Stationary Asphalt Batch Plant for High-Volume, High-Precision Projects

One-Touch Smart Control: Integrated system simplifies 50 steps into one click with real-time IoT monitoring.

High Precision & Automation: ±0.5% weighing accuracy, full-process automation from feeding to discharge.

Engineered for Demanding Roads: Heavy-duty, wear-resistant build for highways, airports, and high-traffic zones.

Mobile Asphalt Batch Plant 24H Fast Relocation: Modular design with plug-and-play setup, no foundation needed.

Boost Daily Output: Powerful asphalt mixer + large screen = 100 extra tons per day.

AI Smart Operation: Auto control, remote app, ±1% weighing accuracy, easy to run.

Global Asphalt Concrete Batch Plant Service – Support You Can Count On

Professional Installation & Training: On-site setup and operator training to ensure smooth start.

Timely Maintenance & Spare Parts: Global network ensures quick delivery and expert maintenance.

Rapid Technical Support: Dedicated professional team provides fast troubleshooting and solutions.

Struggling with inconsistent asphalt quality, project delays, or rising maintenance costs? An asphalt batch plant is the key solution. Designed to produce high-quality asphalt for highways, airports, harbors, and other major projects, the right asphalt batch mix plant helps you achieve stable performance, stay on schedule, and deliver long-lasting results. Ready to solve your challenges and boost efficiency? Keep reading to discover the batch plant for asphalt that fits your needs perfectly.

Curious how our batch asphalt mixing plants perform around the world? See real projects, installation insights, and success stories from our global customers.

Asphalt Batch Plants Are Trusted by Clients in 150+ Countries Worldwide

From highways to airports, our asphalt batch mix plants have been successfully deployed in over 150 countries such as Indonesia, Malaysia, the Philippines, South Africa, Nigeria, Fiji, Kyrgyzstan, and Russia. Explore some notable projects that showcase the performance and impact on real construction sites of our asphalt plants.

For Self-Use and Selling Asphalt Aggregates

- Location: in Malaysia

- Model: ALQ-120

- Production Capacity: 120TPH

- Type: Stationary Batch Type

Customer Feedback: “We rely on the ALQ-120 for consistent high-quality asphalt with precise weighing and smooth automation. Its durable design and smart control system significantly improved our project efficiency in Malaysia.”

For Large Road Construction

- Location: in Medan, Indonesia

- Model: ALQ-80

- Production Capacity: 80TPH

- Type: Stationary Batch Type

Customer Feedback: “Using the ALQ-80 with its reliable smart control and IoT monitoring gave us real-time insights and reduced downtime. Together with AIMIX crushers, it ensured smooth supply and high-quality asphalt for our Medan road project.”

For Supplying Asphalt Aggregates

- Location: in the Philippines

- Model: ALQ-80

- Production Capacity: 80TPH

- Type: Stationary Batch Type

Customer Feedback: “I love how the ALQ-80’s IoT monitoring lets me track the bitumen batch mix plant’s performance live and avoid unexpected downtime. Its sturdy design gives me confidence in a steady asphalt aggregate supply for my projects in the Philippines.”

For Urban Road Construction

- Location: in Uzbekistan

- Model: ALQ-120

- Production Capacity: 120TPH

- Type: Stationary Batch Type

Customer Feedback: “I appreciate how the ALQ-120 asphalt batch plant’s energy-efficient design lowers our operating costs, and the smart monitoring system keeps asphalt quality consistent throughout our urban road projects in Uzbekistan.”

For Road Construction and Maintenance

- Location: in Russia

- Model: ALQ-80

- Production Capacity: 80TPH

- Type: Stationary Batch Type

Customer Feedback: “I’m impressed by the ALQ-80 asphalt batch concrete plant’s robust build and precise automation, which ensures smooth asphalt production for our road construction and maintenance projects in Russia. The support team’s responsiveness adds great value.”

For Self Producing and Selling Asphalt Aggregates

- Location: in Kazakhstan

- Model: ALQ-160

- Production Capacity: 160TPH

- Type: Stationary Batch Type

Customer Feedback: “We consistently produce high-quality asphalt with the ALQ-160. The precise weighing system and automated processes ensure every batch meets our standards, which gives us confidence for highways, airports, and heavy-traffic roads.”

For Supplying Asphalt Aggregates in Road Building

- Location: in Jamaica

- Model: ALQ-120

- Production Capacity: 120TPH

- Type: Stationary Batch Type

Customer Feedback: “The 120 tph batch asphalt plant gives me peace of mind on demanding projects. The plant’s durable design and predictive maintenance features make it reliable, and every batch of asphalt comes out perfectly mixed for heavy traffic roads and airport runways.”

