What Is Concrete Batching Plant? A concrete batching plant is specialized equipment used for producing concrete efficiently and uniformly. It is widely used in various construction projects, including tunnels, bridges, railways, highways, airports, ports, wharves, and water conservancy projects.

AIMIX Concrete Batching Plant Projects

AJ-180 Stationary Batching Plant for Commercial Concrete Production

- Delivery time: 2025

- Location: In Malaysia

- Customer needs: To achieve faster batching cycles and provide high-quality concrete for customers.

- Our solution:We supplied an AJ-180 stationary batching plant with 3m³ Sicoma mixer.

- Plant owner feedback: “This large-scale plant meets our concrete production needs especially during peak construction seasons. We would be glad to introduce Aimix to other customers who have the need of concrete plants.”

AJ-90 Stationary Concrete Batch Plant for Power Plant Project

- Delivery time: 2025

- Location: In Indonesia

- Customer needs: The customer required precision, efficiency, and reliability of concrete plant to ensure project continuity without delays or material loss.

- Our Solution: We supplied a 90m³/h concrete plant equipped with integrated control system, precision feeding system and a high-performance SICOMA twin-shaft mixer.

- Outcomes: 30% reduction in startup time, 50% decrease in operational error rates, 20% increase in production continuity, 10% reduction in material waste, etc.

AJY-75 Mobile Batching Plant for Government Projects

- Delivery time: 2025

- Location: In Ethiopia

- Customer needs: The client needed a concrete production equipment that could meet the strict standards for Government projects.

- Our solution: We offered a 75m³/h mobile concrete plant equipped with JS1500 mixer. This cost-effective solution totally meets the customer’s requirements.

AJSY-35 Compact Batching Plant for Sale in Malaysia

- Delivery time: 2025

- Application: For Roadbed Paving

- Customer needs: The client needed a small-scale batching plant that could be relocated quickly and start production in a short time frame.

- Our solution: We recommended our AJSY35 plant featuring compact design and fast installation capability.

- Results: Despite the limited working area and complex terrain, the AJSY35 was successfully set up and made ready for production in just 10 days. It works efficiently at job site now and the customer is very satisfied with its performance.

Various Types Of Concrete Batching Plants

Stationary Concrete Plant

- Flexibility:Due to its fixed nature, once installed, relocation is difficult, with lower flexibility.

- Production Capacity:25 m³/h to 240 m³/h

- Installation:Requires fixed installation with a foundation.

- Set-Up Time:Longer setup time (10-60 days).

- Applications:Stationary concrete plants are suitable for large-scale infrastructure projects, such as highways, large commercial and residential developments, and long-term industrial projects.

Mobile Concrete Plant

- Flexibility:Can be easily relocated to different construction sites, with high degree of flexibility.

- Production Capacity:60 m³/h to 120m³/h

- Installation:Can be set up quickly and relocated without a foundation.

- Set-Up Time:Quick setup time (7-45 days).

- Applications:Mobile batch mixing plants are suitable for temporary construction projects, such as road maintenance, rural road construction, temporary construction sites, and small building projects.

Wet Mix Batching Plant

- Production Process:All dry materials and water are mixed inside the batching plant to produce wet concrete, then transported to the construction site via concrete mixer trucks.

- Production Capacity:25 m³/h to 240 m³/h

- Quality Control:All the materials are mixed inside the batching concrete plant, with better control over uniformity and consistency of the concrete, ensuring higher quality.

- Equipment Configuration:The configuration is more complex, requiring not only batching and conveying systems but also a mixer and a water supply system to produce wet concrete.

- Applications:Wet mix batching plants are suitable for projects with high concrete quality requirements, such as high-rise buildings and large infrastructure projects, where uniformity and consistency of the concrete are essential.

Dry Mix Batching Plant

- Production Process:All dry materials are mixed dry inside the plant and loaded into mixer truck, where water and other liquids are added and mixed during transportation or upon arrival at site.

