Asphalt plants in Sri Lanka are vital for producing quality asphalt for road and bridge construction. They mix aggregates and asphalt at the right temperature to create durable and smooth surfaces for highways, airports, and other infrastructure. Choosing the right asphalt plants in Sri Lanka ensures the success of construction projects and helps build long-lasting roads. AIMIX provides mobile/portable/batch/drum type asphalt plants. Let’s learn more about these types of asphalt plants for sale in the following.

Case of Asphalt Plants in Sri Lanka

100TPH Asphalt Plant in Sri Lanka

- Model: ALQ100

- Capacity: 100TPH

- Type: Stationary Batch Type

- Delivery Time: June, 2021

- Project: Local Road Construction

Customer Review

We bought AIMIX Asphalt Plant for a road project. It works great, producing high-quality asphalt and helping us stay on schedule. The hot mix plant is reliable, and the after-sales service has been excellent. We’re very happy with it.

Get A Quote

Types of Asphalt plants in Sri Lanka

Asphalt plants play a crucial role in Sri Lanka’s infrastructure development, providing high-quality asphalt mixtures for road construction projects. Depending on project requirements, different types of asphalt plants are available, each offering unique features and benefits. Below is an overview of the key types of asphalt plants in Sri Lanka, along with their key parameters and advantages:

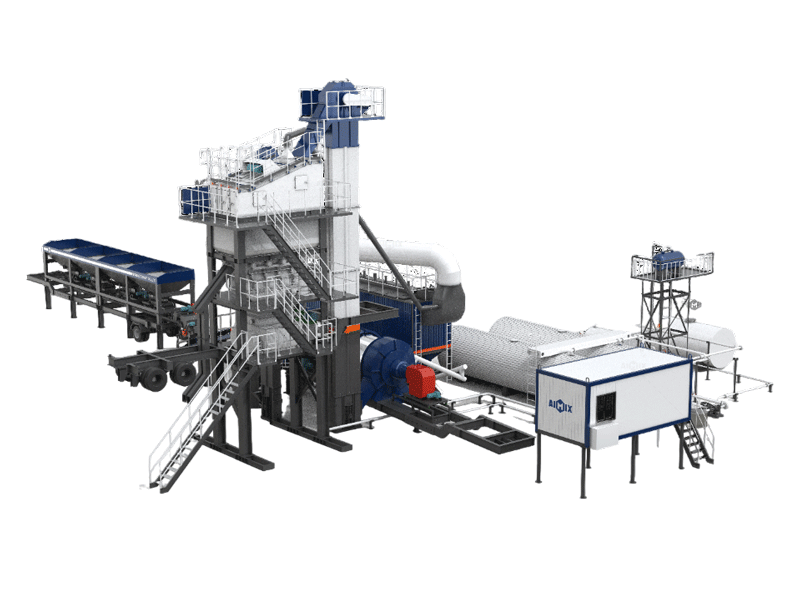

Stationary asphalt plants, including the ALQ series (batch type) and the ALT series (drum type), are perfect for large projects in Sri Lanka. The ALQ series ensures precise mixing and high-quality asphalt, ideal for roads, highways, and airports. The ALT series offers continuous production with low fuel consumption, making it ideal for projects requiring high volumes of asphalt. The stationary asphalt plant is built for efficiency, reliability, and high output.

ALQ Series Stationary Asphalt Batching Plant

Hot Model: ALQ60ALQ80ALQ120

Production Capacity: 40-400T/H

Mixing Cycle: 45s

Fuel Consumption: 70-2500kg/h

Vibrating Screen: 4 to 6 layers

Advantages

- Precise Mixture Control: Ensures consistent asphalt quality.

- Large Capacity: Suitable for major projects like highways and airports.

- Durable: Built for heavy-duty construction.

- Fuel Efficient: Reduces operating costs with optimized fuel consumption.

ALT Series Stationary Asphalt Drum Mix Plant

Model: ALT20ALT60ALT80ALT100

Production Capacity: 20-100T/H

Finished Asphalt Storage: 2m³ to 9m³

Asphalt Tank: 10t to 35t

Advantages

- Continuous Production: Suitable for high-volume, non-stop production.

- Simple Design: Easy to operate and maintain.

