To understand the usage of a stone crusher plant, you first need to know what a crushing plant is You also need to have a clear idea of your upcoming project, such as your budget, project timeframe, raw materials, final product, local standards and the development prospects of stone crushing in your region.

In addition, you need to focus on the equipment itself and the supplier. Only when all these questions have been answered can you narrow down your project and create a plan for it. This article will help you answer your questions, one by one.

Let us start with the first question.

What is a stone crushing plant?

Stone crushing plant is actually a general term, after all, there are many classifications of stone, such as granite, limestone, crushed stone, basalt, quartzite, andesite, cobblestone, river rock, volcanic rock, etc., and different raw materials used in the stone crushing plant are not the same, so the production of the product is also variable.

Below we show you some stone crushing programs we have done for our customers for your better understanding about the usage of stone crushing plants, hope to help you with your project.

Stone crushing plant has a wide range of applications

1000tph Crawler Mobile Crusher In Malaysia

200tph Stone Crushing Plant And Screening Plant in Uzbekistan

150tph Crusher Plant Was On The Way To Paraguay For Crushing Basalt

In addition to the areas mentioned above, stone crushing plants can be used in the following areas: road construction, builsing construction, railroad ballast, landscaping and decorative purpose, processing industry, mining operation, environmental and erosion control, etc.

Secondly, you must be very clear about your budget, in view of the many uncertainties of stone crushing plant, different price of stone crushing plant can produce different output, the following is a stone crushing plant price list provided by AIMIX, but this is only for reference, as mentioned above many times, only the program is completed, there may be a relatively accurate price.

Clarify your budget and equipment price list

But besides the price of the equipment itself, in fact, investing in a set of rock crushing plant is much more than these expenses. Here you will also find a rough list of what you can expect to pay.

Cost of investing in stone crushing plant

The cost of investing in a rock crushing plant can vary greatly depending on factors such as the specific type of plant, the capacity (tons per hour), the features and capabilities of the crushing plant, the input size of the raw material, the moisture content of the raw material, the geographic location of the plant, and other considerations. Below are some key factors that contribute to the overall cost:

Type of stone crushing plant:

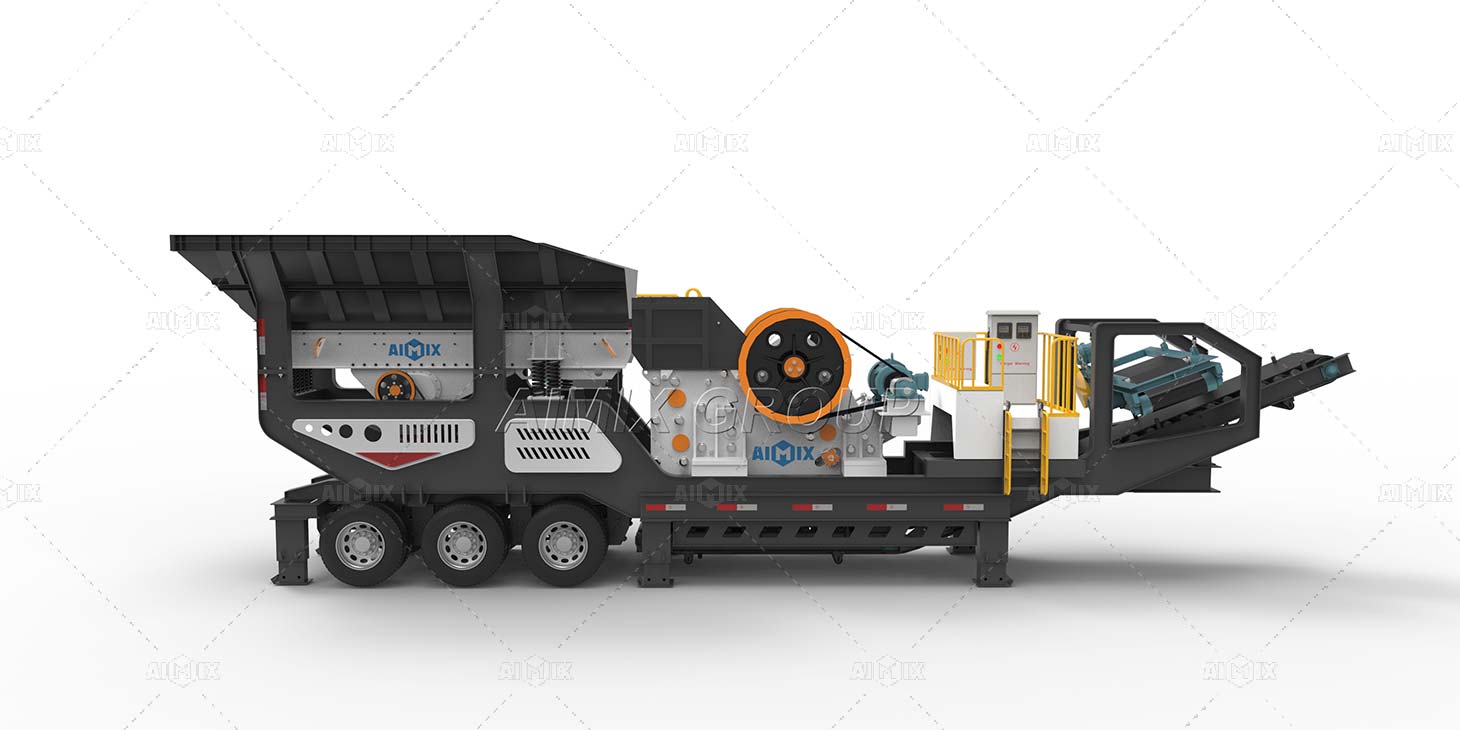

Different types of stone crushing plants have different costs. For example, stationary &mobile, crawler & tire type, their price are different, you still need to make sure which type you need.

So how to determine whether you need a stationary or mobile, need to move the tire type or need to move the track type? I also summarized a few small tips for you.

How to judge which type is ideal choice for your project?

Mobility requirements:

If you need to move the equipment frequently across different locations or terrains, a mobile option (either tire or track) would be more suitable, learn more here: https://aimixgroup.com/mobile-crusher-plant/. For stationary applications where mobility is not essential, a stationary option would suffice.

Terrain conditions:

Tracks generally provide better traction and stability on uneven or soft terrain like mud, sand, or snow. If your work environment involves such conditions, a track-type crusher plant might be preferable. Tires are more suitable for smoother surfaces or when frequent road travel is involved.

Weight distribution:

Tracks distribute weight more evenly over a larger surface area, reducing ground pressure. This can be advantageous in sensitive environments or when operating on fragile surfaces. Tires concentrate weight on smaller contact areas, potentially causing higher ground pressure.

Access limitations:

Consider the size of the equipment and any access constraints at your work location. Mobile equipment with tires may have better maneuverability in tight spaces and narrow pathways, whereas track-type equipment might struggle in such situations.

Cost considerations:

Generally, stationary options tend to be more cost-effective compared to mobile equipment. Additionally, tracks may have higher maintenance costs due to wear and tear, while tires can be more easily replaced. Remember to assess your specific needs and consult industry experts or manufacturers who can provide tailored advice based on your requirements.

Capacity of plant:

The production capacity of the crushing plant, measured in tons per hour, is an important factor that affects the overall cost. Higher capacity plants generally require larger investments.

| Model | APY2-57J | APY2-69J | APY2-750J | APY2-110J |

|---|---|---|---|---|

| Feeder model | APG-3090W | APG-3896W | APG-4211W | APG-4211W |

| Crusher model | APJ-5075E | APJ-6090E | APJ-7510E | APJ-110V |

| Maximum feed size (mm) | 425 | 500 | 630 | 650 |

| Silo volume (m3) | 4 | 5.3 | 7 | 7 |

| Iron separator model (optional) | RCYD(C)-6.5 | RCYD(C)-6.5 | RCYD(C)-8 | RCYD(C)-12 |

| Tire configuration | Parallel double shaft | Parallel double shaft | Parallel three shafts | Parallel three shafts |

| Main belt conveyor model | B650×8.5m | B800×8.5m | B1000×10m | B1000×10m |

| Side out belt conveyor model (optional) | B500×4m | B500×4m | B650×5m | B650×5m |

| Generator power (kW) (optional) | 120 | 160 | 200 | 250 |

| Production capacity (t/h) | 45-100 | 60-160 | 110-320 | 250-400 |

| Transport Length (mm) | 12500 | 12750 | 13270 | 13200 |

| Transport width (mm) | 2600 | 2600 | 2850 | 3000 |

| Transport height (mm) | 3950 | 3950 | 4200 | 4400 |

| Weight (t) | 28 | 39 | 57 | 65 |

| Model | APY2-110C | APY2-160C | APY2-200C |

|---|---|---|---|

| Crusher model | APC-110C | APC-160C | APC-200C |

| Vibrating screen model | APS-1848Y | APS-1860Y | APS-2160Y |

| Maximum feed size (mm) | 160 | 200 | 215 |

| Tire configuration | Parallel double shaft | Parallel double shaft | Parallel double shaft |

