Fast Relocation within 24 Hours, Ready for Any Island Project| Fully Compliant with DPWH & DENR Environmental Standards|High Output up to 400 TPH with 15% Lower Fuel Consumption

Struggling with unpredictable asphalt supply during the Philippines’ typhoon season? Concerned about high transport costs across islands and timely project completion? Our modular stationary and mobile asphalt plant in the Philippines is designed to tackle these local challenges efficiently. Learn how fast deployment, reliable quality, and DENR-compliant asphalt mixing solutions can keep your asphalt road projects on schedule.

Our Asphalt Plant Projects Are Trusted Across the Philippines

Our asphalt plant Philippines is already running successfully in Manila, Cebu, and Davao, helping local people deliver projects on time and meet local standards. These local projects show how our asphalt mixing solutions handle the Philippines’ unique challenges. See below for benchmark projects that prove their reliability and performance.

60TPH Stationary Asphalt Batch Plant for Rural Road Building

- Model: ALQ-60

- Project Location: Local Road Building

Customer Feedback: “The 60tph stationary asphalt batching plant has been a great investment for our project. With IOT remote control, it’s efficient, easy to operate, and consistently delivers high-quality asphalt mix. We’re very satisfied with its performance in Cebu.”

80TPH Stationary Asphalt Batch Plant for Highway Road Building

- Model: ALQ-80

- Project Location: Highway Road Building

Customer Feedback: “The ALQ80 asphalt batching plant in the Philippines delivers consistent output, with aggregate accuracy within ±0.5% and asphalt/powder within ±0.25%. It kept our Manila highway project on schedule—reliable, efficient, and precise every step of the way.”

80TPH Stationary Asphalt Plant for Producing and Selling Aggregates

- Model: ALQ-80

- Project Location: Producing and Selling Aggregates

Customer Feedback: “The 80TPH asphalt plant in Manila is a game-changer. One-click start cuts 50 steps to 1, and IoT monitoring keeps downtime near zero. Automated mixing and unloading let us produce high-quality asphalt and aggregates efficiently every day.”

60TPH Portable Asphalt Mixing Plant for Road Maintenance

- Model: ALYJ-60

- Project Location: in Makati

Customer Feedback: “As a local contractor in Makati, the 60TPH portable asphalt plant has been perfect for our road maintenance projects. It’s quick to set up, easy to operate, and keeps our mix consistent—helping us finish jobs on time with minimal hassle.”

10TPH Small Portable Asphalt Mixer Machine for Road Repair

- Model: ALB-10

- Project Location: in Lapu

Customer Feedback: “Managing small road repairs in Lapu-Lapu used to be a challenge, but the 10TPH portable asphalt mixer changed that. Its portability and quick setup mean we can start work immediately, and the consistent mix quality ensures smooth, durable roads every time.”

Seeing these asphalt plants perform in real Philippine projects proves what works locally. From highways in Manila to small road repairs in Lapu-Lapu, the right plant makes all the difference. Curious which type fits your next job? Let’s explore the asphalt mix plants best suited for the Philippines.

Which Asphalt Plant Works Best for Your Philippine Project?

Every Philippine road project faces unique challenges, from Manila’s busy highways to Cebu’s island roads. Choosing the right asphalt plant can save time, cut costs, and ensure quality. Understanding 5 types of asphalt plants available locally helps you pick the solution that fits the weather, terrain, and project scale perfectly.