Now that you’ve seen our asphalt plants in action across the world, the real question is—which type will maximize your project’s success? Should you go for a stationary asphalt plant for large-scale, continuous production, or a mobile asphalt plant for flexible, on-site use? Let’s explore the options in detail.

Which Asphalt Batch Plant Is Right for Your Project Size?

Choosing the right asphalt batch plant is crucial to your project’s success. Stationary asphalt plants are ideal for large-scale, long-term production with stable output, while mobile asphalt plants offer flexibility, fast relocation, and quick installation on different job sites. Understanding their features will help you decide which one suits your project best.

Stationary Batch Type Asphalt Plant

ALQ40ALQ60ALQ80ALQ100ALQ120ALQ160ALQ200ALQ240ALQ320

- Production Capacity: 40-400 t/h

- Mixing Cycle: 45s

- Asphalt Temperature: 140-180 ℃

- Dust filter: Gravity/Cyclone/Bag/Water dust filter

Benefits of ALQ Series Stationary Asphalt Plant

- Smart Control: One-touch start, simplifies 50 steps to 1.

- Dust Control: ±3cm adjustable telescopic pipes.

- Maintenance: Large ports plus predictive maintenance alerts.

- Energy Saving: +20% cold bin capacity, insulated supply.

- Durability: Wear-resistant parts support million-ton output.

Mobile Batch Type Asphalt Plant

ALYQ40ALYQ60ALYQ80ALYQ90ALYQ100ALYQ120ALYQ160

- Production Capacity: 40-160 t/h

- Mixing Cycle: 45s

- Asphalt Temperature: 120-180 ℃

- Dust filter: Gravity/Cyclone/Bag/Water dust filter

Benefits of ALYQ Series Mobile Asphalt Plant

- Mobile & Flexible: 24-hour fast relocation and quick setup.

- Space-Saving: Quick-connect design, no foundation needed.

- Labor Saving: AI control reduces manpower by 50%.

- High Efficiency: Mixing output +15%, +100 tons daily.

Now that you understand the key features between stationary and mobile asphalt batch plants, the next step is to compare their technical parameters. This will give you a clear idea of capacity, configuration, and which model best matches your project needs.

Key Specifications of Asphalt Batch Plants for Your Road and Bridge Project

When selecting the right asphalt batch plant for sale for your project, understanding its technical specifications is crucial. These details determine the asphalt batching plant’s performance, efficiency, and suitability for your project. Below, we’ve outlined the key specs to help you make an informed decision for your needs.

ALQ Series Stationary Asphalt Batch Plant – Reliable, Efficient, and Built for Long-Term Projects

| Model | ALQ40 | ALQ60 | ALQ80 | ALQ100 | ALQ120 | ALQ160 | ALQ200 | ALQ240 | ALQ320 |

|---|---|---|---|---|---|---|---|---|---|

| Capacity | 40 t/h | 60 t/h | 80 t/h | 100 t/h | 120 t/h | 160 t/h | 200 t/h | 240 t/h | 320 t/h |

| Cold Aggregate Hoppers | 4×4.5m³ | 4×6.5m³ | 4×7.5m³ | 4×7.5m³ | 5×7.5m³ | 5×12m³ | 5×12m³ | 5×12m³ | 6×15m³ |

| Dryer Size | φ1.2m×5.2m | φ1.5m×6m | φ1.5m×6.7m | φ1.65m×7m | φ1.8m×8m | φ2.2m×9m | φ2.6m×9m | φ2.6m×9.5m | φ2.8m×10.2m |

| Fuel consumption | 70-300kg / h | 100-400kg / h | 120-600kg / h | 150-1000kg / h | 150-1000kg / h | 150-1400kg / h | 180-1800kg / h | 180-1800kg / h | 260-2500kg / h |

| Vibrating Screen (Layer) | 4 layers | 4 layers | 4 layers | 4 layers | 5 layers | 5 layers | 5 layers | 5 layers | 6 layers |

| Mixer Capacity | 500kg | 800kg | 1000kg | 1250kg | 1500kg | 2000kg | 2500kg | 3000kg | 4000kg |

| Cycle Time | 45s | 45s | 45s | 45s | 45s | 45s | 45s | 45s | 45s |

| Filter Area | 230m² | 300m² | 420m² | 480m² | 550m² | 650m² | 700m² | 1050m² | 1350m² |

| Asphalt Temperature | 140-180 ℃ | 140-180 ℃ | 140-180 ℃ | 140-180 ℃ | 140-180 ℃ | 140-180 ℃ | 140-180 ℃ | 140-180 ℃ | 140-180 ℃ |

| Total Power | 170kw | 200kw | 300kw | 350kw | 380kw | 490kw | 550kw | 670kw | 865kw |