- Production Capacity:25 m³/h to 180m³/h

- Quality Control:Water and other liquids are added during transport or on-site mixing, concrete uniformity and consistency may be affected, relying on mixing effect of mixer truck.

- Equipment Configuration:The configuration is relatively simple, consisting of batching and conveying systems for dry materials, without the need for complex mixing equipment.

- Applications:Dry mix plants are ideal for projects where concrete quality requirements are less stringent or where the construction site is equipped with mixing equipment and skilled personnel.

Batching Plant Specifications

| Model | AJ-25 | AJ-35 | AJ-50 | AJ-75 | AJ-60 | AJ-90 | AJ-120 | AJ-180 |

|---|---|---|---|---|---|---|---|---|

| Theoretical Productivity (m³/h) | 25 | 35 | 50 | 75 | 60 | 90 | 120 | 180 |

| Mixer Model (Mixer Output L) | JS500 | JS750 | JS1000 | JS1500 | JS1000 | JS1500 | MAO3000/2000(SICOMA) | MAO4500/3000(SICOMA) |

| Mixer Power (kW) | 18.5 | 30 | 2×18.5 | 2×30 | 2×18.5 | 2×30 | 2×37 | 2×55 |

| Mixing Cycle Period (s) | 72 | 72 | 72 | 72 | 60 | 60 | 65 | 65 |

| Max.Aggregate Size (mm) | Φ60 | Φ60 | Φ60 | Φ80 | Φ60 | Φ80 | Φ80 | Φ80 |

| Standard Aggregate Bin Capacity (m³) | 3×3 | 3×5 | 3×8 | 3×12 | 4×7 | 4×15 | 4×15 | 4×20 |

| Kind of Aggregate | 2/3 | 2/3/4 | 3/4 | 3/4 | 4/5 | 4/5 | 4/5/6 | 4/5/6 |

| Max. Discharging Height (m) | 3.8 | 4.1 | 4.1 | 4.1 | 4.1 | 4.1 | 4.3 | 4.3 |

| Overall Weight (ton) | ≈15 | ≈18 | ≈23 | ≈30 | ≈40 | ≈68 | ≈93 | ≈101 |

| Installation Power (kW) | ≈65 | ≈75 | ≈100 | ≈140 | ≈110 | ≈160 | ≈220 | ≈290 |

| Model | AJY25 | AJY35 | AJY50 | AJY75 | AJY100 |

|---|---|---|---|---|---|

| Theoretical Productivity (m³/h) | 25 | 35 | 50 | 75 | 100 |

| Mixer Model (Mixer Output L) | JS500 | JS750 | JS1000 | JS1500 | JS2000 |

| Mixer Power (kW) | 18.5 | 30 | 2x18.5 | 2x30 | 2x37 |

| Mixing Cycle Period (s) | 72 | 72 | 72 | 72 | 72 |

| Max.Aggregate Size (mm) | Φ60 | Φ60 | Φ60 | Φ60 | Φ60 |

| Aggregate Bin Capacity (m³) | 4x4m³ | 4x4m³ | 4x5m³ | 4x6m³ | 4x8m³ |

| Powder Storage Silo (ton) | 1x50 | 1x100 | 1x100 | 2x100 | 3x100 |

| Max. Discharging Height (m) | 3.8 | 3.8 | 4.2 | 4.2 | 4.2 |

| Weighing Range & Accuracy of Aggregate (kg) | 2x900kg±2% | 2x900kg±2% | 2x1200kg±2% | 2x1800kg±2% | 2x2400kg±2% |

| Weighing Range & Accuracy of Cement (kg) | 350kg±1% | 500kg±1% | 600kg±1% | 1000kg±1% | 1200kg±1% |

| Weighing Range & Accuracy of Water (kg) | 200kg±1% | 200kg±1% | 350kg±1% | 450kg±1% | 550kg±1% |

