Whether you’re aiming to produce aggregate for construction, manufacture cement, or supply lime, one thing is clear: your choice of limestone crusher machine is absolutely critical to your success. Get it right, and you unlock maximum productivity, superior product quality, and healthy profits. Get it wrong, and you face constant downtime, unexpected costs, and subpar results. In this guide, we’ll walk you through everything, from crusher mechanics and smart plant design to actionable business advice,helping you make confident, profitable decisions for your limestone operation.

Know Your Rock First: Material Traits That Shape Every Decision

Before you even look at a limestone crusher, you need to understand what you’re feeding it. Limestone is medium hard, brittle, and usually low to medium in abrasiveness. That sounds easy, but two hidden variables can disrupt your plan: moisture and clay. Wet, sticky fines can clog chutes and screens. Oversized feed can overload a secondary crusher. Poor pre-screening can blow up your fines ratio. So start with a short checklist:

✅Max feed size (Max): what comes after blasting or ripping? 300–700 mm changes your primary crusher choice.

✅Moisture and clay: above ~5–8% moisture or visible clay seams need pre-screening and possibly washing.

✅Target products: do you need premium concrete-grade aggregates? Or more sand for margin?

✅Environmental needs: dust, noise, and water management drive layout choices.

Mastering Limestone Crushing: The Best Crushers for Primary, Secondary & Tertiary Processing

Selecting the right limestone crusher is essential for efficient operation. It shapes your crusher plant’s efficiency, product quality, and long-term profitability. Because limestone varies in hardness, moisture, and required end-product size, each crushing stage demands a specialized machine designed to perform a specific task. Below, we break down the major rock crusher types used in primary, secondary, and tertiary limestone crushing, helping you quickly determine which limestone machine fits your production strategy.

Limestone Jaw Crusher

- Why Use it? Limestone raw ore has a large particle size (500–1200 mm), requiring powerful primary crushing; Jaw crushers use a compression method and are the most adaptable to varying feed sizes. simple structure and easy maintenance, suitable for harsh mining environments

- Characteristics of the Produced Aggregate: 150–300 mm particle size; Irregular particle shape, with many needle-like and flaky particles; Low fines content, coarse gradation

- Best Applications: as a preliminary process for secondary/tertiary crushing; Coarse crushing stage in cement plants and stone quarries; not directly used in final concrete production

Impact Crusher for Limestone

- Why use it? Limestone is brittle and has low impact resistance; utilizes high-speed impact + multiple rebounds; High content of cubic particles in the finished product.

- Characteristics of the Crushed Limestone: 5-40 mm output size; Cubic particle shape, with few needle-shaped or flaky particles; Controllable powder content.

- Most suitable projects: High-grade highway concrete; Ordinary commercial concrete (C30–C50); Limestone for cement clinker; Manufactured sand for construction (pre-processing)

Cone Crushing Machine for Limstone Crushing

- Why use it? Although limestone doesn’t have high strength, high output and continuous, stable production are required; Cone crushers use layered crushing, suitable for large-scale operations; Low wear and stable energy consumption.

- Characteristics of the crushed aggregate: 5-40 mm output size; Relatively good particle shape , but still contains some flaky and elongated particles; High strength and stable gradation.

- Best for projects: Ordinary commercial concrete; Cement-stabilized crushed stone base course; Highway subgrade, railway ballast (sections without shaping requirements)

VSI Crushers

- Why use it? Excellent particle shape and continuous gradation, perfectly meeting the requirements of high-end engineering projects. VSI crusher is a high-speed impact crusher (stone-on-stone/stone-on-iron) that systematically improves aggregate particle shape.

- Characteristics of the produced aggregate: 0–5 mm, 5–10 mm particle size; Approaching the particle shape of natural sand

- Most suitable projects: High-strength, high-performance concrete (C60+); High-speed rail and airport runways; Bridges and tunnel linings; High-quality manufactured sand as a substitute for natural sand

Having explored the three-stage crushing process tailored to limestone’s physical properties, from primary reduction to precision shaping, it’s clear that the selection of limestone crusher for sale directly impacts operational efficiency and product quality. Now, let’s examine how strategic combinations of these crushers address diverse industrial demands. Custom configured crushing lines can optimize limestone processing for different requirements like aggregate grading, contamination control, and energy efficiency. Continue to explore more.