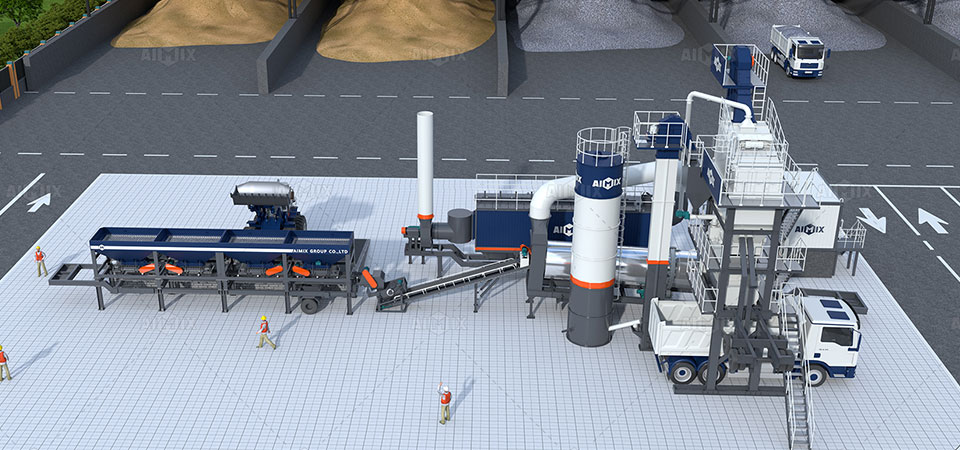

ALQ Series – Stationary Asphalt Batch Mixing Plant

- Capacity: 40-400 t/h

- Vibrating Screen: 4–6 layers

- Mixer Capacity: 500–4000 kg

- Fuel Consumption: 70–2500 kg/h

- Asphalt Temperature: 140-180 ℃

- Dust filter: Gravity/Cyclone/Bag/Water dust filter

Stationary Asphalt Batch Plant Features

- Aggregate ±0.5%, bitumen ±0.25% ensures consistent mix quality.

- One-click start, AI control, and IoT monitoring for efficiency and safety.

- Wear-resistant components last over 1 million tons of production.

- Ideal for highways, airports, and industrial projects.