| Weighing Range & Accuracy of Additive (kg) | 30kg±1% | 30kg±1% | 30kg±1% | 30kg±1% | 50kg±1% |

| Overall Weight (ton) | ≈15 | ≈20 | ≈25 | ≈31 | ≈37 |

| Installation Power (kW) | ≈65 | ≈75 | ≈90 | ≈125 | ≈180 |

Concrete Production Solutions

|

|

|

|---|---|---|

| 90m3/h, 120m3/h, 180m3/h, 240m3/h | Production Capacity | 25 m3/h, 35m3/h, 50m3/h, 75m3/h, 90m3/h, 120m3/h, 180m3/h |

| AJ-90, AJ-120, AJ-180, AJ-240 | Model | AJ-25, AJ-35, AJ-50, AJ-75, AJ-90, AJ-120, AJ-180 |

| Mainly produces ready-mixed concrete for on-site pouring. | Finished Product | Mainly produces concrete for precast components. |

| Suitable for large construction projects and infrastructure development, such as roads, bridges, and airports, where a significant amount of on-site poured concrete is required. | Applications | Suitable for precast component factories, residential community construction, and commercial buildings where precast concrete elements are needed. |

| Ingredients (cement, aggregates, water, and admixtures) are measured and mixed at a ready mix concrete plant, transported to the construction site using a concrete transit mixer to keep it agitated, and then poured into the required formwork to cure and harden. | Production Process | In a precast plant, concrete is poured into reusable molds, cured under controlled conditions for strength and durability, and then transported to the construction site for assembly. |

| Mixers, silos, batching systems, conveying systems, and concrete mixer trucks | Configurations | Mixers, molds, steam curing equipment, storage yards, and more |

| Precise proportioning,consistency in quality, solves the need for long-distance concrete, ensuring high strength and durability and extending the life of the building | Features | Shortened construction period; reduced costs for on-site material storage and management, use high-quality concrete and reinforce steel to ensure the durability and strength of the structure |

Benefits of Choosing Aimix Combination Solutions

Speed Project CompletionStreamlined operations reduce setup time and improve overall workflow, leading to faster project completion.

Consistent QualityAutomated systems ensure precise batching and mixing, resulting in uniform concrete quality with minimal human error.

Cost SavingsConsolidated processes lower operational costs, optimize resource use, and reduce waste, contributing to budget efficiency.

Increased ProductivityHigh-capacity equipment and reduced downtime lead to increased production and the ability to meet large demands.

Flexibility and ScalabilityThe solution can be tailored to specific project needs and easily scaled up as demands grow.

Improved LogisticsCentralized control and efficient transportation systems ensure smooth coordination and timely concrete delivery.

Environmental ComplianceEco-friendly operations, including dust control and water recycling, help meet environmental regulations.

Reliable SupportComprehensive after-sales service and operator training ensure long-term reliability and effective system management.

Risk ReductionFewer suppliers and streamlined processes reduce risks related to delays, compatibility issues, and supply chain disruptions.

How To Choose The Batching Concrete Plant?

Choosing the right batching concrete plant is crucial for ensuring the efficient production of high-quality concrete and optimizing the overall performance of your construction projects. You are advised to consider the following factors to match the batching plant’s capabilities with your specific needs.

Confirm Project Requirements

Determine the specific needs of your project, including required production capacity, types of concrete mixes, and delivery methods. This will help you know how do you start a concrete batching plant.

Assess Site Conditions

Assess including available space, access to utilities, and environmental regulations, to determine the suitability for installing a concrete batching equipment.

Decide Batching System

Decide between stationary, mobile, or portable batching plants based on project duration, mobility requirements, and production volume. You also need to know how do concrete mixer plants work.

Evaluate Automation Level

Evaluate the level of automation and control systems offered by different batching plants to ensure efficient operation, accurate batching, and ease of monitoring.