- Cost-Effective: Lower initial cost compared to batch plants.

- Fuel Efficient: Uses less fuel, especially when burning coal.

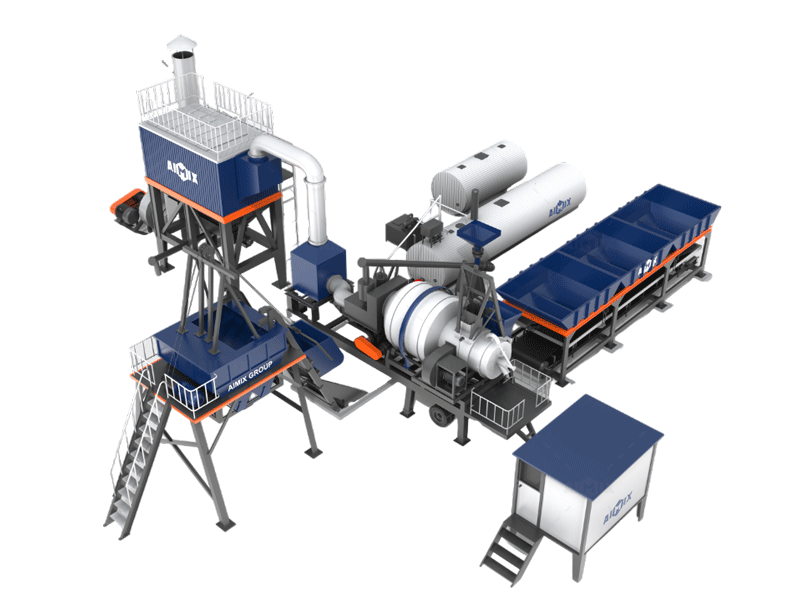

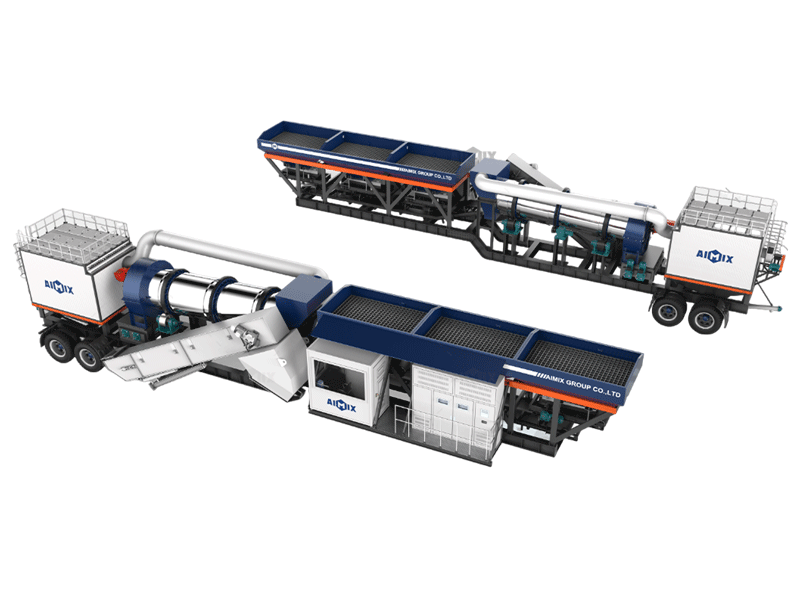

Mobile asphalt plants, including the ALYQ, ALYJ, ALYT, and ALYZ series, are designed for flexibility and easy transport, making them ideal for various projects in Sri Lanka. They are quick to set up and perfect for both small and large-scale jobs. The ALYQ and ALYJ series are compact and cost-effective, while the ALYT series offers continuous production. The ALYZ series combines eco-friendly features for large projects. Mobile asphalt plant in Sri Lanka can deliver efficient and high-quality asphalt production.

ALYQ Series Batch Type Mobile Asphalt Plant

Model: ALYQ60ALYQ80ALYQ120ALYQ160

Production Capacity: 40-160T/H

Mixing Cycle: 45s

Mixer Capacity: 800kg to 2200kg

Cold Aggregate Hoppers: 3m³×3 to 5m³×4

Advantages

- Portable: Easy to move and set up on different sites.

