Start crushing.

- Low running cost: tires, hubs, and brakes match common truck parts. Service is simple and fast.

Crawler (Tracked) Chassis

- Self‑propelled: crawl from pile to pile without a truck. Follow the excavator. Keep the cycle tight.

- All‑terrain grip: steel or rubber tracks bite into mud, rock, and slopes. Weather won’t stop you.

- Precision positioning: inch‑forward control places the feeder exactly where you need it. Fewer rehandles.

- Remote control: operators relocate from a safe distance. One person, one handset, zero fuss.

- Instant readiness: no outriggers needed on firm ground. Engage the engine and move.

Strong Growth Signals for Mobile Crushing & Screening Equipment Investment

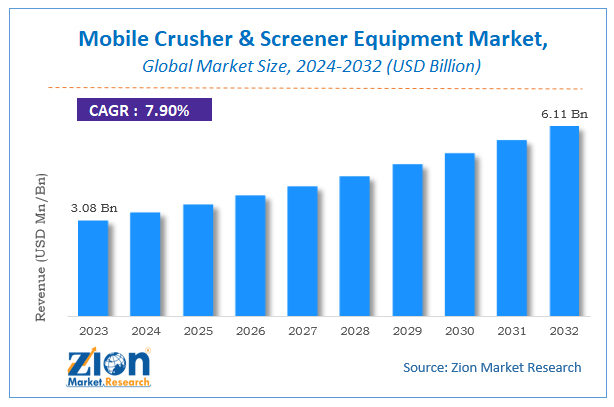

According to Zion Market Research, the global market size for mobile crushing and screening equipment is expected to grow to approximately $6.11 billion by 2032, with a compound annual growth rate (CAGR) of about 7.9% from 2024 to 2032. This sustained growth highlights the strong long-term investment potential of mobile crushing equipment worldwide.

Key Market Growth Drivers

The expansion of the mobile crushing and screening market is driven by several core factors:

Rapid expansion of the global construction industry Large-scale infrastructure projects, road construction, and urban development continue to increase the demand for on-site aggregate production..

Accelerated urbanization and infrastructure development Cities require faster, more flexible crushing solutions that reduce material transportation and improve project efficiency..

Growing demand for manufactured sand (M-sand) As natural river sand resources decline, manufactured sand has become a cost-effective and environmentally friendly alternative, further driving the need for reliable crushing and screening equipment.

With strong market demand, stable growth forecasts, and expanding applications, owning a mobile crusher plant has become a highly promising business opportunity. When you invest in a mobile crusher plant, choosing the right manufacturer is just as important as choosing the right market. You can consider cooperating with AIMIX Group manufacturer. We’re delivering real, measurable benefits to your project. Ready to see what sets us apart? Let’s dive into what you can benefit from our mobile crushing plants.

Maximize Your Crushing Potential – The Unbeatable Benefits of Our Mobile Crushing Plants

Integrated Design, Save Time and Costs

Combining feeding, crushing, and screening into one compact unit, this all-in-one design streamlines the entire crushing process. It reduces setup time, minimizes labor costs, and eliminates the need for additional supporting equipment—perfect for projects requiring fast execution and tight budgets.

Flexible Crusher Configurations, Adapt to Every Job

The system allows for various secondary crushing setups, such as fine jaw crushers or impact crushers. This modular flexibility makes it suitable for a wide range of materials, from hard rock to construction waste. The tailored mobile crushing solutions can maximize crushing efficiency across different working conditions.

Tri-Axle Chassis, Move Anywhere, Anytime

Equipped with a heavy-duty tri-axle chassis, it offers excellent load capacity and on-road mobility. It enables fast relocation between job sites without disassembly. Therefore, the mobile crusher is ideal for remote areas, tunnels, and hydropower projects where flexibility and rapid deployment are key.

Sled Plate Supports, Superior Stability During Operation

The sled plate support system increases ground contact area and distributes weight more evenly. This ensures exceptional stability, even on soft ground or uneven terrain. Besides, it can reduce the vibration Amplitude to improve the stability of equipment during operation.

How Does A Mobile Crushing Plant Work?

The mobile crushing plant consists of several components, like crushers, feeders, and screens. These key components work in harmony to crush and screen materials on-site. Here is an overview of how the mobile crusher plant work:

The mobile crushing plant is transported to the job site and set up. Its mobility allows it to be moved closer to the material source.

Raw materials are fed into the feeder, which regulates the amount of material entering the mobile crusher.

The material is crushed in the crusher, where it is broken down into smaller pieces. The type of crusher machine used will determine the final size and shape of the material.

After crushing, the material may go through a screening process to separate it into different sizes. Oversized materials can be sent back for further crushing.

The processed material is then discharged onto conveyor belts or directly into trucks for transport.

Once the site’s material is processed, the mobile plant demonstrates its core value: rapid mobility. The conveyors are folded in, the mobile crusher is lowered and secured, and it is ready to move. Wheeled crusher plants hook to a truck for highway-speed towing to the next site. Tracked crusher plants use their own propulsion to crawl to the next pile or loading area on site, often without needing a transport vehicle. This step, taking mere minutes to hours instead of days, enables zero downtime between jobs and maximizes productive uptime.

How to Choose A Right Mobile Crushing Plant?

Choosing the right equipment is more than just comparing mobile crushing plant price — it requires careful consideration of your project’s needs, site conditions, and long-term operation goals. To help you make the best decision on mobile crushing & screening plant, here are the key factors to focus on:

Specify Your Needs

First, you need to determine your needs, you need to know clearly what kind of project you are buying this mobile stone crusher plants for because there are more kinds of mobile crushing plants, different kinds also have different fields of application, so you must contact your engineer to negotiate your needs before asking for a quotation.