Consider Maintenance Requirements

Consider the maintenance needs and accessibility of components such as mixers, conveyors, and control systems to minimize downtime and maintenance costs.

Consider Environment Impact

Consider regulatory compliance, pollution prevention, resource conservation, climate change mitigation, and sustainability, ensuring responsible business practices.

Examine Supplier Reputation

Select reputable suppliers with a proven track record in manufacturing reliable plants, providing excellent customer support, and offering warranty and after-sales services.

Consider Cost & Budget

Compare the initial investment costs of batching plant, including equipment price, installation fee, and operational costs, with long-term benefits such as productivity, quality, and reliability.

Main Systems Of Concrete Batching Mixing Plant

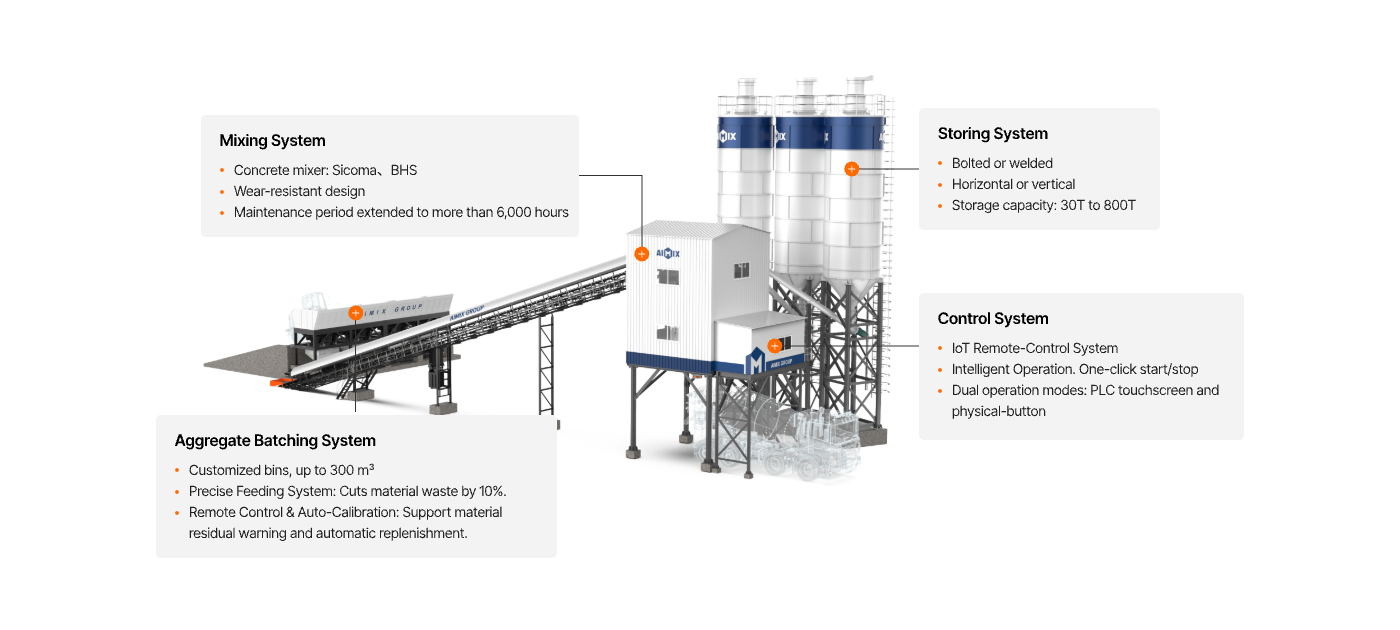

Mixing System

Our mobile, stationary, central mix or ready mixed plants adopt a compulsory concrete mixer, which has good mixing performance and strong adaptability for mixing ordinary concrete and special concrete. In addition, a compulsory concrete mixer ensures the good quality of concrete in the concrete batching mixing plant, You can also choose a concrete drum mixer, planetary concrete mixer according to the demand of your project.