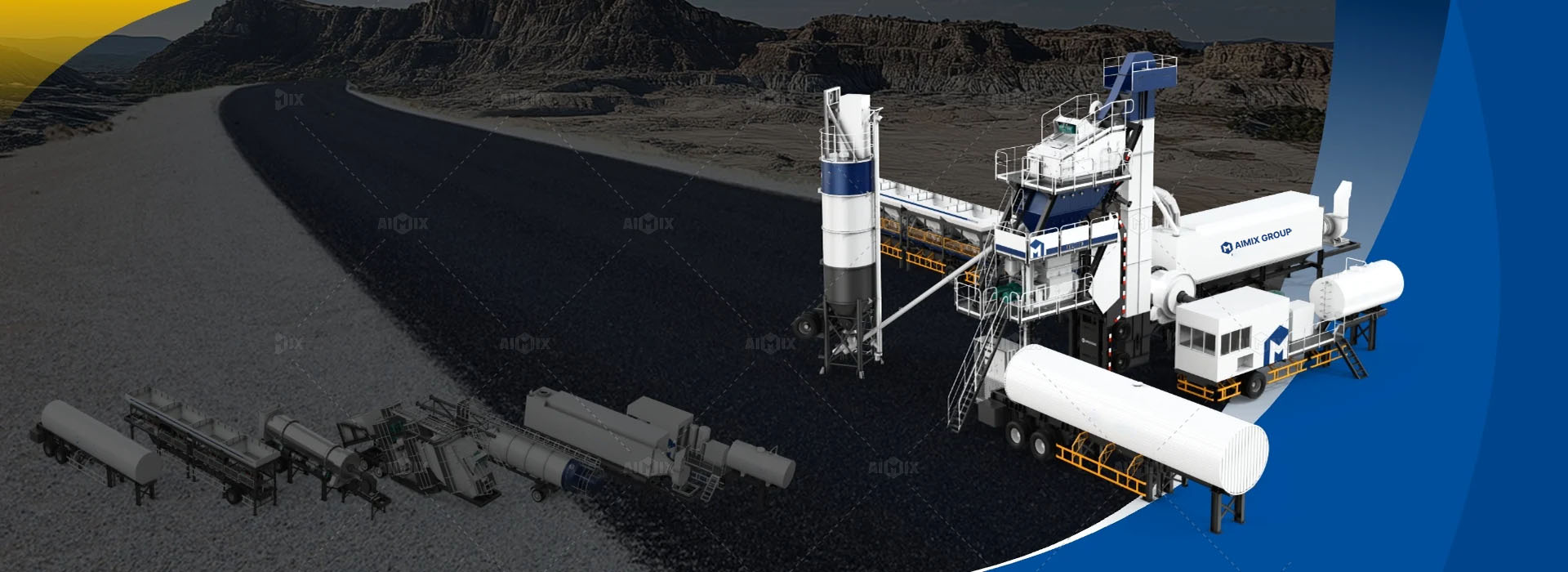

ALYQ Series – Mobile Asphalt Batch Mixing Plant

- Capacity: 40-160 t/h

- Mixer Capacity: 800–2200 kg

- Mixing Cycle: 45s

- Fuel Consumption: 54–205 kW equivalent

- Dust Filter Area: 370–620 m²

- Installation: 7 days for first installation, and fast relocation within 24h

Batch Type Mobile Asphalt Plant Features

- Fast Relocation: Modular design with plug-in connections, 24h ready-to-run.

- AI Control: Automatic weighing, self-calibration, remote monitoring via app.

- Labor Saving: Reduces operators from 4 to 2 while maintaining mix consistency.

- Multi-Site Adaptability: Perfect for island projects and dispersed sites.

ALT Series – Stationary Drum Mix Asphalt Plant

- Capacity: 20-100 t/h

- Power: 40–200 kW

- Asphalt Temperature: 120-180 ℃

- Fuel Consumption: 13–15 kg/t

- Cold Aggregate Hopper Volume: 3.5–6.5 m³

- Finished Product Hopper Volume: 3–9 t

Stationary Asphalt Drum Mix Plant Features

- Continuous Mixing: Stable output for uninterrupted operation.

- High Thermal Efficiency: Optimized drum design reduces heat loss by 15–20%.

- Low Investment: Affordable initial cost and maintenance.

- Rural Road Suitability: Perfect for county highways and village network paving.

ALYT Series – Mobile Asphalt Drum Mix Plant

- Capacity: 20-120 t/h

- Relocation Time: 3–5 days

- Power: 34–200 kW

- Fuel Consumption: 5–7.5 kg/t (Diesel)

- Finished Asphalt Bin: 2–7 m³

- Cold Aggregate Hopper Volume: 3.5–6.5 m³

Mobile Asphalt Drum Mix Plant Features

- Modular Mobility: Quick disassembly and transport for flexible deployment.

- Terrain Adaptability: Can work in hills, mountains, and low clearance areas.

- Dust Control: Bag or water collector for compliance with environmental rules.

- Fast ROI: Minimal idle time, low relocation cost for contractors.

ALB Series Portable Asphalt Mixer Machine

ALB-2ALB-5ALB-10ALB-15ALB-20

- Capacity: 2-20 t/h

- Price Range: $20,000-$35,000

- Mixing Time: 10-15 min/batch

- Asphalt Temperature: 120-210 ℃

- Chassis Type: Mini trailer or 4–6 wheel

Key Features of ALB Series

- Compact & Mobile: Easy to transport on trailers or tricycles.

- Efficient Heating: Rapid temperature rise with low fuel use.

- Simple Operation: Quick batch adjustment and easy cleaning.

- Best for Small Repairs: Ideal for potholes, village roads, and urban patching.

Now that you’ve explored the key asphalt plant types for Philippine roads, imagine which one could transform your next project. Dive into the detailed specs—capacity, fuel efficiency, and mixer performance—to see exactly how it fits your city streets, rural highways, or island sites. Don’t just choose a plant—find the one that powers your project to success.

Technical Specifications – Find the Perfect Asphalt Plant for Your Philippine Project

Now it’s time to get precise. These technical tables break down each asphalt plant’s capacity, fuel consumption, mixer size, cycle time, and more. Whether you’re handling city streets in Manila, rural highways in Visayas, or island roads in Mindanao, this data helps you compare models and make the right choice with confidence.