ALYQ Series Mobile Asphalt Batch Plant – Flexibility and Efficiency for Medium Projects

| Model | ALYQ60 | ALYQ80 | ALYQ100 | ALYQ120 | ALYQ160 | |

|---|---|---|---|---|---|---|

| Capacity | t / h | 60 | 80 | 100 | 120 | 160 |

| Mixer capacity | kg | 800 | 1200 | 1300 | 1700 | 2200 |

| Mixing cycle | s | 45 | 45 | 45 | 45 | 45 |

| Total power | Gasoline(kW) | 54 | 63.5 | 104.5 | 125 | 157.5 |

| Coal(kW) | 75 | 86.5 | 127.5 | 169 | 205 | |

| filter area | m2 | 370 | 420 | 480 | 510 | 620 |

After comparing the technical parameters of different asphalt batch plants, the next key question is: how much will it cost? Let’s explore the price range of batch type asphalt plants and the factors that influence your investment.

Find the Best Asphalt Batch Plant at the Right Price

Looking for the best asphalt batch plant price for your project? We offers asphalt batch plants for sale ranging from $50,000 to $1,000,000, covering small, medium, and large-scale construction needs. With us, you don’t just get a competitive price—you get stable quality, reliable performance, and strong after-sales support. Send a message to explore our asphalt plant price list to find the asphalt mixing and batching plant that fits both your needs and your budget.

Key Factors Affecting Your Investment

After reviewing prices and investment considerations, the question becomes: which asphalt batching plant for sale is right for you? Let’s take a quick look at our model selection guide to find the plant that delivers the best balance of performance and cost.

How to Find the Perfect Asphalt Batch Plant: A Quick Model Selection Guide

Choosing the right asphalt batch plant is key to project efficiency, cost savings, and high-quality asphalt production. Whether you prioritize capacity, mobility, automation, or budget, our quick selection guide will help you identify the best model for your specific project requirements.

1. Calculate Production Size of Batch Type Asphalt Plant

Determine the production capacity of the asphalt batch mixing plant based on the annual production of the project:

Annual production within 200,000 tons: the production rate should not be less than 80 tons/hour.

Between 200,000 and 300,000 tons per year: the production rate should be 120 tons per hour.

For an annual production of more than 300,000 tons: Typically, a production rate of 150-200 tons/hour is usually required.

For example, the ALQ80 asphalt batching plants near me, with a production rate of 80 t/h, is suitable for 8 hours of work per day and can produce up to 640 tons per year. While ALQ100 can produce 800 tons per day, which is suitable for projects with an annual output of more than 250,000 tons.

2. Construction Site Conditions

Considering the special requirements and site conditions of each construction, the site selection needs to meet the following considerations:

Space layout: The decision between a mixing plant or blending plant depends on the construction site’s size and layout.

Convenience of equipment layout: Ensure that the asphalt batch mix plant layout is reasonable and convenient for the supply of raw materials and unloading of mixing materials.

Production and installation period and one-time investment cost: Consider the equipment’s installation time and initial cost for a successful project launch as planned. For instance, our updated mobile asphalt batch plant can be transfer and installed within 24 hours before production.

3. Technical Performance and Quality Requirements

The technical performance of the bitumen batch mix plant for asphalt directly affects the production efficiency and the quality of the mixture:

Measuring accuracy: A precise weighing system (±0.1–0.3% error) guarantees correct asphalt ratios.

Mixing quality: Advanced mixers ensure asphalt homogeneity, improving road durability by 15–20%.

Efficiency and Energy Consumption: Choose plants with optimized burners—modern ALQ asphalt batch plants can save 10–15% fuel costs per ton compared with older models.

4. Cost-Effectiveness Considerations

Comprehensively consider the initial investment and operating costs of the equipment and the productivity and quality improvement it brings:

Equipment price: Evaluate the price and performance ratio of the hot mix plant and choose the product with high cost performance.

Operating costs: Expect about $2–$5/ton in electricity and fuel. Choosing an energy-efficient model can save $20,000–$50,000 annually.