- Flexible: Great for smaller projects with changing locations.

- Efficient Fuel Use: Compatible with various fuel types.

- Quick Setup: Fast installation, ideal for urgent projects.

ALYT Mobile Asphalt Drum Mix Plant in sri lanka

Hot Model: ALYT20ALYT60ALYT80ALYT120

Production Capacity: 20-120T/H

Asphalt Temperature: 120-180°C

Finished Product Hopper: 2t to 20t

Cold Aggregate Hoppers: 3m³×3 to 5m³×4

Advantages

- Compact: Ideal for small spaces and limited areas.

- Affordable: Low cost, great value for smaller contractors.

- Easy to Move: Can be relocated easily for different projects.

- Customizable: Options for additional features like dust collectors.

ALYJ Series Simple Portable Asphalt Mixing Plants

Hot Model: ALYJ10ALYJ40ALYJ60ALYJ80

Production Capacity: 10-80T/H

Asphalt Temperature: 120-180°C

Asphalt Tank: 10t to 35t

Dust filter: Bag / Water Dust Filter

Advantages

- Energy Efficient: Reduced fuel consumption for continuous operations.

- Quick Installation: Easy to set up and use for urgent needs.

- Durable: Built to withstand tough working conditions.

- Portable: Flexible and can be moved between sites.

AYLT Series Integrated Continuous Mobile Asphalt Batch Plant

Hot Model: AYLZ100AYLZ120

Production Capacity: 80-120T/H

Cold Aggregate Hoppers: 3×8m³k

Filter Area: 320m² to 400m²

Drying Drum: φ1.7m×7m to φ1.8m×7m

New Asphalt Plant Advantages

Asphalt Plant Technical Specification

The technical specifications of an asphalt plant are essential for choosing the right model for your project. Key factors such as capacity, fuel consumption, mixer size, and power requirements play a big role in ensuring the asphalt plants in Sri Lanka fits your needs. Below are the detailed specifications for different asphalt plant models to help you select the best option for your construction project.

| Model | ALQ40 | ALQ60 | ALQ80 | ALQ100 | ALQ120 | ALQ160 | ALQ200 | ALQ240 | ALQ320 |

|---|---|---|---|---|---|---|---|---|---|

| Capacity | 40 t/h | 60 t/h | 80 t/h | 100 t/h | 120 t/h | 160 t/h | 200 t/h | 240 t/h | 320 t/h |

| Cold Aggregate Hoppers | 4×4.5m³ | 4×6.5m³ | 4×7.5m³ | 4×7.5m³ | 5×7.5m³ | 5×12m³ | 5×12m³ | 5×12m³ | 6×15m³ |

| Dryer Size | φ1.2m×5.2m | φ1.5m×6m | φ1.5m×6.7m | φ1.65m×7m | φ1.8m×8m | φ2.2m×9m | φ2.6m×9m | φ2.6m×9.5m | φ2.8m×10.2m |

| Fuel consumption | 70-300kg / h | 100-400kg / h | 120-600kg / h | 150-1000kg / h | 150-1000kg / h | 150-1400kg / h | 180-1800kg / h | 180-1800kg / h | 260-2500kg / h |

| Vibrating Screen (Layer) | 4 layers | 4 layers | 4 layers | 4 layers | 5 layers | 5 layers | 5 layers | 5 layers | 6 layers |

| Mixer Capacity | 500kg | 800kg | 1000kg | 1250kg | 1500kg | 2000kg | 2500kg | 3000kg | 4000kg |

| Cycle Time | 45s | 45s | 45s | 45s | 45s | 45s | 45s | 45s | 45s |

| Filter Area | 230m² | 300m² | 420m² | 480m² | 550m² | 650m² | 700m² | 1050m² | 1350m² |

| Asphalt Temperature | 140-180 ℃ | 140-180 ℃ | 140-180 ℃ | 140-180 ℃ | 140-180 ℃ | 140-180 ℃ | 140-180 ℃ | 140-180 ℃ | 140-180 ℃ |

| Total Power | 170kw | 200kw | 300kw | 350kw | 380kw | 490kw | 550kw | 670kw | 865kw |