ALQ Series – Stationary Asphalt Batch Plants for Philippine Highways

| Model | ALQ40 | ALQ60 | ALQ80 | ALQ100 | ALQ120 | ALQ160 | ALQ200 | ALQ240 | ALQ320 |

|---|---|---|---|---|---|---|---|---|---|

| Capacity | 40 t/h | 60 t/h | 80 t/h | 100 t/h | 120 t/h | 160 t/h | 200 t/h | 240 t/h | 320 t/h |

| Cold Aggregate Hoppers | 4×4.5m³ | 4×6.5m³ | 4×7.5m³ | 4×7.5m³ | 5×7.5m³ | 5×12m³ | 5×12m³ | 5×12m³ | 6×15m³ |

| Dryer Size | φ1.2m×5.2m | φ1.5m×6m | φ1.5m×6.7m | φ1.65m×7m | φ1.8m×8m | φ2.2m×9m | φ2.6m×9m | φ2.6m×9.5m | φ2.8m×10.2m |

| Fuel consumption | 70-300kg / h | 100-400kg / h | 120-600kg / h | 150-1000kg / h | 150-1000kg / h | 150-1400kg / h | 180-1800kg / h | 180-1800kg / h | 260-2500kg / h |

| Vibrating Screen (Layer) | 4 layers | 4 layers | 4 layers | 4 layers | 5 layers | 5 layers | 5 layers | 5 layers | 6 layers |

| Mixer Capacity | 500kg | 800kg | 1000kg | 1250kg | 1500kg | 2000kg | 2500kg | 3000kg | 4000kg |

| Cycle Time | 45s | 45s | 45s | 45s | 45s | 45s | 45s | 45s | 45s |

| Filter Area | 230m² | 300m² | 420m² | 480m² | 550m² | 650m² | 700m² | 1050m² | 1350m² |

| Asphalt Temperature | 140-180 ℃ | 140-180 ℃ | 140-180 ℃ | 140-180 ℃ | 140-180 ℃ | 140-180 ℃ | 140-180 ℃ | 140-180 ℃ | 140-180 ℃ |

| Total Power | 170kw | 200kw | 300kw | 350kw | 380kw | 490kw | 550kw | 670kw | 865kw |

ALYQ Series – Mobile Asphalt Batch Plants for Island & Rural Roads

| Model | ALYQ60 | ALYQ80 | ALYQ100 | ALYQ120 | ALYQ160 | |

|---|---|---|---|---|---|---|

| Capacity | t / h | 60 | 80 | 100 | 120 | 160 |

| Mixer capacity | kg | 800 | 1200 | 1300 | 1700 | 2200 |

| Mixing cycle | s | 45 | 45 | 45 | 45 | 45 |

| Total power | Gasoline(kW) | 54 | 63.5 | 104.5 | 125 | 157.5 |

| Coal(kW) | 75 | 86.5 | 127.5 | 169 | 205 | |

| filter area | m2 | 370 | 420 | 480 | 510 | 620 |

ALT Series – Fixed Drum Mix Plants for Local Road Networks

| Courts Models | ALT20 | ALT40 | ALT60 | ALT80 | ALT100 |

|---|---|---|---|---|---|

| Capacity | 20 t/h | 45 t/h | 60 t/h | 80 t/h | 100 t/h |

| The ability to | 40kw | 75kw | 120kw | 165kw | 200kw |

| Cold Aggregate Hoppers | 3.5m³×1 | 4m³×4 | 4m³×4 | 6.5m³×4 | 6.5m³×4 |

| Finished Product Hopper | 3t | 3t | 7t | 7t | 9t |

| Asphalt Temperature | 120-180 ℃ | ||||

| Fuel consumption | 13-15kg/t | ||||

| Asphalt Tank | 10 t | 20 t | 30 t | 30 t | 35 t |

| Control room | 2.2m | 2.2m | 3m | 3m | 3.5m |

| Option | Bag dust filter | ||||

ALYT Series – Mobile Drum Plants for Hills & Remote Areas

| Model | ALYT20 | ALYT40 | ALYT60 | ALYT80 | ALYT100 | ALYT120 |

|---|---|---|---|---|---|---|

| Output | 20t/h | 45t/h | 60t/h | 80t/h | 100t/h | 120t/h |

| Power | 34kw | 65kw | 105kw | 135kw | 170kw | 200KW |

| Cold Aggregate Feeding System | 3.5m³×1 | 4m³×4 | 4m³×4 | 6.5m³×4 | 6.5m³×4 | 6.5m³×4 |