Maintenance & service: Regular wear parts replacement averages $3,000–$5,000/year; plants with better after-sales service reduce downtime and overall costs.

5. Mix Quality Requirements and Flexibility

According to the specific requirements of the project, consider the need for mix quality and flexibility of the equipment:

Mix quality: Both mobile and stationary asphalt plants achieve accurate mix ratios (±0.5%) and uniform asphalt, meeting highway-grade standards.

Flexibility: Recipe switching allows production of multiple asphalt grades (AC-13, AC-20, SMA, etc.) in one plant—critical for contractors handling diverse projects.

After selecting the right model, the next question is: where will it deliver the greatest value? Explore the main projects and applications where bitumen batching plants help clients achieve reliable and cost-effective asphalt production.

What Projects Are Related to Asphalt Batching Plants?

Our asphalt batching plants for sale are trusted worldwide for a wide range of construction projects. Whether it’s paving busy city streets, building major highways, or constructing airport runways, our plants deliver consistent, high-quality asphalt tailored to your project’s needs. Here are some common applications and real-world scenarios:

Urban Roads Construction

Perfect for city streets requiring high-quality asphalt.

Bridge Construction

Ideal for producing strong asphalt for durable bridges.

Industrial Parks Construction

Supports infrastructure projects in industrial areas.

Airport Runway Construction

Provides high-performance asphalt for long-lasting runways.

Highway Construction

Best for large-scale projects that require efficient asphalt production.

Rural Roads Construction

Reliable for developing rural infrastructure with consistent asphalt quality.

Having explored the diverse projects that rely on asphalt batching plants, the next question is: why is the demand for these asphalt batch plants near me growing so rapidly? Let’s look at the global market trends, growth drivers, and what this means for the road and bridge construction industry.

Why Is the Batch Mix Asphalt Plant Market Booming?