Storing System

In general, aggregates are stored in open-air places. The powder is stored in a closed silo. Admixture is stored in steel structural containers. Cement is stored in a cement silo. Our cement silo is equipped with a digital display, which can provide an accurate indication of the cement remains in the silo. In addition, the capacity of our cement silo is usually in a range from 20 to 200 tons, so it can be customized by our users in line with their different needs.

Weighing System

The weighing system is a key component that affects the quality and the cost of concrete. You need to know this part if you want to understand how a concrete batch plant works. It is divided into three parts: aggregate weighing, powder weighing, and liquid weighing. Aggregates mainly include large stones, small stones, sand; liquid containing water, and liquid admixture; the powder is divided into cement, fly ash, and slag. All the weighing are operated at the same time and controlled by the computer. Users can input the ratio to the computer according to their different requirements.

Batching System

Our concrete batching machine can mix three to six kinds of aggregates, such as sand, rocks, gravel, fly ash, and cement. I have to say, our aggregate batching machine has high work efficiency. The batching machines have two bins, three bins, and four bins available for choice.

Conveying System

The conveying system consists of three parts. Aggregate is conveying by hopper and belt. The hopper conveying has the advantages of small transportation area and low cost and the belt conveying has the advantages of high efficiency and long transmission distance. Water and liquid admixtures are transported by the pump. Cement is conveyed by a screw conveyor from the cement silo to the concrete mixer.

Control System

The whole control room is big and bright, which is equipped with air conditioning. Our concrete batching plant is controlled by a microcomputer, which is really convenient to operate and maintain for users. In the absence of automatic control, the manual operating system can still control the whole concrete mix plant.

Dust Removal System

The dust removal system of the on site concrete batching plant is composed of a dust collector and dust removal pipe. Our dust removing device of On-Site Conrete Batching Plants can purify the air to realize concrete construction, which is really good.

How Does A Concrete Batching Plant Work?

A concrete batching plant is a facility where raw materials like cement, aggregates, water, and additives are combined to produce concrete. The concrete batching plant’s design and operations ensure that the concrete is produced efficiently, consistently, and to the required specifications. Here is a step-by-step explanation of how a concrete batching plant works and there are mainly four steps in the whole concrete production process: feeding, batching, mixing, and discharging.

Materials Feeding: Firstly, users need to use the wheel loader to transport all kinds of aggregate to the concrete batching machine. Such as pebble, sand, and small-size stone.

Weighing and Batching: Secondly, there are two types of batching: aggregate batching and powder batching. After finishing the weighing, the aggregate batching will be conducted in the aggregate batching machine, and cement is stored in the silo, then measured and moved to the mixer via the screw conveyor. And these two powders will enter the twin-shaft concrete mixer through a screw conveyor. By the way, According to the types of aggregate, you can choose the type of aggregate batching machine. AIMIX usually provides users with a three-bin batching machine or a four-bin batching machine.

Materials Mixing: Thirdly, it is the most important process: mixing. When all of the raw materials enter the mixer machine, open the switch, mixing shaft will begin to stir the materials for mixing operations.

Discharging and Delivering: Finally, when the materials are mixed at the stipulated time, the finished concrete mixture will be discharged from the discharge outlet. And there will be concrete transit mixers to transport the fresh concrete to the construction site.

Important Tips For Concrete Batching Plant Maintenance

Regular Inspection and Cleaning

- Daily Visual Checks: Inspect the entire batch plant daily for any signs of wear, damage, or malfunction. Pay special attention to the mixer, conveyors, and weigh systems.

- Clean Regularly: Remove concrete buildup in the mixer, chutes, and other areas where residue might accumulate. Use a high-pressure water jet or mechanical tools to prevent hardened concrete from affecting operations.

