Natural disasters occur frequently, with approximately 30,000–50,000 km of roads worldwide damaged each year due to earthquakes, floods, and typhoons, resulting in direct economic losses of tens of billions of dollars. Delays in reopening emergency routes can increase socio-economic losses by 0.5%–1% per day. In post-disaster road recovery, time is life, and speed is value—the first 48 hours to reopen key roads are especially critical.

This article provides a comprehensive, quantitative analysis of the strategic value of rapid deployment asphalt plants in both emergency road reopening and long-term reconstruction. It aims to help decision-makers and construction teams implement efficient, economical, and sustainable asphalt road recovery solutions.

Global Disasters and Road Infrastructure Status

Global road infrastructure faces multiple pressures. According to the International Road Federation (IRF), between 2015 and 2024, natural disasters caused more than 1,200 major road damage incidents, each affecting an average road length of approximately 500 km. Bridge damage, washed-out roadbeds, and key route interruptions often limit the speed and resource allocation of traditional road recovery efforts.

Disaster Types and Road Damage Characteristics

Different types of disasters have distinct damage patterns and recovery difficulties:

| Disaster Type | Typical Damage | Average Affected Road Length | Average Repair Period | Special Construction Challenges |

|---|---|---|---|---|

| Earthquake | Pavement cracks, bridge collapse, landslides | 450–600 km | 7–14 days | Unstable subgrade, high need for temporary bridge supports |

| Flood | Roadbed erosion, bridge damage, mud coverage | 400–550 km | 5–10 days | Difficulty controlling material moisture; construction machinery vulnerable |

| Typhoon/Hurricane | Flooding, fallen trees blocking roads | 350–500 km | 3–7 days | Strong winds and water limit construction time windows |

| Volcanic Eruption | Lava coverage, ash contamination | 100–300 km | 7–14 days | High temperatures and ash affect machinery and operational safety |

Regional Differences in Road Damage

Social and Economic Impacts

Asphalt road disruptions not only affect traffic but also directly impact rescue efficiency and regional economic recovery:

Reduced rescue efficiencyImpeded traffic delays material transport and patient evacuation, with each day of delay potentially increasing economic losses by 0.5%–1%.

Impact on residents’ daily lifeAccess to schools, hospitals, and basic supplies is restricted, exacerbating social anxiety if recovery is delayed.

Logistics and economic effectsKey road closures can create logistics bottlenecks, increasing transportation costs by 10–15% and slowing regional economic recovery.

Current Road Recovery Status and Challenges

- Limitations of traditional construction methods: stationary asphalt plants and manual repair processes have long setup cycles (averaging 7–14 days), insufficient for the “golden 48-hour” emergency reopening window.

- Complex construction environment: Damaged roads often involve collapsed bridges, landslides, or flooded areas, complicating machinery transport and construction.

- Material and resource constraints: Temporary construction materials are often insufficient in disaster areas, and damaged roads limit transportation efficiency.

The frequent occurrence of natural disasters worldwide places unprecedented pressure on road infrastructure. Damage to roads not only affects transportation but also has direct consequences on disaster relief and economic recovery. Understanding these damage patterns is essential for further examining the current status of the post-disaster road recovery industry.

Global Demand for Post-Disaster Road Recovery

Post-disaster road recovery is not just an engineering task but also a comprehensive test of time, resources, technology, and management capacity. With the increasing frequency and intensity of natural disasters worldwide, the demand for road reopening and restoration has become more multidimensional.

Time Sensitivity: The Golden 48 Hours

According to international disaster relief experience, the first 48 hours after a disaster are the critical window for road reopening. Beyond this period, rescue efficiency drops sharply, and delays significantly affect community life and economic recovery:

- Reopening main routes within 48 hours can improve relief material transport efficiency by 40–60%.

- If road recovery is delayed beyond 72 hours, socio-economic losses may increase by 10–15%.

- The time cost of emergency road reopening accounts for 20–30% of overall recovery costs.

Complexity of Construction Environments

Disaster-affected asphalt roads are often located in severely damaged or geographically constrained areas, making construction highly complex:

| Environmental Condition | Challenge | Requirements for Construction Solutions |

|---|---|---|

| Road collapses, bridge failures | Difficult machinery transport | Highly mobile construction equipment |

| Flooding, mud coverage | Difficulty in moisture control | Waterproof, anti-settlement construction materials |

| Narrow or mountainous roads | Large traditional equipment cannot access | Small, modular construction equipment |

| High temperatures or volcanic ash zones | Rapid equipment wear, hazardous operations | Heat-resistant, wear-resistant equipment |

Material and Resource Constraints

Temporary road construction in disaster zones often faces material shortages and transport restrictions:

- Average temporary material reserves are only 30–40% of actual demand.