| Finihsed Asphalt Storage Bin | 2m³ | 2.5m³ | 4.5m³ | 5m³ | 7m³ | 7m³ |

| Asphalt Temperature | 120-180℃ | 120-180℃ | 120-180℃ | 120-180℃ | 120-180℃ | 120-180℃ |

| Fuel Consumption(Fuel Oil) | 5-7.5kg/t | 5-7.5kg/t | 5-7.5kg/t | 5-7.5kg/t | 5-7.5kg/t | 5-7.5kg/t |

| Fuel Consumption(Burning Coal) | 13-15kg/t | 13-15kg/t | 13-15kg/t | 13-15kg/t | 13-15kg/t | 13-15kg/t |

| Asphalt Tank | 10t | 20t | 30t | 30t | 35t | 35t |

| Option | bag dust collector / water dust collector | bag dust collector / water dust collector | bag dust collector / water dust collector | bag dust collector / water dust collector | bag dust collector / water dust collector | bag dust collector / water dust collector |

| Whole Plant Option | whole mobile / semi-mobile / fixed | whole mobile / semi-mobile / fixed | whole mobile / semi-mobile / fixed | whole mobile / semi-mobile / fixed | whole mobile / semi-mobile / fixed | whole mobile / semi-mobile / fixed |

ALB Portable Asphalt Mixers – Small Road Repairs Across the Philippines

| Model | 0.38-0.4 m³ | 0.5 m³ | 0.7 m³ | 1 m³ | 1.5 m³ | 2 m³ | 3 m³ (Dual Tank) |

|---|---|---|---|---|---|---|---|

| Chassis Type | Mini Trailer Tricycle | Mini Trailer Tricycle | 4-Wheel | 6-Wheel | 6-Wheel | 6-Wheel | 6-Wheel |

| Diesel Generator | Changchai Diesel Engine | Changchai Diesel Engine | Weifang Diesel Engine | Weifang Diesel Engine | Weifang Diesel Engine | Weifang Diesel Engine | Weifang Diesel Engine |

| Power Output | 12 kW | 12 kW | 30 kW | 30 kW | 30 kW | 30 kW | 30 kW |

| Main Burner | 200,000 kcal | 200,000 kcal | 400,000 kcal | 440,000 kcal | 440,000 kcal | 440,000 kcal | 440,000 kcal (2 units) |

| Secondary Burner | 200,000 kcal | 200,000 kcal | 200,000 kcal | 200,000 kcal | 210,000 kcal | 220,000 kcal | 220,000 kcal |

| Mixing Tank Temperature | 120-165℃(Adjustable) | 160-210℃(Adjustable) | 160-210℃(Adjustable) | 160-210℃(Adjustable) | 160-210℃(Adjustable) | 160-210℃(Adjustable) | 160-210℃(Adjustable) |

| Fuel Type | Diesel | Diesel | Diesel | Diesel | Diesel | Diesel | Diesel |

| Fuel Consumption | 2.5-5L per batch | 4-5L per batch | 4-5L per batch | 5-6L per batch | 6-7L per batch | 6-7L per batch | 8-10L per batch |

| Mixing Motor | 2.2 kW | 5.5 kW | 5.5 kW | 5.5 kW | 5.5 kW | 5.5 kW | 5.5 kW |

| Dust Removal System | / | Water Dust Removal | Water Dust Removal | Water Dust Removal | Water Dust Removal | Water Dust Removal | Water Dust Removal |

| Tank Capacity (m³) | 1 m³ | 1.75 m³ | 2.35 m³ | 3.25 m³ | 4.25 m³ | 5 m³ | 4.25 m³ * 2 |

| Mixing Volume (tons/m³) | 0.25 m³ / 0.5 tons | 0.5 m³ / 1 ton | 0.7 m³ / 1.4 tons | 1 m³ / 2 tons | 1.5 m³ / 3 tons | 2 m³ / 3 tons | 1.5 m³ / 3 tons (Dual Tank) |

| Production Time Per Batch | 10-15 min/batch | 10-15 min/batch | 10-15 min/batch | 10-15 min/batch | 10-15 min/batch | 10-15 min/batch | 10-15 min/batch (Dual Tank) |