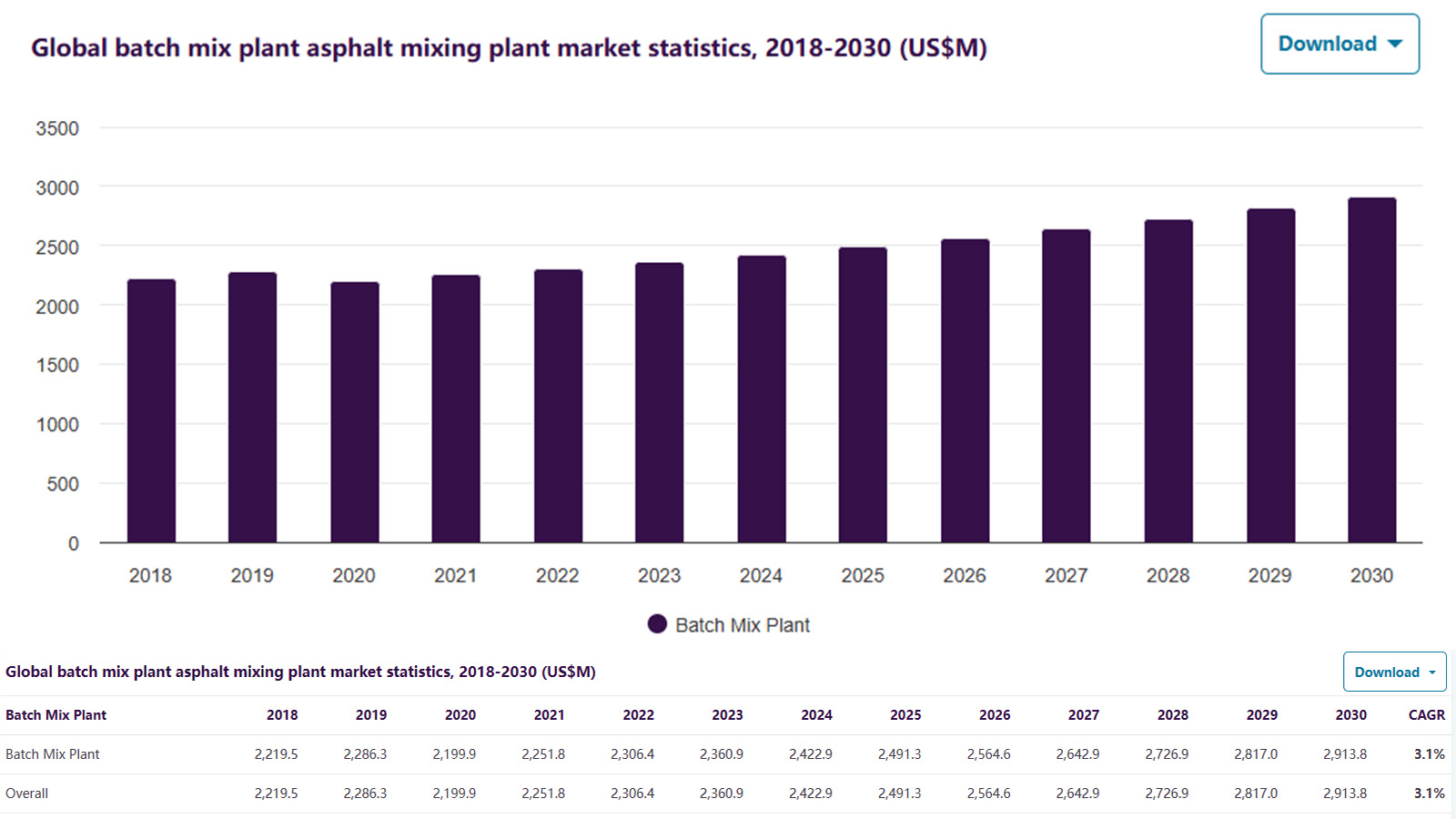

The global batch mix asphalt mixing plant market was valued at USD 2,422.9 million in 2024 and is expected to grow at a CAGR of 3.1% from 2024 to 2030, reaching USD 2,913.8 million by 2030. This steady growth reflects strong demand driven by infrastructure development and technological advancements. What does this mean for the road and bridge construction industry?

Key Reasons for Investment

- Rising Demand for Infrastructure: With more road and bridge projects globally, especially in emerging markets, the need for efficient asphalt production is growing rapidly.

- Advanced, Cost-Effective Technology: Modern plants feature automation, energy-saving designs, and eco-friendly systems, lowering costs while boosting quality and production efficiency.

- Customizable Solutions: Asphalt batch plants for sale are adaptable to meet specific needs for highways, urban roads, and bridge construction, enhancing their value across various projects.

Why It’s a Smart Investment

- Expanding Global Markets: The rise of infrastructure projects in Asia and Africa boosts demand for asphalt batch plants for sale.

- Long-Term Cost Savings: Batch mix asphalt plants improve mix quality, reducing future maintenance and ensuring road durability.

- Sustainability: Eco-friendly technology and low operational costs align with global trends toward green construction.

Don’t miss out—invest in the asphalt batch mix plant market and capitalize on the growing demand for quality road and bridge construction! (Source from: Horizon Grand View Research)

With the asphalt batching plant market expanding globally, the asphalt batch plant near me is increasingly essential for construction projects. To ensure safe and efficient operation while maintaining asphalt quality, let’s review the key precautions every operator should follow.

Precautions for Using A Batch Type Asphalt Plant

Ever faced sudden breakdowns, or rising operating costs with your asphalt plant? Many contractors encounter these issues, and they often stem from ignoring key precautions during operation. To keep your asphalt batch plant safe, efficient, and reliable, it’s crucial to understand the most common problems and solutions of asphalt mixing plant. Let’s explore how you can prevent costly downtime and achieve steady asphalt production.

Construction Environment Requirements

Construction Environment Requirements

- Good construction environment: The construction site needs favorable conditions for smooth progress.

- Safety management regulations: Personnel must adhere to site safety regulations for safe construction site operations.

Safety Signage Setup

Safety Signage Setup

- Entrance of construction site: Place safety signs at the construction site entrance to remind personnel to pay attention to safety.

- Dangerous working area: Warning signs placed in high-temperature and machinery operation areas prevent accidental injuries.

Personnel Dafety Education

Personnel Dafety Education

- Pre-job safety education: construction personnel must have pre-job safety education and understand the safety operation regulations.

- Safety production manual: Create safety manuals for each work type and provide one to every construction worker.

- Training for special trades:Trades like electrician and welder need professional training and licensing. AIMIX offers multilingual manuals for global projects.

Protective Measures

Protective Measures

- Fire prevention measures: The construction site needs fire protection and adequate extinguishing gear.

- Anti-electricity measures: Ensure safe grounding of all electrical equipment to prevent electric shock accidents.

- Explosion-proof measures: Take necessary explosion-proof measures in work areas with explosion hazards.

- Fall prevention measures: To work at height safely, use fall prevention devices, safety ropes, and harnesses.