- Damaged transport routes extend the construction cycle by 3–5 days.

- Rising demand for reusable or locally recycled materials improves flexibility and cost efficiency.

Regional Variations in Recovery Needs

Disaster recovery requirements vary significantly across regions:

Quantified Global Road Reopening Demand

Based on data from the past decade of disaster events:

| Region | Avg. Annual Road Damage Length | Avg. Road Reopening Period | Main Construction Approach |

|---|---|---|---|

| Southeast Asia | 8,000–10,000 km | 2–5 days | Temporary paving, mobile asphalt plants |

| Japan | 1,500–2,000 km | 3–7 days | High-precision mix paving, bridge support |

| North America | 2,500–3,000 km | 3–6 days | Combined approach with fixed + mobile plants |

| Volcanic Zones | 500–800 km | 5–10 days | Clearing + heat-resistant paving |

Globally, the post-disaster road recovery industry is developing rapidly, yet traditional construction methods still show clear limitations. Faced with urgent reopening needs and geographically dispersed project sites, the shortcomings of existing approaches are increasingly evident—driving the industry toward more efficient and flexible construction solutions.

Traditional Road Recovery Models and Their Limitations

In global post-disaster road recovery practices, traditional construction models remain dominant. However, when faced with complex environments and urgent time requirements, they show clear limitations such as low efficiency, poor flexibility, and high costs. As disasters increase in frequency and intensity, these shortcomings increasingly constrain rescue efforts and economic recovery.

Stationary Asphalt Plant Construction Model

Fixed asphalt mixing plants are typically located near cities or main highways, transporting asphalt mixes long distances to construction sites. Their characteristics are as follows:

| Indicator | Typical Value/Description |

|---|---|

| Commissioning Period | 14–20 days, including installation, testing, and trial runs |

| Hourly Output | 60–150 tons/hour (medium plants); 200–400 tons/hour for large plants |

| Per-Shift Output | 800–1,200 tons/shift (10-hour operation, fixed plant) |

| Transport Dependence | High; asphalt transport costs account for 30–40% of total cost per ton |

| Site Requirements | Large land area; requires leveled ground and stable power supply |

Limitations

- Long commissioning cycle: Equipment installation, testing, and trial runs are time-consuming, making it impossible to meet the “golden 48-hour” emergency recovery window.

- High and restricted transport costs: Severe road interruptions or collapses hinder asphalt delivery, raising costs and reducing efficiency.

- Poor flexibility: Fixed asphalt plants cannot adapt to narrow roads, mountainous areas, or landslide zones, limiting mobility.

- Slow emergency response: In cases of multi-point damage, fixed asphalt mixing plants cannot quickly cover all affected areas.

Manual Repairs and Cold Mix Construction

Post-disaster recovery also often relies on manual repairs and cold mix techniques:

CharacteristicsFlexible; suitable for limited spaces and damaged sections; no need for large equipment.

Construction EfficiencyEach asphalt road worker can pave approximately 50–100 m² per day.

LimitationsLow efficiency, limited material quality and pavement durability, unsuitable for long-distance or high-traffic roads.

Case Example: In the 2022 Philippines flood disaster, cold mix patching was used to reopen a 5 km main road. The process took 7 days and only allowed single-lane traffic. Long-term restoration still required fixed plant operations afterward.

Risks and Economic Impacts

| Construction Model | Avg. Road Recovery Time | Cost Level | Social & Economic Risks |

|---|---|---|---|

| Fixed Asphalt Plant | 7–14 days | High | Delayed reopening, hindered rescue, 10–15% increase in socio-economic losses |

| Manual Repair/Cold Mix | 5–12 days | Medium | Low efficiency, poor durability, higher future maintenance costs, limited reopening benefits |

Key Challenges of Traditional Models

- Complex disaster environments: Landslides, flooding, collapsed bridges, and mountainous roads restrict machinery access, delaying recovery.

- Severe time pressure: The golden 48-hour window for reopening cannot be met, directly reducing rescue efficiency and increasing losses.