| Production Capacity (T/h) | 2-3 T/h | 4-6 T/h | 5.6-8.4 T/h | 8-12 T/h | 12-15 T/h | 15-18 T/h | 18-20 T/h |

| Applications | Small road repairs, manhole repairs | Road repairs, courtyard paving | Road repairs, courtyard paving | Road repairs, courtyard paving | Road repairs, courtyard paving | Road repairs, courtyard paving | Road repairs, courtyard paving |

| Inverter | 380V-24V | 380V-24V | 380V-24V | 380V-24V | 380V-24V | 380V-24V | 380V-24V |

| Hot Melt Kettle Capacity | 200L | 400L | 400L | 500L | 500L | 500L | 500L |

| Vibration System / Air Pump (Slag Removal Device) | / | 0.1/8 type air pump (0.1 m³ flow) | 0.1/8 type air pump (0.1 m³ flow) | 0.1/8 type air pump (0.1 m³ flow) | 0.1/8 type air pump (0.1 m³ flow) | 0.1/8 type air pump (0.1 m³ flow) | 0.1/8 type air pump (0.1 m³ flow) |

| Material Ratio | 3%-5% oil-stone ratio (new material) | 3%-5% oil-stone ratio (new material) | 3%-5% oil-stone ratio (new material) | 3%-5% oil-stone ratio (new material) | 3%-5% oil-stone ratio (new material) | 3%-5% oil-stone ratio (new material) | 3%-5% oil-stone ratio (new material) |

| Automatic Loading Hopper | / | Hoist Bottom Discharge | Hoist Bottom Discharge | Hoist Bottom Discharge | Hoist Bottom Discharge | Hoist Bottom Discharge | / |

| Weight (Tons) | 1.8 T | 3.8 T | 4.2 T | 4.8 T | 5.6 T | 5.6 T | 6.5 T |

| Starting Method | Electric Control | Electric Control / Electric Start | Electric Control / Electric Start | Electric Control / Electric Start | Electric Control / Electric Start | Electric Control / Electric Start | Electric Control / Electric Start |

| Dimensions (LWH, mm) | 5200*1600*2000 | 5200*1600*2000 | 6000*2000*2750 | 6200*2300*2950 | 6600*2300*2950 | 6900*2300*3250 | 6600*3300*2950 |

| Material | Double-layer manganese plate (single layer thickness 5.75mm), rock wool insulation layer 5cm*6 | Double-layer manganese plate (single layer thickness 5.75mm), rock wool insulation layer 5cm*6 | Double-layer manganese plate (single layer thickness 5.75mm), rock wool insulation layer 5cm*6 | Double-layer manganese plate (single layer thickness 5.75mm), rock wool insulation layer 5cm*6 | Double-layer manganese plate (single layer thickness 5.75mm), rock wool insulation layer 5cm*6 | Double-layer manganese plate (single layer thickness 5.75mm), rock wool insulation layer 5cm*6 | Double-layer manganese plate (single layer thickness 5.75mm), rock wool insulation layer 5cm*6 |

You’ve explored the key specs and capabilities of our asphalt plants—now let’s see the price range. Whether it’s repairing village roads in Mindanao or building highways in Manila, knowing the investment helps you plan confidently and choose the plant that best fits your project needs.

What is the Asphalt Plant Equipment Price Range in the Philippines

Our asphalt plant equipment for the Philippines covers a wide range of capacities and project needs, with asphalt plant prices from $20,000 to $1,000,000. The exact cost depends on your project size, location, and production requirements. Share your project details with us, and we’ll provide a customized solution and personalized quote to ensure the best fit and value for your investment.

Knowing the price range gives you a clear starting point, but that’s just the beginning. In the Philippines, island transport, hilly roads, and unstable power can all affect your choice. Don’t stop at cost—understand the local conditions. Keep reading our selection guide to see clear, measurable references and find the right asphalt plant for your project.