Building Your Winning Strategy: Industry-Focused Limestone Crusher Plant Configurations

A single crusher alone rarely fulfills all your operational needs. Success in your limestone crusher plant operations hinges on seamlessly connecting the right machines in a strategic order. Each step, each piece of equipment, is a note in your performance. Let’s explore how to orchestrate these elements to achieve specific goals among different industries, ensuring every operation resonates with efficiency and effectiveness.

Construction Aggregates (Road Base, Concrete, Asphalt Mixes)

Flow: Vibrating Feeder → Jaw Crusher (Primary) → Cone Crusher (Secondary) → Vibrating Screen

Optional: Closed-circuit recirculation + VSI for premium shape

Why:

- Jaw + Cone delivers strong reduction and consistent grading

- Closed-circuit screening ensures perfect sizing with minimal waste

- Cubical output available with VSI shaping when the market value depends on particle geometry

Sand-Focused Operations (Manufactured Sand Production)

Flow: Jaw Crusher → Impact Crusher or Cone Crusher → VSI Sand Maker → Washing System + Fines Recovery

Why:

- VSI crusher ensures tight particle size distribution and premium sand shape

- Washing removes impurities for higher-value clean sand

- Fines recovery reduces water usage and minimizes material loss

- Ideal for markets demanding quality M-sand for concrete and asphalt

Cement Manufacturing (Raw Meal Preparation)

Flow: Feeder → Jaw Crusher → Hammer Crusher / Impact Crusher → Raw Mill / Ball Mill

Optional: Closed-circuit recirculation + VSI for premium shape

Why:

- Creates fine, uniform feed that mills can process efficiently

- Impact or hammer stages help achieve the necessary fine fraction before grinding

- Supports simultaneous drying if moisture is present

- Delivers steady, predictable material flow to maximize kiln performance

Pro Tip: Always include a “Scalping” Screen before the primary crusher to remove fine dirt and small material that would otherwise reduce capacity. And never forget Dust Suppression systems – they are essential for environmental compliance and worker health.

Real-World Cases: How Global 1000+ Users Apply AIMIX Limestone Crushing Solutions

100-120 TPH Limestone Crusher Plant in Zanzibar, Tanzania

- Output size: 0-5mm, 5-10mm, 10-20mm, and 20-30mm

- Configuration: Vibrating Feeder + Jaw Crusher + Impact Crusher + Vibrating Screen

- Application: supplying aggregate for his contracted projects.

- Customer Feedback: “Our project costs have significantly decreased since we implemented the AIMIX crushing plant. No more worrying about premium prices for aggregates. It’s a reliable and permanent solution for our needs.”

200 TPH Limestone Crusher Plant in Indonesia

- Output size: 5-10mm, 10-15mm, 15-20mm and 20-35mm

- Configuration: Vibrating Feeder + Jaw Crusher + Fine Jaw Crusher + Vibrating Screen

- Application: for his own paper manufacturing factory and aggregate sale business.

- Customer Feedback: “We went from struggling to keep up to having more than enough high-quality material. Now we’re not only supplying our paper industry, but selling to construction companies, thanks to this partnership, which has built our competitive advantages.”

Customized 300-350 TPH Limestone Crushing Plant in Kazakhstan

- Output size: 5-10mm; 10-15mm; 15-25mm

- Configuration: Vibrating Feeder + Jaw Crusher + Impact Crusher + Vibrating Screen

- Application: for sand and aggregate production.

- Customer Feedback: “Since using this machinery, our production efficiency has significantly improved, making us a successful local stone supplier. Aimix’s stone crushing plant is very reliable and cost-effective, with high customer satisfaction.”

150 tph Mobile Limestone Crusher Plant for Road Construction

- Processing material: limestome

- Output size: 5-10mm; 10-15mm; 15-25mm

- Main equipment: Feeder + Jaw Crusher + Cone Crusher + Vibrate Screen

- Customer reviews: “The project took a total of 6 months to complete and go into production. AIMIX provided comprehensive services throughout the process. Once operational, the system ran smoothly and the output met our expectations. We are very satisfied with the mobile crushing plant.”

These are just some of our representative real-world cases for your reference. For your own projects, it is necessary to configure a customized crushing soution to meet construction goals. However, do you know how to choose a suitable mini limestone crusher machine to configure crushing line for your project? With diverse options available in terms of capacity, power, and design, selecting the right crusher for crushing limestone can be challenging. What should you pay attention to when selecting one? Forward to some guidances below.