- Material and energy constraints: Disaster zones often lack temporary road materials, and fixed plants require stable electricity, limiting adaptability.

- Inability to cover multiple disaster points: Fixed plants cannot be rapidly deployed to dispersed sites, complicating coordination and management.

- Insufficient long-term durability: Manual patching and quick fixes may reopen roads temporarily but lack durability and resilience, requiring repeated maintenance.

Traditional road recovery models face evident limitations in disaster zones: long commissioning times, low flexibility, high transport dependence, and limited efficiency, all of which fail to meet the urgent demands of global post-disaster recovery. Their weaknesses extend beyond operational efficiency, as policy and standard implementation also play critical roles.

Policy, Standards, and Procurement Logic Analysis

Global post-disaster road recovery is not only an engineering and technical issue but is also deeply influenced by policies, regulations, industry standards, and procurement logic. These factors directly shape the choice of construction models, equipment configuration, and material applications, providing both institutional and market foundations for the adoption of rapid deployment asphalt plants.

International Emergency Road Recovery Policies

Multiple countries and international organizations have introduced policies for emergency road clearance and infrastructure recovery:

Road Construction Standards and Quality Requirements

While disaster road recovery standards vary by country, the overall trend balances rapid clearance with long-term durability:

| Country/Region | Post-Disaster Road Standards | Key Indicators | Equipment Requirements |

|---|---|---|---|

| United States | ASTM D5361/D5362 | Pavement compaction ≥95%, temperature control ±10°C | High output, precise temperature control |

| European Union | EN 13108 | Pavement thickness and durability for multi-climate adaptation | Rapid commissioning, modular layout |

| Japan | JIS A 5015 | High seismic resistance and surface smoothness | High-precision mixing, quick start-up |

| Southeast Asia | ASEAN Guidelines | Emphasis on rapid clearance and temporary traffic | Strong mobility, on-site flexibility |

Procurement Logic and Disaster Zone Needs

Procurement decisions for post-disaster road recovery projects are influenced by the following factors:

- Time Sensitivity: Efficiency in reopening roads directly drives preference for rapid deployment equipment.

- Equipment Flexibility: Modular units capable of operating in narrow, damaged, or mountainous areas are favored.

- Material Adaptability: Equipment that can process temporary paving materials or recycled asphalt plays a key role in procurement choices.

- Cost and Affordability: Disaster recovery budgets are often limited, favoring solutions with lower transport, installation, and operation costs.

- Long-Term Durability: While short-term reopening is critical, decision-makers also value equipment and methods that ensure long-term pavement quality.

Global Procurement Quantitative Analysis

Based on data from international post-disaster recovery projects over the past five years:

| Region | Annual Asphalt Plant Procurement (units) | Average Equipment Specs | Key Procurement Considerations |

|---|---|---|---|

| Southeast Asia | 15–25 | Mobile, 100–150 t/h | Speed of deployment, flexibility |

| Japan | 5–10 | High-precision fixed, 200–300 t/h | Accuracy, seismic durability, long-term quality |

| North America | 8–12 | Combination of fixed + mobile, 150–250 t/h | Output capacity, multi-scenario adaptation |

| Europe | 3–8 | High-capacity fixed, 300–400 t/h | Durability, regulatory compliance |

Policies and standards are not merely legal requirements—they directly impact project budgets, construction timelines, and resource allocation. Within these institutional frameworks, the market scale and economic benefits of post-disaster road recovery can be quantified. The next section will analyze global market costs, construction efficiency, and potential market space, providing a data-driven foundation for the application of rapid deployment asphalt plants.

Market and Economic Analysis

The application of rapid deployment asphalt plants in post-disaster road recovery not only demonstrates technical advantages but also directly impacts market demand and economic benefits. This section analyzes the global post-disaster road recovery market size, construction cost structure, and the potential economic value of rapid deployment equipment.

Global Post-Disaster Road Recovery Market Size

- According to UN and World Bank statistics, over the past decade, there have been an average of 350–400 natural disaster events per year worldwide, causing $20–30 billion in road infrastructure losses annually.

- Emergency road reopening demand is concentrated in Southeast Asia, the Pacific Rim earthquake zones, North American flood regions, and volcanic zones, accounting for 60–70% of global demand.

- Focusing on county and rural roads, urban road upgrades, and key traffic arteries, there are approximately 15,000–20,000 post-disaster road reopening projects per year, requiring 3–4 million tons of asphalt mix.