| Feeding belt conveyor model (optional) | B650 | B800 | B1000 |

| Output belt conveyor model (optional) | B500 | B650 | B650 |

| Under-sieve belt conveyor model | B650 | B800 | B1000 |

| Generator power (kW) (optional) | 240 | 280 | 320 |

| Production capacity (t/h) | 50-230 | 80-390 | 120-420 |

| Transport Length (mm) | 13800 | 13800 | 14500 |

| Transport width (mm) | 3000 | 3000 | 3000 |

| Transport height (mm) | 4400 | 4400 | 4500 |

| Weight (t) | 32 | 37 | 42 |

| Model | APY3-1010F | APY3-1210F | APY3-1214F | APY3-1315F |

|---|---|---|---|---|

| Feeder model | APG-3090W | APG-3896W | APG-3896W | APG-4211W |

| Crusher model | APF-1010H | APF-1210H | APF-1214H | APF-1315H |

| Vibrating screen model | APS-1548Y | APS-1848Y | APS-1860Y | APS-2160Y |

| Tire configuration | Parallel three shafts | Parallel three shafts | Parallel three shafts | Parallel three shafts |

| Return belt conveyor model | B650 | B650 | B800 | B1000 |

| Feeder belt conveyor model | B650 | B800 | B800 | B1000 |

| Under-sieve belt conveyor model | B800 | B800 | B1000 | B1000 |

| Production capacity (t/h) | 70-150 | 100-285 | 150-350 | 180-500 |

| Transport length (mm) | 13000 | 15800 | 15800 | 16500 |

| Transport width (mm) | 2500 | 2550 | 2550 | 3000 |

| Transport height (mm) | 4200 | 4500 | 4500 | 4500 |

| Weight (t) | 41 | 45 | 53 | 60 |

Type of stone crusher plant:

The choice of crushers and other equipment in the rock crushing plant affects the cost. High-quality and high-performance crushers may cost more to purchase, but they also offer greater efficiency and durability.

Infrastructure and site preparation:

The cost of site preparation, including necessary infrastructure such as foundations, access roads and electrical systems, adds to the overall investment.

Operational costs:

Ongoing operating costs, including fuel, maintenance and labor, should be considered. Energy efficient features and automation can have an impact on operating costs over the life of the facility.

Regulatory compliance:

Environmental and safety compliance may require additional investment. This includes the implementation of dust control measures, environmental monitoring systems and safety features.

Geographical location:

The location of the plant can affect costs due to factors such as transportation of raw materials and finished goods, labor costs, and local regulations.

Quality of suppliers and equipment:

The choice of suppliers and the quality of equipment can have an impact on costs. High quality equipment can result in higher initial costs, but also lower maintenance costs and a longer service life.

Financing and interest rates:

The type of financing and applicable interest rates can affect the overall cost of the investment. Consideration of financing options is critical to determining the economic viability of the project.

Market conditions:

Market conditions and demand for construction materials can affect costs. In times of high demand, equipment and construction costs may increase.

To obtain an accurate cost estimate, it is advisable to contact equipment suppliers, request detailed project plans and consider professional advice from experts in the field. The cost of a rock crushing plant can vary considerably depending on project-specific details and local conditions.

Next, let us look at what AIMIX is doing to reduce costs and increase efficiency.

AIMIX helps you to reduce the above costs

AIMIX can avoid overinvesting or buying unnecessary features by working with you to determine the specific production requirements of your project, including capacity, end product specifications and quality requirements, and recommending the right equipment. At the same time, we provide you with more than 2 solutions.

AIMIX creates a proactive and regular preventive maintenance program for all equipment. Timely maintenance can extend the life of the machines

After the arrival of stone crusher plant, AIMIX will ensure the operating and daily maintenance staff are well-trained. Proper training can lead to efficient operation, reduced downtime, and the early detection of potential issues, preventing costly repairs.

AIMIX will configure reasonable dust removal equipment according to the construction conditions and environment of your site. Implement effective dust control measures to comply with environmental regulations and minimize the impact on surrounding areas. This may include installing dust suppression systems, enclosing crushers, and using water sprays.