Philippines Asphalt Equipment Selection Guide: Localized Key Conditions

Have you ever struggled with moving heavy asphalt equipment across islands, tackling steep hilly sites, or dealing with unstable electricity in the Philippines? These local conditions can make or break your project. To help contractors choose the right asphalt hot mix plant with confidence, we’ve created this practical guide, quantifying key factors like capacity, transport, and cost. Whether it’s a small village road or a busy highway, you’ll quickly see which equipment fits your needs best.

| Module | Key Considerations | Recommended Indicators | Practical Value |

|---|---|---|---|

| Geography & Transport | Inter-island transport | Weight ≤ 45 tons, dismantled width ≤ 3.2 m | Philippines is an archipelago; equipment ≤45 tons can be shipped easily, width ≤3.2 m allows access to rural and urban roads. |

| Construction site slope | ≤ 12° | Most rural and hilly roads have slopes of 10–12°, ensuring safe deployment and preventing tipping risks. | |

| Road load capacity | ≤ 12 tons | Small bridges and village roads have limited load; exceeding 12 tons may damage pavement or bridges. | |

| Power & Fuel | Power stability | Voltage fluctuation ±8–10% | Remote areas often experience unstable grids; equipment must handle ±8–10% voltage changes. |

| Fuel consumption | Small: 5–7 L/batch, Medium: 50–120 L/h, Large: 200–450 kg/h | Matches local diesel/coal prices, reduces operational fuel costs. | |

| Project Scale & Capacity | Small projects | 2–15 t/h | Suitable for village roads, schools, community road repair; flexible for small-scale work. |

| Medium projects | 40–100 t/h | Ideal for county roads, branch roads, and small city streets. | |

| Large projects | 120–320 t/h | Suitable for highways, main city roads, and bridge projects; meets large-scale demand. | |

| Environmental & Regulations | Dust emission | ≤ 20 mg/m³ | Complies with urban dust control requirements; safer for residential areas. |

| Noise level | ≤ 85 dB | Meets city regulations; prevents disturbance near schools and communities. | |

| Budget & Investment | Initial investment | $20,000–$1,000,000 | Covers small, medium, and large equipment to fit different company budgets. |

| Total cost ratio | Fuel, electricity, labor, transport, and maintenance ~30–50% | Helps anticipate total project cost and avoid budget overruns. | |

| Financing options | 3–6 months installment or project-phase payment | Supports Philippine contractors with flexible cash flow. | |

| Operation & Maintenance | Number of operators | Small: 1–2, Medium: 2–4, Large: ≥5 | Match operator count to equipment scale; reduces labor cost. |

| Maintenance interval | Blades/liners: 3–5 years, vibrating screen motor: 2000 hours maintenance-free | Extends equipment life; reduces downtime and repair frequency. | |

| Spare parts availability | 1–3 days in major cities | Slightly slower in remote areas but usually does not affect project schedule. |

You’ve seen how choosing the right asphalt equipment matters for performance and efficiency in the Philippines. But even the best asphalt mix plant Philippines can’t run without the proper permits. Let’s dive into the essential regulations you need to follow to start smoothly and stay compliant.

Essential Regulations and Permits Before Setting Up an Asphalt Plant in the Philippines

Thinking of setting up an asphalt plant in the Philippines? Imagine your new asphalt mixer plant ready to produce high-quality mixes, but delays from missing permits or environmental approvals hold you back. Knowing the right steps—from zoning and building permits to ECC and fuel safety—can save you weeks and thousands of pesos. This guide walks you through the essentials, so your investment starts strong and runs smoothly.

| Step | Responsible Agency | Requirement | Estimated Timeline | Approx. Cost (PHP) | Key Notes / Tips |

|---|---|---|---|---|---|

| Company Registration & Business Permit | SEC / DTI / LGU | Company registration, Barangay Clearance, Mayor’s Permit | 2–4 weeks | 10,000–50,000 | Foreign investors must check ownership limits; prepare documents in advance |

| Land Selection & Zoning Clearance | City Planning Office (MPDC) | Land proof submission, Locational/Zoning Clearance | 2–6 weeks | 5,000–20,000 | Choosing land near major roads or construction sites reduces transport costs |

| Environmental Compliance (ECC / CNC) | EMB / DENR | EIA for large plants, CNC for small plants | 1–3 months | 50,000–150,000 | Plan environmental measures early to avoid delays |