Construction Cost Analysis

Using traditional fixed asphalt plants for post-disaster road reopening involves the following cost structure:

| Cost Type | Percentage | Description |

|---|---|---|

| Equipment Installation & Civil Works | 30–40% | Limited by road damage; temporary foundations or modifications needed |

| Material Transport | 25–35% | Disaster-affected transport routes increase difficulty and cost |

| Labor & Management | 20–25% | Includes operators, inspectors, maintenance, and coordination |

| Maintenance & Downtime Loss | 10–15% | Equipment failures can prolong construction cycles |

Value of Rapid Deployment Asphalt Plants

- Modular design, fast installation, and easy relocation can reduce 30–50% of civil and transport costs.

- Intelligent operation systems can cut labor requirements by ~50%.

- Continuous operation and high capacity can shorten construction cycles by 70–80%, reducing economic losses.

Quantified Economic Benefits

For a typical small-to-medium county asphalt road reopening project (3 km length, 6 m width):

| Indicator | Traditional Fixed Asphalt Plant | Rapid Deployment Asphalt Plant | Improvement |

|---|---|---|---|

| Commissioning Period | 10 days | 2–3 days | Reduced by ~70–80% |

| Daily Output | 50–60 tons | 90–100 tons | Increased by ~80% |

| Material Transport Cost | High | Medium–Low | Saved ~35% |

| Labor Input | 4 persons/shift | 2 persons/shift | Saved 50% |

| Total Project Cost | 100% | ~80–85% | Reduced ~15–20% |

Investment and Market Potential Analysis

When the market size, construction costs, and economic potential are clearly understood, the key question emerges: How can road reopening efficiency be maximized under limited time and resources? Rapid deployment portable asphalt plants provide a crucial solution for this high-pressure environment.

Application Analysis of Rapid Deployment Asphalt Plants in Post-Disaster Road Recovery