Know The Capacity

Consider Mobility and Site Conditions

- Choose wheeled type if your site has solid roads and you expect to move the plant between projects with the help of a trailer.

- Opt for crawler type if your project requires on-site mobility across difficult terrain or frequent repositioning without external traction equipment.

Your working environment plays a critical role in selecting the right mobile crushing plant. If your project requires frequent relocation across rough or uneven terrain, mobility and ground adaptability become essential. In contrast, sites with solid roads and fixed work zones demand a different approach.

Look for Customizable Configurations

Evaluate After-Sales Support

Consider the Total Investment, Including Price

Determine Right Mobile Crusher Manufacturers

Crawler vs Wheeled Mobile Crusher — Which One Fits Your Project?

|

|

|

|---|---|---|

| Moves independently on-site using tracks; ideal for construction or demolition sites with uneven, muddy, or rough terrain | Mobility | Moves on paved or solid ground; best for urban projects or sites that require frequent relocation over long distances |

| Excellent — handles slopes, soft ground, and off-road conditions; suitable for mines, quarries, and rough job sites | Terrain Adaptability | Limited — requires flat, hard surfaces; recommended for highways, urban road construction, and aggregate plants on even ground |

| Quick on-site setup; can start crushing immediately after positioning; perfect for flexible, multi-location projects | Setup & Relocation | Fast on paved surfaces, but often needs additional equipment for site changes; ideal for projects on smooth, easily accessible roads |

| Generally higher upfront cost due to track system; justified for long-term projects with tough terrain | Investment Cost | Usually lower initial investment; good for budget-sensitive projects or short-term assignments |

| Track system requires regular inspection; extremely reliable in harsh conditions, suitable for heavy-duty long-term operations | Maintenance | Tires are easier to maintain; less wear on smooth surfaces; suitable for light to medium-duty projects and urban sites |

Now that you understand the key differences between crawler and wheeled mobile crushers, you likely have a clear idea of which type best fits your project. The next important step is to consider the investment cost. With so many mobile crusher plant manufacturers on the market, how can you ensure you get a fair and reasonable price without compromising on quality or performance?

Useful Tips to Help You Get a Fair and Accurate Quote

When buying a mobile crusher plant, the price depends on many factors: project location, product type, site conditions, and equipment configuration. Before focusing on a number, you need to clarify these factors. The more detailed information you provide — including local climate, air pressure, and voltage — the more accurately a supplier can recommend the right product and configuration for your project. Here are three practical steps to get the most accurate and reasonable mobile crushing and screening plant price:

Find a Reliable Supplier

Mobile crusher plants are large, complex equipment. Choosing a trustworthy supplier is essential for ensuring product quality and reliable service.

- Search online and shortlist at least five suppliers.

- Compare their reputation, product range, and customer feedback.

- Only work with suppliers who can guarantee quality and after-sales support.

Visit the Factory

After shortlisting suppliers, visit their factories if possible. On-site inspection helps you evaluate:

- Factory size and production capacity

- Staff expertise and production technology

- Quality testing procedures and shipping capabilities

Negotiate with Full Understanding

Once you choose a preferred supplier, discuss the quotation carefully. Understand what influences the price:

- Production technology and materials used

- Patents, certifications, and customization options

- After-sales support and warranty

- Real customer feedback to confirm performance

Getting a fair price is just the first step. Choosing the right mobile crushing plant also means considering long-term performance, maintenance, operator training, and flexible applications for your projects. By taking all these factors into account, you ensure your investment delivers reliable operation, maximum efficiency, and long-term profitability.

AIMIX offers proven mobile crushing and screening solutions tailored to your project needs. With our experience, customization options, and global support, we help you select the right equipment and get the best value. Don’t wait, contact us right now to get your accurate quote and start maximizing your project’s efficiency and ROI.

Related Products – Stationary Crushing Plant

Anyone who understands the crushing industry probably knows that in addition to mobile crushing trucks, engineers usually analyze the customer’s needs and combine jaw crusher, cone crusher, impact crusher, feeding equipment and screening system to form a set of inconvenient “stationary” crushing plant. Here we see what is the difference between stationary and mobile crushing plant.

What Are The Differences Between Stationary And Mobile Crusher Plant

1. Mobility

2. Setup And Installation

3. Operational Flexibility

4. Production Capacity

5. Infrastructure Requirements

It’s important to note that these differences may vary depending on specific models and configurations of crusher plants. The choice between stationary and mobile types depends on factors such as project duration, mobility needs, production requirements, and site conditions.

If you are interested in the stationary crushing plant, you can browse the following programs we have done for our customers.

200TPH Stationary Crusher Plant For Crushing Granite

Configurations:

APG-4211W (vibrating feeder)

APJ-7510E (jaw crusher)

APC-160C(compound cone)

APS-2160Y4 (vibrating screen)

150TPH Stationary Crusher Plant For Concrete Production

Configurations:

APG-3895W (vibrating feeder)

APJ-6090E (jaw crusher)

APC-132C-M (medium crushing compound cone crusher)

APC-132C-F (fine crushing compound cone crusher)

APS-2160Y4 (vibrating screen)

The above is about the mobile crushing plant, there are related products fixed crushing plant introduction, in fact, the crushing program is very flexible, may be a little bit of a small change will affect the results of the whole program, if we show the program does not meet your project needs, welcome to inquire, our engineers will answer your questions and solve problems, to develop the most reasonable program!