How to Choose a Suitable Crusher Machine for Limestone?

When choosing a limestone crusher rock in the market, you need to carefully consider various factors to ensure the optimal performance and efficiency of the limestone crushing process. Here I have listed some main factors to consider for reference:

Understand The Limestone Properties

Determine the Required Output Specifications

- Identify the size of the final product needed (e.g., coarse aggregate, fine aggregate, powder). The types of crushed limestone will determine the types limestone crushing machine and the number of crushing stages needed.

- Smaller particle sizes may require additional crushing stages or the use of a finer crusher, like VSI crusher. Besides, if you need powder materials in limestone crusher cement plant, there would be limestone grinding machine, like ball mill, for addition processing after crushing process.

Estimate Production Scale

Consider the Mobility Needs

Considering the above three important facors, you can preliminarily select the best limestone crushing equipment with suitable production capacity. These crushers can form into limestone crusher plant for your operation.

Capitalize on Growth: Why You Should Start a Limestone Crushing Venture Today!

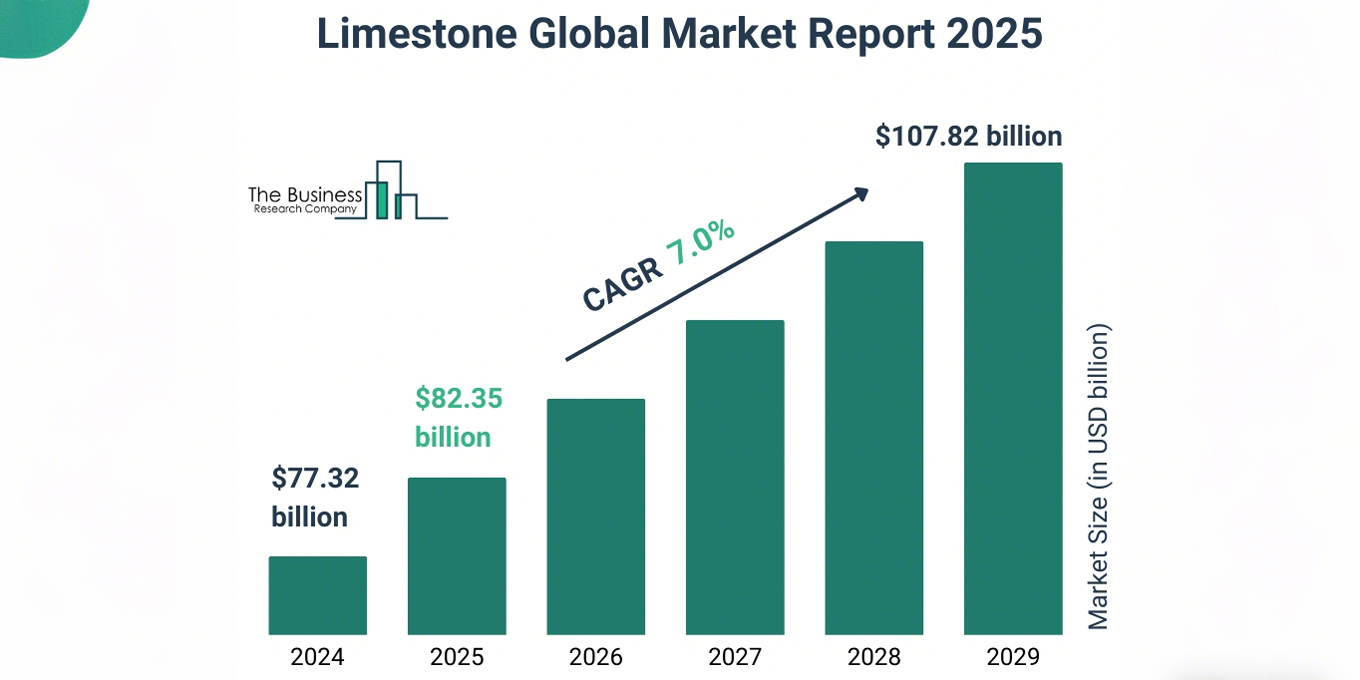

The global limestone market is on an impressive growth trajectory, fueled by infrastructure development, urbanization, and an increasing demand for sustainable building materials. With projections indicating a Compound Annual Growth Rate (CAGR) of over 7% in the coming years, there’s no better time to dive into the limestone crushing industry. Delaying now could mean missing out on a prosperous and forward-thinking venture.