| Model | ALYQ60 | ALYQ80 | ALYQ100 | ALYQ120 | ALYQ160 | |

|---|---|---|---|---|---|---|

| Capacity | t / h | 60 | 80 | 100 | 120 | 160 |

| Mixer capacity | kg | 800 | 1200 | 1300 | 1700 | 2200 |

| Mixing cycle | s | 45 | 45 | 45 | 45 | 45 |

| Total power | Gasoline(kW) | 54 | 63.5 | 104.5 | 125 | 157.5 |

| Coal(kW) | 75 | 86.5 | 127.5 | 169 | 205 | |

| filter area | m2 | 370 | 420 | 480 | 510 | 620 |

| Courts Models | ALT20 | ALT40 | ALT60 | ALT80 | ALT100 |

|---|---|---|---|---|---|

| Capacity | 20 t/h | 45 t/h | 60 t/h | 80 t/h | 100 t/h |

| The ability to | 40kw | 75kw | 120kw | 165kw | 200kw |

| Cold Aggregate Hoppers | 3.5m³×1 | 4m³×4 | 4m³×4 | 6.5m³×4 | 6.5m³×4 |

| Finished Product Hopper | 3t | 3t | 7t | 7t | 9t |

| Asphalt Temperature | 120-180 ℃ | ||||

| Fuel consumption | 13-15kg/t | ||||

| Asphalt Tank | 10 t | 20 t | 30 t | 30 t | 35 t |

| Control room | 2.2m | 2.2m | 3m | 3m | 3.5m |

| Option | Bag dust filter | ||||

| Model | ALYJ10 | ALYJ15 | ALYJ20 | ALYJ30 | ALYJ40 | ALYJ60 | ALYJ80 | |

|---|---|---|---|---|---|---|---|---|

| Capacity | 10 t/h | 15 t/h | 20 t/h | 30 t/h | 40 t/h | 60 t/h | 80 t/h | |

| The ability to | Petrol | 48kw | 59kw | 68kw | 106kw | 132kw | 146kw | 186kw |

| Burning coal | 67kw | 78kw | 91kw | 129kw | 170kw | 192kw | 262kw | |

| Cold Aggregate Hoppers | 3m³×3 | 3m³×3 | 3m³×3 | 5m³×3 | 5m³×3 | 5m³×3 | 5m³×4 | |

| Finished Product Hopper | 2t | 5t | 5t | 9t | 9t | 9t | 20 t | |

| Asphalt Temperature | 120-180 ℃ | |||||||

| Fuel consumption | Petrol | 5-7.5kg/t | ||||||

| Burning coal | 13-15kg/t | |||||||

| Option | Water dust filter, Bag dust filter, Control room, Asphalt heat tank, Mineral flour tank | |||||||

| Model | AYLZ100 | AYLZ120 |

|---|---|---|

| Yield(under standard working conditions) | 80-100t/h | 100-120t/h |

| composition structure | Ingredient drying, dust removal and mixing mobile unit | Ingredient drying, dust removal and mixing mobile unit |

| Asphalt and fuel supply mobile units | Asphalt and fuel supply mobile units | |

| Powder supply system mobile unit(optional) | Powder supply system mobile unit(optional) | |

| Measuring accuracy | Aggregate±2% | Aggregate±2% |

| Powder ±1% | Powder ±1% | |

| Asphalt ±1.5% | Asphalt ±1.5% | |

| Dust emission concentration | ≤50mg/Nm3 | ≤50mg/Nm3 |

| Hot aggregate discharge temperature stability | ±5℃ | ±5℃ |

| Discharge temperature stability of finished product | ±3℃ | ±3℃ |

| Equipment operation reliability | ≥95% | ≥95% |

| Operation method | Fully automatic control (manual control) | Fully automatic control (manual control) |

| Dimensions | Maximum reference: length 26.7mx width 3.43mx height 4.5m | Maximum reference: length 26.7mx width 3.43mx height 4.5m |

| Total installed power | Maximum 180kw | Maximum 230kw |

| Overall machine quality | About 70t | About 75t |

| Ingredients bin volume | 3x8m³ | 3x8m³ |

| Drying drum | φ1.7m (diameter) ×7m (length) | φ1.8m (diameter) ×7m (length) |

| Bag filter | 320㎡ | 400㎡ |

| Continuous mixing host | Motor 2x22Kw | Motor 2x30Kw |

| Asphalt tank | Direct heating 30m³+5m³ diesel tank | Direct heating 30m³+5m³ diesel tank |