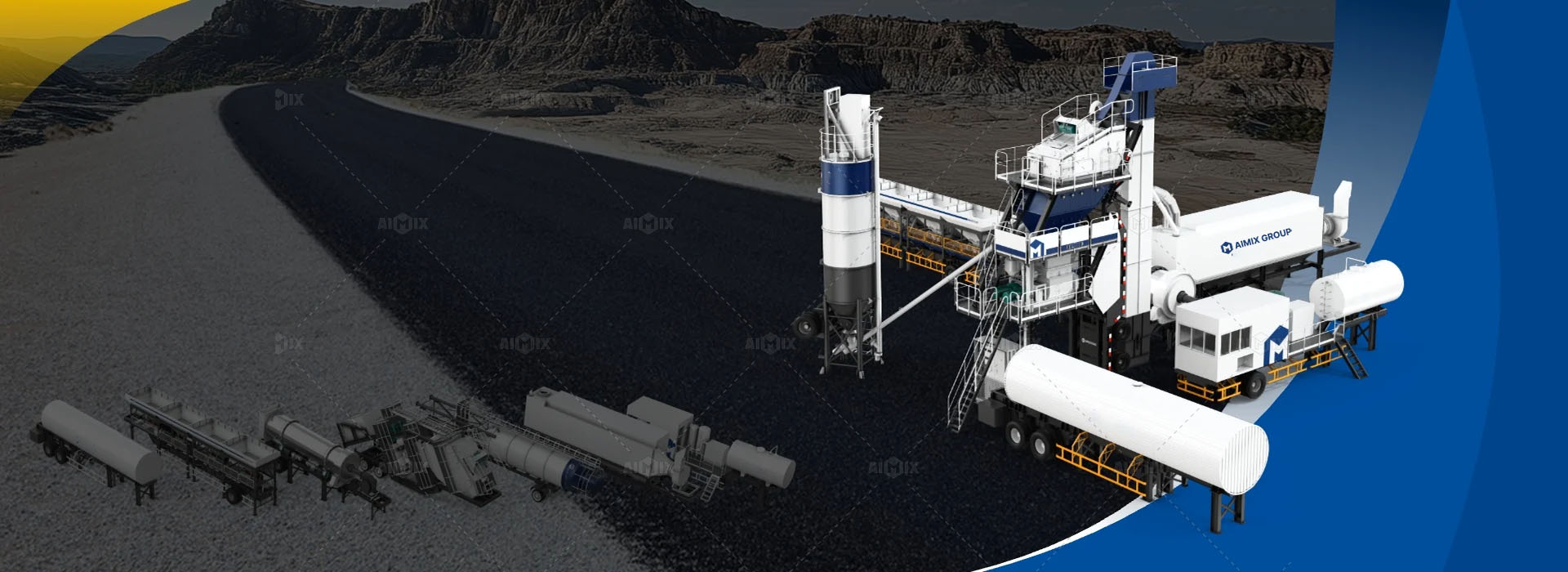

In the context of frequent global disasters, road reopening has become the top priority for restoring order in both urban and rural areas. Rapid Deployment Asphalt Plants (RDAPs), with their rapid response, high mobility, and efficient construction capabilities, have emerged as a key technical solution for emergency road access and short-term maintenance projects. The ALYQ90 mobile asphalt mixing plant serves as a representative example, demonstrating the practical value of RDAPs in disaster recovery.

Post-Disaster Construction Features and Rapid Response Capability

| Feature | Description | Post-Disaster Application Value |

|---|---|---|

| Modular Structure | Magnet-based modular design, plug-in connectors, fast installation with 7 mobile units | Can be assembled quickly in disaster zones; first installation completed within 7 days, subsequent relocations operational within 24 hours—meeting the golden emergency window |

| High Output & Efficiency | 90 tons/shift, up to 100 tons/day (10-hour operation) | Ensures continuous paving of single-lane roads under disaster recovery conditions |

| Intelligent Operation System | AI-based smart control with e-inspection, fault warning, and remote monitoring | Improves efficiency, reduces human error, minimizes downtime |

| Efficient Mixing System | High-power turbulent mixing system | Guarantees material uniformity and quality stability, even in harsh disaster environments |

| Material & Environmental Adaptability | Capable of using recycled asphalt or temporary materials; equipped with gravity + baghouse dust collection | Meets resource limitations in disaster zones while ensuring environmental compliance and reducing transport needs |

Quantified Construction Efficiency

In a typical county-level road recovery project, the ALYQ90 demonstrates significant improvements:

| Indicator | Traditional Fixed Asphalt Plant | ALYQ90 Rapid Deployment Plant | Improvement |

|---|---|---|---|

| Commissioning Period | 7–14 days | 7 days for first installation; 24 hours for relocation | Reduced by ~70–80% |

| Daily Construction Length | 1–2 km | 3–5 km | Increased by 2–2.5x |

| Dependence on Material Transport | High | Medium–Low | 30–50% cost savings |

| Labor Requirement | 4 workers | 2 workers | 50% labor reduction |

| Maintenance Cycle | Medium | 2,000 hours vibration screen maintenance-free; mixing blades/liners last 5 years | Significantly reduced downtime risk |

Target Customers and Application Scenarios

The ALYQ90 mobile asphalt mixing plant is designed for small to medium-sized road construction contractors and maintenance firms, particularly suited for:

- Small to medium projects: County and municipal roads, community roads, parking lots, small airport runways, and hydropower access roads

- Dispersed or remote projects: Multiple short-duration projects (weeks to months), often requiring generator support

- Budget-constrained companies: Those unable to invest in costly fixed asphalt mixing plants

- Rapid response needs: Frequent relocations and urgent construction requiring fast commissioning

- Core Value: High mobility, fast relocation, reduced capital investment, continuous production, and guaranteed output quality.

Global Post-Disaster Application Potential

| Region | Disaster Type | ALYQ90 Application Advantages |

|---|---|---|

| Southeast Asia | Floods, typhoons | Narrow roads and waterlogging—equipment can be deployed quickly for road reopening |

| Japan | Earthquakes, landslides | High-precision repairs, flexible layout for localized restoration |

| North America | Floods, storms | Modular plants deployed at multiple points to cover damaged roads |

| Volcanic Zones | Volcanic ash coverage | Heat- and wear-resistant, suitable for complex material conditions |

Rapid deployment asphalt plants have already proven their value in practice. However, the future of this industry will be shaped by technological innovation, policy support, and evolving market demand, defining the next stage of global post-disaster road recovery.

Industry Trends and the Development Outlook for Rapid Deployment Asphalt Plants

With the increasing frequency of natural disasters and the aging of infrastructure worldwide, the post-disaster road recovery industry faces urgent timelines, fragmented projects, and highly complex construction environments. As a core construction technology, Rapid Deployment Asphalt Plants (RDAPs) are shaping the industry’s development trends and market outlook.