| Building Permit & Fire Safety | City Building Office + Fire Department | Building structure & fire safety review | 2–4 weeks | 10,000–50,000 | One-time approval avoids insurance claim issues |

| Fuel Storage & Hazardous Materials Permit | Fire Dept + LGU + Energy Regulator | Fireproof, leak-proof fuel storage, safety distances | 2–6 weeks | 10,000–30,000 | Compliant storage reduces accident risk |

| Tax Registration | BIR | Tax ID, income tax, VAT, withholding tax | 1–2 weeks | - | Register early to enable legal cost deductions |

| Employee Social Security & Insurance | SSS / PhilHealth / Pag-IBIG | Social security, health insurance, housing fund | 1–2 weeks | - | Legal contracts ensure employee confidence and stability |

Company Registration & Business Permit

Land Selection & Zoning Clearance

Environmental Compliance (ECC / CNC)

Building Permit & Fire Safety Approval

Fuel Storage & Hazardous Materials Permit

Tax Registration

Employee Social Security & Insurance

💡 Tip: Follow the sequence: Company registration → Land approval → Building permit → ECC → Fuel permit. Environmental compliance and fuel storage are critical checkpoints.

Seeing is believing. You’ve learned the rules—now see them in action! Watch our asphalt plants running smoothly on-site in the Philippines, producing high-quality mixes while fully complying with local regulations. Don’t just imagine your project—see it in motion and get inspired for your own success.

Watch Our Asphalt Plants in Action Across the Philippines

Want to see our asphalt plants working live in the Philippines? From busy Manila highways to provincial road projects, these on-site Youtube videos show real operations, workflow, and production efficiency in local conditions. Watch how our equipment handles materials, maintains quality, and stays compliant—giving you a true sense of performance before investing in your own asphalt mixing plant.

From busy city highways to provincial roads, our asphalt plants in the Philippines show reliability and efficiency. High-quality asphalt production is ready for any project. But the demand is growing—upcoming road and bridge developments will need even more. Read on to see where these major projects are taking shape next.

Upcoming Philippine Road & Bridge Projects Driving Asphalt Demand

The Philippines is gearing up to build and upgrade more than 550 km of major road networks and over 120 bridges starting from 2025, including a ₱37 billion (≈ US$650 million) program in Mindanao. With such scale, the demand for high‑quality asphalt mix production will soar—making now the perfect time to align equipment, logistics, and strategy for the opportunities ahead.

Urgent Bridges Construction Project for Rural Development

25 priority bridges totaling 18.78 km across 11 regions; each bridge requires 1,200–1,500 tons of asphalt. Phased construction runs from 2025 to 2028.(DPWH)

Mindanao Transport Connectivity Improvement Project

Highway network upgrades in Mindanao (~250 km) with ~15,000 tons of asphalt needed; budget US $454.94 million. Continuous asphalt supply ensures timely completion.(World Bank)

SALEx Expressway Project

40.65 km elevated expressway around Metro Manila, 25,000 tons of asphalt needed. Timeline: 2025–2030. High-quality asphalt guarantees smooth, long-lasting roads. budget US $2.66 billion.

Laguna Lakeshore Road Network

Coastal roads and dikes connecting Taguig to Laguna (~35 km); 8,000–10,000 tons of asphalt for resilient pavements; part of the 52 flagship projects. Proper asphalt mix ensures durability.

Philippines & SEA Localized Support: Real Capabilities You Can Rely On

As a professional asphalt plant supplier, we back every asphalt plant in the Philippines with real, measurable support. From local warehouses stocked with critical parts to on-site teams ready to solve problems within hours, we make sure your operations stay uninterrupted. You can rely on our presence and expertise—because trust comes from proven action, not promises.

Get Your Perfect Asphalt Plant in the Philippines Today!

Ready to bring reliable, high-performance asphalt production to your project in the Philippines? Whether you need a stationary, mobile, or compact asphalt plant, we can help you find the perfect solution tailored to local conditions. Contact us today for a personalized quote and see how our expertise and local support can turn your asphalt vision into reality.