| New powder supply system | Horizontal (or vertical) powder tank 30m³/50m³ (optional) | Horizontal (or vertical) powder tank 30m³/50m³ (optional) |

| Model | ALYT20 | ALYT40 | ALYT60 | ALYT80 | ALYT100 | ALYT120 |

|---|---|---|---|---|---|---|

| Output | 20t/h | 45t/h | 60t/h | 80t/h | 100t/h | 120t/h |

| Power | 34kw | 65kw | 105kw | 135kw | 170kw | 200KW |

| Cold Aggregate Feeding System | 3.5m³×1 | 4m³×4 | 4m³×4 | 6.5m³×4 | 6.5m³×4 | 6.5m³×4 |

| Finihsed Asphalt Storage Bin | 2m³ | 2.5m³ | 4.5m³ | 5m³ | 7m³ | 7m³ |

| Asphalt Temperature | 120-180℃ | 120-180℃ | 120-180℃ | 120-180℃ | 120-180℃ | 120-180℃ |

| Fuel Consumption(Fuel Oil) | 5-7.5kg/t | 5-7.5kg/t | 5-7.5kg/t | 5-7.5kg/t | 5-7.5kg/t | 5-7.5kg/t |

| Fuel Consumption(Burning Coal) | 13-15kg/t | 13-15kg/t | 13-15kg/t | 13-15kg/t | 13-15kg/t | 13-15kg/t |

| Asphalt Tank | 10t | 20t | 30t | 30t | 35t | 35t |

| Option | bag dust collector / water dust collector | bag dust collector / water dust collector | bag dust collector / water dust collector | bag dust collector / water dust collector | bag dust collector / water dust collector | bag dust collector / water dust collector |

| Whole Plant Option | whole mobile / semi-mobile / fixed | whole mobile / semi-mobile / fixed | whole mobile / semi-mobile / fixed | whole mobile / semi-mobile / fixed | whole mobile / semi-mobile / fixed | whole mobile / semi-mobile / fixed |

Strategic Importance of Investing in Asphalt Mixing Plants in Sri Lanka

Investing in asphalt mixing plants in Sri Lanka holds significant strategic value, especially considering the country’s ongoing infrastructure development and increasing demand for high-quality road construction materials. Below are the key reasons why this investment is both timely and beneficial. Let’s see the advantages of investing an asphalt mixing plant.

Meeting Local Market Demand

Sri Lanka’s rapid infrastructure growth, including urban road expansions and rural connectivity projects, has created a consistent demand for asphalt. Establishing a local asphalt plant reduces reliance on imported materials, cuts transportation costs, and ensures timely supply to construction sites, thereby enhancing project efficiency.

Alignment with Government Infrastructure Plans

The Sri Lankan government is actively investing in infrastructure, particularly through Public-Private Partnership (PPP) initiatives. These projects offer lucrative opportunities for companies involved in road construction and material supply. Investing in an asphalt mixing plant positions your business to capitalize on these high-priority projects.

Enhanced Operational Efficiency

Owning a local asphalt plant allows construction companies to streamline operations by controlling the production process. This leads to better material quality, reduced wastage, and a more agile response to project requirements. Such operational advantages are critical in maintaining competitiveness in Sri Lanka’s growing construction market.

Cost Reduction and Long-Term Benefits

By localizing asphalt production, businesses can avoid significant costs associated with importing materials. Furthermore, modern asphalt plants equipped with energy-efficient technologies and pollution control systems contribute to long-term cost savings and compliance with environmental regulations.

Supporting Sustainable Development

Sri Lanka is increasingly prioritizing eco-friendly infrastructure development. Investing in advanced asphalt plants with sustainable features—such as reduced emissions, energy-efficient operations, and waste recycling capabilities—aligns with these goals and enhances the credibility of businesses in the market.

Seizing Future Growth Opportunities

With urbanization accelerating and rural road networks expanding, the demand for asphalt is expected to grow steadily. A strategic investment in asphalt mixing plants positions businesses to seize emerging opportunities in the construction and infrastructure sectors, ensuring long-term profitability.