Our engineer will help user fine-tune the crushing process to minimize over-crushing and unnecessary processing. This can help in reducing wear and tear on crusher equipment and improve overall efficiency.

We will do our best to control the cost of raw materials from the production of crushing plant, control the production cost of crushing plant as well as the process. Negotiate with suppliers for better pricing on equipment, spare parts, and consumables.

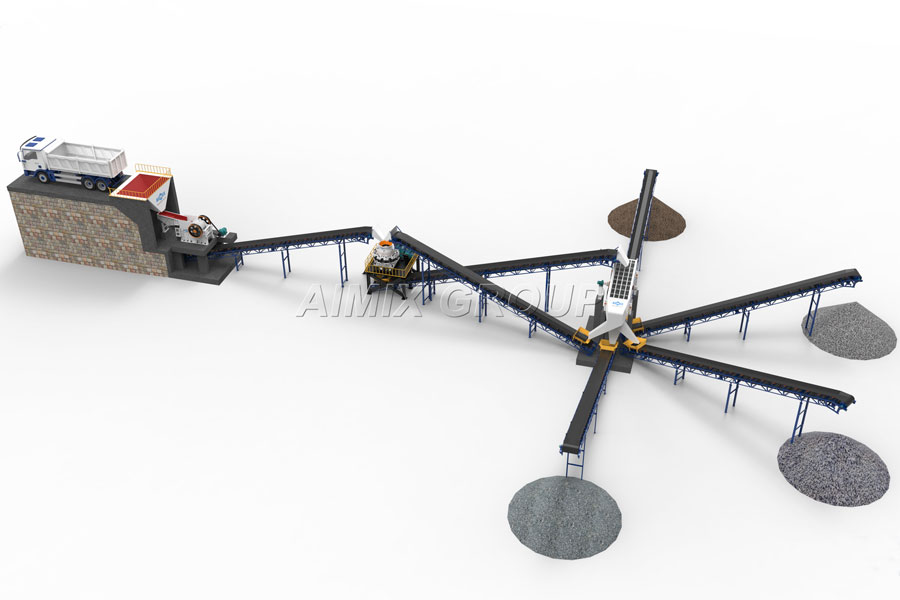

Efficiently plan and design the layout of the stone crushing plant to minimize the need for extensive site preparation and infrastructure. This includes optimizing the flow of materials and minimizing the distance between processing stages.

Through these ways, we believe that the cost of your investment in stone crushing plant will be greatly reduced.

So knowing how to lower the costs, next, why not invest one?

Maybe you still have some concerns, I fully understand your feelings, after all, investing in a stone crushing plant price is not expensive, but we can not only focus on the investment cost, we need to see the huge market potential after investment. Let us understand the benefits of investing in a stone crushing plant for your local development.

If you want to investigate the prospects of the Stone Crushing Plant industry, you can consider the following aspects:

7 ways to investigate the prospects of the Stone Crusher Plant

-

Market Demand:

Study the market size, growth trends, and future projections for the industry to understand the local and global demand in areas such as construction, infrastructure, and mining.

-

Competitive analysis:

To understand the competitive landscape in the target market, including the main competitors, the characteristics of their products and services, and their market share.

-

Technological development:

To study the emergence and application of new technologies in the industry, such as automation equipment, intelligent control systems, etc., and to understand the potential of these technologies to improve efficiency and reduce costs.

-

Regulatory environment:

Understand the legal, regulatory and environmental requirements associated with stone crushing plants to ensure your investment complies with local and national regulations.

-

Sustainability and environmental impact:

Consider the environmental impact of stone crushing plants and sustainability initiatives and practices within the industry. Concerns in this area are growing and could have a significant impact on the industry’s growth.

-

Economic factors:

Analyze the impact of macroeconomic factors such as gross domestic product (GDP) growth, interest rates, investment and construction activity on the industry.

-

Geographic location:

consider the market conditions, infrastructure needs and competition in the location of the stone crushing plant, which may vary from region to region.

A combination of these factors, along with proper due diligence and market research, can help you better understand the prospects of the Stone Crushing Plant industry and make informed investment decisions.

See here, I do not know whether you have no doubt about the usefulness of the stone crushing plant. In fact, the usefulness of stone crushing plant is particularly flexible, configuration slightly change a little, out of the finished product has been very different.

But in fact, I would like to say is that, early to buy early to use, early to seize the market opportunity, and in addition to investing in the equipment, you do not want to do you can also resell or rent, is also a good income.

AIMIX is always here for your coming.