Global Post-Disaster Road Recovery Industry Trends

Rising Disaster Frequency and Intensity

- UN data shows that over the past 20 years, global natural disasters have grown at an average annual rate of 3–5%.

- Floods, typhoons, and earthquakes increasingly damage roads, driving up demand for rapid-access construction.

- The “Golden 48 Hours” has become a critical benchmark for rescue operations and infrastructure recovery.

Rapid Technological Iteration

- Modular, mobile, and rapid-deployment equipment has become the industry mainstream.

- Recycled asphalt, temporary paving materials, and hybrid construction solutions are improving resource utilization and flexibility.

Stricter Policies and Standards

- Governments are imposing higher requirements on both response speed and road durability.

- Rapid deployment equipment must balance efficiency, environmental compliance, and long-term performance.

Globalization and Multi-Point Collaboration

- International relief and infrastructure aid projects are on the rise, requiring multi-point deployment and cross-border construction.

- Modular RDAPs are easily transported and deployed internationally, meeting the needs of multi-disaster recovery.

Technological Development and Innovation Directions

| Technology Focus | Development Trend | Industry Value |

|---|---|---|

| Modularization & Mobility | Split transport, quick assembly, multi-point deployment | Meets dispersed projects and short-term disaster recovery needs |

| Intelligent Control & Remote Management | Automation, data monitoring, fault alerts | Improves efficiency and reduces operator risk |

| Environmental Protection & Energy Saving | Enclosed heating systems, low-emission design | Complies with regulations and adapts to harsh conditions |

| Material Adaptability | Recycled asphalt, temporary paving materials | Meets material shortages and temporary road needs |

Market Demand and Application Scenarios

Based on disaster recovery projects over the last decade:

- Regional Concentration: Demand is strongest in Southeast Asia, the Pacific earthquake belt, and North America’s flood-prone regions.

- Project Characteristics: Small to medium scale, dispersed, short cycles, frequent relocation.

- Equipment Preference: Small to medium-sized mobile plants account for over 60% of adoption.

- Growth Trend: The global RDAP market is projected to grow at 8–12% annually over the next five years.

- Return on Investment: Each day of delay in post-disaster road reopening can cause 0.5–1% of regional GDP loss, underscoring the value of rapid deployment solutions.

The Value of ALYQ90 Mobile Asphalt Plant in Global Disaster Recovery

In the context of frequent disasters and urgent road reopening demands, the ALYQ90 mobile asphalt plant demonstrates exceptional value:

Golden 48-Hour Deployment

- First installation within 7 days; subsequent relocations operational in just 24 hours.

- Aligns with the critical post-disaster golden window, ensuring rapid road reopening.

Significant Construction Efficiency Gains

- Output of 90 tons/day, roughly 2x higher than conventional small to mid-scale fixed plants.

- Strong multi-project continuous operation, enabling simultaneous recovery across damaged road networks.

Cost and Resource Savings

- Modular design reduces foundation and relocation costs.

- Labor needs reduced by 50%, while material utilization is enhanced—substantially lowering overall costs.

Adaptability to Harsh Environments

- Supports recycled asphalt and temporary materials; adapts to floods, typhoons, earthquakes, and volcanic ash.

- Intelligent operation system and remote monitoring ensure continuous work and reduce human error.

Global Application Potential

- Southeast Asia (Floods/Typhoons): Rapid deployment for rural road reopening.

- Japan (Earthquakes/Landslides): Flexible layout for localized high-precision repairs.

- North America (Storm Damage): Modular, multi-point deployment to cover widespread road failures.

- Volcanic Regions: Heat- and wear-resistant design suited for extreme material conditions.

The global post-disaster road recovery industry is defined by urgent timelines, dispersed projects, and harsh environments. Rapid Deployment Asphalt Plants, particularly the ALYQ90, align perfectly with small to medium-scale, short-term recovery needs, offering unmatched speed, flexibility, and efficiency.

Seize the Opportunity: Rapid Deployment Asphalt Plants for Post-Disaster Road Recovery

Frequent global disasters cause widespread road damage, while traditional construction methods are too slow and inflexible to meet urgent reopening needs. Growing policy requirements and market pressure make efficiency and cost control more critical than ever. If you want to boost efficiency and shorten project timelines, contact us today and let our asphalt plant deliver a fast, dependable solution for your construction needs.