Investing in asphalt mixing plants in Sri Lanka is not just a response to current market needs; it is a forward-thinking strategy to secure a strong foothold in the nation’s infrastructure development landscape. By addressing local demand, reducing costs, and supporting sustainable practices, this investment offers substantial benefits for contractors and developers alike.

Asphalt Plant Exported Worldwide

AIMIX asphalt plants are trusted by clients globally and have been successfully delivered to various countries. The hot mix asphalt plant for sale in Sri Lanka is widely used in infrastructure projects, such as roads and highways. Below are some project pictures showcasing their applications in different regions.

How to Select the Right Asphalt Plants in Sri Lanka?

Choosing the right asphalt plant for sale in Sri Lanka for your construction needs in Sri Lanka requires a careful evaluation of several key factors. Whether you’re working on road construction, highway projects, or other infrastructure developments, making the right choice will ensure efficiency, cost-effectiveness, and quality. Let’s learn how to choose the right asphalt plant in detail.

Know Your Production Needs

Determine the output you need based on the size and scope of your project. Small roads may require lower-capacity plants (20-60 tph), while larger projects like highways or airports need plants with higher output (100-400 tph).

Quality of Asphalt

Think about the type of asphalt you need. The Asphalt Mixing Plant in Sri Lanka can offer precise control for high-quality or modified asphalt, which is crucial for high-traffic roads or long-lasting infrastructure.

Site Location and Space

Consider the size of your construction site. If space is limited or you need flexibility, a mobile asphalt plant might be a better choice. For larger, fixed sites, a stationary asphalt plant would be more suitable.

Project Duration

Will the plant be used for a single project or multiple projects? For short-term projects, a mobile asphalt plant might be ideal. For long-term use, investing in a stationary asphalt mixing plant could be more cost-effective.

Budget and Operating Costs

Make sure the tarmac asphalt plant for sale in sri lanka fits your budget, not just in terms of purchase price but also in operating costs. Consider fuel efficiency, maintenance costs, and any additional features that might help reduce long-term expenses.

Environmental Considerations

Check whether the hot mix plant meets local environmental standards, such as emissions control and noise levels. In Sri Lanka, complying with environmental regulations is important, especially for projects in urban areas.

By taking these factors into account, you can select the best asphalt plant for sale in sri lanka for your needs and ensure your project runs smoothly and on budget.

How to Reduce the Cost of Asphalt Batch Mixing Plants in Sri Lanka?

Reducing the cost of buying and operating an asphalt batch mix plant in Sri Lanka involves strategic planning and informed decision-making. Here are some key tips to help you lower asphalt batch mixing plant cost in Sri Lanka while ensuring quality:

Evaluate Your Project Needs CarefullyAvoid overspending by choosing an asphalt plant that fits your production requirements. Understand the output capacity, fuel efficiency, and type of asphalt mix you need for your projects in Sri Lanka.

Purchase Directly from Reputable SupplierBuy from trusted manufacturers to eliminate extra costs added by intermediaries. Asphalt Plant manufacturers like AIMIX offer high-quality plants at competitive prices, ensuring value for money.

Compare Local and International OptionsPurchasing locally reduces transportation costs and allows faster installation. However, buying from reliable international suppliers like AIMIX can give you access to advanced technology and lower base prices.

Check for Comprehensive After-Sales SupportAlways inquire about warranties and after-sales services. Good support, including installation, maintenance, and technical guidance, can save you significant repair and downtime costs later.

Consider the Plant’s Energy EfficiencyInvest in energy-efficient equipment to reduce fuel consumption during operation. Over time, this can lead to substantial savings in operational expenses.

Plan for Long-Term UsageA durable, high-performance asphalt plant may cost more upfront but reduces replacement and repair expenses in the long run. Opt for quality over low prices to maximize returns.

By following these steps, you can balance asphalt plant cost and quality effectively. Contact AIMIX for tailored advice and the best deals on asphalt batch mixing plants suited to your needs in Sri Lanka!

What Are the Main Components of Asphalt Plants?