Rising Demand = Guaranteed Profitability

Limestone is a cornerstone for cement, concrete, and road base materials. Global infrastructure projects and residential construction are accelerating, creating unmatched demand for crushed limestone.

Low Entry Barriers, High ROI Potential

Today’s modern crushing equipment is not only scalable but also energy-efficient, providing a quick return on investment. Modular plants enable startups to kick off on a small scale and expand as demand increases.

Future-Proof Your Investment

As predicted, 68% of the world’s population will live in cities by 2050, driving decades of construction demand. In addition, the recycled aggregates can’t fully replace limestone, ensuring long-term relevance in sustainable development.

Don’t let indecision rob you of a golden investment opportunity. Partner with AIMIX, a trusted supplier of crushing equipment, secure the necessary permits, and launch your limestone crushing business while demand is at its peak. Contact us right now for a free feasibility analysis.

What Is The Process Of Limestone Processing?

The limestone processing involves several key stages, each designed to transform raw limestone into a different particle size of materials that can be used in various fields. Here is an overview of the process:

Quarrying

- Drilling & Blasting: It all starts here. Proper fragmentation in the quarry means consistent, optimal-sized feed for your primary crusher.

- Loading & Hauling: Excavators and haul trucks bring the raw material to the plant’s receiving hopper.

Crushing

First, the raw limestone is fed into a primary crusher (e.g., jaw crusher or gyratory crusher). Crushing them into smaller pieces for further processing. Then, transporting the materials to the secondary crushers such as impact crushers or cone crushers.

Secondary & Tertiary Crushing

For finer products, material goes to cone or impact crushers. This is where you really shape the final product’s size and gradation. Feed a sand making machine if you need better cubicity or higher 0–5 mm share. Pair with washing and fines recovery if you demand clean sand.

Screening

The crushed limestone is screened to separate fine particles from coarser ones. Oversized material may be sent back to the lime stone crusher for further reduction. The last set of screens divides the crushed material into different product piles: 0-5mm, 5-10mm, 10-20mm, etc.

Storage and Packaging

The processed limestone is then stored in silos or stockpiles before being packaged and transported to the end users.

Keep It Running Smoothly: Simple Maintenance Wins

Regular maintenance isn’t just a cost—it’s a crucial investment that safeguards your operations from potential catastrophic downtime. In any system, whether mechanical, electrical, or environmental, proactive care can make all the difference. A well-planned maintenance routine not only enhances efficiency but also extends the lifespan of your limestone crusher equipment for aggregate. Here’s your routine to ensure everything runs smoothly.

Daily and Weekly

- Inspect bearings, listen for abnormal noise, and check vibration trends.

- Verify belt tracking and tension. Clean under return rollers.

- Check screen media and adjust tension to stop blinding and pegging.

- Grease points per schedule. Confirm lubrication flow and temperatures.

Wear Parts

- Jaw Crusher: watch nip angle and CSS; flip or change plates before output drifts.

- Impact Crusher: monitor blow bars, breaker plates, and rotor balance. Keep spare sets on site.

- Cone Crusher: track liner wear with cavity level and power draw; change before production drops.

- VSI Crusher: inspect anvils/rock shelf and impellers; balance the rotor after changes.

Preventive vs. Predictive

- Set inspection intervals by hours and load, not just calendar.

- Use sensors for temperature and vibration. Remote alerts prevent surprise downtime.

- Keep a parts list tied to serial numbers for fast ordering.

Safety and Downtime

- Enforce lockout-tagout. Guard all rotating parts. Use lift points for liners and bars.

- Plan shutdowns with checklists, tools, and crews ready. Bundle jobs to reduce stops.

The above is a brief overview of the maintenance tips for the limestone processing equipment, which is one of the most important ways to reduce the maintenance costs and improve your return on investment.

AIMIX, one of the most experienced manufacturers and developers of equipment, both stationary type and mobile type with best limestone crusher price. We are waiting for your inquiries 24 hours a day! We hope we can establish a long-term and friendly relationship, we are your most faithful limestone crushing equipment supplier, helping you to develop the most suitable limestone crushing solution and selecting the ideal limestone crushing plant is our first mission. Contact us for the best limestone crusher machine price right now!