Consistent Lubrication

- Lubricate Moving Parts: Regularly apply lubricants to all moving parts such as mixer shafts, conveyor belts, and bearings to reduce friction and wear.

- Follow Manufacturer’s Guidelines: Use the lubricants recommended by the concrete plant manufacturer and adhere to the specified lubrication schedule.

Calibration of Weighing Systems

- Frequent Calibration: Regularly calibrate the weighing systems for cement, aggregates, water, and admixtures. Accurate measurements are essential for maintaining the quality of the concrete mix.

- Check Sensors and Load Cells: Ensure that sensors and load cells are functioning correctly and are free from obstructions or damage.

Monitor and Maintain Electrical Systems

- Inspect Wiring: Regularly check all electrical wiring and connections for signs of wear, corrosion, or loose connections. Address any issues immediately to prevent electrical failures.

- Control Panel Maintenance: Keep the control panel clean and ensure that all buttons, switches, and displays are working correctly. Address any malfunctions promptly.

Proper Silo Maintenance

- Check for Moisture: Ensure that cement and fly ash silos are sealed properly to prevent moisture ingress, which can cause material clumping and blockages.

- Inspect Pressure Relief Valves: Regularly check the pressure relief valves on silos to ensure they are functioning correctly and preventing over-pressure.

Ensure Adequate Safety Measures

- Emergency Systems: Test all emergency stop buttons and safety systems regularly to ensure they are operational. These systems are vital for preventing accidents.

- Personal Protective Equipment (PPE): Ensure that all personnel wear appropriate PPE such as hard hats, gloves, and safety glasses, especially during maintaining concrete batch mixing plant.

Maintain Conveyor Systems

- Inspect Belts: Check conveyor belts for signs of wear, tears, or misalignment. Replace or repair any damaged belts to avoid material spillage and production delays.

- Lubricate Rollers: Regularly lubricate the rollers and pulleys to ensure smooth operation and prevent belt slippage.

Water and Admixture System Checks

- Check for Leaks: Regularly inspect the water and admixture dosing systems for leaks or blockages. Ensure that the dosages are accurate and consistent with the mix design.

- Clean Filters: Regularly clean or replace water and admixture filters to ensure the quality and consistency of the materials being used.

Environmental Considerations

- Dust Control: Maintain the dust collection system to minimize environmental impact and ensure compliance with local regulations.

- Proper Waste Disposal: Implement proper disposal methods for concrete waste, used filters, and other materials generated during maintenance.

Monitor Mixer Performance

- Check Mixing Efficiency: Regularly assess the performance of the mixer to ensure it is producing uniform and high-quality concrete. Adjust the mixing time or blade configuration if needed.

- Inspect Gearboxes and Motors: Ensure that the mixer’s gearbox and motor are operating smoothly without overheating or unusual noises.

How To Start A Batching Plant of Concrete?

Starting a concrete batching plant involves several steps, from planning and site selection to the actual setup and operation.

Research and Plan

Study market demand and competitors. Plan capacity and resources.

Location

Choose a convenient site. Consider regulations & space requirements.

Permits and Regulations

Obtain necessary permits. Ensure compliance with regulations.

Equipment

Purchase or rent quality equipment. Consider reliability and efficiency.

Raw Materials

Secure suppliers. Establish quality control measures.

Training and Testing

Train staff, focusing on safety and efficiency. Test equipment, addressing any issues before full operation.

Marketing

Develop a marketing strategy. Highlight advantages and benefits.

Operations and Maintenance

Establish SOPs. Implement maintenance schedules.

If you are not very clear about this aspect, you can leave us a message, and we have professional engineers and salesmen who will make engineering plans for you.

Global Concrete Plants Cases

As a reputable and experienced batching plant manufacturer, our concrete batching plant sales have expanded to more than 100 countries and we have established a global presence, providing reliable and efficient solutions for concrete production across various regions. Get to know more Aimix concrete plant cases from around the world now.