Generally, the asphalt plants in sri lanka consists of an aggregate batching machine, drying system, burning system, hot aggregate lifting system, vibrating screen, hot aggregate storage bin, weighing and mixing system, asphalt supply system, filler supply system, dust removal, finished product bin, and container type control system, etc. Here is a picture about asphalt plant components in the following.

Ways to Find Reputable Asphalt Plant Manufacturers in Sri Lanka

Finding the right asphalt plant manufacturer in Sri Lanka is crucial for ensuring high-quality asphalt production and smooth project execution in Sri Lanka. With numerous options available, it’s essential to choose asphalt plant suppliers & exporters in Sri Lanka that meets your specific requirements, from reliable equipment to strong after-sales support.

Research Local Market Leaders

Start by identifying well-established asphalt batch mixing plant manufacturers in Sri Lanka. Local companies often have a better understanding of regional construction needs, making them a reliable choice. You can visit their facilities or inquire about their projects to ensure their expertise. AIMIX, for example, has a strong presence in Sri Lanka, offering high-quality asphalt plants designed for the local market.

Explore Online Resources

Use search engines like Google or construction-specific platforms to search for asphalt plant manufacturers in Sri Lanka. Look for manufacturers with a solid reputation and good customer reviews. AIMIX’s online presence, with detailed product descriptions, videos, and customer feedback, can help you assess its credibility and make an informed decision.

Consult Industry Professionals

Reach out to contractors or construction experts who are experienced in using asphalt plants in Sri Lanka. These professionals can give you valuable insights based on their experience with different equipment and manufacturers. AIMIX is frequently recommended by industry professionals for its reliable equipment and customer support in Sri Lanka.

Visit Completed Projects

If possible, visit ongoing or completed projects where asphalt plants have been used. Contact project managers to learn about the performance of the equipment. Manufacturers like AIMIX, which has supplied asphalt plants to numerous projects in Sri Lanka, can offer proven solutions based on real-world performance.

Attend Trade Shows or Networking Events

Trade exhibitions and construction industry events in Sri Lanka provide opportunities to meet asphalt plant suppliers in Sri Lanka directly. These events allow you to compare different suppliers, view equipment in person, and even speak with past customers. AIMIX often participates in such events, showcasing its innovative asphalt plants and connecting with potential clients.

Verify After-Sales Support and Services

Reliable manufacturers should offer strong after-sales support, including maintenance, training, and timely spare parts. AIMIX excels in this area, providing extensive customer support, training services, and local assistance to ensure smooth operations of your hot mix asphalt plant for sale in sri lanka.

By using these strategies, you can make a well-informed decision when selecting a reputable asphalt plant manufacturer in Sri Lanka. AIMIX’s high-quality large or mini asphalt plant and strong after-sales service make it a great choice for construction projects in the region. Partnering with reliable suppliers like AIMIX can further enhance your investment’s success. AIMIX offers tailored solutions, advanced equipment, and exceptional after-sales support to meet your unique needs. Contact us today to explore how we can help you achieve your infrastructure goals in Sri Lanka!

AIMIX Asphalt Plant Service in Sri Lanka

AIMIX offers a comprehensive range of services for asphalt plants, ensuring that clients receive not only top-quality equipment but also reliable support throughout the life of the plant. Here’s an overview of the key services we provides:

Customized Solutions

AIMIX understands local construction needs and offers asphalt plants designed for Sri Lanka’s conditions, ensuring optimal performance for your projects.

Local Installation and Support

AIMIX provides on-site installation by local experts familiar with Sri Lankan infrastructure, making setup quick and easy.

Training for Operators

AIMIX offers training in local languages, helping your team understand asphalt plant operations and maintenance.

After-Sales Service

AIMIX provides fast local support, ensuring minimal downtime and quick access to spare parts.

Ongoing Technical Assistance

AIMIX offers continuous technical support to keep your asphalt plant running smoothly.

Long-Term Relationship

AIMIX aims to build long-term partnerships by delivering reliable asphalt plants and services that meet your needs.

In Conclusion

All in all, selecting the right asphalt plant for your project in Sri Lanka is key to achieving quality and efficiency. AIMIX provides reliable asphalt plants and local support to meet your needs. Want to know the asphalt plant price? For more details or to get a quote about the price list of asphalt mixing plant in Sri Lanka, feel free to contact us. Let us help you with your asphalt production today!