After understanding the key precautions for safe and efficient operation, the next step is to see how an asphalt batch plant actually works. Let’s explore the working processes that make high-quality asphalt production possible.

How Does an Asphalt Batch Plant Work?

How does an asphalt batch mix plant work? The working principle of batch mix asphalt plant mainly includes key steps such as aggregate processing, asphalt treatment, mixing and conveying of finished products. Integrated with advanced automation and precise control systems, it ensures high-quality output and operational efficiency. Let’s learn how does an asphalt batch plant work together!

1. Aggregate Handling

Storage and Conveying: Various aggregates (e.g. sand, gravel, mineral powder) are stored separately in silos and fed into subsequent processing plants via an automated conveying system that ensures stable supply.

Screening and Drying: Aggregates are screened and dried efficiently to remove impurities and moisture, improving mixture stability and quality.

Heat Treatment: Heating maintains aggregate temperature for optimal asphalt adhesion, especially in cold or high-altitude environments.

2. Asphalt Treatment

Heating and Storage: Asphalt binder is stored in insulated tanks and heated with precise temperature control to ensure proper flow and adhesion while minimizing energy loss.

Measuring and Batching: High-precision metering systems measure asphalt quantities with minimal error, supporting consistent mix ratios.

3. Mixing and Blending

The Mixing process: Pre-heated aggregates and asphalt binder are mixed in exact proportions using a high-efficiency mixer to produce a uniform and stable asphalt mixture.

Time and Speed: Automated mixing mechanisms ensure thorough blending within optimized cycle times, enhancing production efficiency.

4. Finished Product Transportation

Unloading and storage: The asphalt mix is unloaded and conveyed automatically to storage silos or directly loaded onto trucks, reducing manual labor and exposure.

Transportation and application: Finished asphalt is transported promptly to construction sites for road, runway, or infrastructure paving.

5. Control System

Automated control: Equipped with an intelligent IoT-enabled system that monitors, adjusts, and reports operational parameters in real-time, ensuring consistent quality and efficient production management.

Through the coordinated operation of these key automated and precise steps, the batch asphalt plant efficiently produces high-quality hot-mix asphalt mixtures that meet stringent construction and environmental standards.

Having explored the inner workings of an asphalt batch plant, it’s time to see the technology in action. Watch our on-site videos from projects worldwide to understand how our plants deliver consistent, high-quality asphalt efficiently.

Watch Our Batch Asphalt Plants in Action Around the World

Seeing is believing! Our asphalt batch plants have been successfully used in numerous projects worldwide, delivering high-quality asphalt efficiently and reliably. These videos showcase real on-site operations, installation processes, and project outcomes, giving you a clear picture of our plants’ performance in different environments.

After seeing our asphalt batch plants in action across global projects, you might have questions about features, operation, and selection. Let’s explore some frequently asked questions to help you better understand and choose the right plant for your needs.

Everything You Need to Know About Asphalt Batch Plants

What Is an Asphalt Batch Plant?

What Are the Main Components of an Asphalt Batch Mix Plant?

Flow Diagram of the Asphalt Batch Mix Plant Process

What’s the Difference Between Batch Type Asphalt Plant and Drum Type Asphalt Plant?

What Comprehensive Asphalt Batch Plant Support Can You Get?

Looking for a partner you can truly rely on? we are dedicated to ensuring the seamless operation of your asphalt batch mix plants with comprehensive support. As one of outstanding asphalt plant suppliers, our global scale and experience provide measurable, project-focused support for asphalt construction worldwide:

1,000 Staff with 40+ Years of R&D

Our dedicated team combines decades of research and practical experience, offering on-site supervision, in-depth operator training, and tailored guidance for projects of any size.

100+ Service & Maintenance Network

With a dense network of service centers and maintenance points, we provide localized, fast-response support to minimize downtime and maintain smooth plant operations everywhere.

200,000㎡ Production Base

Our expansive production base allows large-scale manufacturing, ensuring rapid delivery of asphalt batch plants and all critical spare parts, even for urgent international projects.

Exports to 190+ Countries and Regions

Having delivered asphalt plants to diverse climates and construction standards, we demonstrate proven expertise in handling complex site conditions and ensuring reliable operations globally.

Get Reliable Performance with Our Asphalt Batch Plant

As a leading asphalt batch mix plant supplier, we are trusted globally for innovation, quality, and after-sales service. Our asphalt batch plants near me are efficient, reliable, and eco-friendly, ensuring top performance for road and bridge construction. Choose our asphalt batch mix plant for sale for superior quality and lasting value. Contact us today!